Control system of stranding machine and control method of stranding machine

A technology of control system and stranding machine, which is applied in the direction of cable/conductor manufacturing, textile and paper making, and control parts, etc. It can solve the problems of increasing costs, reducing efficiency, and not being able to track cables in real time, so as to save costs and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

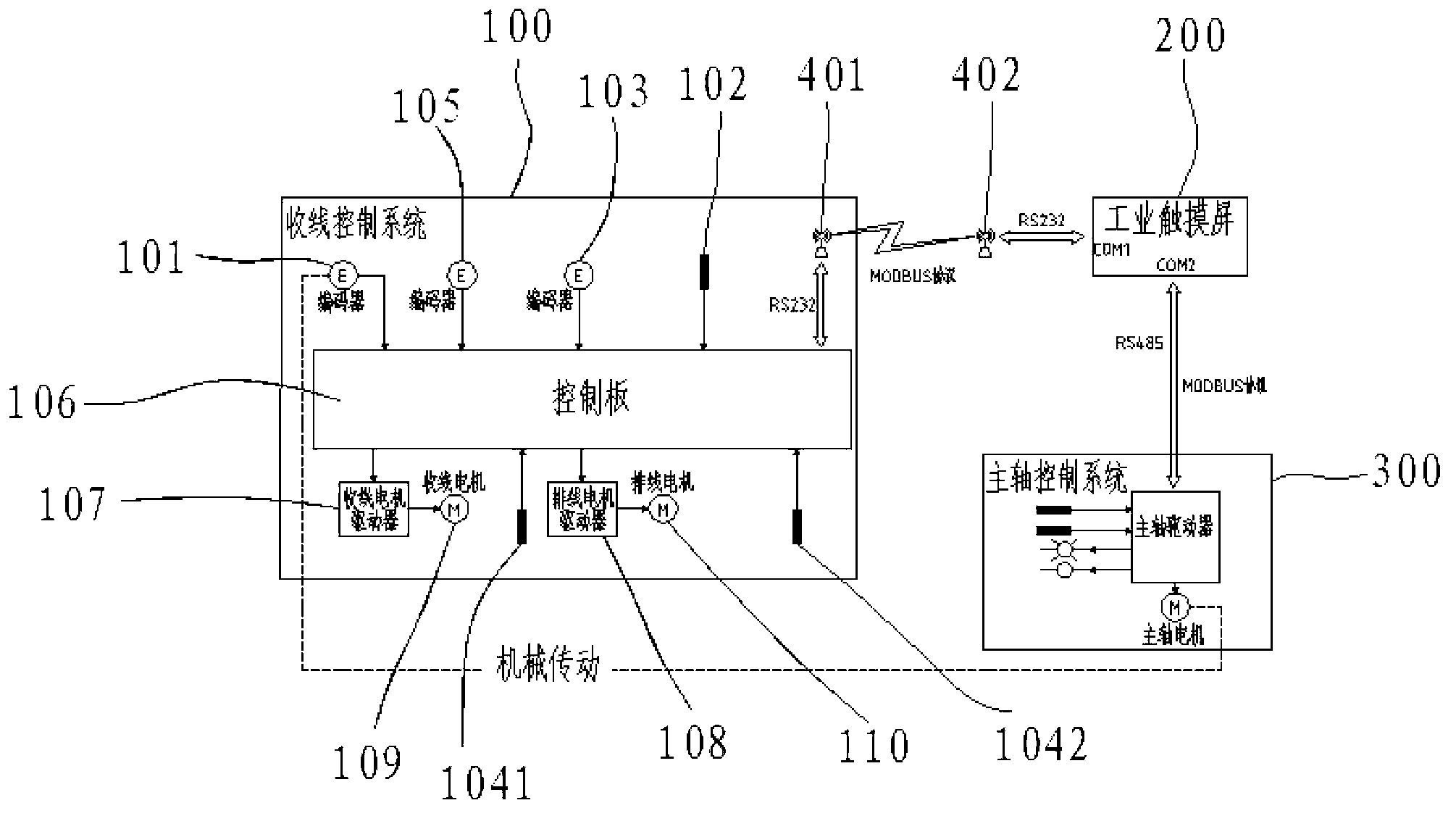

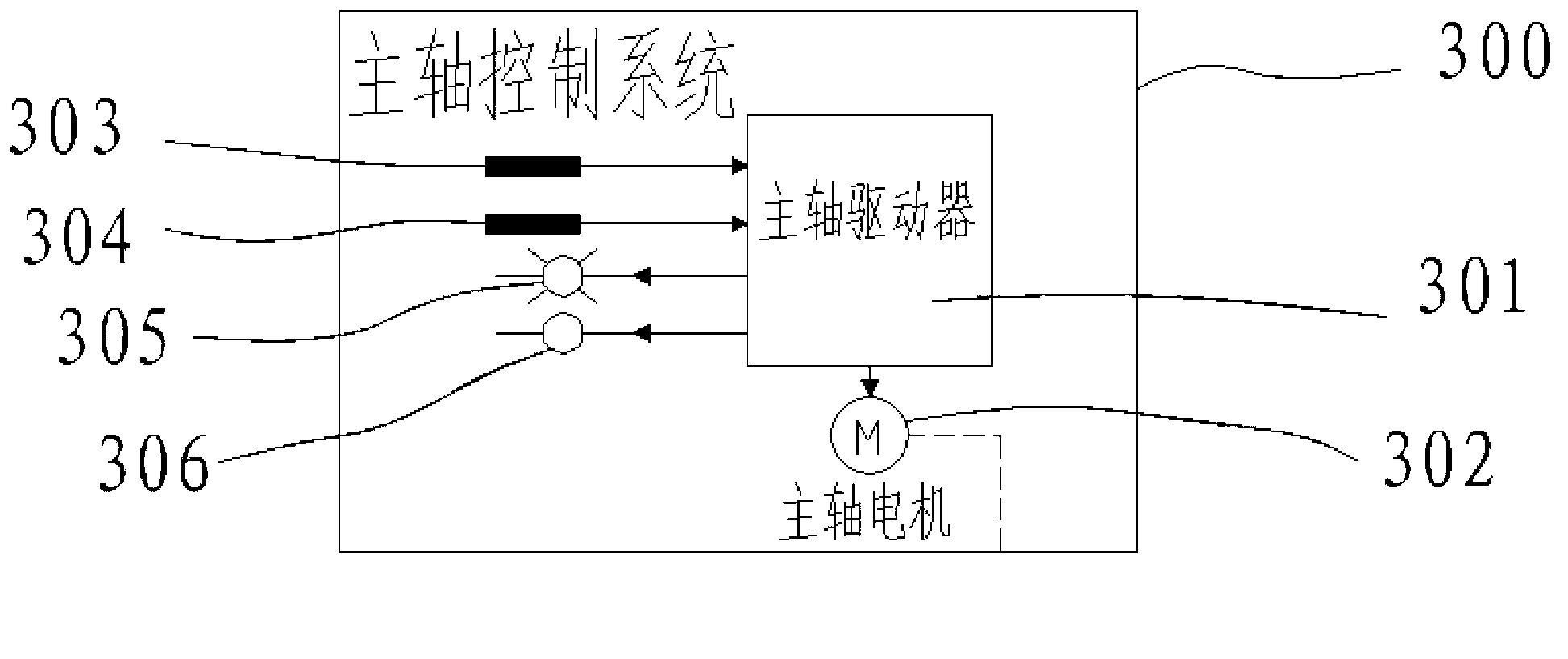

[0036] refer to figure 1 , in an embodiment of the present invention, a stranding machine control system, which includes a human-computer interaction module, a main shaft control module 300, and a wire take-up control module 100, and the main shaft control module 300 includes a drive unit for driving the main shaft— , the take-up control module 100 includes a control unit 106 and a detection unit one 101 and a drive unit two respectively connected with the control unit 106 signal, the human-computer interaction module is connected with the drive unit one of the spindle control module 300 and the take-up control module 100 respectively The control unit 106 signal connection, the detection unit one is connected with the spindle control module 300 signal, the human-computer interaction module and the spindle control module 300 are connected through the MODBUS pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap