Method for the operation of a transmission device in a vehicle drive train

一种变速装置、车辆动力的技术,应用在车辆变速箱、传动装置、传动装置控制等方向,达到低操作成本、简单方式和方法、避免变速器状态的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

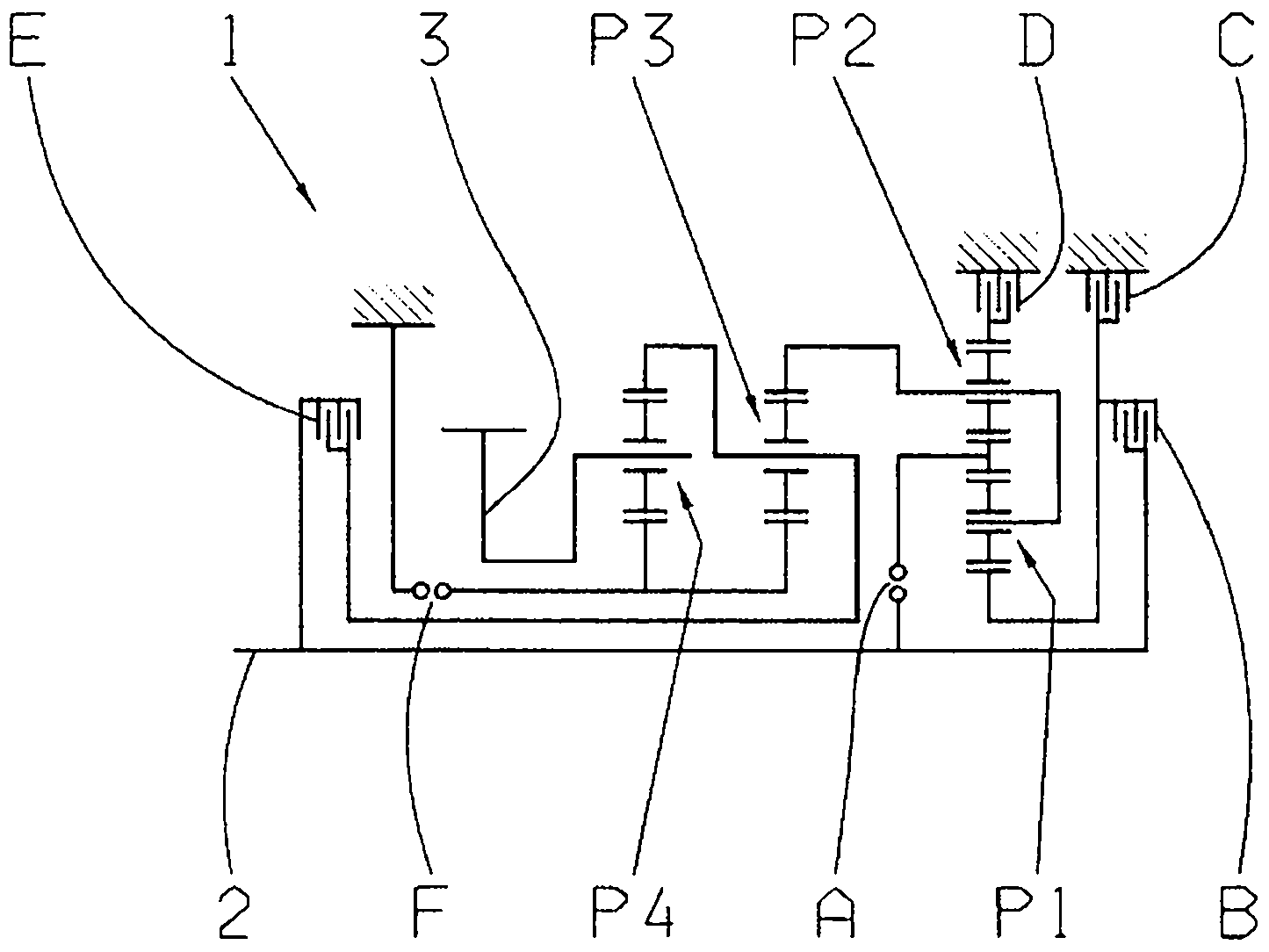

[0018] figure 1 A schematic diagram of the gears of the transmission 1 or of the multi-stage transmission known in principle from DE 10 2008 000 429 A1 is shown. The transmission 1 comprises a drive shaft 2 , which is connected to an output of the vehicle in the installed state in the vehicle, and a driven shaft 3 , which is operatively connected to the engine.

[0019] Furthermore, the transmission 1 comprises four planetary gear sets P1 to P4, the first and second planetary gear sets P1, P2, which are preferably configured as planetary gear sets with a negative gear ratio, form a switchable front gear set, while the third and second The four planetary gear sets P3, P4 constitute the main gear set. Furthermore, the transmission 1 comprises six shifting elements A to F, of which shifting elements C, D and F are in the form of brakes and shifting elements A, B and E are in the form of shifting clutches.

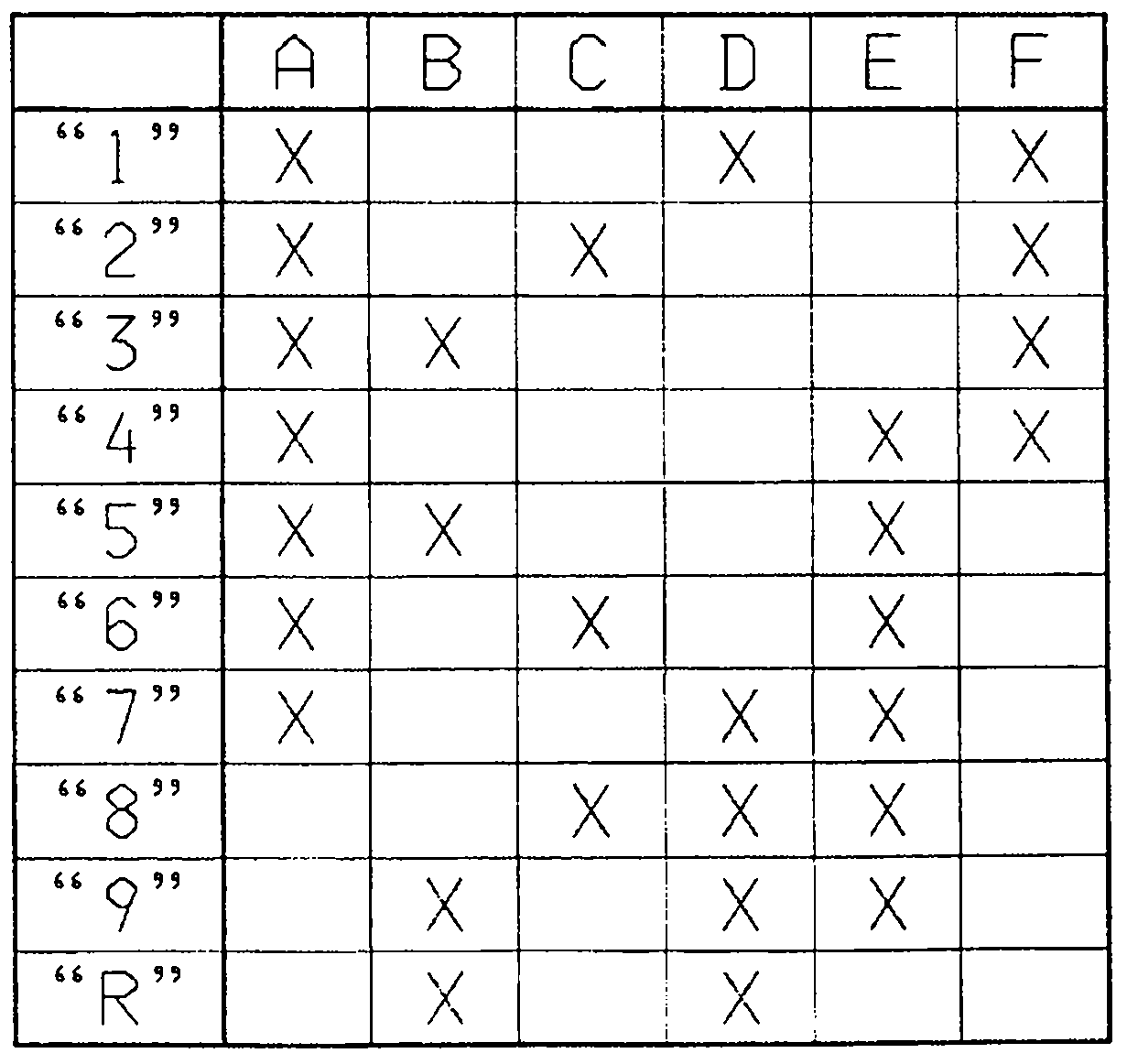

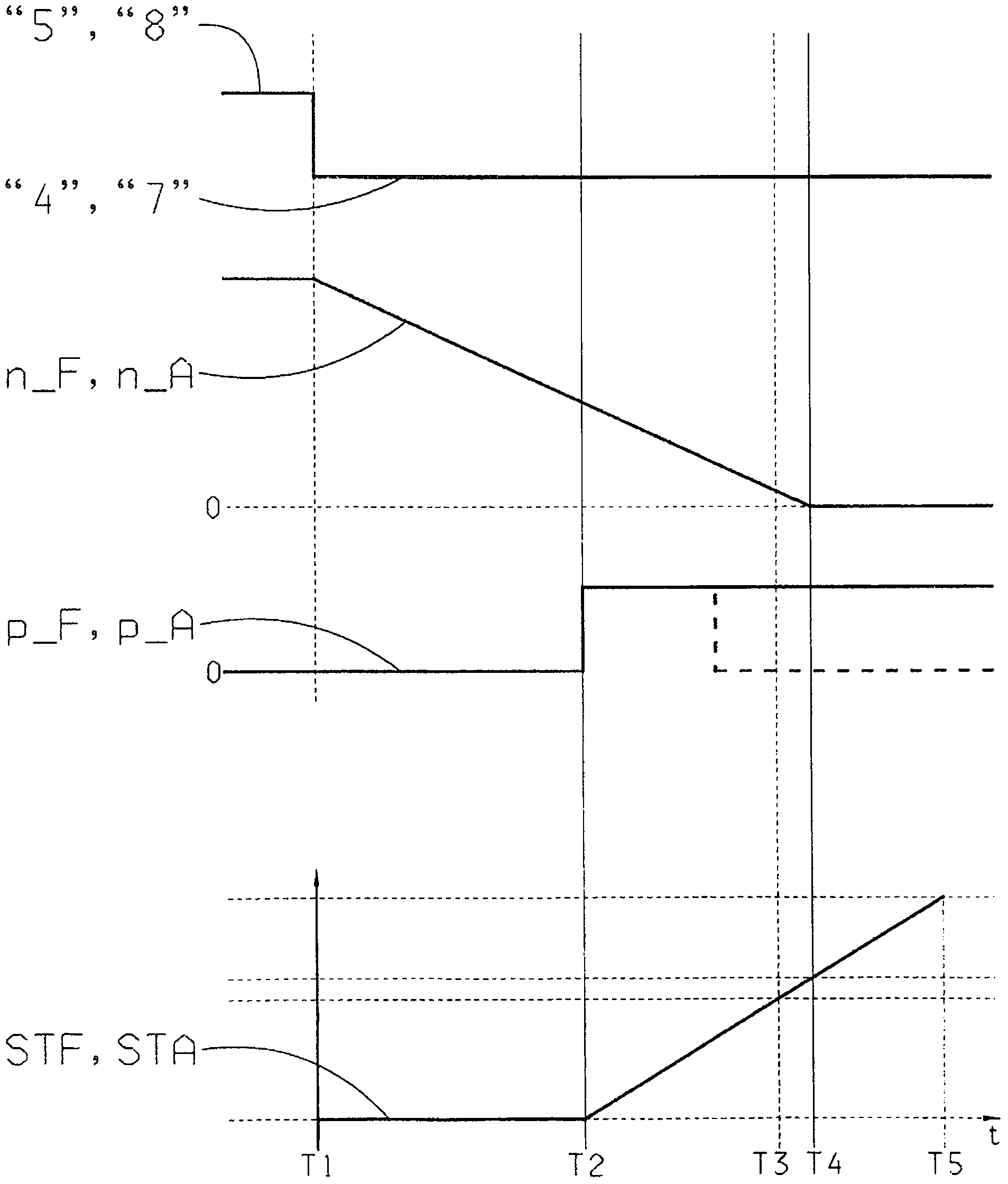

[0020] According to figure 2 The shifting logic described in detail i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com