Microplastic floatation grading separation device in wetland deposits and method thereof

A fractional separation and sedimentation technology, applied in separation methods, separating solids from solids with airflow, filtration separation, etc., can solve the problem that fine particles and plant residues cannot be separated by filtration, research cannot be carried out, and microplastic identification Inability to accurately judge problems, to achieve the effect of avoiding fine particles of sediment and plant residues, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

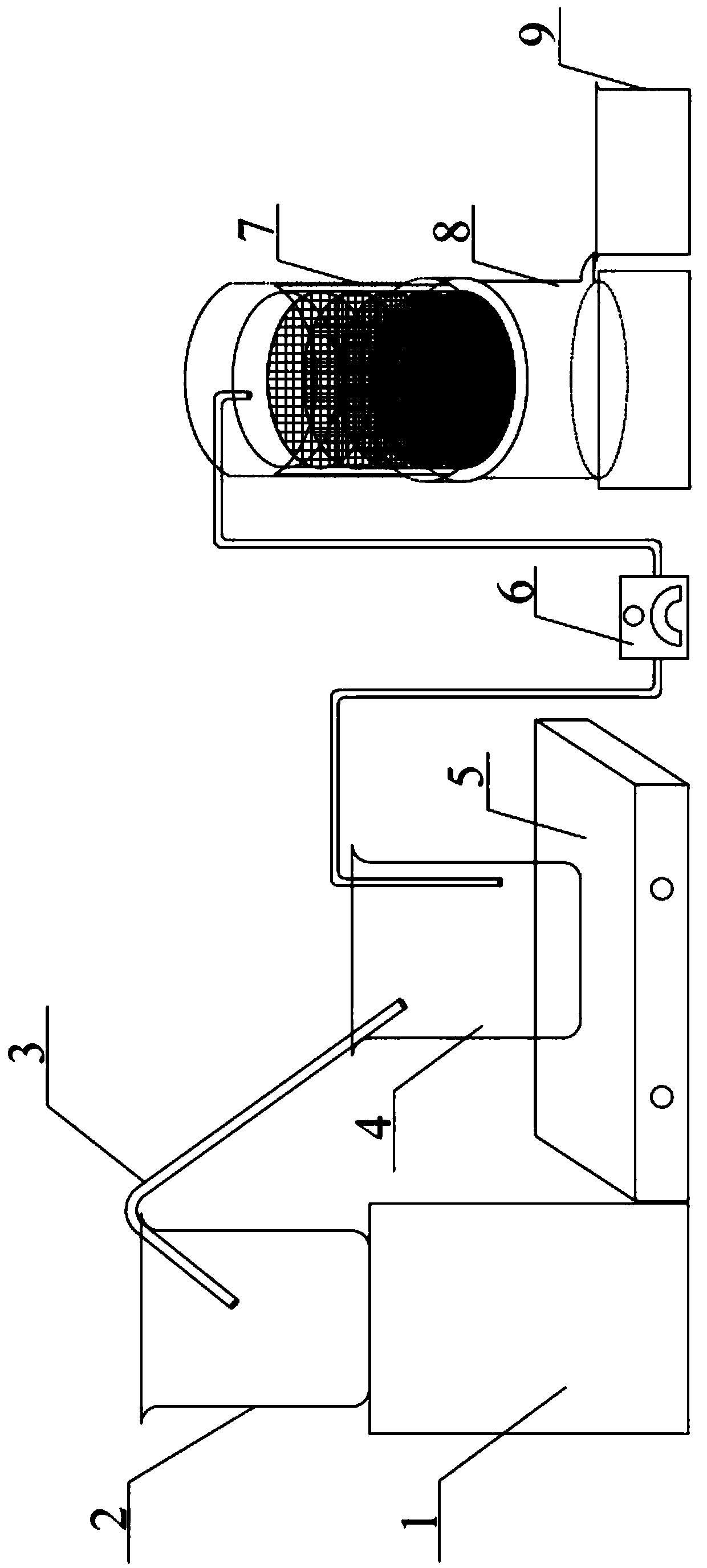

[0028] Please check figure 1 , the flotation fractionation and separation device for microplastics in wetland sediments, including an elevated platform 1 , a siphon device, a pump 6 , a screen filter system, an agitator 5 and a recovery container 9 . This siphon device comprises first container 2, second container 4 and siphon tube 3, and this siphon tube 3 connects first container 2 and second container 4; 5 is a magnetic stirrer, the magnetic stirrer includes a magnetic table and a rotor, and the stirring is realized through the cooperation of the magnetic table and the rotor; the first container 2 is placed on the elevated table 1, and the second container 4 is placed on the magnetic table Above, the height of the first container 2 is higher than that of the second container 4; the rotor is placed in the second container 4. The screen filter system includes a filter container 8 and a filter unit 7 arranged in the filter container 8 . The pump 6 is connected to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com