Bearing device of chameleon paint sample wafer and chameleon paint sample wafer manufacturing method

A technology of a bearing device and a manufacturing method, which is applied to measuring devices, thermometer parts, thermometers, etc., can solve the problems of low temperature resolution, inability to realize chemical reactions, and inability to move butterfly-shaped metal samples, and achieves the ability to monitor the heating temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0028] The invention provides a carrying device for a temperature-indicating paint sample. The above-mentioned carrying device is used to carry the temperature-indicating paint sample into or out of the heating source. The temperature-indicating paint samples mentioned in this embodiment are all rectangular samples cut from a high-temperature alloy plate of the same material as the engine hot-end part, and the above-mentioned temperature-indicating paint samples are obtained after the steps of cleaning, spraying, and curing the rectangular samples. The size of the temperature-indicating paint sample is 20mm×10mm.

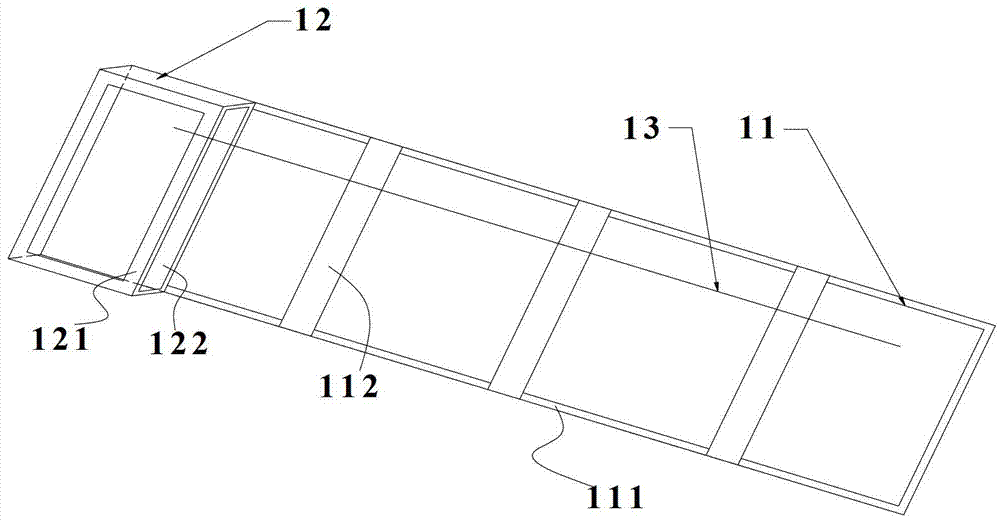

[0029] Such as figure 1 As shown, the carrying device includes a support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com