Three-dimensional reflecting measurement device and method

A measuring device and reflective technology, applied in the direction of measuring device, optical device, radio wave measuring system, etc., can solve the problems of too large or too small measuring angle, unsuitable for the object to be measured, unable to measure, etc., so as to improve the installation efficiency , Improve the efficiency of installation, the effect of light overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The three-dimensional reflective measuring device proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

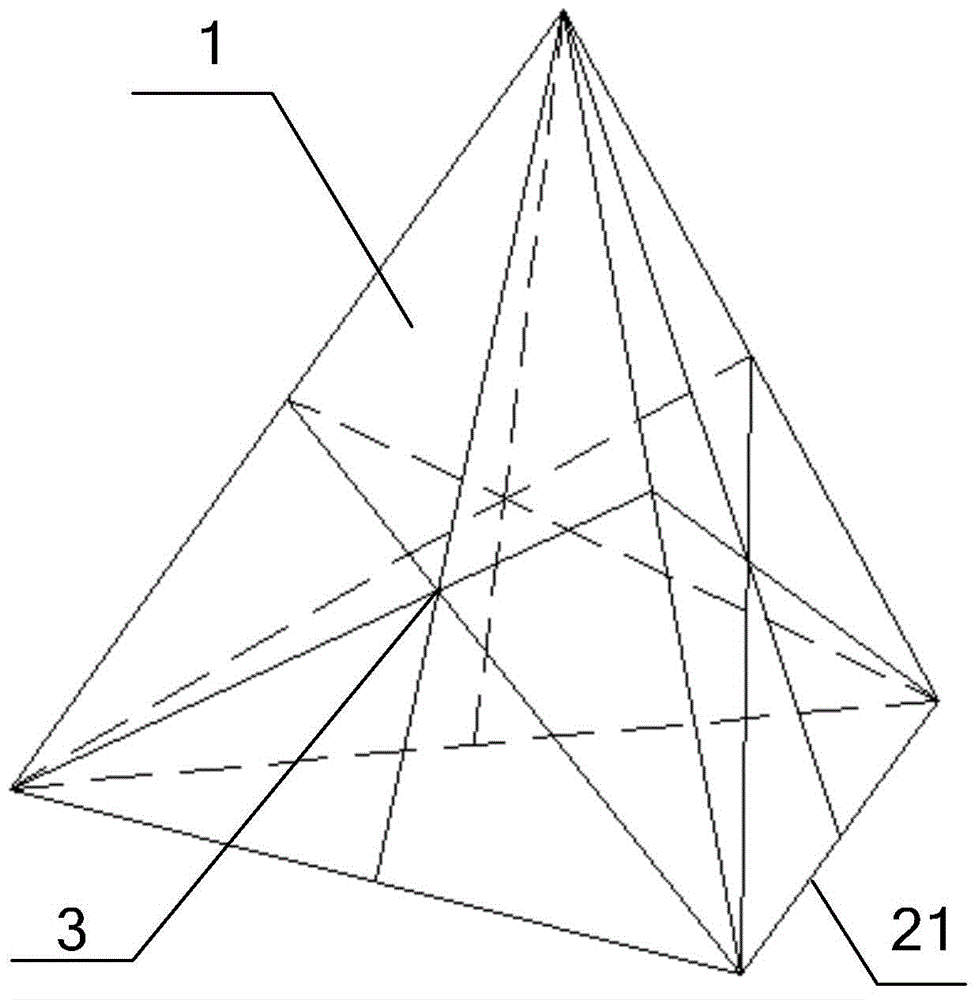

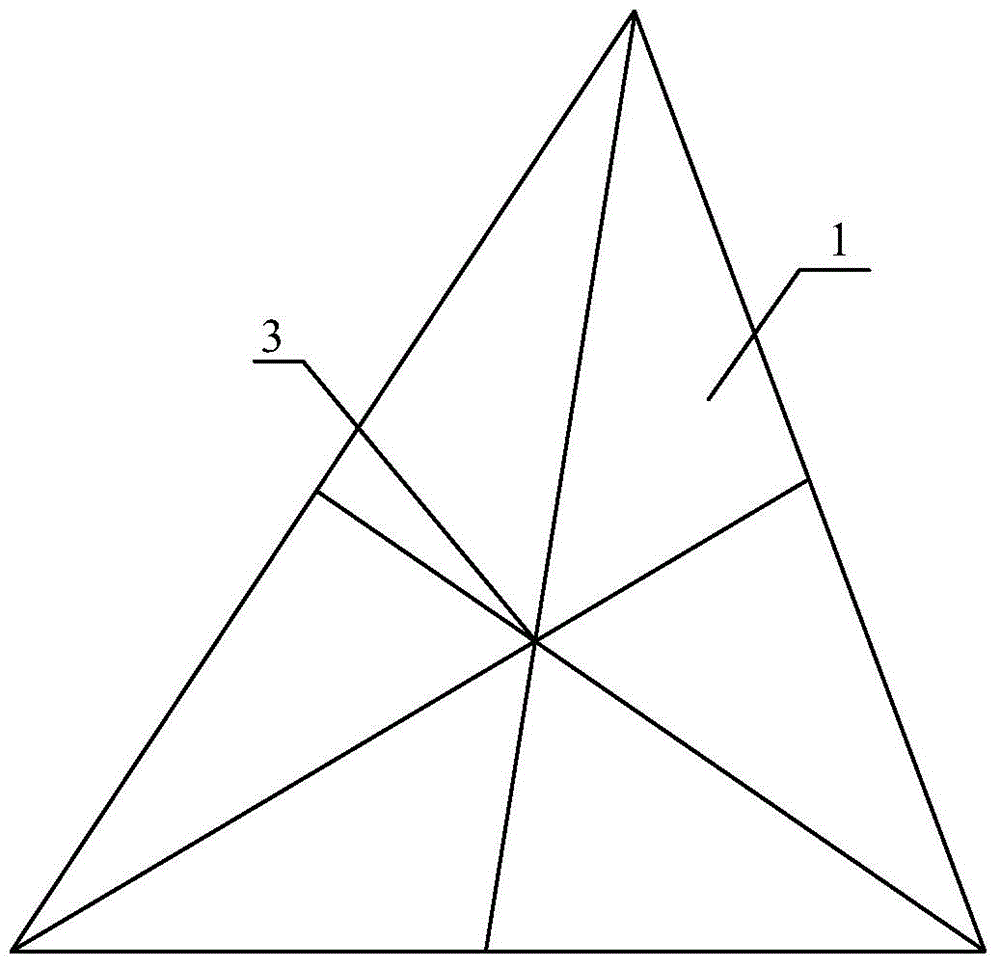

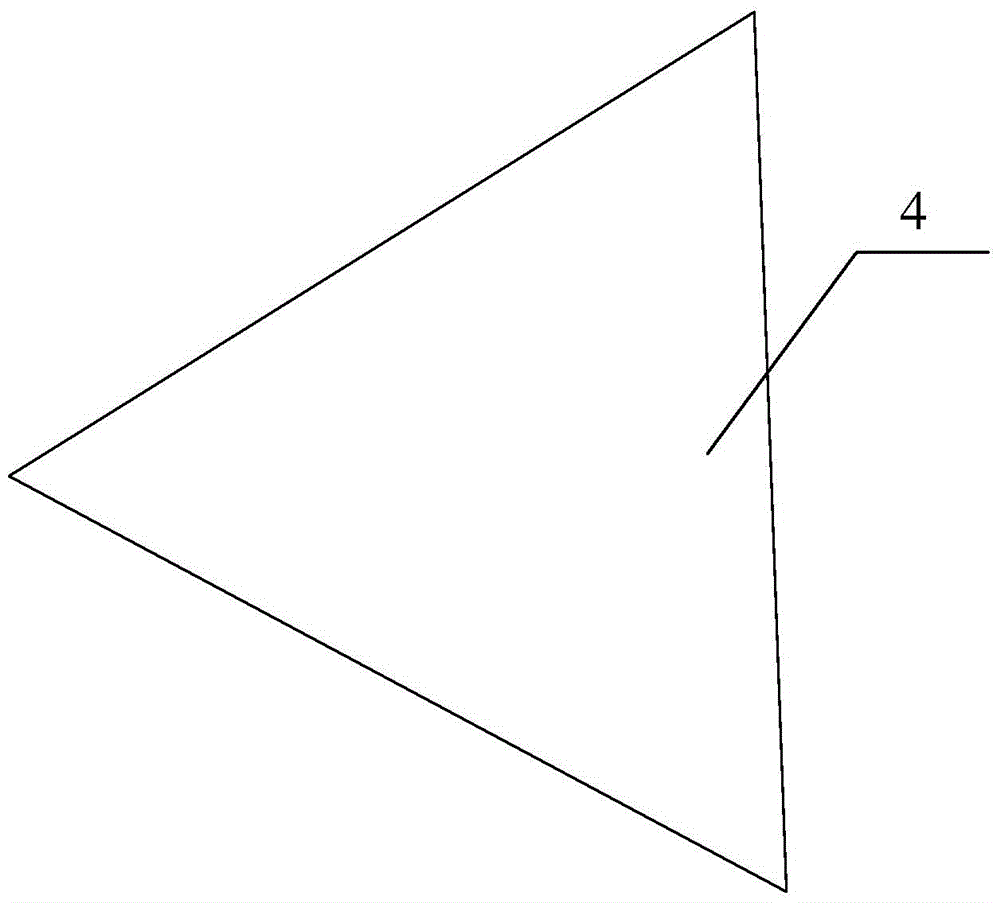

[0029] combine Figure 1 to Figure 4 , the present embodiment discloses a three-dimensional reflective measuring device, comprising a regular pyramid 2 (also referred to as a base material), the bottom surface of the regular pyramid 2 is provided with a bonding layer, and the remaining surfaces are respectively provided with The reflective material layer 3 forms a reflective surface, and the center 3 of each reflective surface is marked on each reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com