Activated cathode diaphragm electrolyzer with metal anodes

A metal anode and active cathode technology, applied in electrolysis process, electrolysis components, cells, etc., can solve the problems of high voltage, poor use effect and high DC power consumption of electrolysis equipment, and achieve low DC power consumption, reasonable structure and uniform pole spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

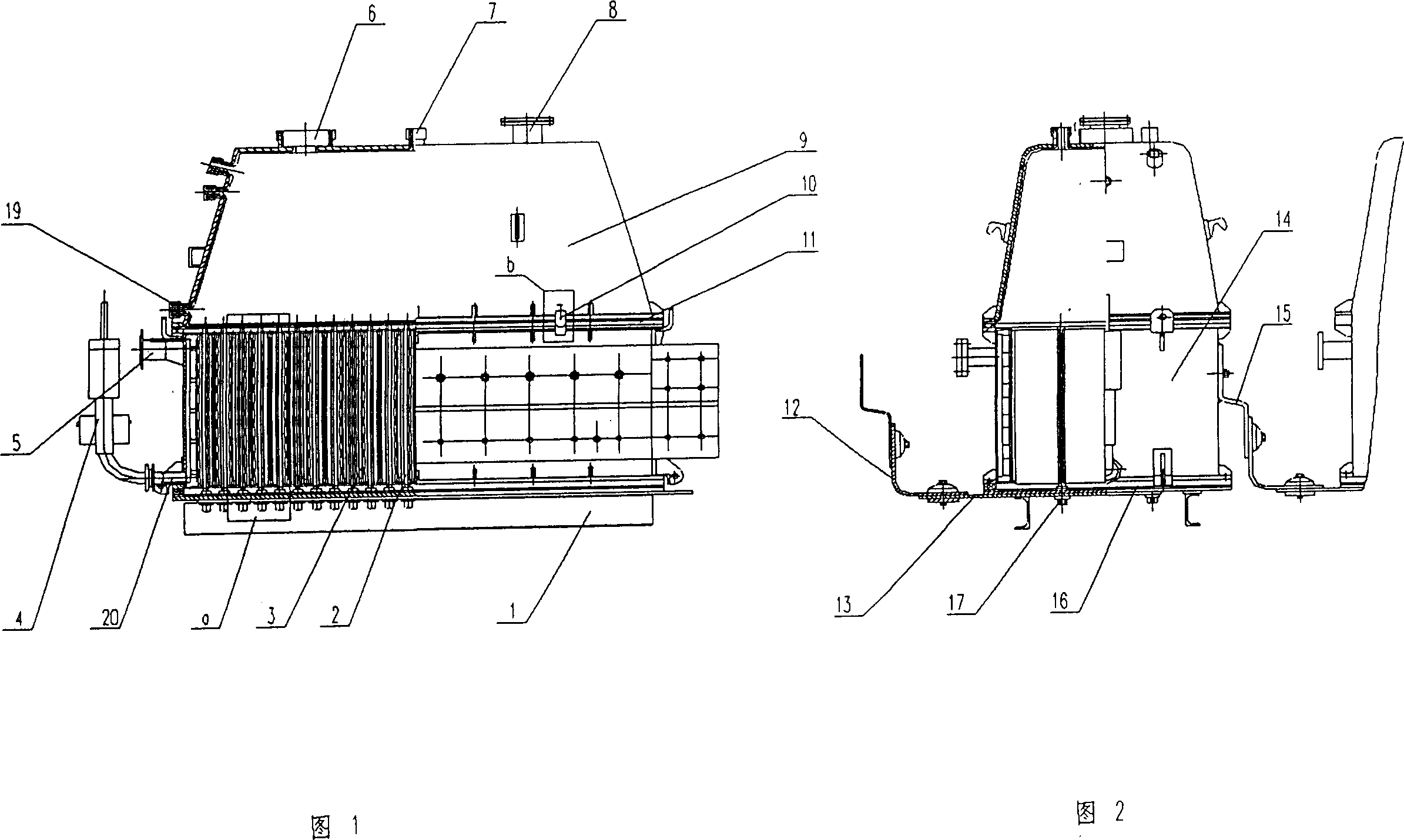

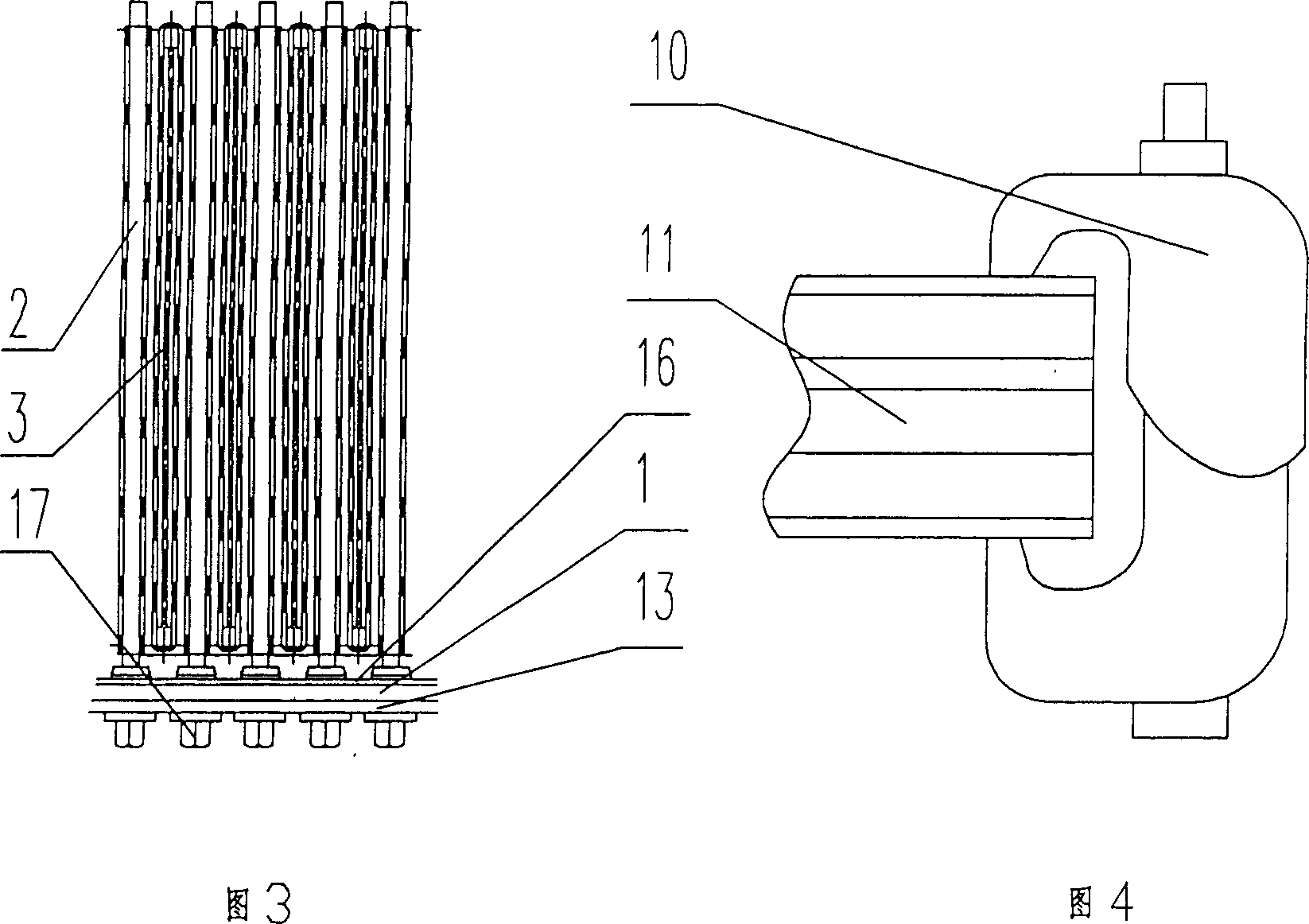

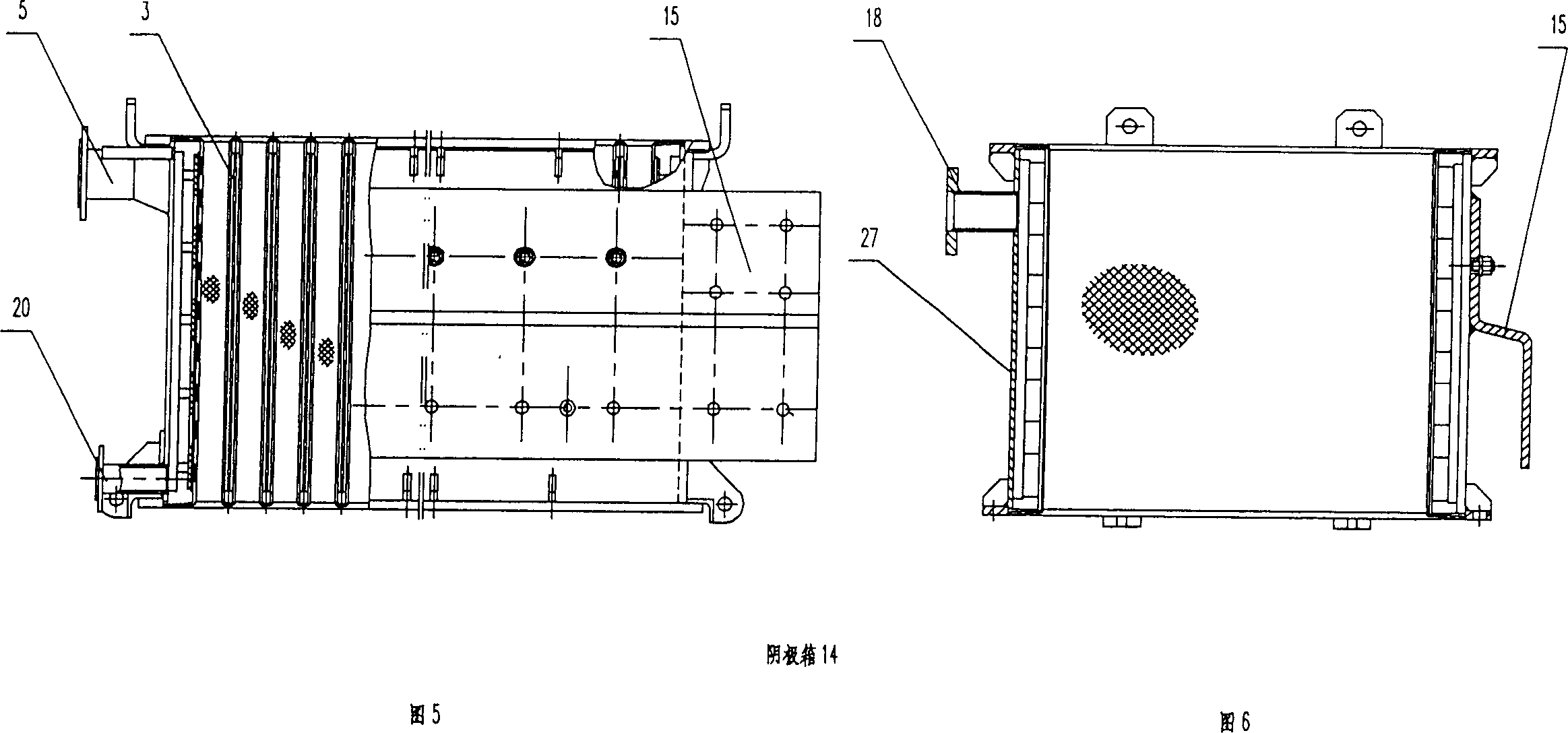

[0038] The active cathode diaphragm method metal anode electrolysis cell shown in Figures 1 and 2 is mainly composed of a cell cover 9, a cathode box 14, an anode assembly 28 and a dripper 4, etc., and the shell 27 is also provided with a hydrogen outlet 5, The lye outlet 20 and the adsorption port 18. The cathode box 14 is shown in Figures 5 and 6, which is composed of a cathode box shell 27 and a cathode plate mesh bag 3. The cathode box shell 27 is provided with a hydrogen outlet 5 and a lye outlet 20. The side of the cathode box 14 is welded with " The upper flange of the cathode box 14 in the shape of the cathode copper plate 15 is sealed and fixed with the tank cover 9 through the rubber gasket 11 and the C-shaped clip 10, as shown in Figure 4. The tank cover 9 has a chlorine outlet 6, a salt water inlet 7 and explosion-proof There is an explosion-proof film at the port 8, the explosion-proof port 8. To prevent corrosion, the tank cover 9 is lined with an anti-corrosion lay...

Embodiment 2

[0050] In the active cathode diaphragm method metal anode electrolytic cell of the present invention, the structure of the cathode frame 22 of the cathode plate mesh bag 3 can also adopt such as Figure 13 , 14 The slub steel structure shown in 15, 16 is formed by welding slub steel 30 and flat steel bars 31 with square steel, and slub steel 30 is rolled by round steel. In order to provide enough space for the gas to rise during the electrolysis reaction, dozens of round holes are punched in the flat steel bar 31, and the place where the cathode mesh 21 and the slub joints of the slub steel 30 are in contact are welded firmly with argon arc welding. The advantages of the cathode framework of this structure are the uniformity of the plane, better rigidity, simple welding, not easy to deform, and uniform current distribution, which is beneficial to the entire electrolytic cell to improve the electrolysis performance and reduce the DC power consumption of ton NaOH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com