Full-automatic coal mine ventilation air methane collecting device

A collection device, fully automatic technology, applied in the direction of safety devices, mining devices, mining equipment, etc., can solve the problems of waste of resources, large exhaust air gas emissions, environmental pollution, etc., to simplify the structure, improve efficiency and gas utilization rate, to avoid the effect of explosion hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

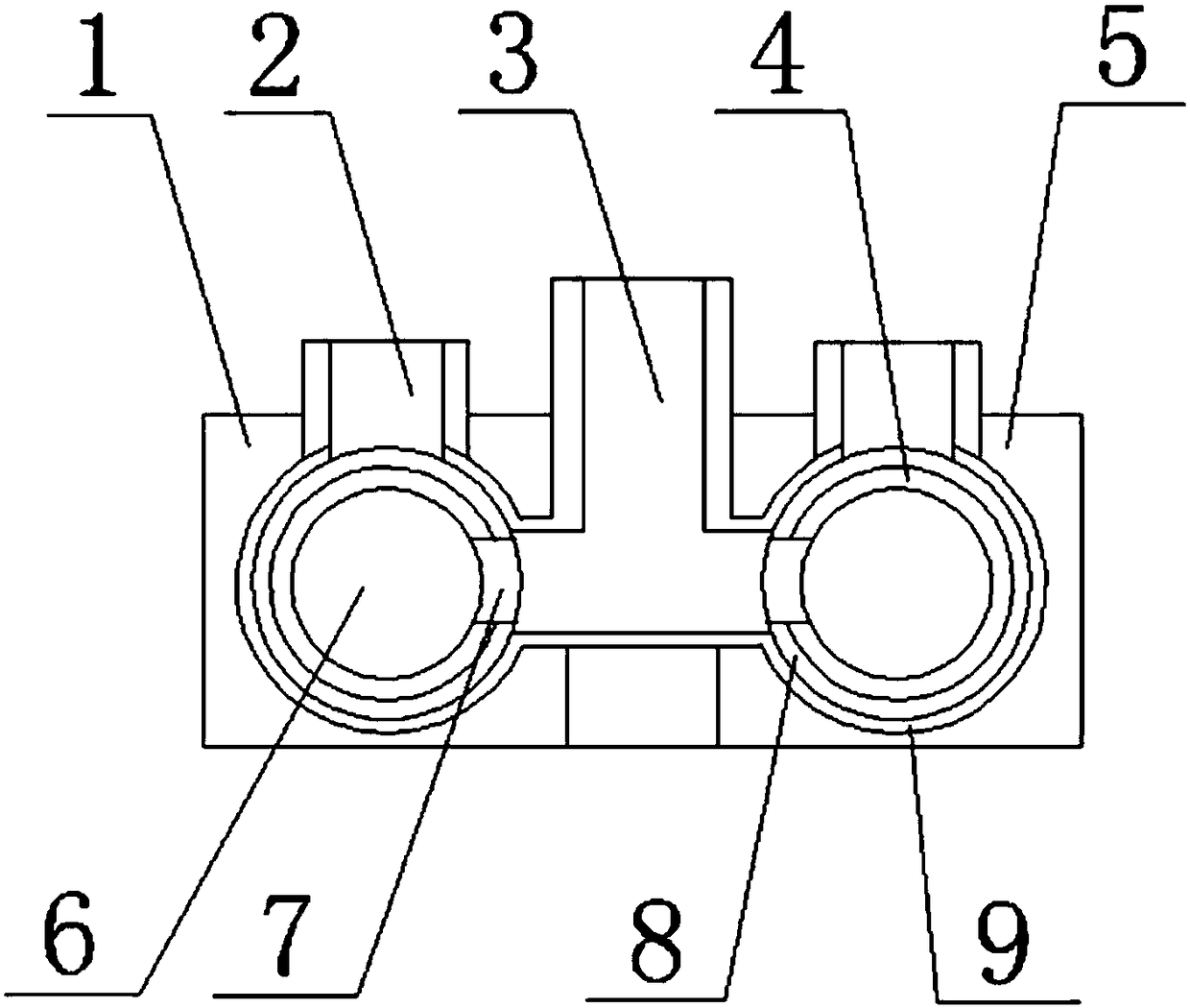

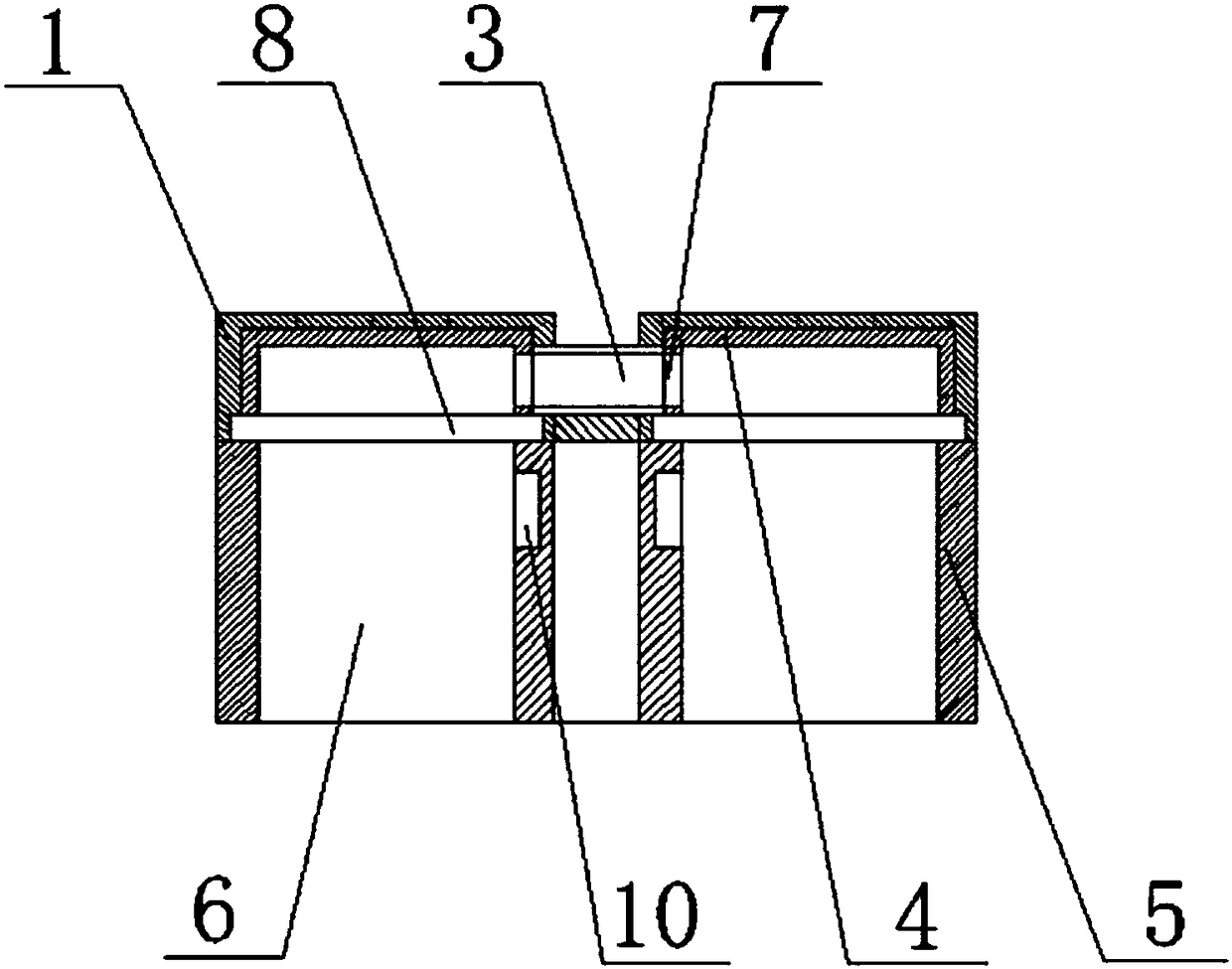

[0018] A fully automatic coal mine exhaust air collection device, comprising a diffusion tower 1, a diffusion tower 5, a rotating air channel 4 and a exhaust air pipeline 3, the diffusion tower 1 and the diffusion tower 5 are arranged side by side, and the diffusion tower 1 and the diffusion tower 5 are arranged in parallel. It is the diffusion air duct 6, the gas concentration sensor 10 is arranged on the inner wall of the diffusion air duct 6, the exhaust air duct 3 is arranged between the diffusion tower 1 and the diffusion tower 5, and the rotating air duct 4 is arranged on the diffusion tower 1 Above, the outer side of the rotating air duct 4 is provided with a protective cover 9, the bottom of the rotating air duct 4 is a rotating mechanism 8, and the rotating air duct 3 is provided with an air outlet 7, and the air outlet 7 of the rotating air duct 3 is connected with the exhaust duct 2 and exhaust air. Pipeline 3 corresponds. An application method of a full-automatic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com