A thermal spray tooling

A technology of thermal spraying and tooling, applied in the direction of workpiece clamping device, metal material coating process, coating, etc., can solve the problems of increasing labor intensity of operators, redundant actions of operators, and clamping can not be completed in one step, etc. Achieve the effects of reducing redundant actions, easy installation, and practical functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

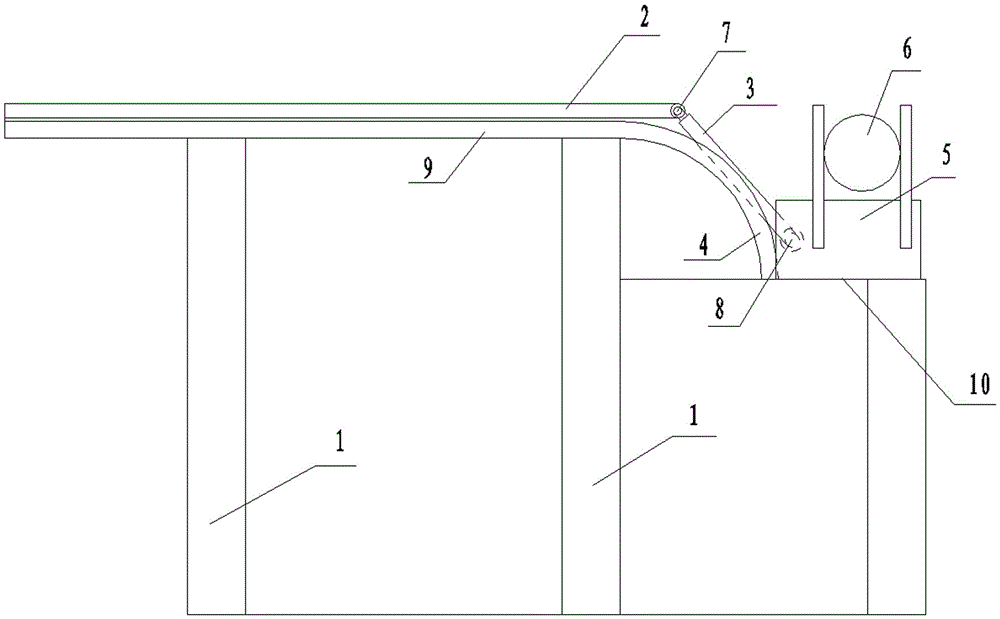

[0009] Example: such as figure 1 Shown, a kind of thermal spraying tooling comprises support 1, and guide rail is provided with on support 1, and guide rail comprises horizontal guide rail 9 and the arc guide rail 4 of docking, and the end of arc guide rail 4 is provided with horizontal support platform 10; There is a guide rod, the guide rod includes a horizontal rod 2 and a hinged rotating rod 3, the outer end of the horizontal rod 2 is connected to the output end of the hydraulic press, and the power is provided by the hydraulic press to pull the fixture and the workpiece. The outer end of the rotating rod 3 is hinged with the fixture 5, and the inner side of the fixture 5 is attached to the arc guide rail 4, and the workpiece 6 is clamped on the opening of the fixture 5; when the fixture 5 passes through the arc guide rail 4 from top to bottom, the opening direction of the fixture 5 is determined by The horizontal direction becomes vertical upwards. The horizontal rod 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com