Process for manufacturing V-shaped skin provided with built-in filler

A manufacturing process and filler technology, which is applied in the field of V-shaped skin manufacturing technology with built-in fillers, can solve problems such as being too thin, affecting the overall skin size, and being too small, and achieve the effect of improving processing efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

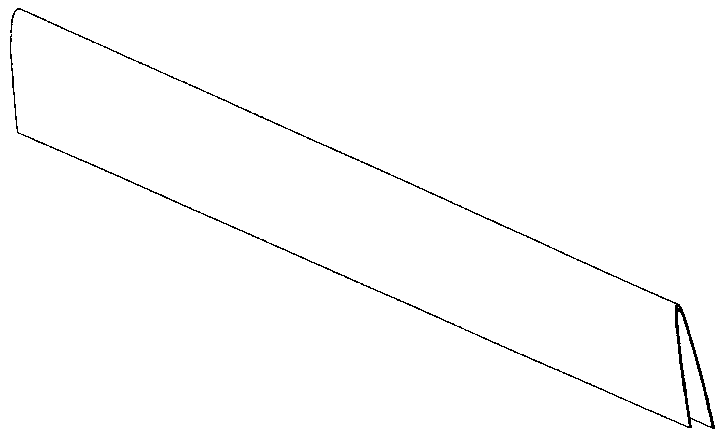

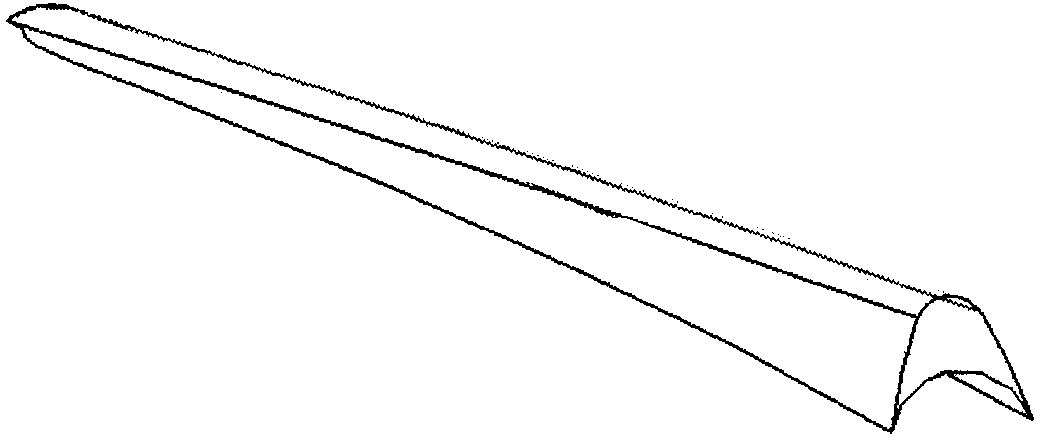

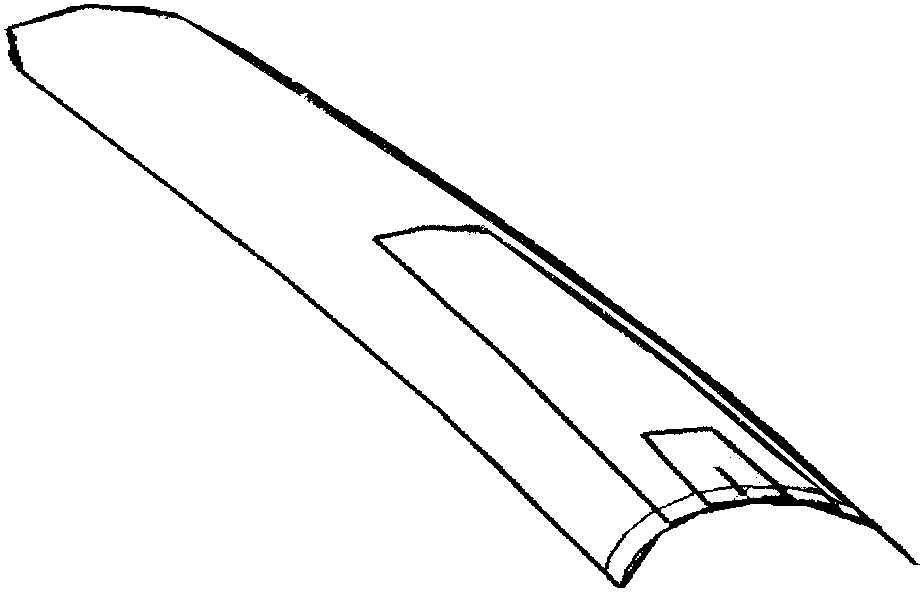

[0018] Such as figure 1 A "V"-shaped hyperbolic structure skin is shown, the outer surface of the skin is the aerodynamic profile surface, and the inner surface is the assembly surface, and its R angle is as follows figure 2 As shown in , there is a non-uniform cross-section filler between the inner and outer skins of the front end of the part, that is, along the length direction of the skin, the thickness of the built-in filler is the largest, and then the thickness gradually decreases to form a non-uniform cross-section filler. . The V-shaped skin manufacturing process with built-in fillers, the steps are as follows:

[0019] 1) Production of hard cover:

[0020] Use 4 layers of glass cloth as the main layer of the cover, and 1 layer of tooling prepreg as the reinforcement layer, and put it into the heating box at 180 ° C for 3 hours;

[0021] 2) Design and manufacture of fillers:

[0022] Use Fibersim software to design the layup of the filler, convert the irregular fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com