Top frame joint-welding tool of top protective frame

A technology for roof frames and roof guards, which is applied in the field of manufacturing equipment for battery forklift roof guards, and can solve problems such as low positioning accuracy, low operating efficiency, and high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

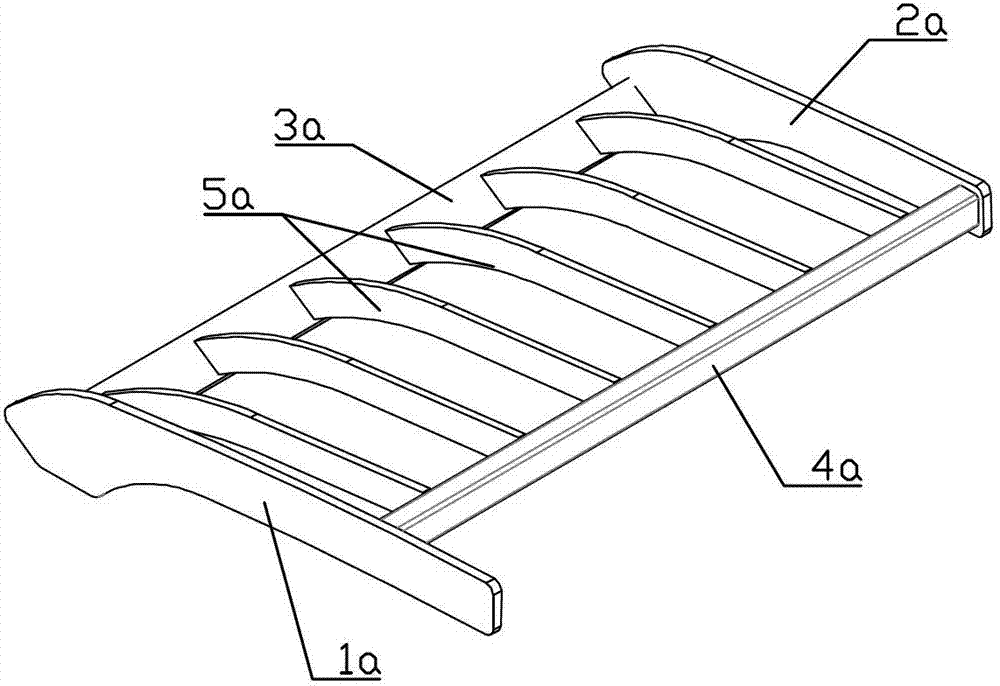

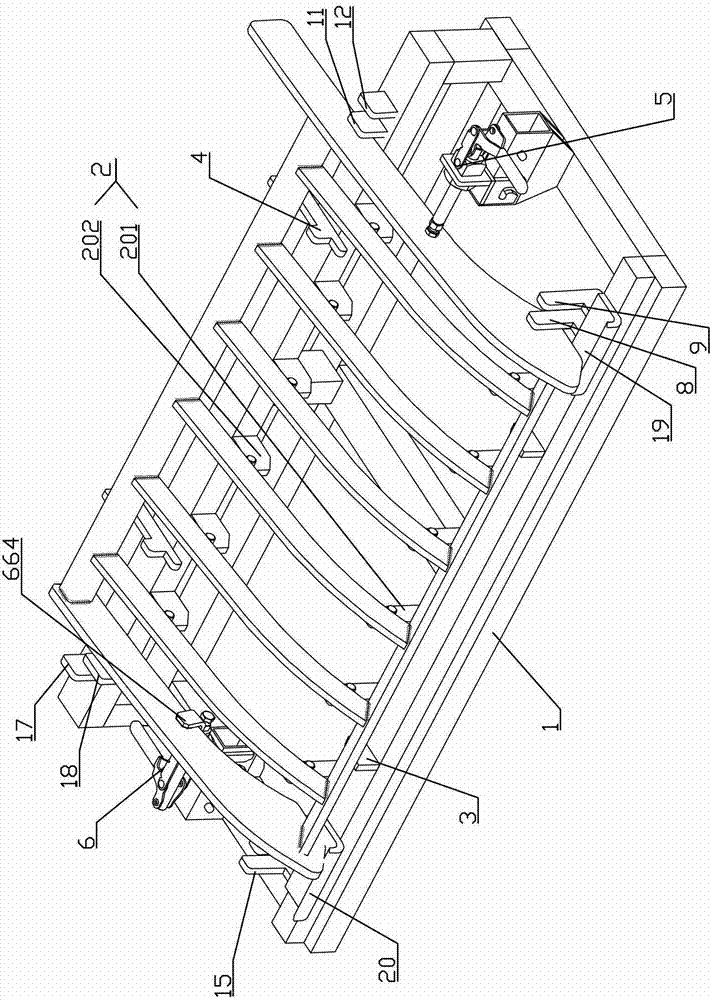

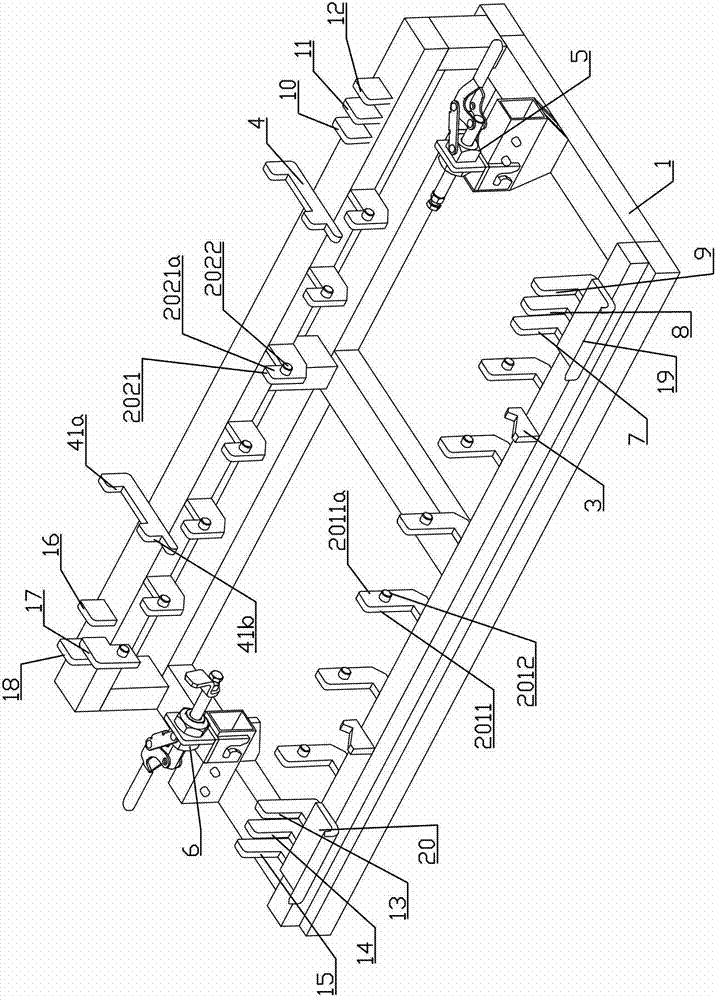

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 5 ;

[0026] The top frame tailor welding tooling of the roof guard given in this embodiment includes a base 1, a rib plate limiting mechanism 2, a front plate limiting block 3, a beam limiting block 4, a left plate clamping mechanism 5, a right Plate clamping mechanism 6, the first left plate limit block I7, the second left plate limit block I8, the third left plate limit block I9, the first left plate limit block II10, the second left plate limit block Plate limiter II11, third left plate limiter II12, first right plate limiter I13, second right plate limiter I14, third right plate limiter I15, first right Plate limit block II16, second right plate limit block II17 and third right plate limit block II18, left plate front end limit block 19, right plate front end limit block 20.

[0027] Wherein, the rib plate limiting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com