Deep-sea micro-motor adopting micro-clearance rotary motive sealing and having pressure-balanced inner and outer chambers

A rotary seal, micro-gap technology, applied in electrical components, electromechanical devices, electrical components, etc., can solve problems such as motor failure, motor handling, inconvenience, damage, etc., to achieve stable operation, high cost performance, and long working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0087] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

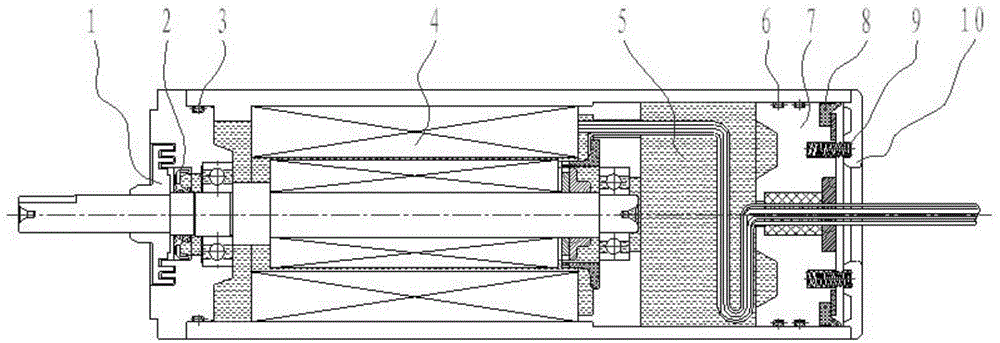

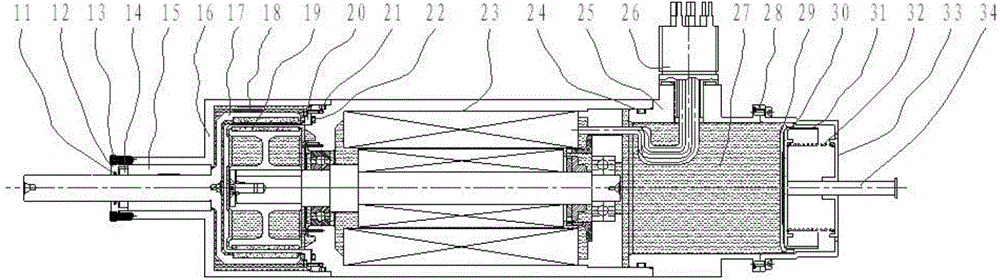

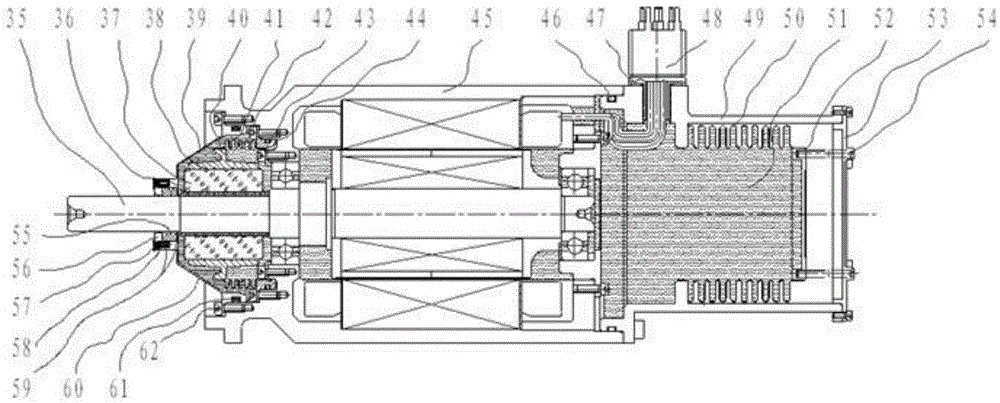

[0088] image 3 A schematic diagram of the structure of the deep-sea micro-motor of the present invention is shown. Such as image 3 As shown, the present invention provides a deep-sea micro-motor with a micro-gap rotary dynamic seal and balanced internal and external cavity pressures. Dust-proof rotary dynamic seal assembly, bellows type internal and external cavity pressure balance assembly, pressure-resistant socket 48 and rear end cover 53.

[0089] Figure 4 A schematic structural view of the micro-gap rotary dynamic seal assembly of the present invention is shown. Such as Figure 4 As shown, the micro-gap rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com