Pneumatic double-storage-tank drainage controller

A dual-storage and controller technology, applied in the direction of tank trucks, containers, large containers, etc., can solve the problems of bulky structure, lower production efficiency, leakage and discharge of medium in storage tanks, etc., to protect personnel safety, improve work efficiency, and The effect of water isolation and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

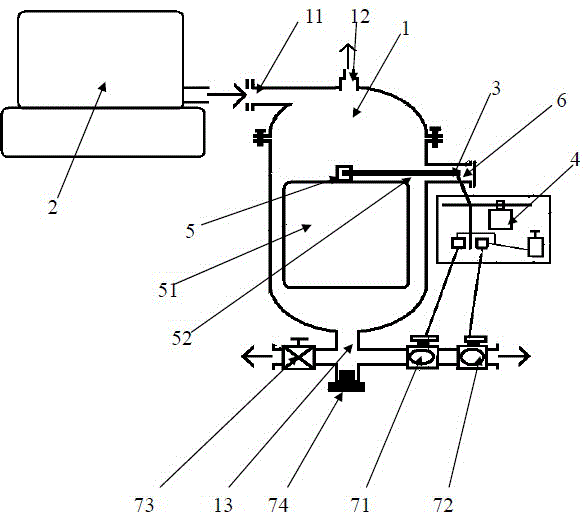

[0032] The specific implementation is as follows, below the discharge port 13 is a four-way pipeline, the upper opening is connected to the discharge port 13, the lower opening is provided with a sewage plug 74, the left horizontal opening is installed in series with a drain valve 71 and an air-closing valve 72, and the right horizontal opening Install manual drain valve 73.

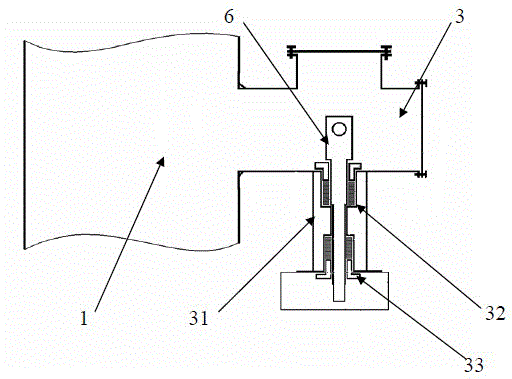

[0033]The liquid level linkage device 5 includes a floating ball 51 and a buoyancy lever 52. The floating ball 51 floats on the liquid level in the sedimentation water storage tank 1, and can change its height according to the rising and falling of the liquid level. The upper end of the floating ball 51 is movably connected to the end of the buoyancy lever 52 , and the other end of the buoyancy lever 52 extends into the inside of the sealing chamber 3 and is movably connected to the rotating shaft 6 .

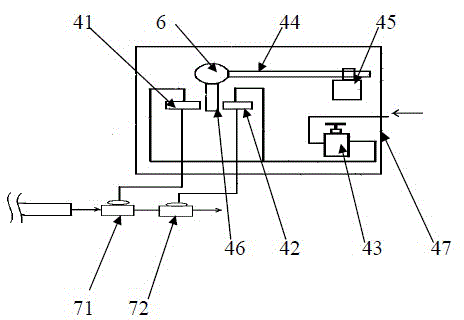

[0034] The valve control device 4 is composed of a high interface pneumatic switching valve 41, a low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com