A kind of ogs touch screen manufacturing method

A manufacturing method and touch screen technology, applied in the field of touch screen, can solve the problems of affecting production efficiency and yield, open circuit, high cost, etc., and achieve the effect of improving the bonding yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

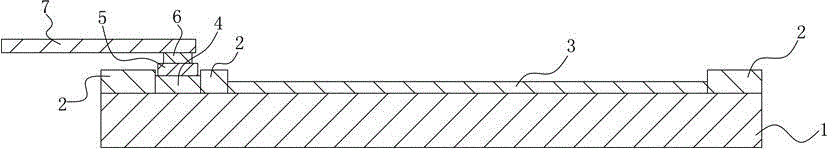

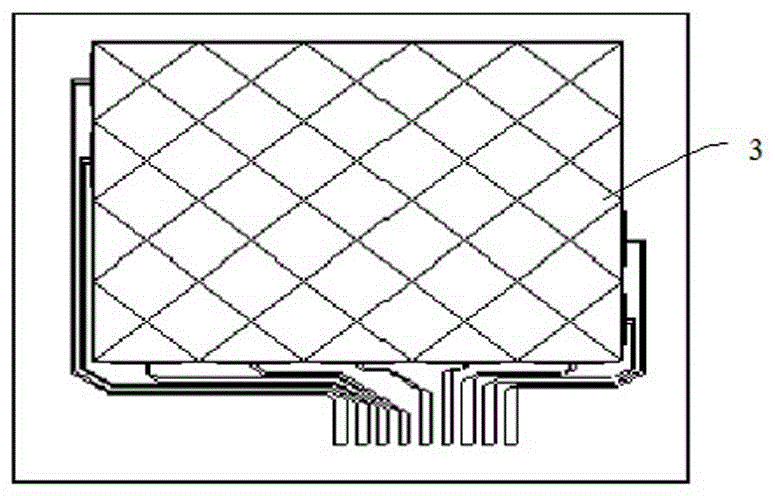

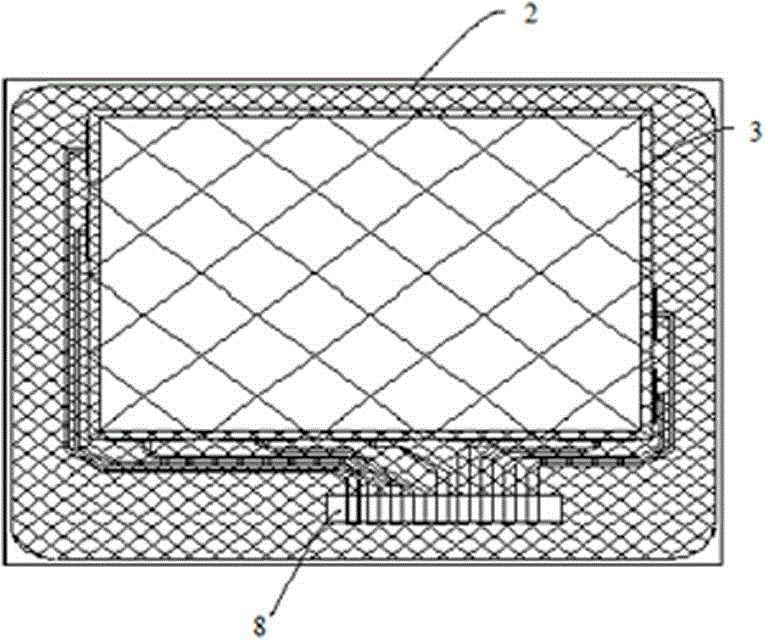

[0032] In order to facilitate the understanding of those skilled in the art, the principle of the present invention will be further described in detail below in conjunction with specific embodiments.

[0033] Such as Figure 1-Figure 5 As shown, the present invention discloses a method for manufacturing an OGS touch screen. The method for manufacturing an OGS touch screen includes the following steps:

[0034] (1) For the glass substrate 1, a traditional cleaning machine can be used. First, use a water solvent with a cleaning agent content of about 5% to brush twice through the hair wheel, and then perform ultrasonic cleaning with DI water (ion pure water) , and then brushed with DI water, rinsed, and dried;

[0035] (2) Vacuum sputtering coats a layer of niobium oxide Nb2O5 of about 70 - 150 Å on the back of the cleaned and dried glass substrate 1 as an electrode shadow removal layer;

[0036] (3) Then vacuum coat the back of the erasing layer, set the temperature at 400-50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com