Rolling brush intelligent guardrail cleaning machine

A cleaning machine and rolling brush technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of smooth traffic, high energy consumption, and high mechanical cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

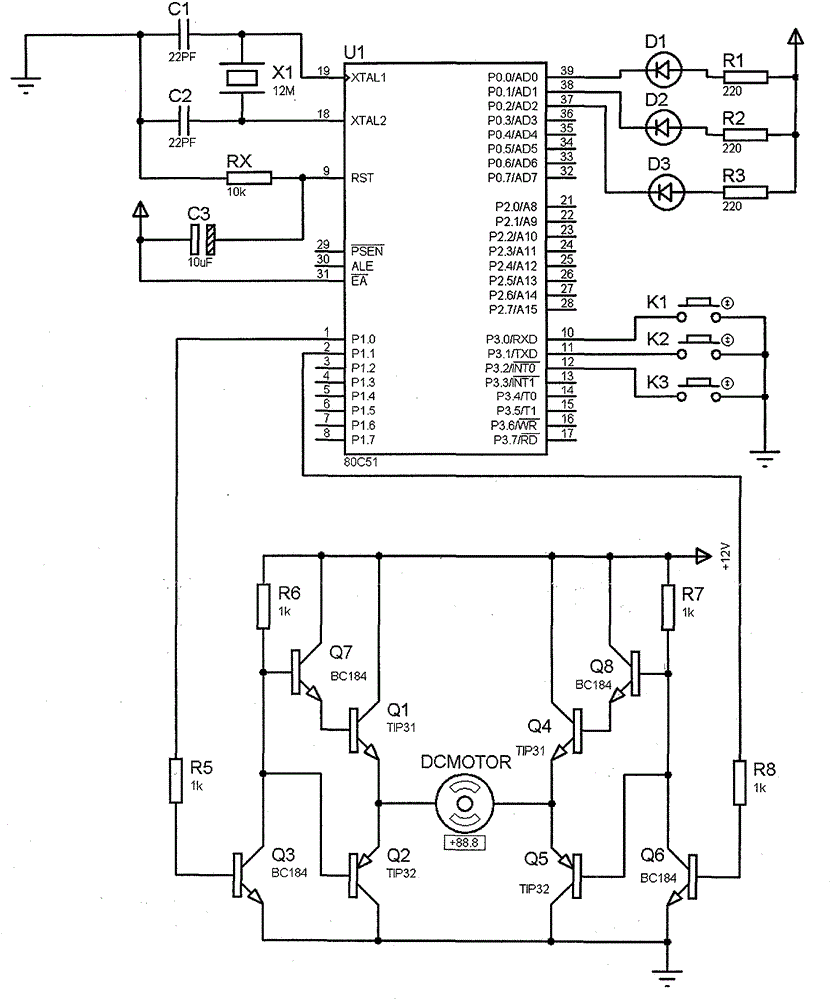

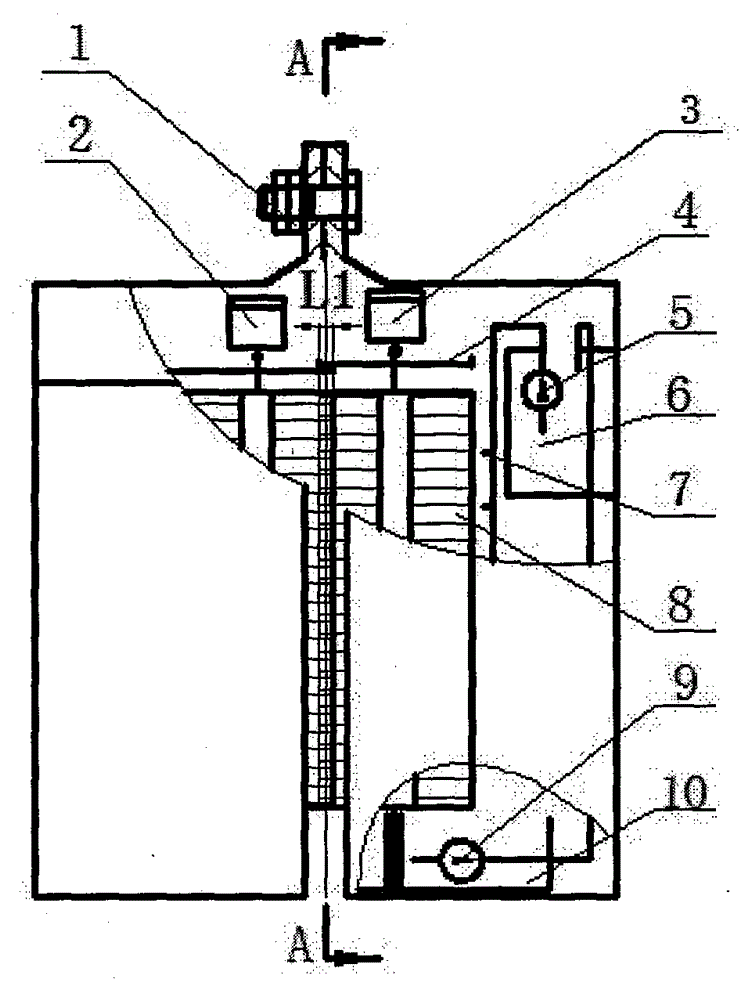

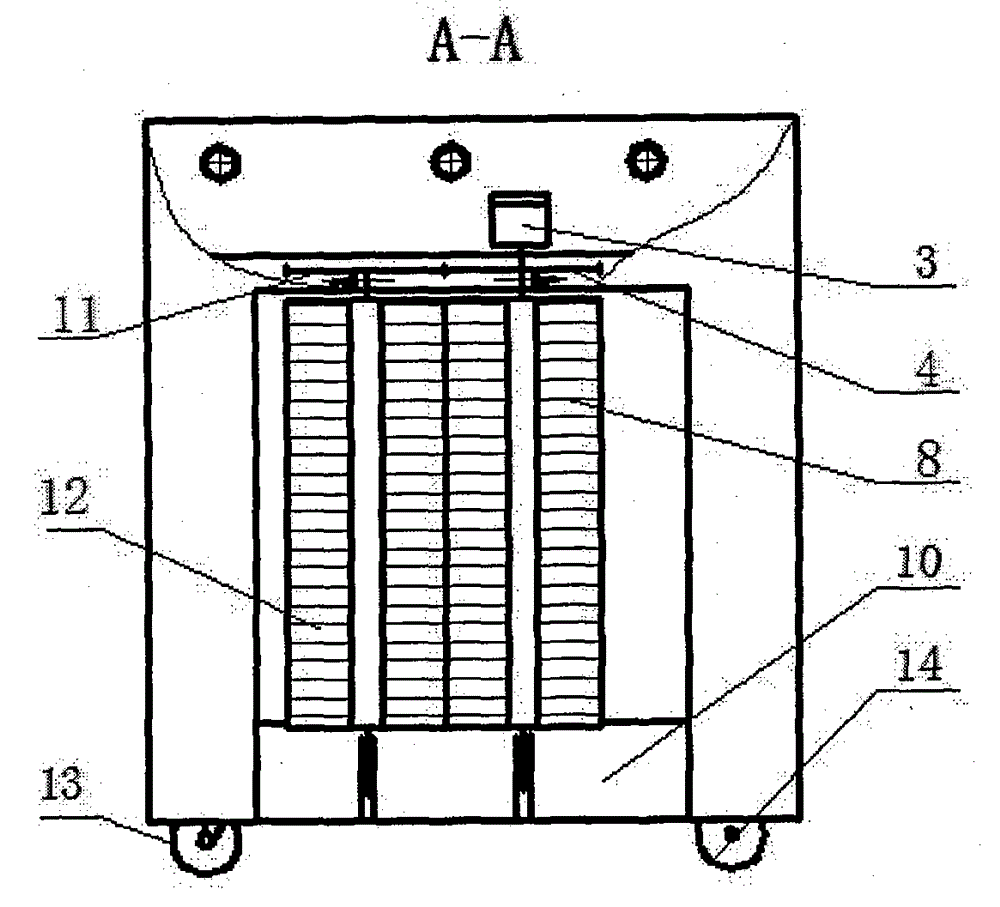

[0017] The cleaning mechanism of the rolling brush type intelligent guardrail cleaning machine, the motor b3 is coaxially connected with the gear a4 and the rolling brush a8, the gear a4 is meshed with the gear b11, the gear b11 is coaxially connected with the rolling brush b12, and the motor b3 drives the rolling brush a8 1. The roller brush b12 rotates to clean the right side of the guardrail, the roller brush a8 rotates clockwise, and the roller brush b12 turns counterclockwise.

[0018] The cleaning mechanism of the rolling brush type intelligent guardrail cleaning machine, the motor a2 is coaxially connected with the gear d19 and the rolling brush d18, the gear c17 is coaxially connected with the rolling brush c16, the gear c19 is meshed with the gear c17, and the motor a2 drives the rolling brush d18 , Roller brush c16 rotates to clean the left side of the guardrail, roller brush c16 rotates clockwise, and roller brush d18 turns counterclockwise.

[0019] Roller brush a8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com