Method and system for air-fuel ratio control

An air-fuel ratio and fuel technology, which is applied in fuel injection control, electrical control, charging system, etc., can solve problems such as emission problems, complex calculations, and damage to the output of oxygen sensors, so as to reduce emissions, improve exhaust emissions and improve engine performance. performance, and the effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

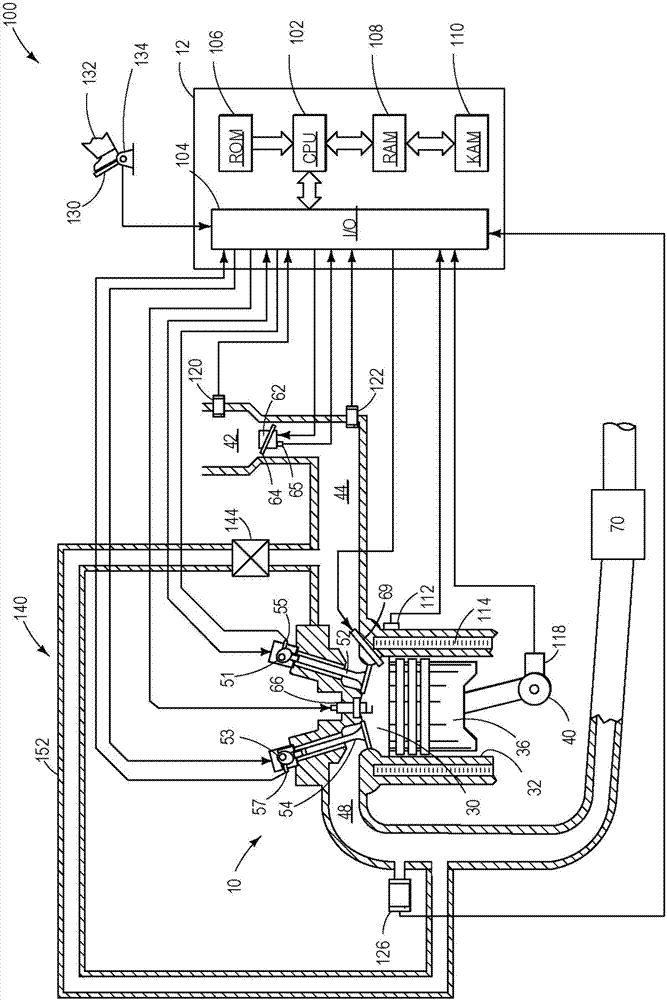

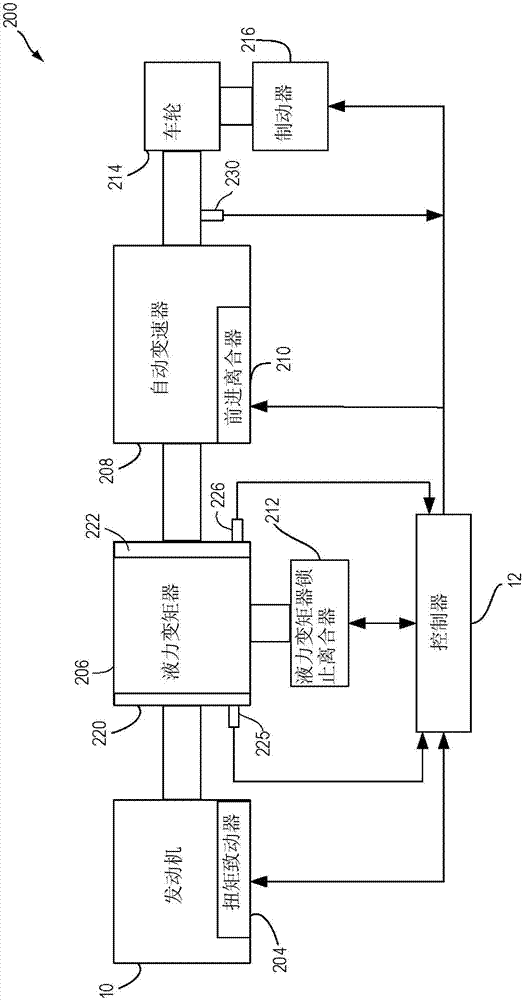

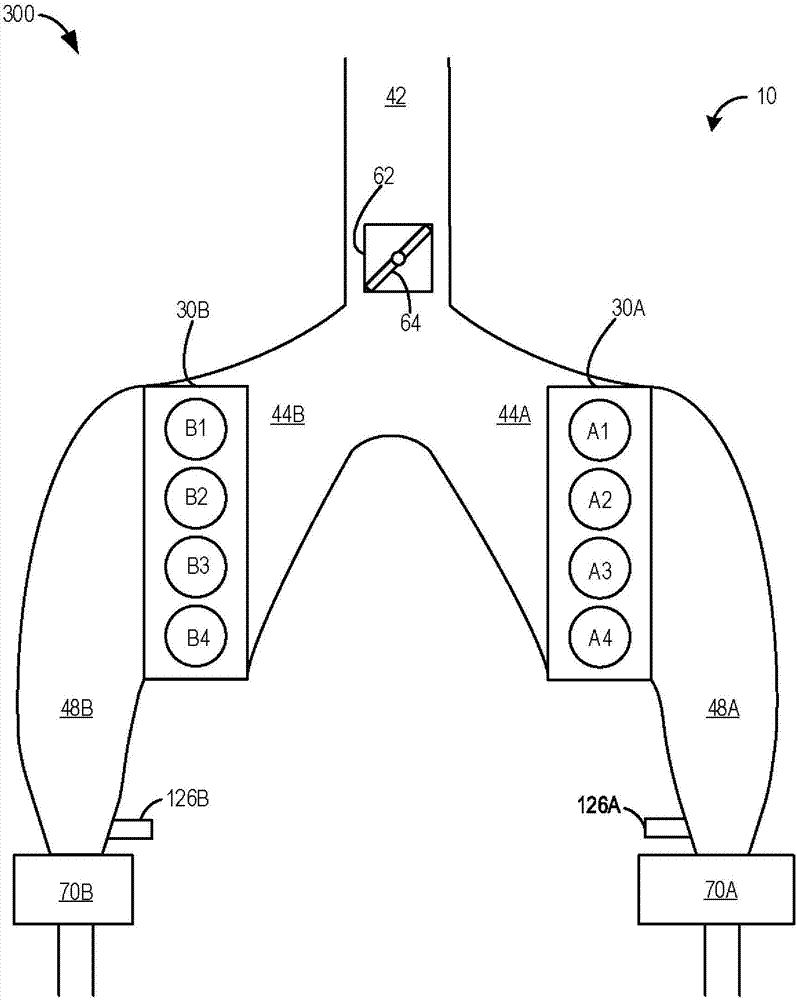

[0022] The following description relates to systems and methods for detecting and correcting air-fuel ratio imbalances and injector errors during DFSO. figure 1 A single cylinder of an engine including an exhaust gas sensor upstream of an emission control device is shown. figure 2 An engine, transmission, and other vehicle components are depicted. image 3 A sample V-8 engine is shown with a pair of cylinder banks, an exhaust manifold, and an exhaust sensor. Figure 4 A method for determining the status of a DFSO is shown. Figure 5 A method of initiating open loop air-fuel ratio control during DFSO is shown. Image 6 An example method is presented for performing open loop air-fuel ratio control based on inter-cylinder air-fuel ratio corrections. Figure 7 Sample graph data showing groups of two consecutive fuel pulses injected into cylinders with different pulse widths and learned measurements for inter-cylinder air-fuel variation based on lambda value during open-loop ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com