Testing device for functional characteristic test of valve

A technology of functional characteristics and test equipment, applied in measuring equipment, vibration testing, testing of mechanical components, etc., can solve problems such as the inability to simulate the working environment of valves, and the ground test environment is not realistic enough, to achieve the effect of ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention below in conjunction with specific embodiment:

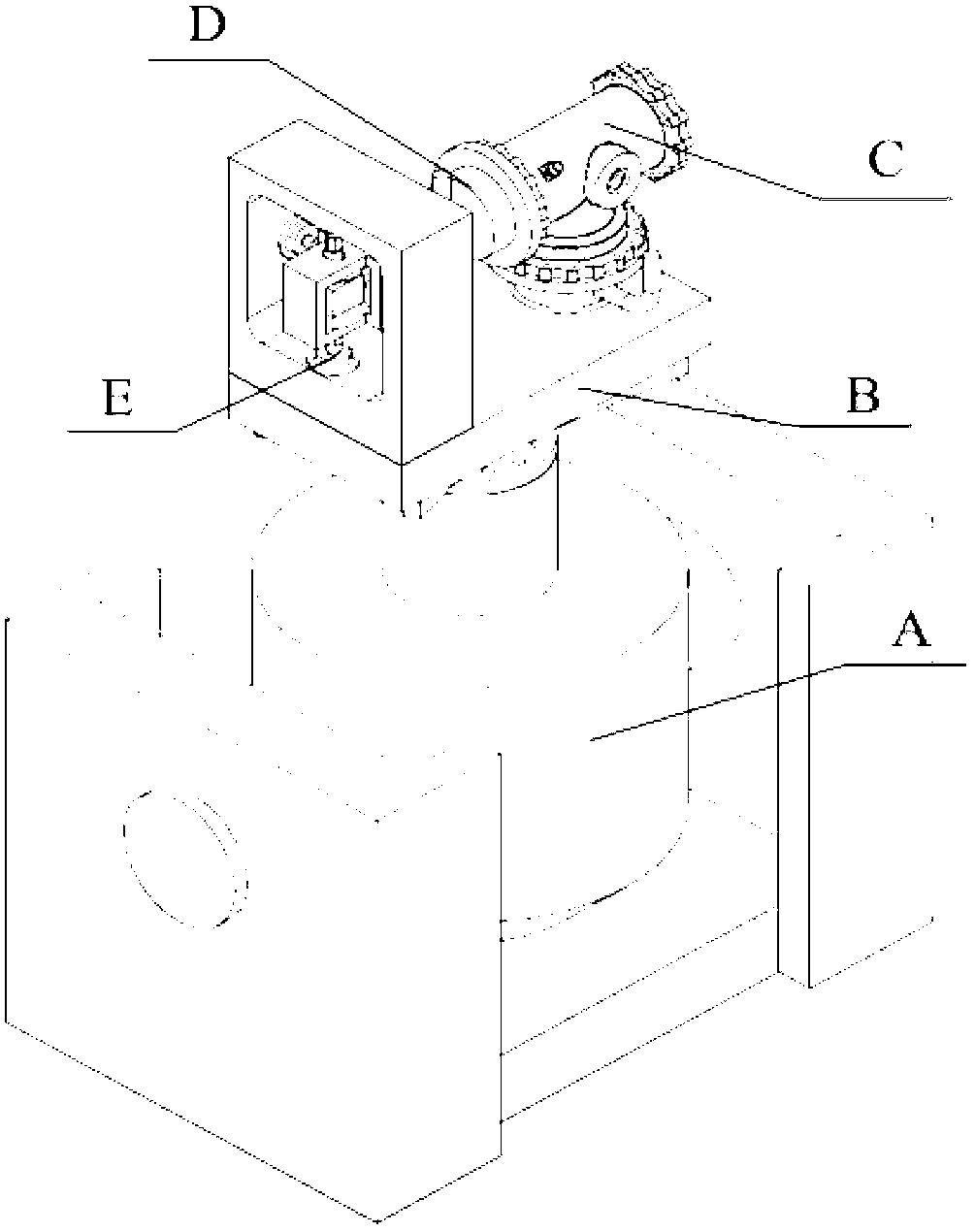

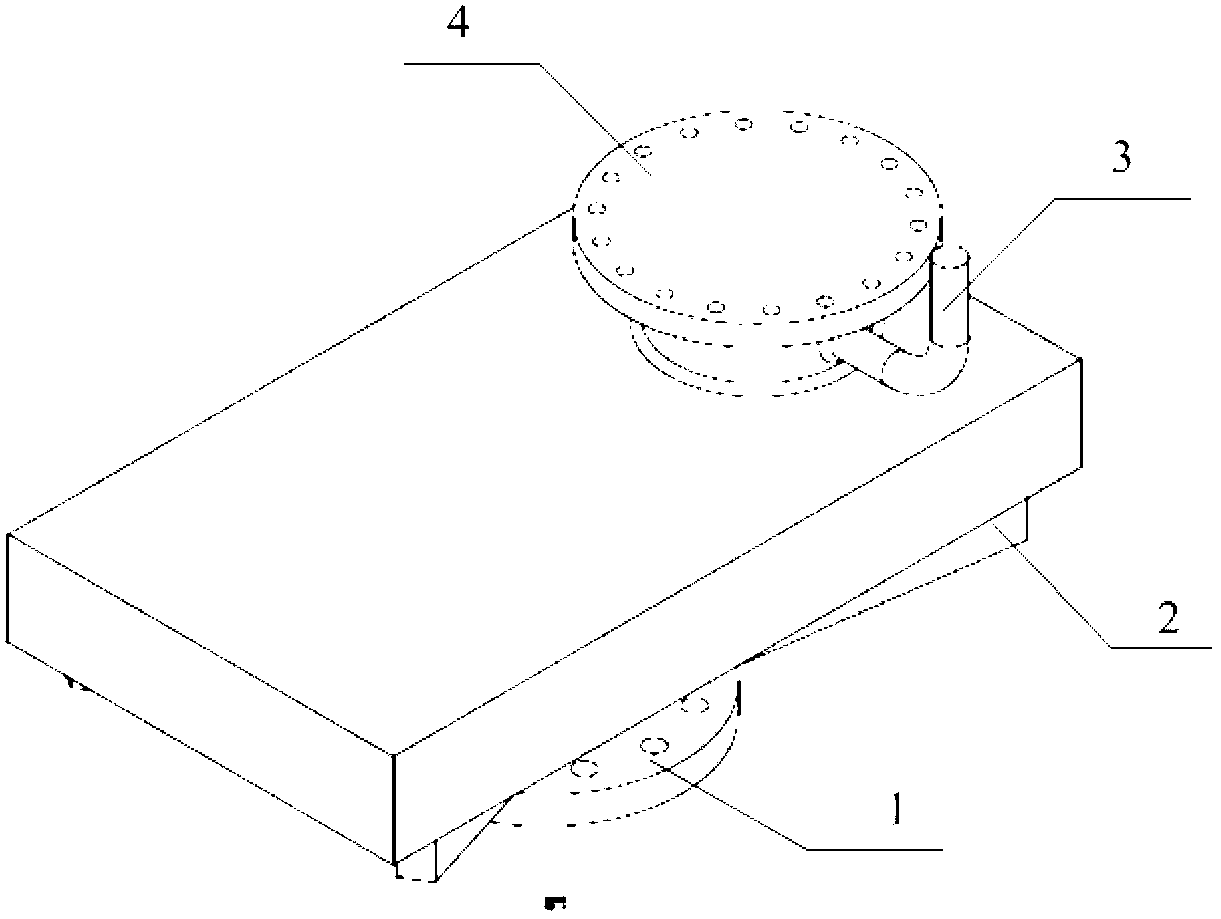

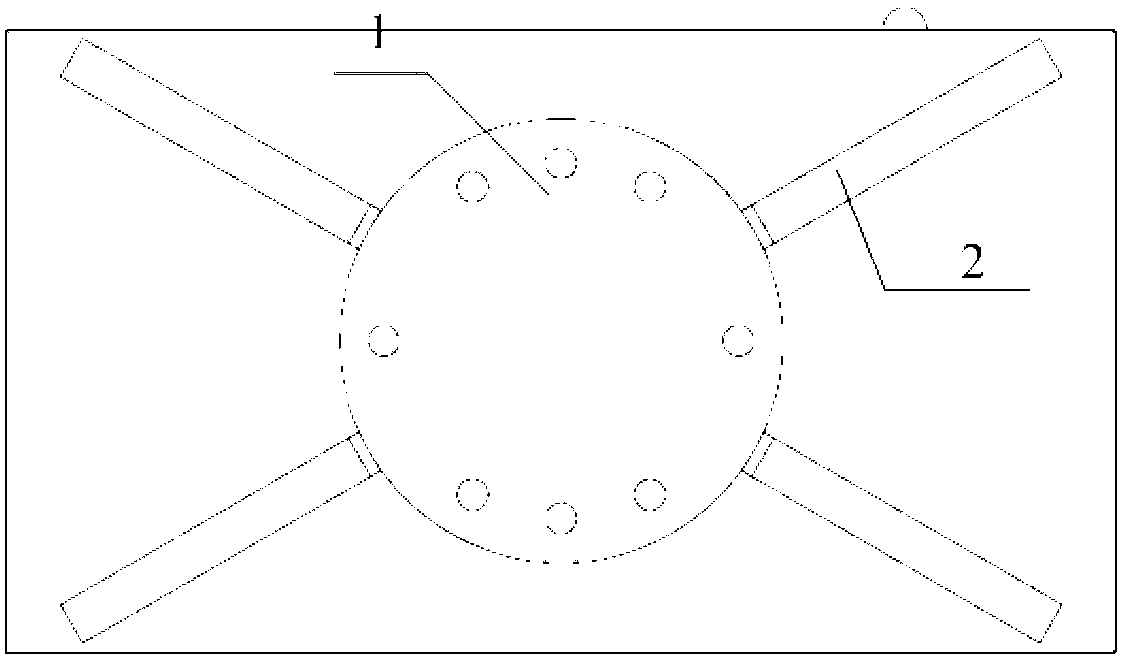

[0027] Refer to attached figure 1 , A test device used in the valve functional characteristic test in this embodiment is composed of a vibration table A, a vibration table frame B, a bending moment loading frame E and a test connector D. The bending moment loading frame and the valve test piece C to be tested are fixedly installed on the vibration table, and the vibration table frame is fixedly installed on the shaking table. The bending moment provided by the frame is transmitted to the valve test piece through the test connector. In this embodiment, the bending moment loading frame provides the bending moment of the valve in four directions, positive and negative, along the y and z directions, as shown in Figure 5 As shown, the outlet flange direction of the valve is defined as the x direction, the inlet direction of the valve is defined as the y direction, and the direction perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com