Evaluation method of part flatness error based on minimum area

An error evaluation, minimum area technology, applied in the field of part flatness error evaluation, can solve the problems of poor calculation stability, difficult application of minimum area method, limited number of sampling points, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

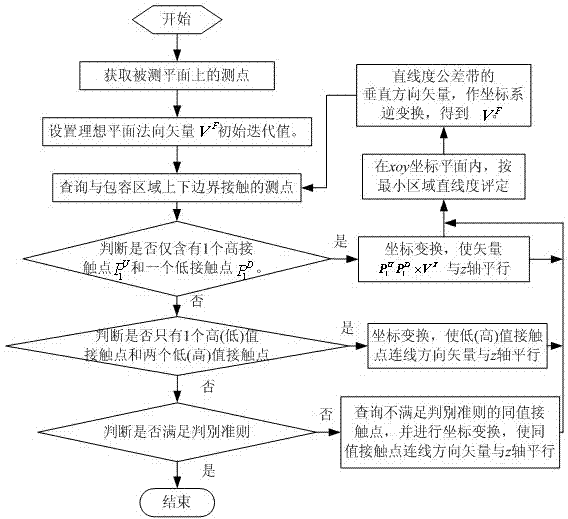

[0043] The following is attached figure 1 Embodiments of the present invention will be described in detail.

[0044] Step 1: Place the measured plane on the measurement platform, measure and obtain points on the plane in the measurement space Cartesian coordinate system , =1, 2,... n , n is the number of measuring points and n is a positive integer greater than 3, all measuring points Form a point set ; Randomly select 3 measurement points that are not on the same straight line, and calculate the normal vector of the plane with 3 points , as the iterative initial value of the ideal plane normal vector corresponding to the measured plane.

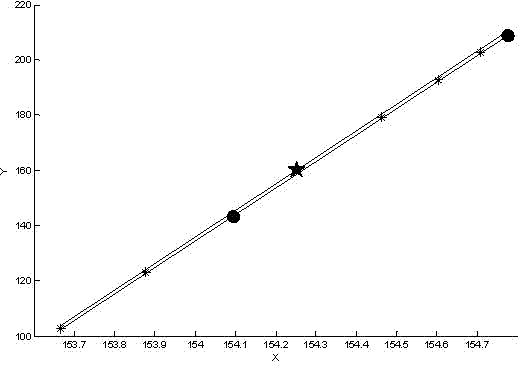

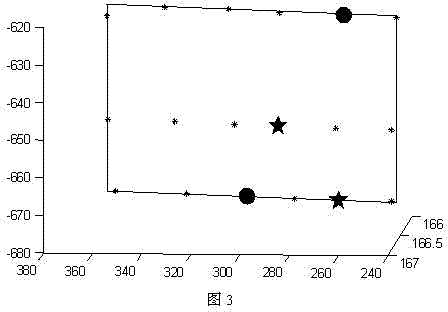

[0045] Step 2: Calculate the measurement point set in sequence The distance from each measuring point to the ideal plane , and record the measuring point set respectively The measuring points corresponding to the maximum distance and the minimum distance from each measuring point to the ideal plane; the measuring points co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com