Bottle separating device

A bottle-splitting and bottle-screwing technology, which is applied in packaging, bottle filling, liquid bottling, etc., can solve problems such as large contact area, increased production cost, and damage to containers and bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

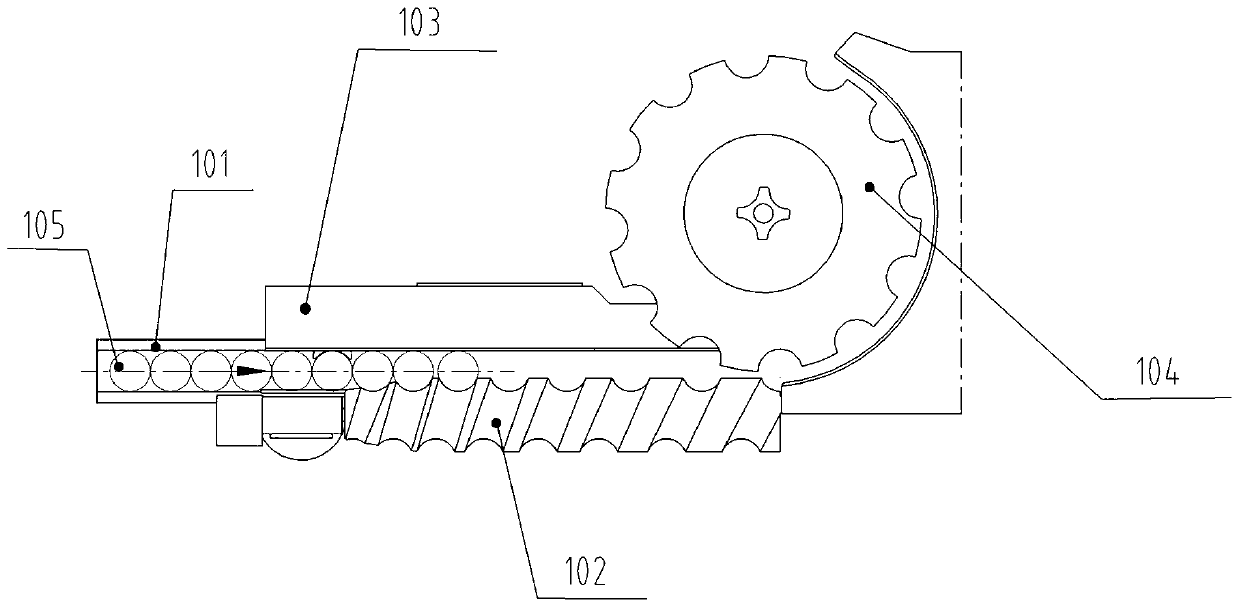

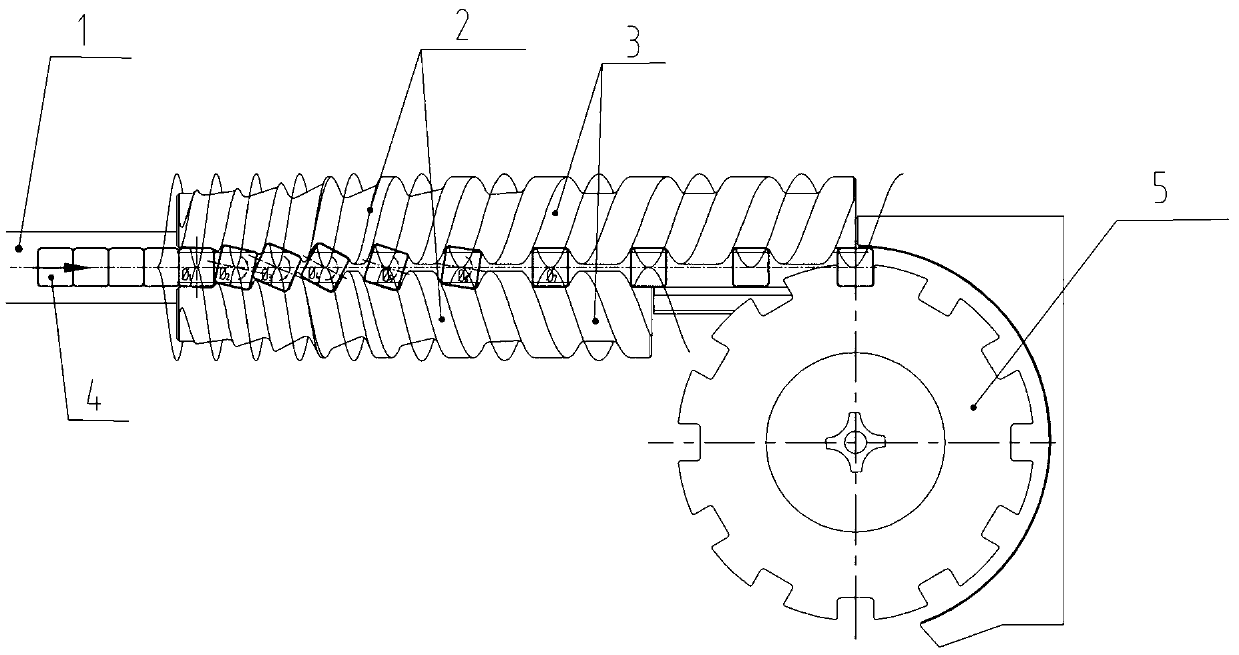

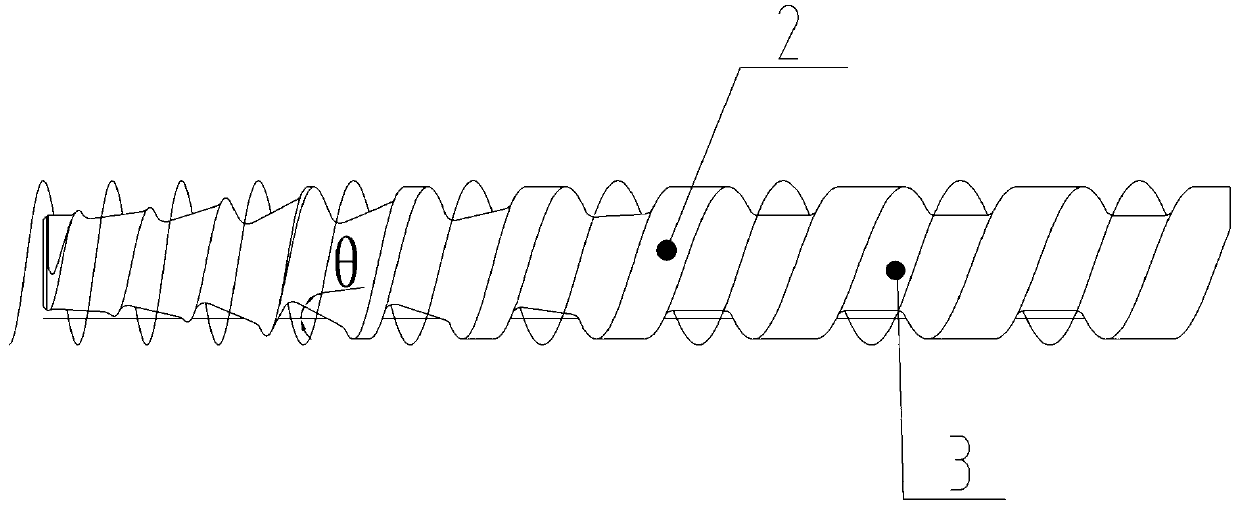

[0011] like figure 2 As shown, the bottle-separating device includes a transmission track 1, a bottle-separating screw 2 is respectively provided on both sides of the transmission track 1, the spiral grooves 3 on the two bottle-separating screws are corresponding and the spiral grooves on the two bottle-separating screws are corresponding. The direction of the spiral is opposite. The container bottles 4 are sequentially transported to the bottle-separating screw by the transmission track, and the container bottles are inserted into the corresponding spiral grooves on the bottle-separating screws on both sides of the transmission track one by one, and move forward with the rotation of the bottle-separating screws on both sides. It is completely stuck between the adjacent containers and bottles, so that the adjacent containers and bottles are accurately and effectively separated, and the separated containers and bottles are transported out one by one in a straight line or into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com