Method for accurately and quickly detecting water absorption capacity of plant fibers

A technology of plant fiber and water absorption capacity, which is applied in the field of accurate and rapid detection of the water absorption capacity of plant fibers, can solve problems such as reducing the strength of cement stone and increasing the risk of bleeding, and achieves the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for accurately and quickly detecting the water-absorbing capacity of plant fibers, comprising the steps of:

[0027] S1, immerse the shredded sisal fiber in water for 24 hours, and absorb water to reach saturation;

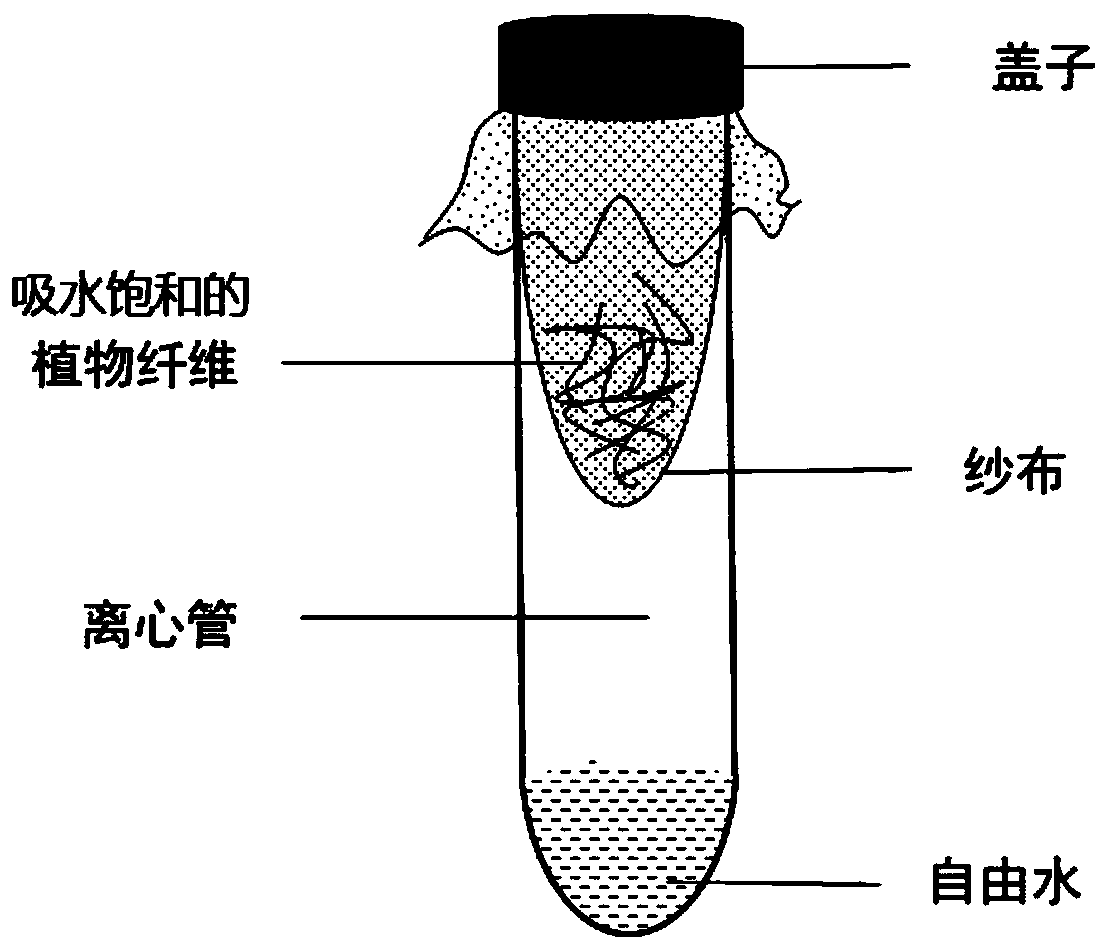

[0028] S2, after the sisal fiber is pulled out, the sisal fiber is centrifuged several times to remove free water: the sisal is wrapped with gauze, placed in a 50mL centrifuge tube, and the edge of the gauze is fixed with the lid of the centrifuge tube tighten, such as figure 1 As shown; centrifuge at 4000rpm for 10min, pour off the free water centrifuged in the centrifuge tube; then centrifuge at 6000rpm for 10min, pour off the free water centrifuged again in the centrifuge tube; then centrifuge at 8000rpm for 10min, pour off Remove the free water centrifuged again in the centrifuge tube; then centrifuge at 8000rpm for 2 minutes, no new free water will be produced in the centrifuge tube, and end the centrifugation;

[0029] S3, weighing the qual...

Embodiment 2

[0037] A method for accurately and quickly detecting the water-absorbing capacity of plant fibers, comprising the steps of:

[0038] S1, immerse the shredded coconut shell fiber in water for 24 hours, and absorb water to reach saturation;

[0039] S2, after the coconut shell fiber is pulled out, the coconut shell fiber is centrifuged several times to remove free water: the coconut shell is wrapped with gauze, placed in a 50mL centrifuge tube, and the edge of the gauze is fixed with the cover of the centrifuge tube tighten, such as figure 1 As shown; centrifuge at 4000rpm for 10min, pour off the free water centrifuged in the centrifuge tube; then centrifuge at 6000rpm for 10min, pour off the free water centrifuged again in the centrifuge tube; centrifuge at 8000rpm for 2min, centrifuge No new free water is produced in the tube, and the centrifugation ends;

[0040] S3, weighing the quality of the coconut shell fiber after multiple centrifugation in S2 is 4.75g, denoted as m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com