Method for Predicting Rock Drillability Grade Values in Different Drilling Directions in Shale Formation

A shale and stratum technology, which is applied in the field of predicting rock drillability grades in different drilling directions of shale strata, can solve the problems that the experimental evaluation method of rock drillability has not been proposed, and can save the cost of coring and reduce the cost of coring. Reduce the effect of repetitive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

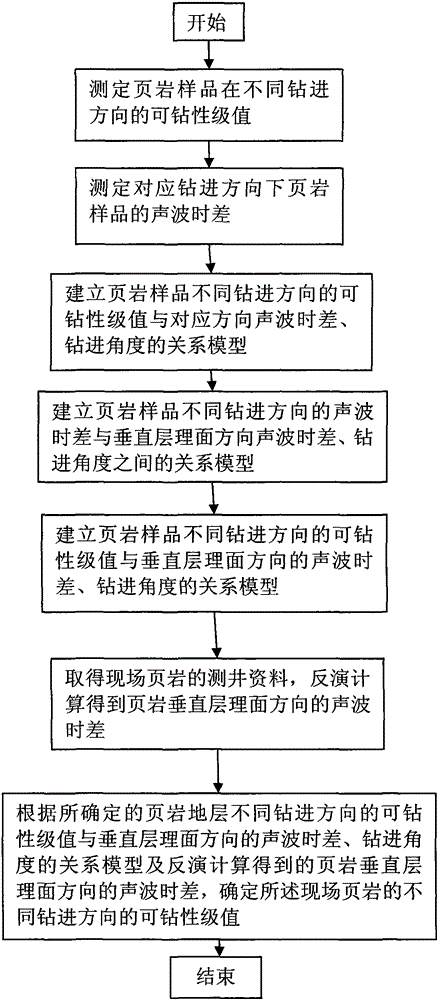

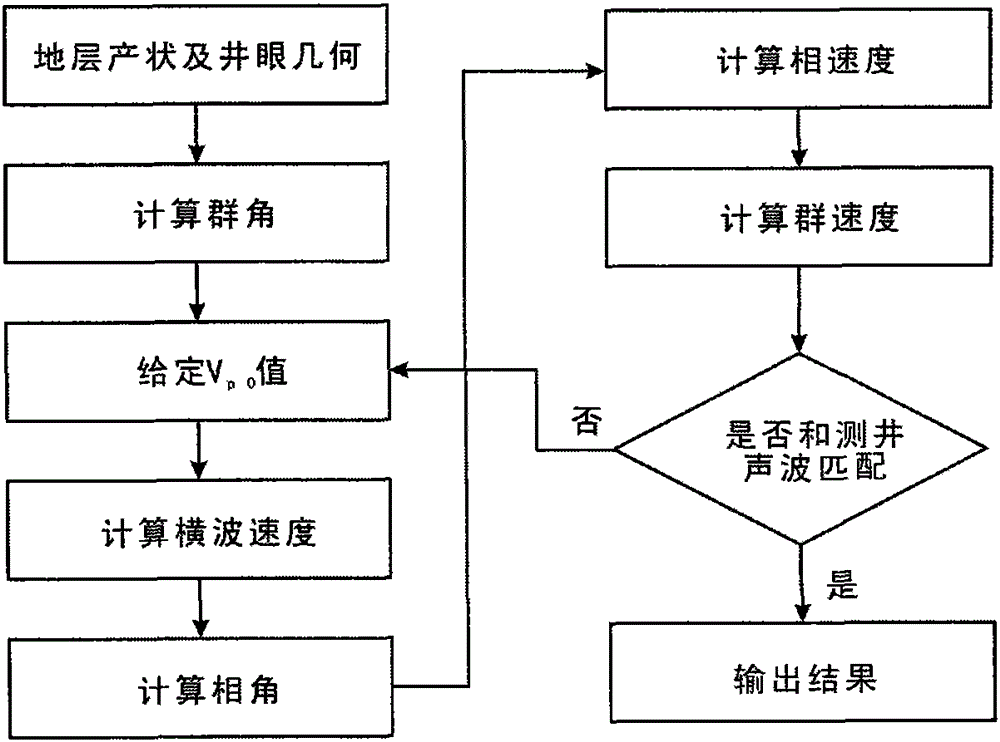

[0017] Such as figure 1 As shown, the method for predicting the rock drillability level value of different drilling directions in shale formations includes the following steps:

[0018] Step 1. Determine the drillability level of shale samples in different drilling directions. The specific method is as follows:

[0019] 1) Use a coring machine to take out cores with a diameter of 76.2 mm and a length of 50 mm in different bedding directions from the entire shale sample, and use a lathe to flatten the two end faces of the core. If it exceeds 0.2mm, put the core into the oven and bake at 100°C for 24 hours;

[0020] 2) Put the treated cores with different bedding directions into the rock drillability measurement system in sequence, and measure the drillability grade values of the cores with different bedding directions respectively;

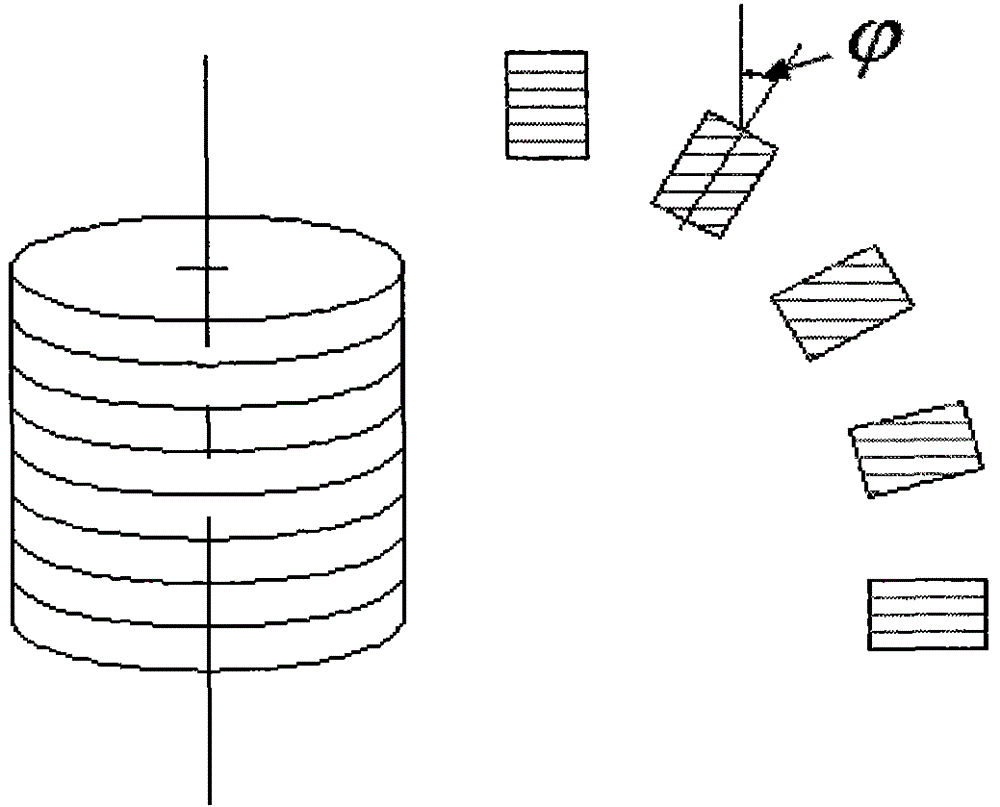

[0021] Drilling direction, which is the axial direction of the shale sample, is the same as figure 2 The angles shown are in the same relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com