Patents

Literature

32results about How to "Meet real-time detection requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

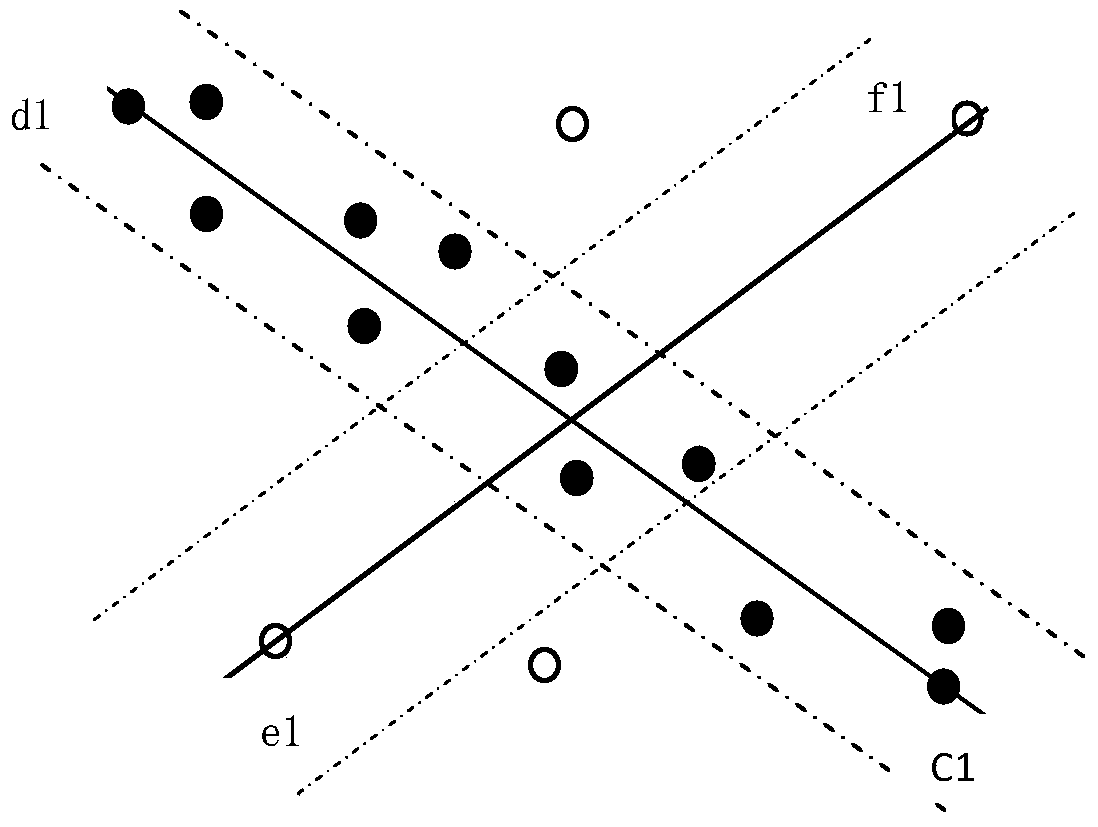

Newton's theorem-based method for detecting ellipses in shot object images

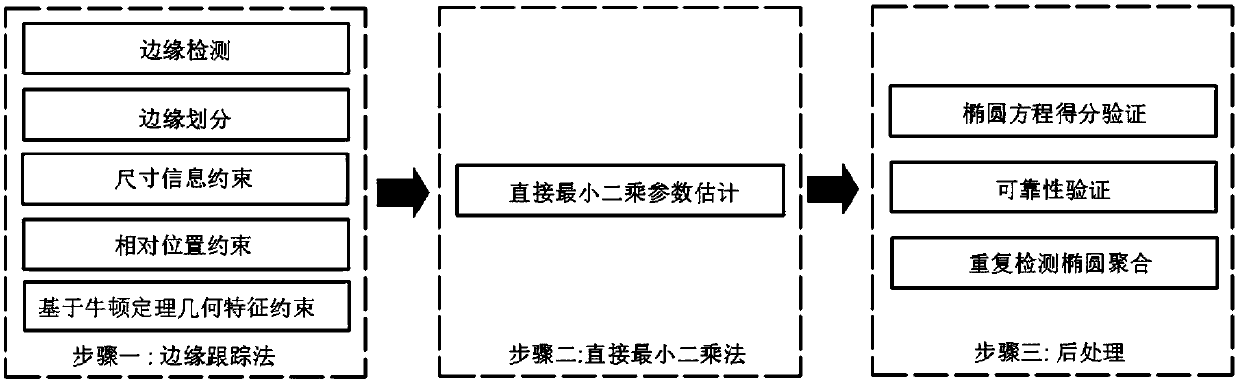

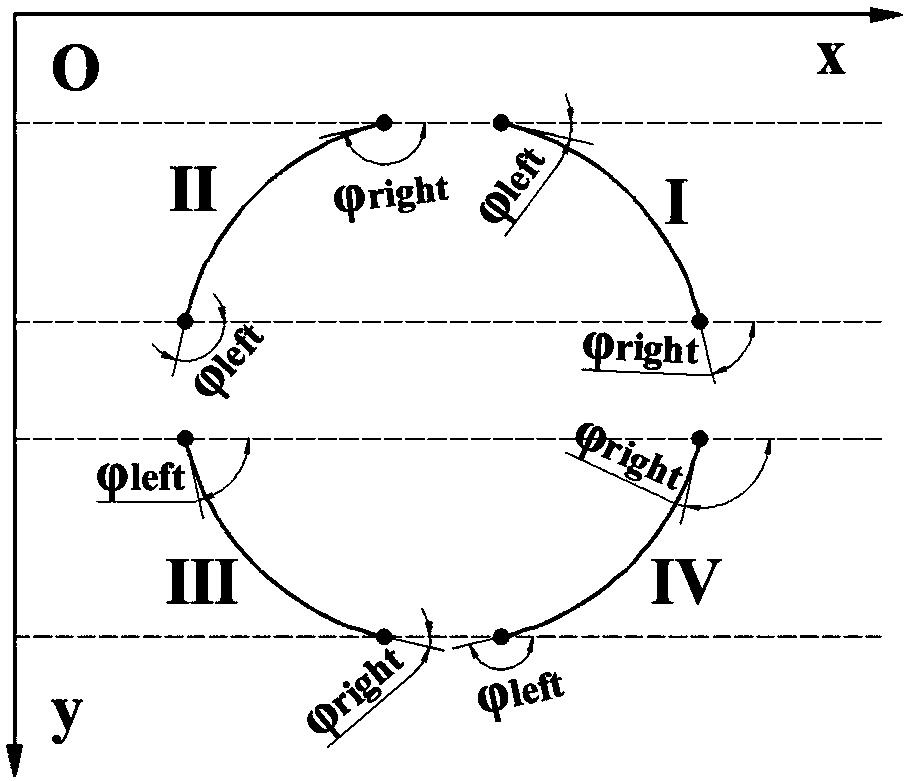

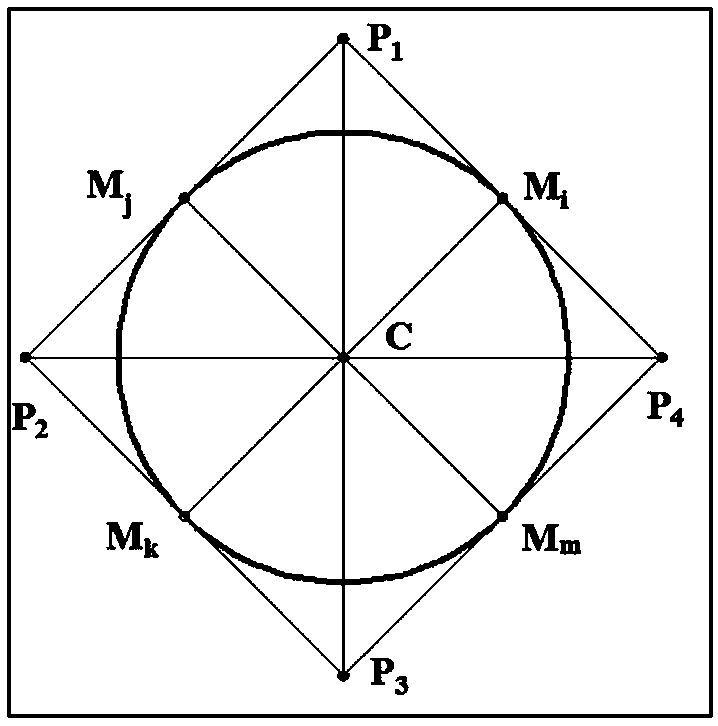

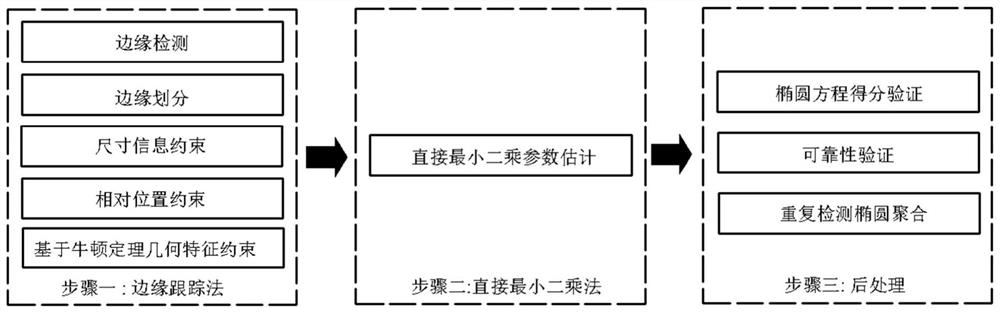

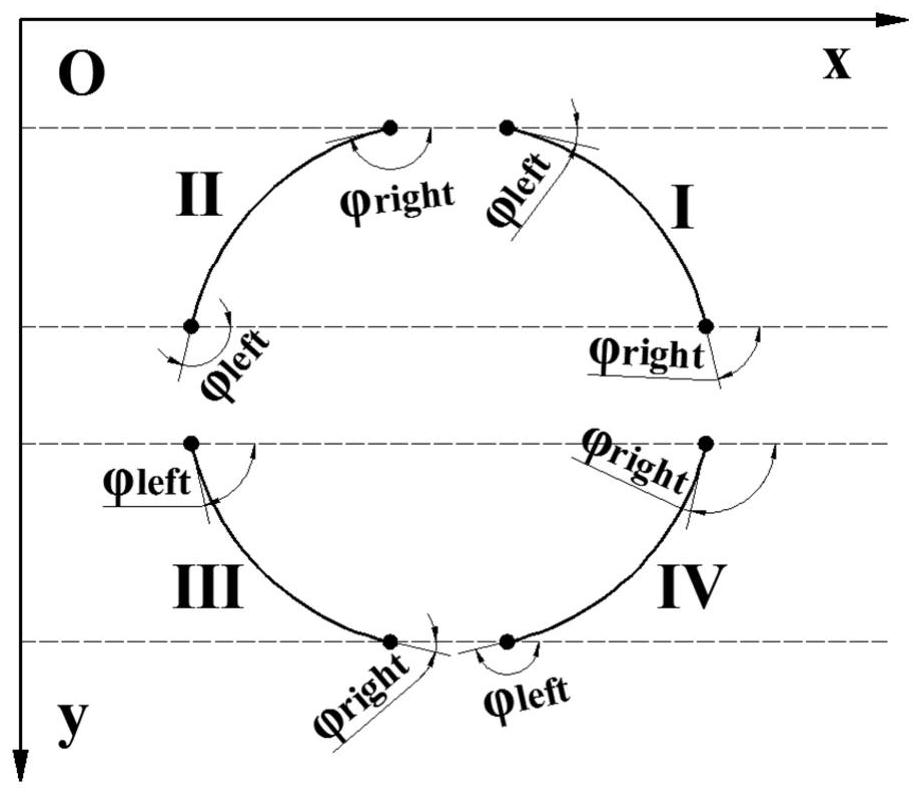

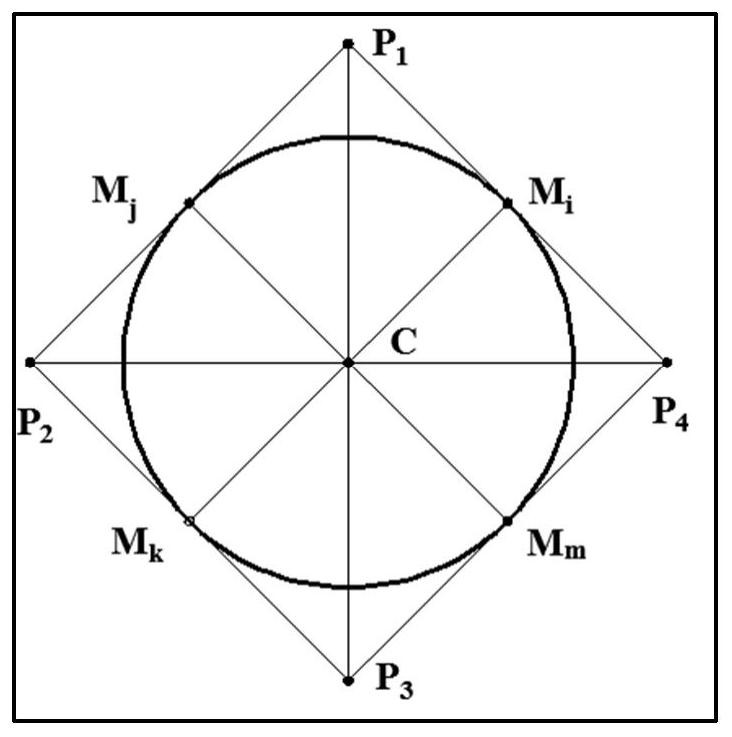

The invention discloses a Newton's theorem-based method for detecting ellipses in shot object images. According to the method of the invention, in a pre-processing stage, invalid edge information is removed according to arc dimension constraints; edge gradient information is extracted, the slope of each edge point is calculated, and edges are divided into four categories according to the slope information; arcs which satisfy a condition of constituting an ellipse are aggregated according to the relative positional relationships of endpoints and Newton's theorem-based geometric constraints; theleast squares method is directly adopted to estimate the parameters of arcs belonging to the same set; and the validity of fitted ellipses is verified, ellipses that do not satisfy a verification condition are removed, and ellipses requiring repeated detection are aggregated. Since a large number of invalid edges are removed, dimensions, relative positions and Newton's theorem-based geometric constraints are adopted, the precision and speed of ellipse detection are significantly improved.

Owner:ZHEJIANG UNIV

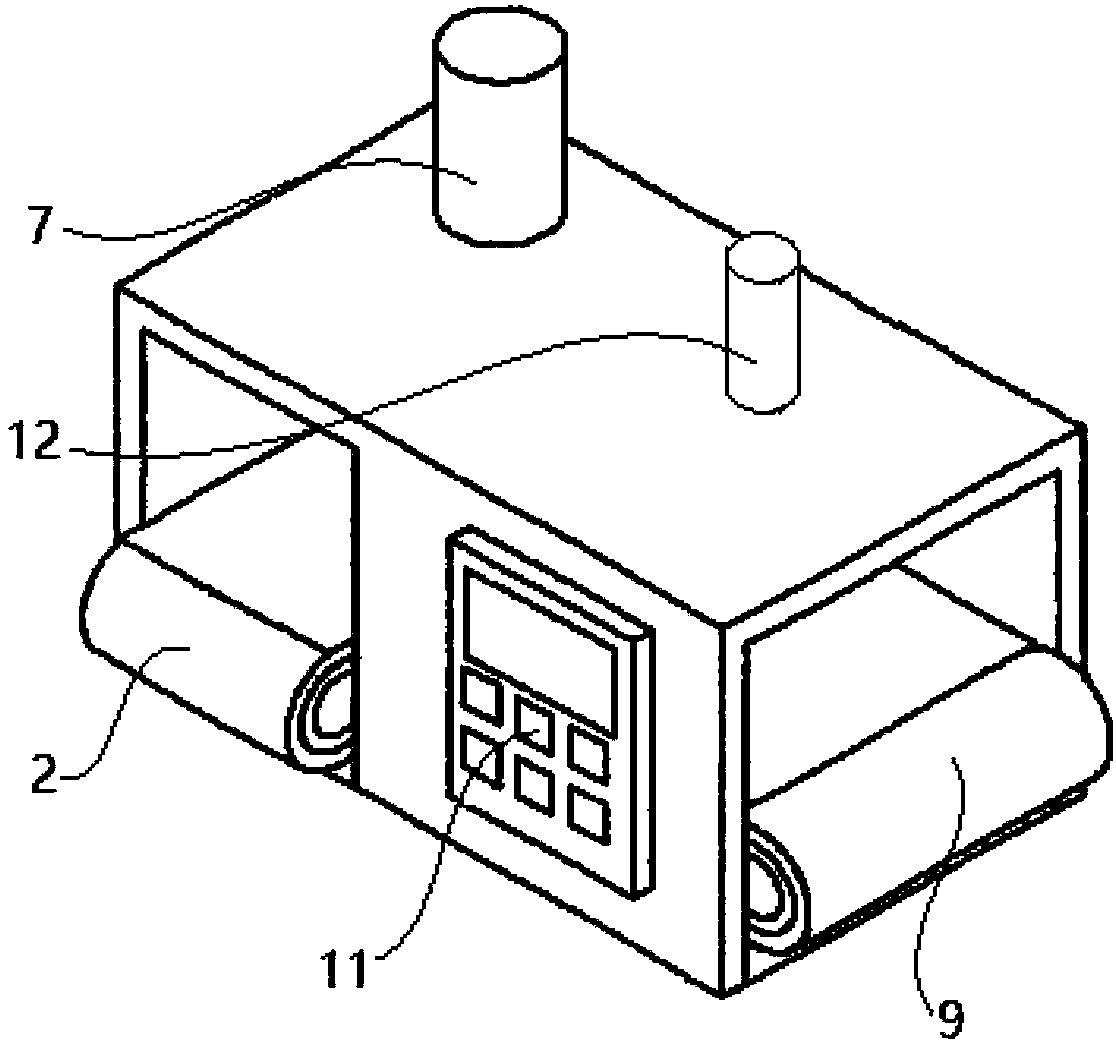

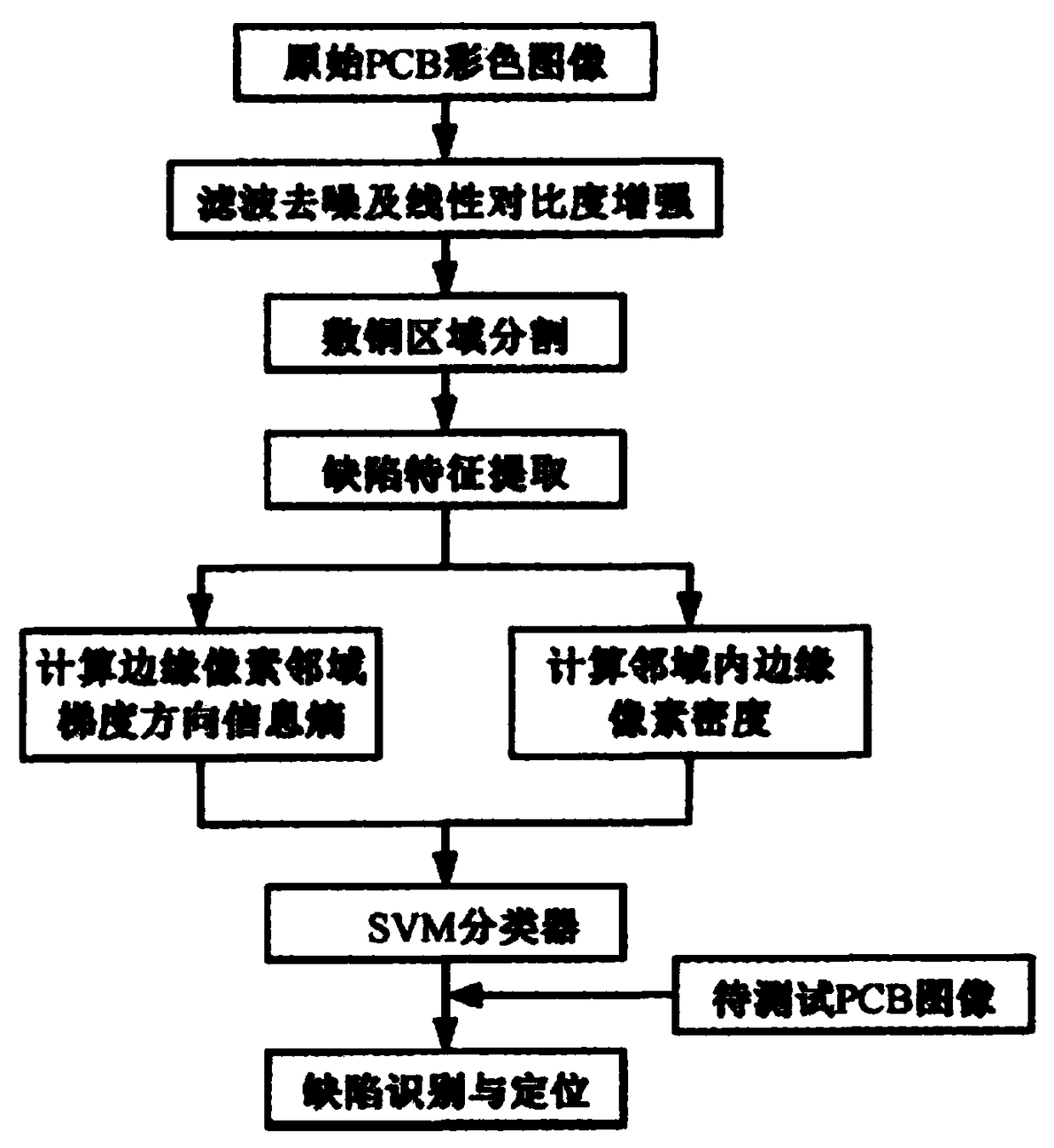

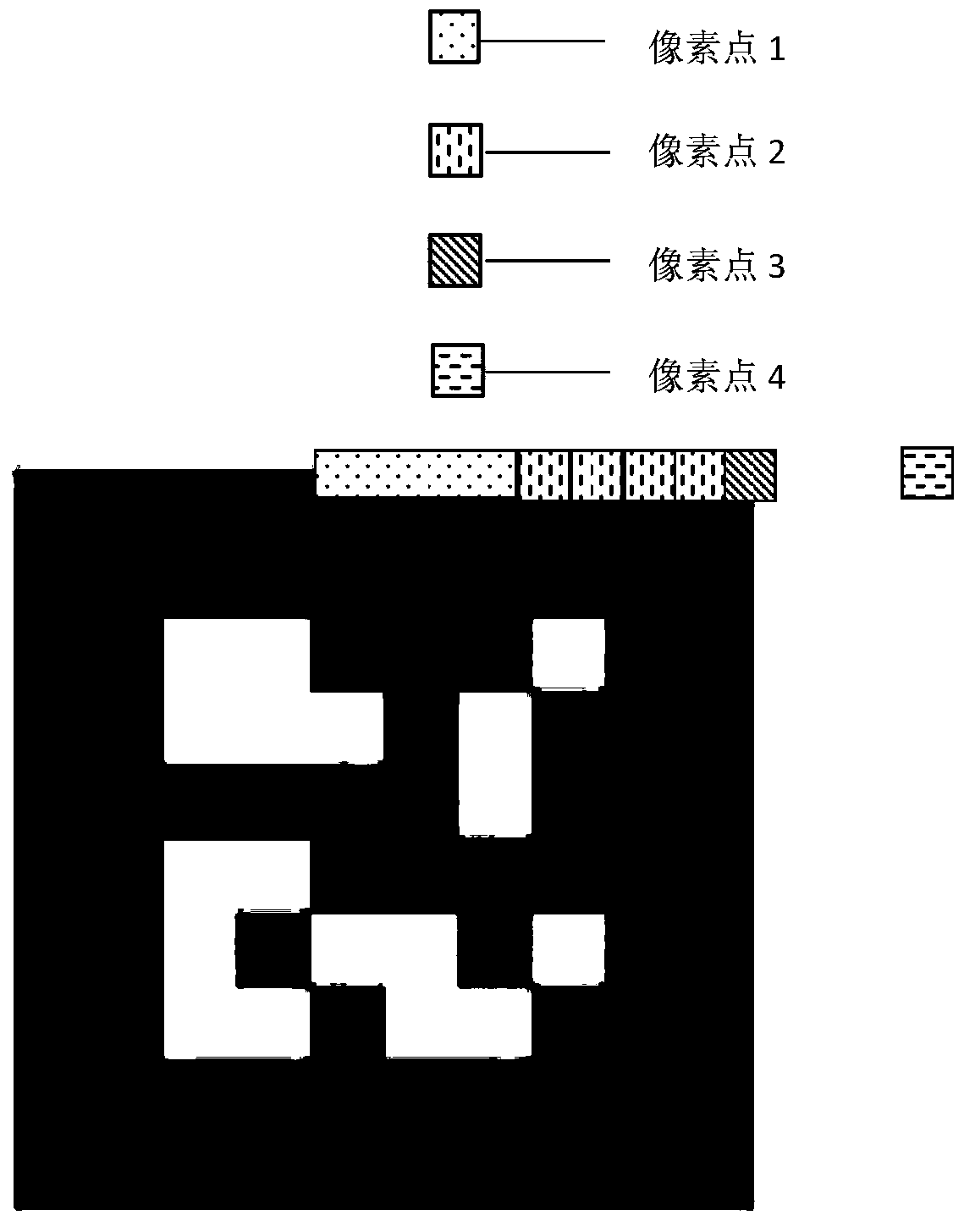

Artificial intelligent image recognizing based detection system for printed circuit board

PendingCN108311409AEasy and accurate segmentationReasonable structureSortingPrinted circuit boardEngineering

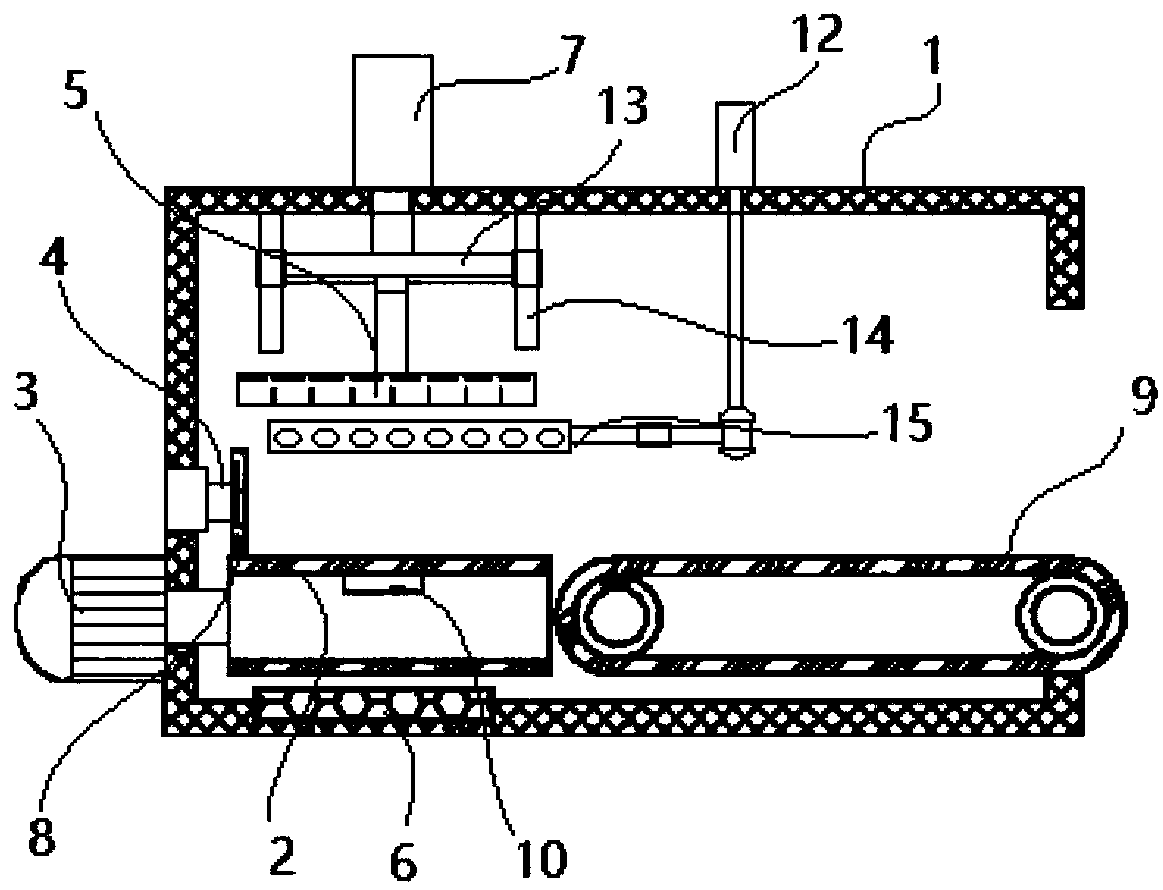

The invention discloses an artificial intelligent image recognizing based detection system for a printed circuit board. The system comprises a housing, a conveyor belt, an air pump, a motor, a telescoping rod, a pushing plate, a detector, a receiver, a sensor and a controller, wherein a feeding port and a discharging port are correspondingly formed in the front surface and the rear surface of thehousing; a motor and a defective product outlet are correspondingly arranged at the left end and the right end of the housing; the air pump is fixed to the top part of the housing; the controller is fixed to the outer surface of the housing. With the adoption of the system, general defects of a bare printed circuit board can be quickly and accurately positioned, including short circuit, open circuit, hole, excessive copper and scratch; the requirement on real-time detection in the production process is met; the system is reasonable in structure, convenient to operate, and high in automation degree; an artificial intelligent method replaces a traditional algorithm to realize automatic detection; the system is of a noncontact type, and is high in detection accuracy, fast, high in interference resistance, and convenient to connect to an ERP quality detection module in a communication manner.

Owner:JIANGSU ZONBERATION INFORMATION TECH CO LTD

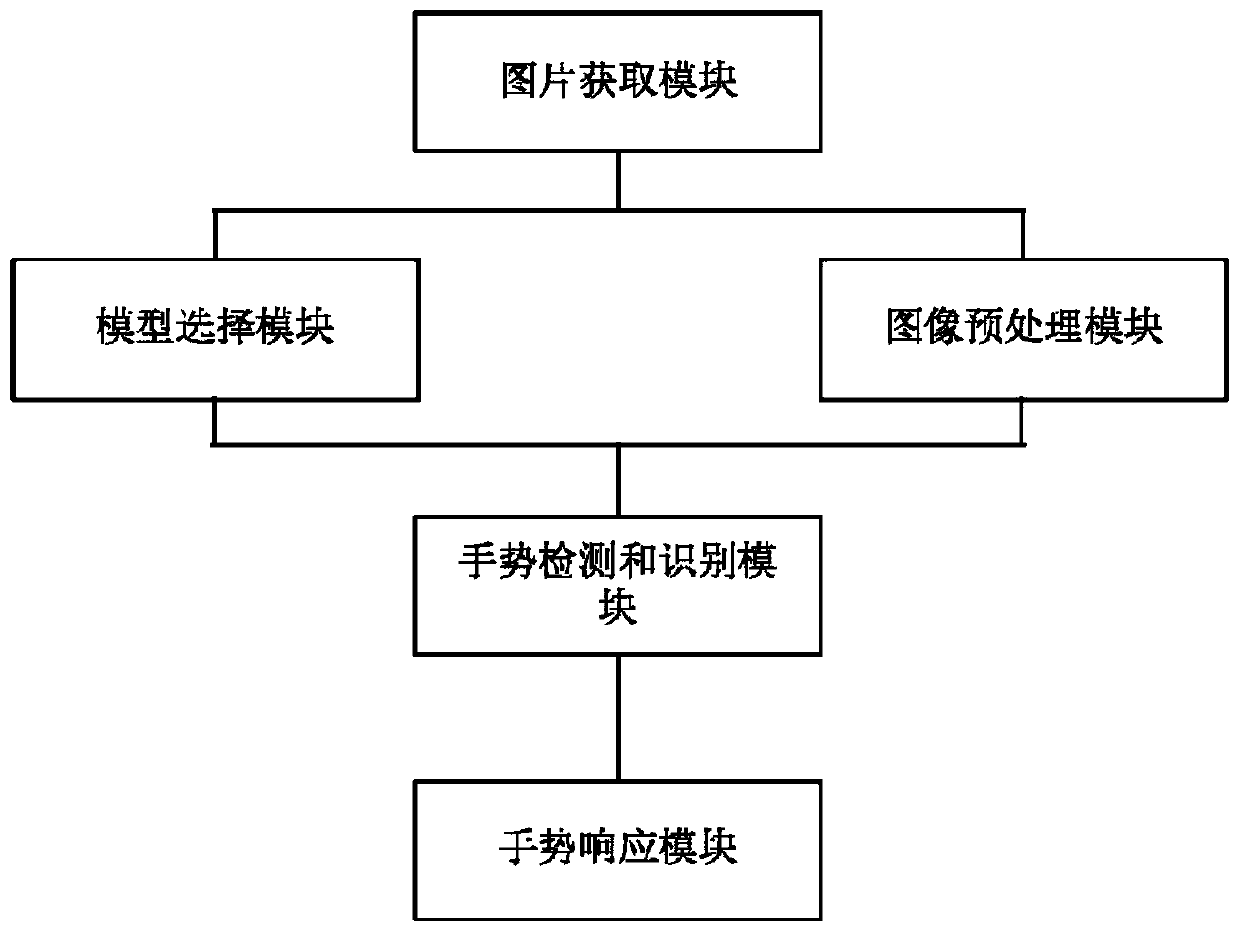

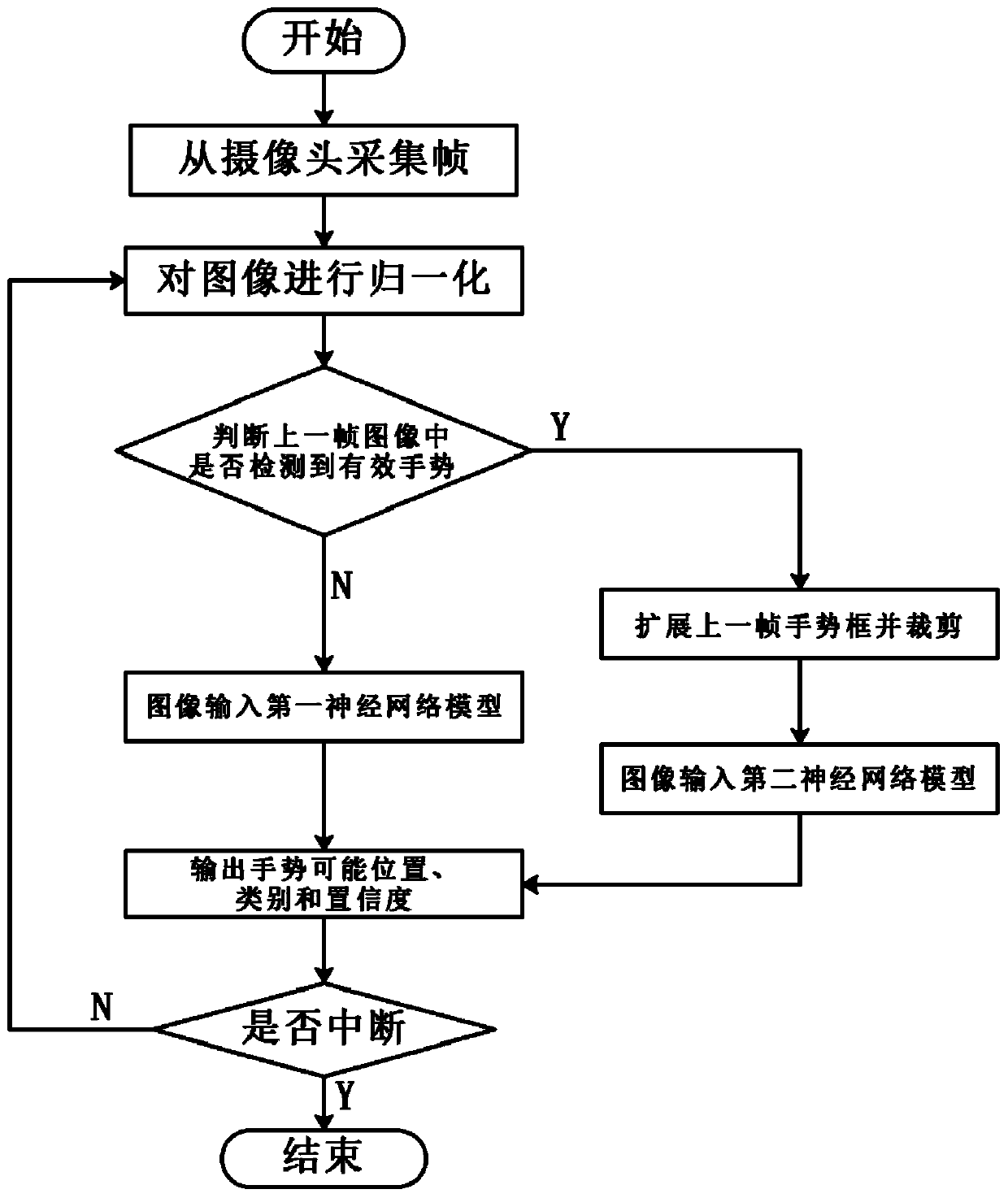

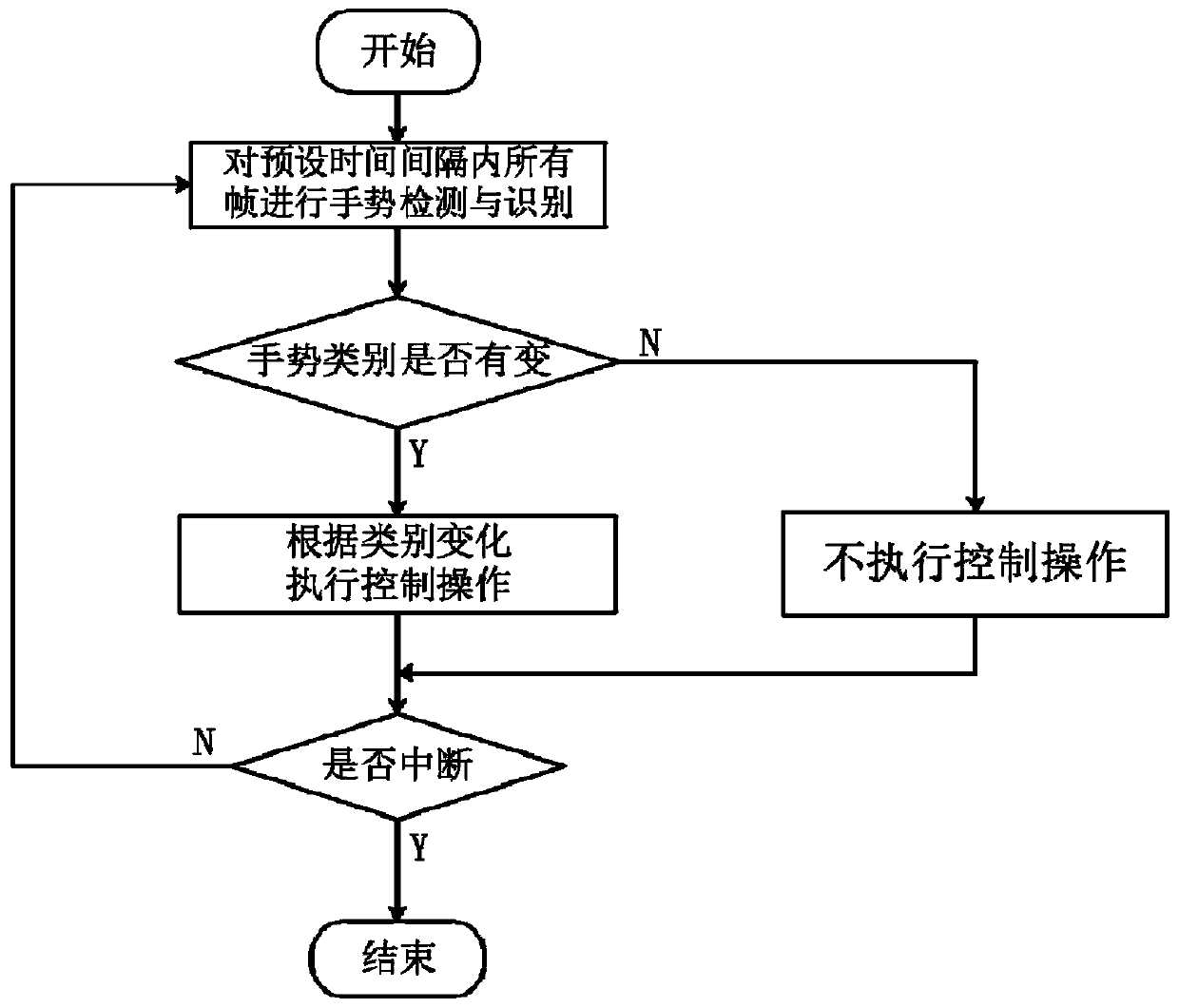

Effective gesture recognition method and device, control method and device and electronic device

ActiveCN110458095ALow costEasy to useCharacter and pattern recognitionNeural architecturesRecognition algorithmComputer terminal

The invention provides an effective gesture recognition method and device, an effective gesture control method and device and an electronic device, and the method comprises the steps: S11, obtaining acurrent frame image collected by a camera; S12, performing gesture detection and recognition on the current frame image according to a preset recognition algorithm to obtain a possible region, a gesture category and confidence of a gesture in the current frame image; S13, sequentially carrying out gesture detection and recognition on all image frames of the video within a fixed time interval after the current frame to obtain a possible region, a gesture category and a confidence coefficient of a gesture in the image; and S14, judging whether the proportion of the image frames with the same gesture in the image frames within the fixed time interval is greater than a preset proportion threshold value or not, and if so, considering the gesture as a valid gesture. Gesture detection and recognition can be effectively and rapidly carried out on the embedded terminal, and convenient and rapid man-machine interaction is carried out.

Owner:RECONOVA TECH CO LTD

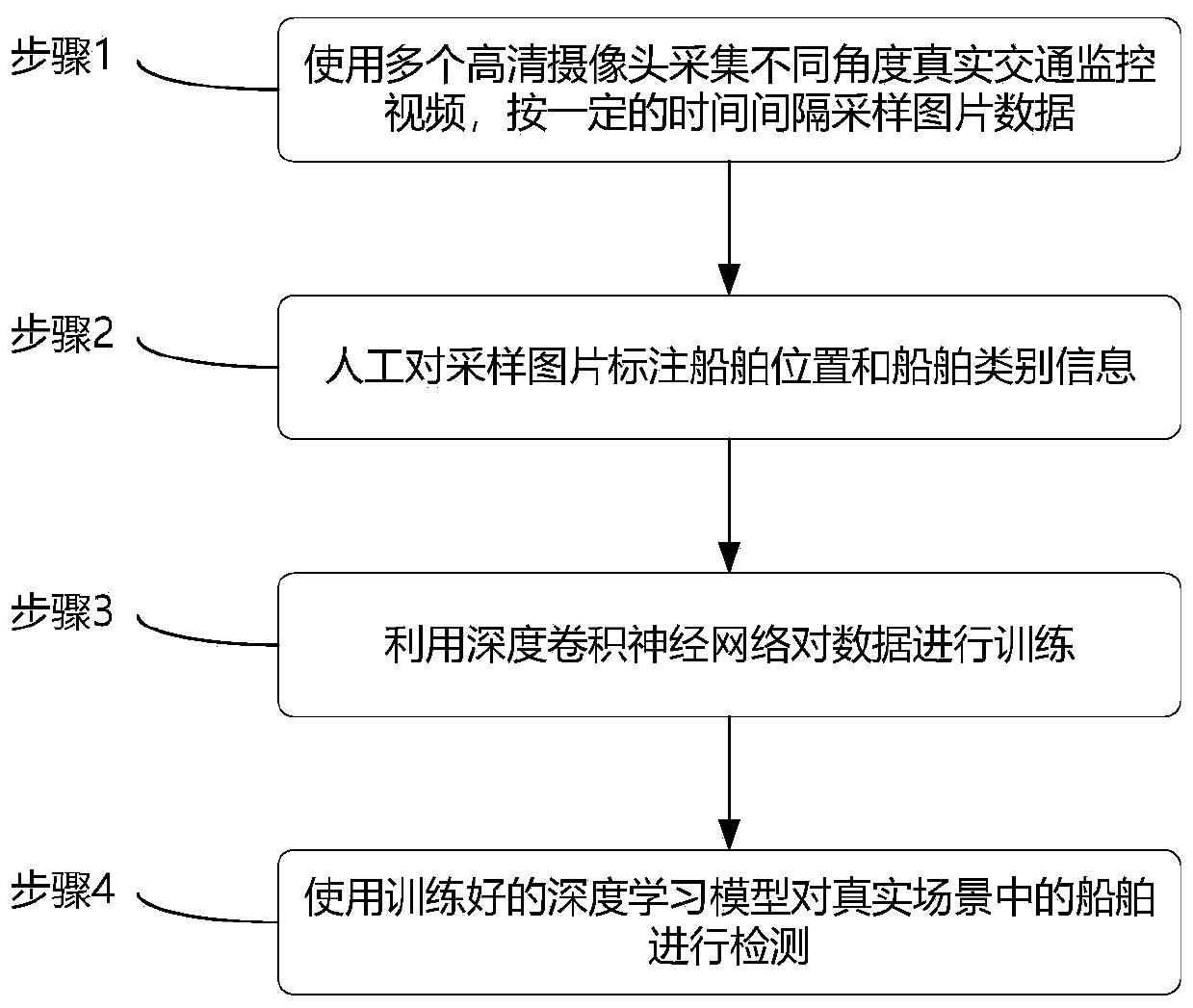

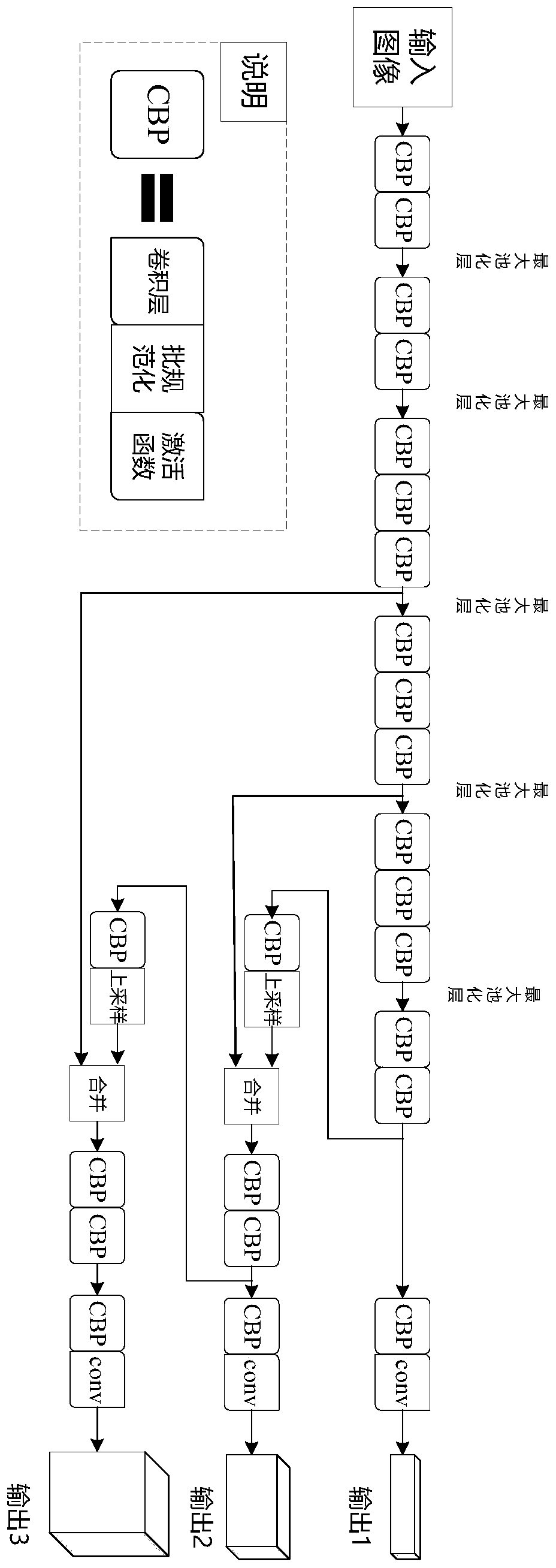

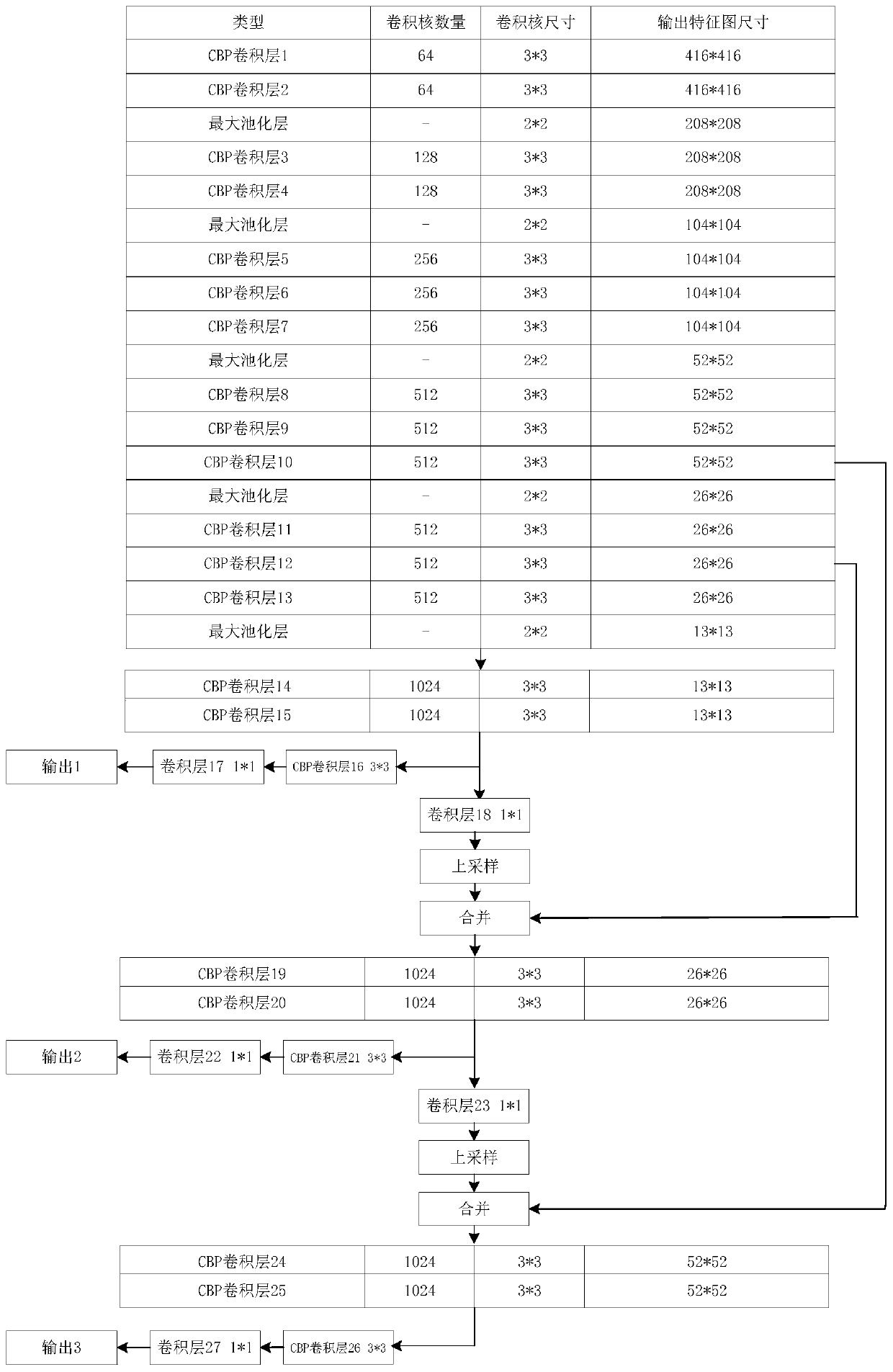

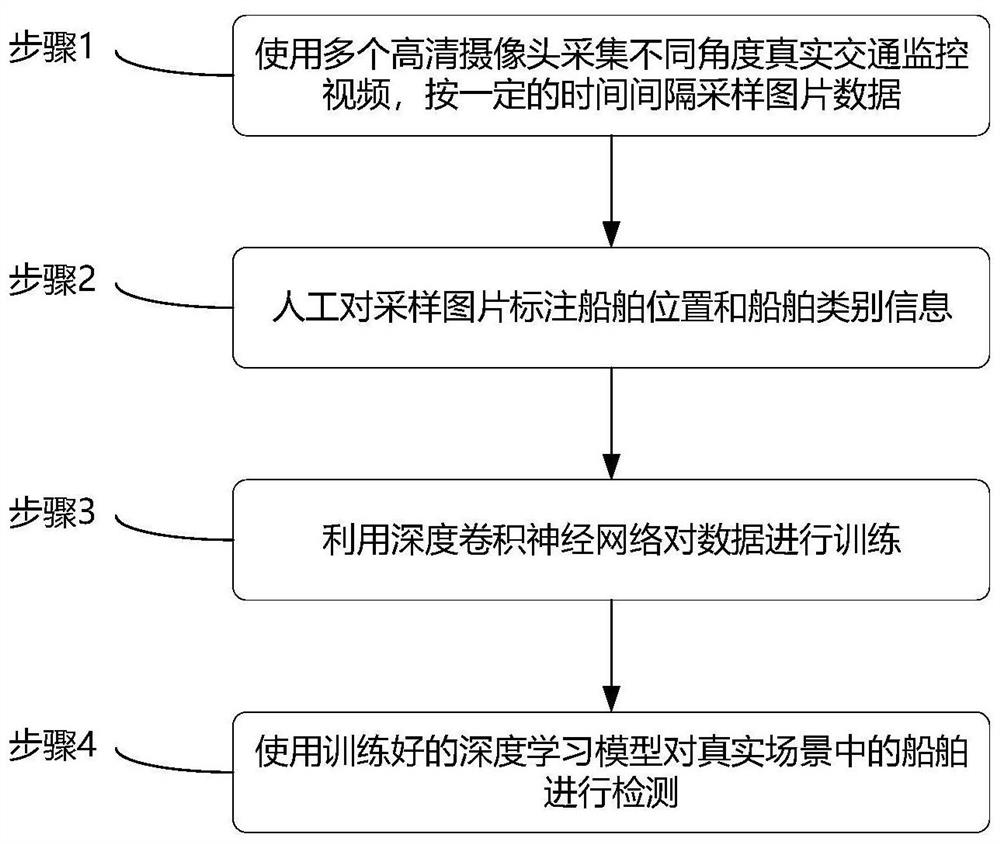

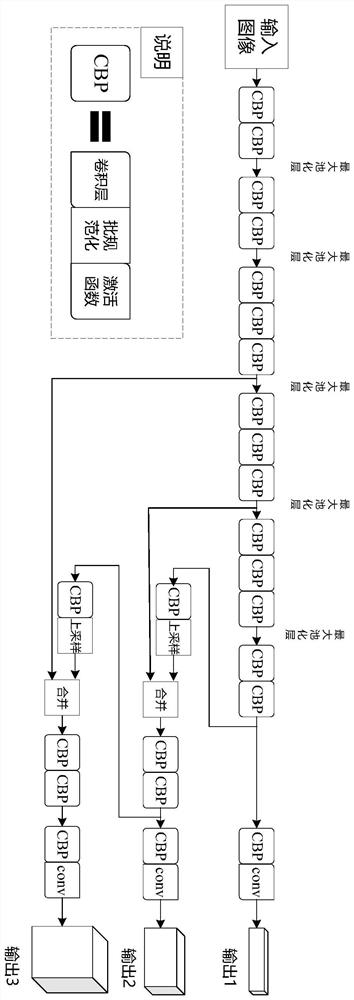

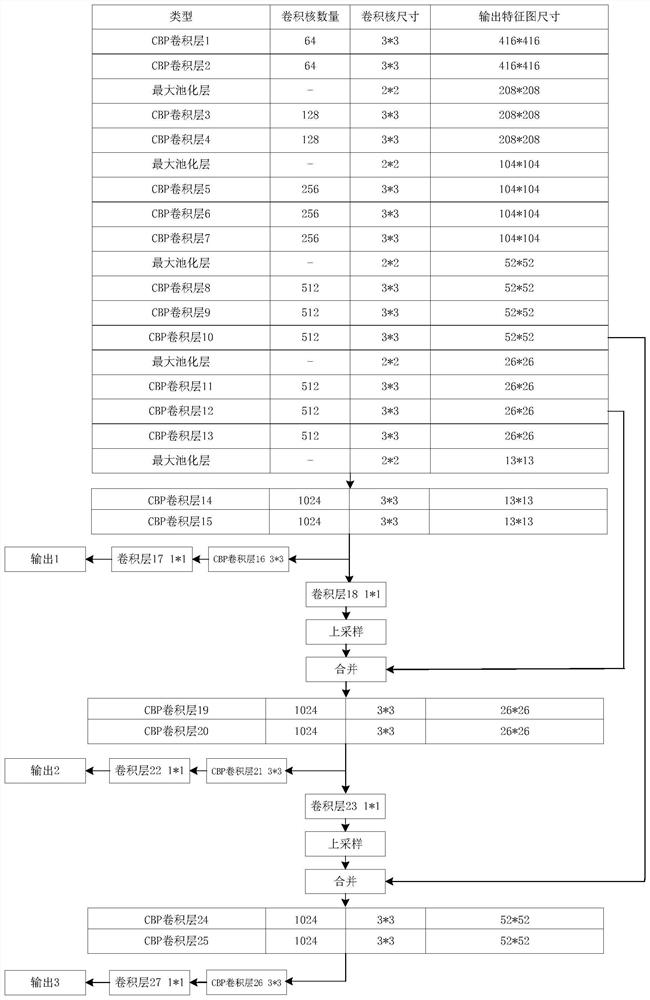

Automatic ship detection method for inland river bridge areas

ActiveCN110060508AImplement automatic detectionReduce workloadCharacter and pattern recognitionMarine craft traffic controlPattern recognitionNetwork model

The present invention discloses an automatic ship detection method for inland river bridge areas, the method comprises: 1) collecting traffic surveillance videos of real inland river bridge areas andobtaining original sampled image data; 2) performing manual label to the original sampled image data and forming a label image; 3) using depth convolution neural network to learn characteristics of the label image, classifying the characteristics learned, and obtaining a trained deep learning model; 4) using the trained deep convolution neural network model to detect ships in real scene, framing out position of the ships with rectangular frames, and indicating classification of the ships. The method has good adaptability to different weather, different lighting conditions and nighttime dark conditions, and can achieve relatively high accuracy, and has processing speed reaching real-time requirements.

Owner:WUHAN UNIV OF TECH

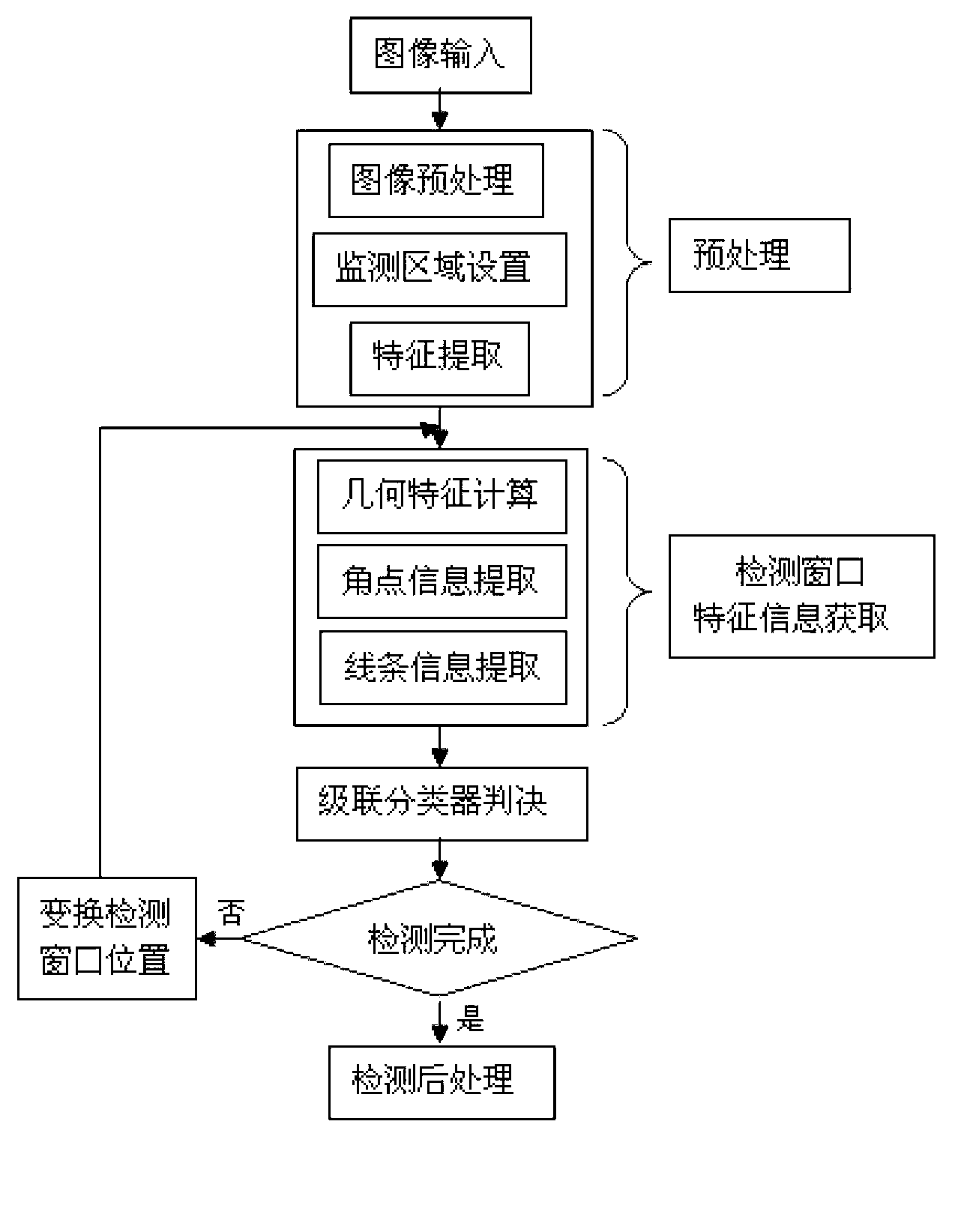

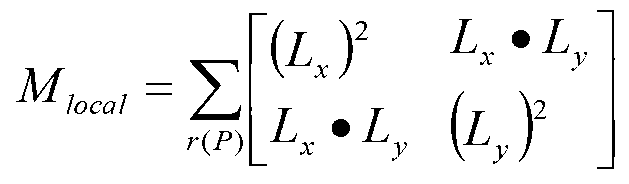

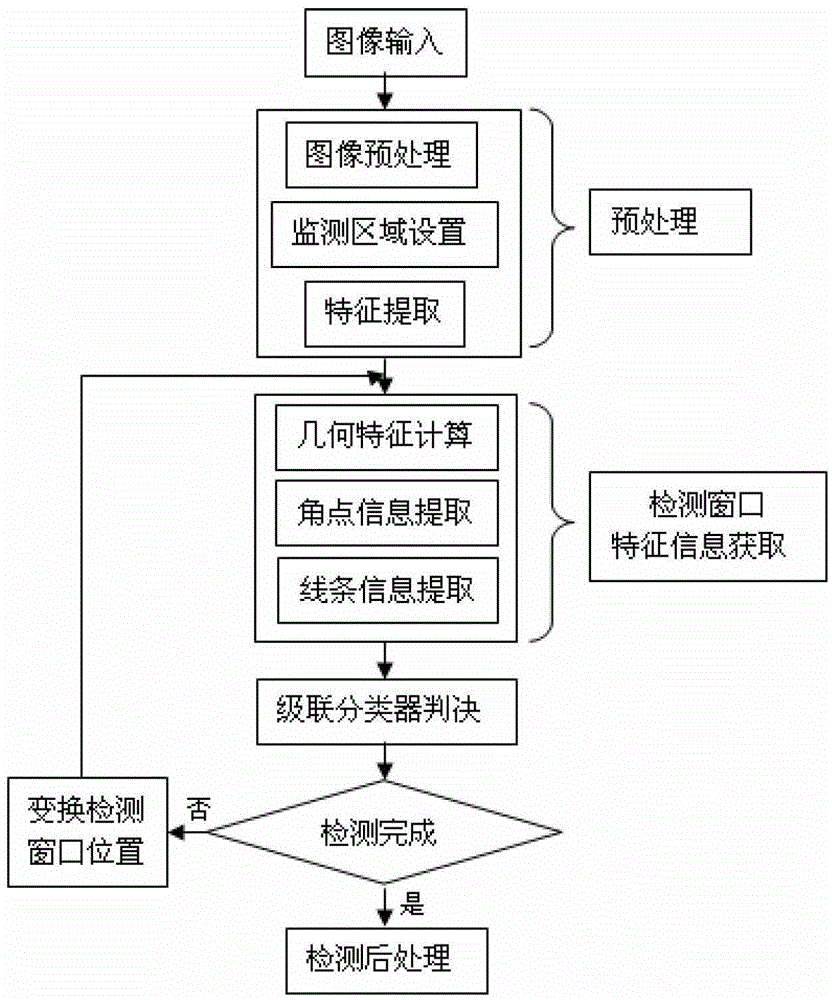

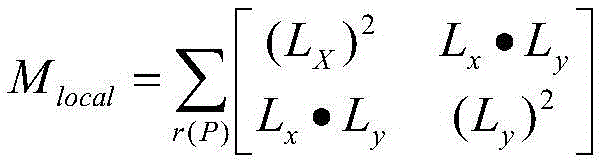

Vehicle detection method based on multi-feature fusion

ActiveCN103295003AImprove reliabilityAccurate detectionCharacter and pattern recognitionAngular pointVehicle detection

The invention provides a vehicle detection method based on multi-feature fusion. The vehicle detection method based on the multi-feature fusion comprises the steps of step 1, establishing one or a plurality of monitoring areas (ROI (region of interest)) in an input image; step 2, extracting Harris angular points and longitudinal gradient information in the ROI on the basis of a grayscale map of an image to be detected; step 3, computing a geometry size of a detection window at a certain position inside the ROI according to a circumscribed trapezoid of an obtained monitoring area; step 4, counting an angular point number of the detection window and computing the distribution symmetry of the angular points; step 5, extracting structured horizontal line information on the basis of a longitudinal gradient in the detection window; step 6, utilizing a cascaded strong classifier to judge whether a current detection window is a vehicle area, if so, reserving the current detection window, and if not, dismissing the current detection window; step 7, moving the detection widow according to a certain step size, switching to the step 3, and repeating the steps from the step 3 to the step 7; and step 8, reducing the probability of the repeated detection of the same target through detection result combination.

Owner:BEIJING BOOSTIV TECH

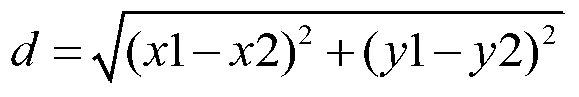

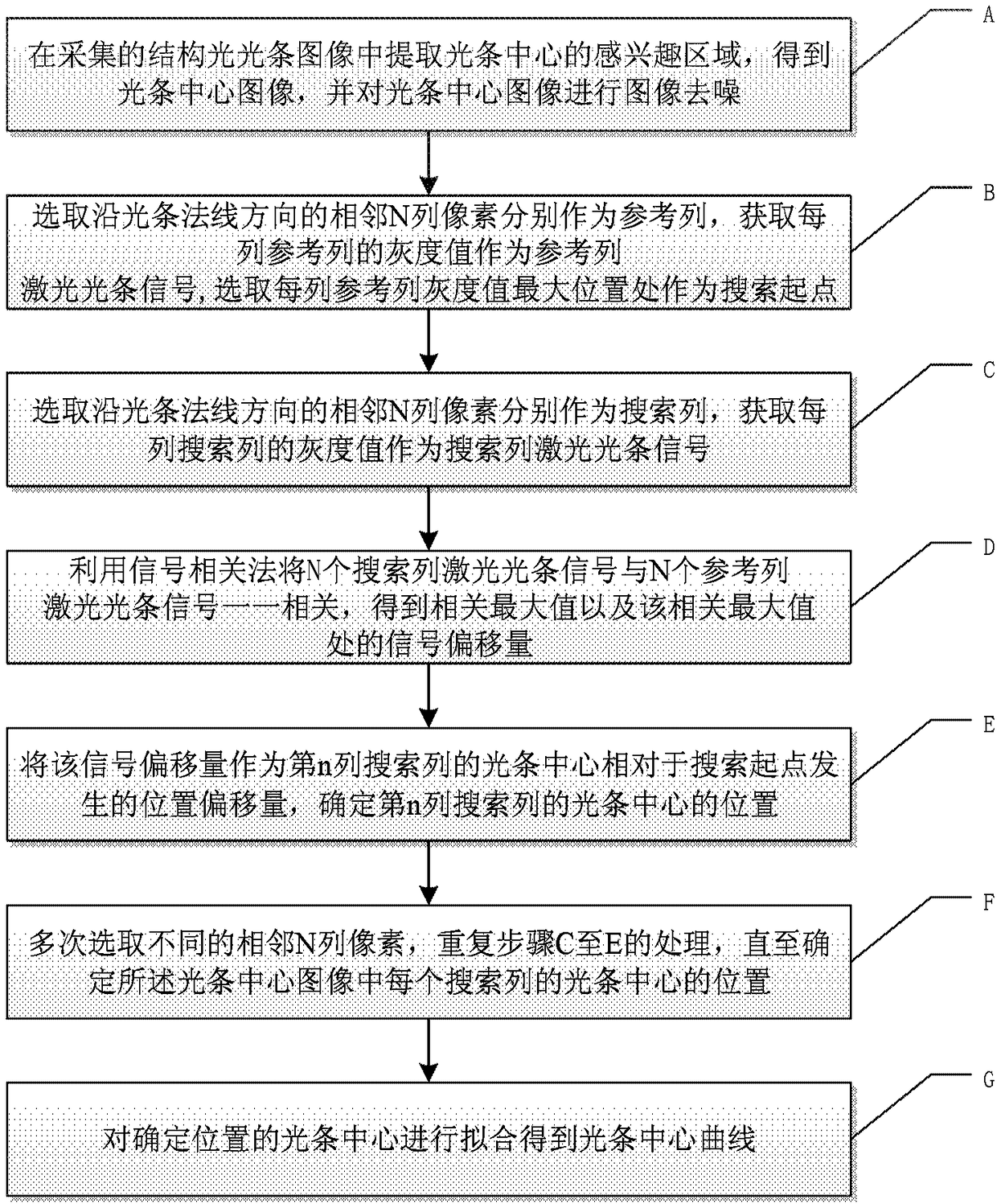

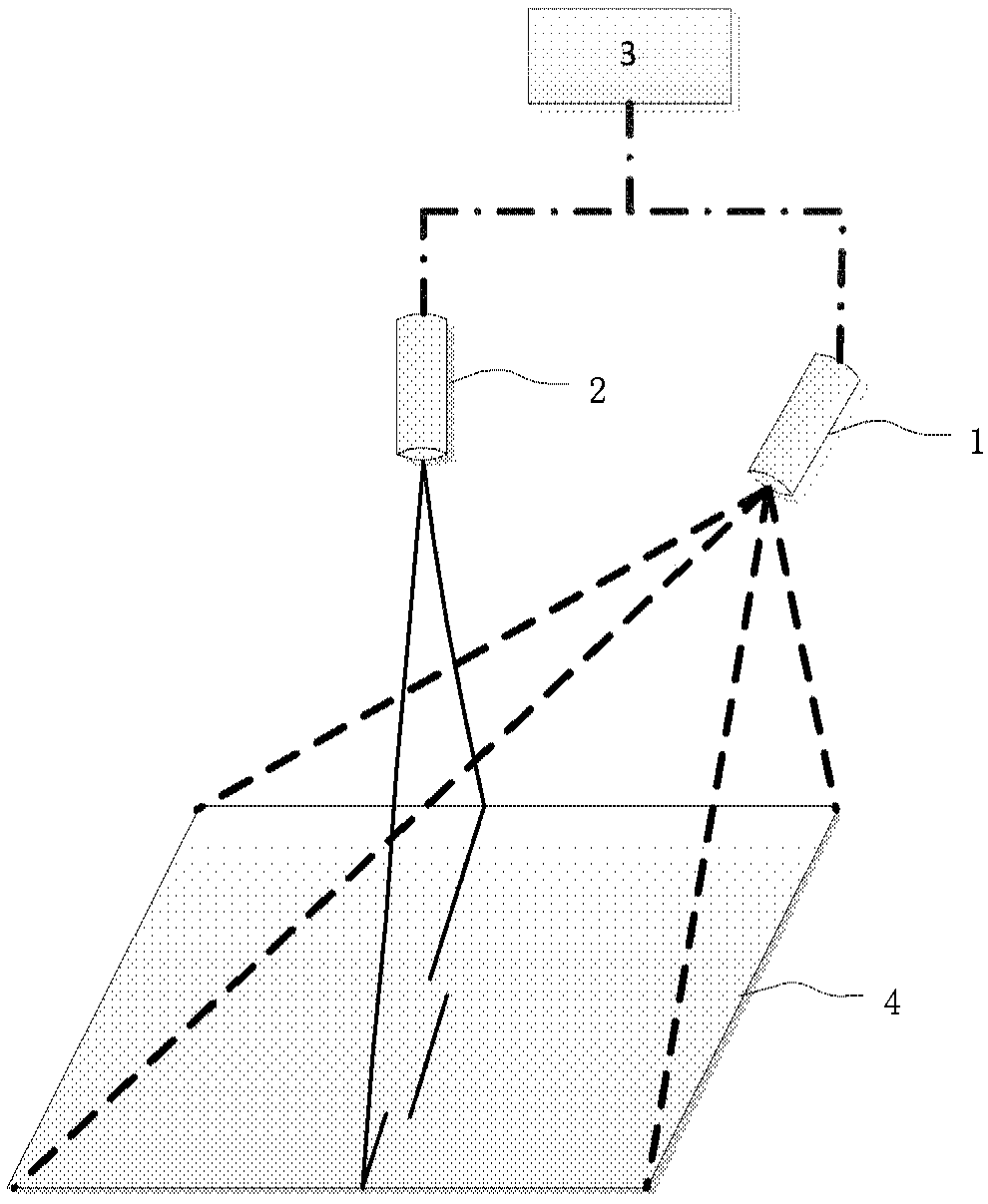

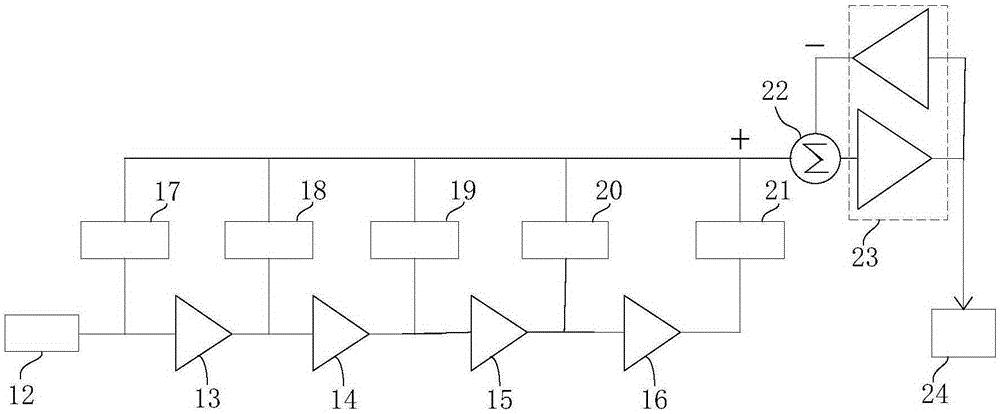

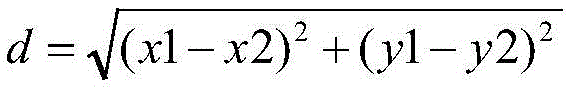

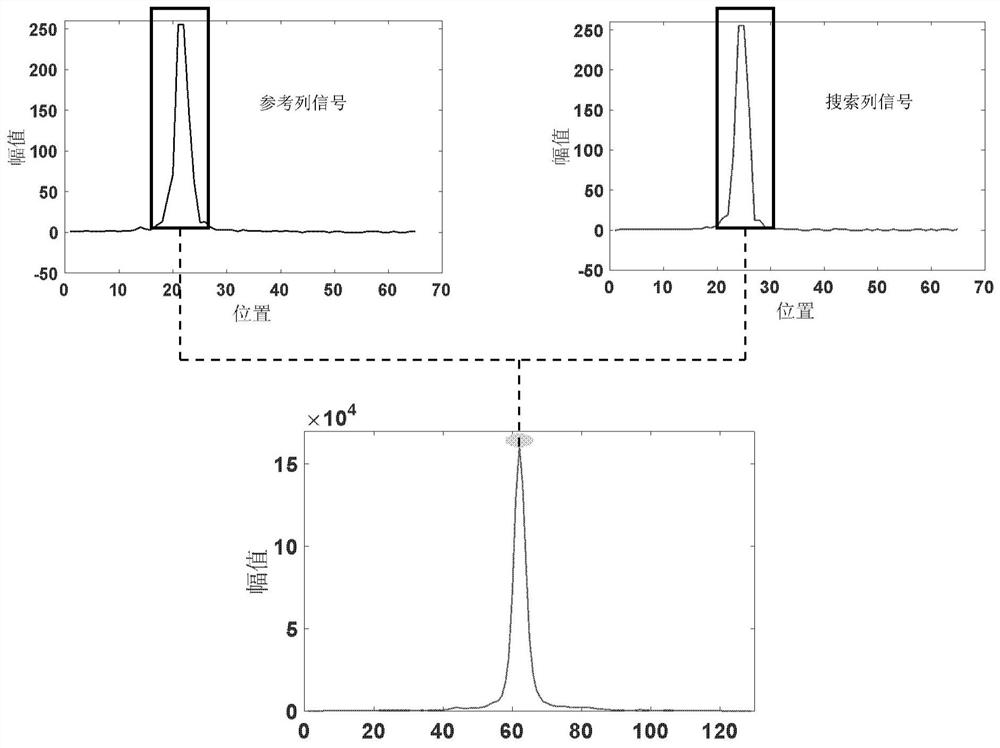

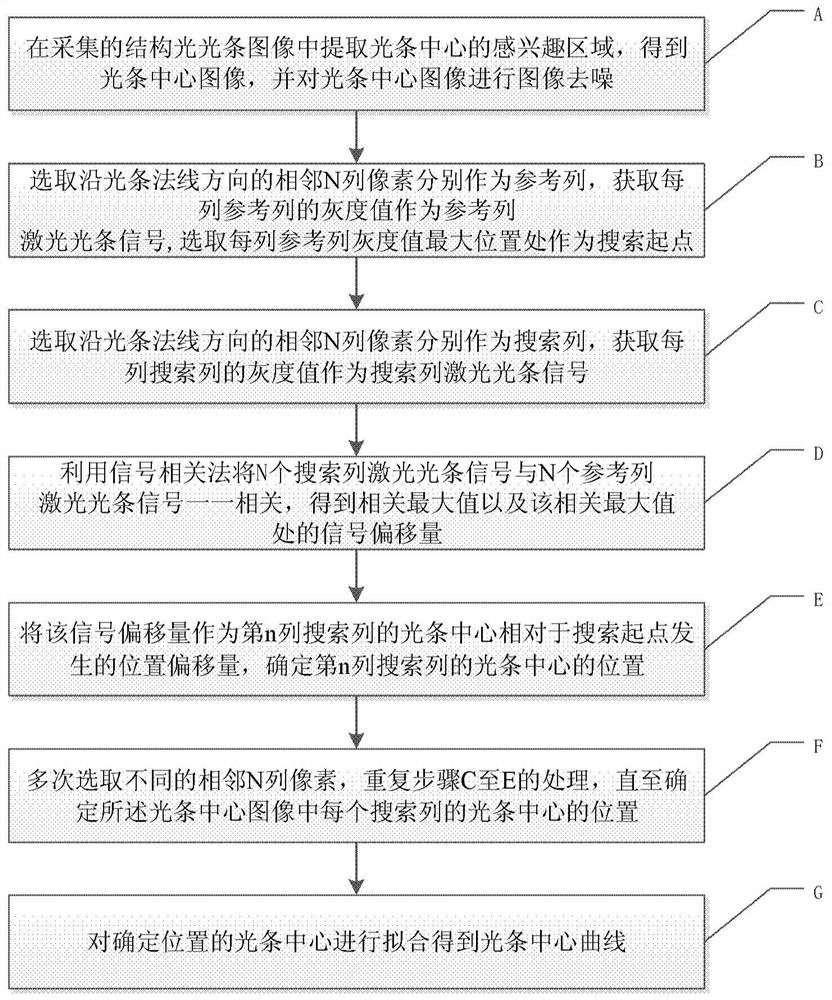

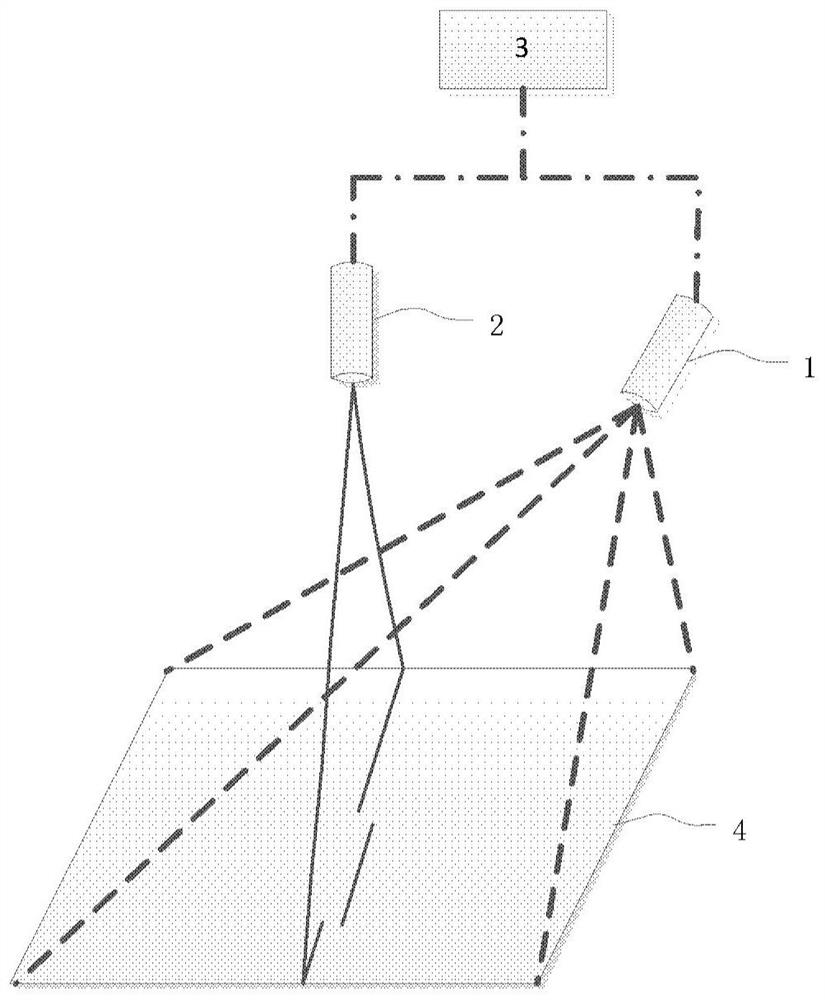

Structured light stripe center extracting method and device for wheel track detection

ActiveCN108564621AAvoid disconnectionPrecise location of breakpointsImage analysisUsing optical meansSignal correlationOptoelectronics

The invention relates to a structured light stripe center extracting method and device for wheel track detection. The method comprises the following steps: acquiring a light strip center image; selecting N reference lines and N search lines in the light stripe center image in the normal direction of the light stripe to acquire N reference line laser light stripe signals and N search line laser light stripe signals; performing one-to-one correlation on the N reference line laser light stripe signals and the N search line laser light stripe signals according to a signal correlation method to acquire a correlation maximum value and signal offset corresponding to the correlation maximum value; determining the light stripe center position of the middlemost line of the N search lines according to the signal offset, and repeatedly selecting different search lines until the light stripe center position of each search line is determined. According to the method and the device, the problem thatthe laser light stripe is broken can be solved well, the light stripe center can be extracted rapidly and efficiently, and the real-time detection requirement of the system can be met.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

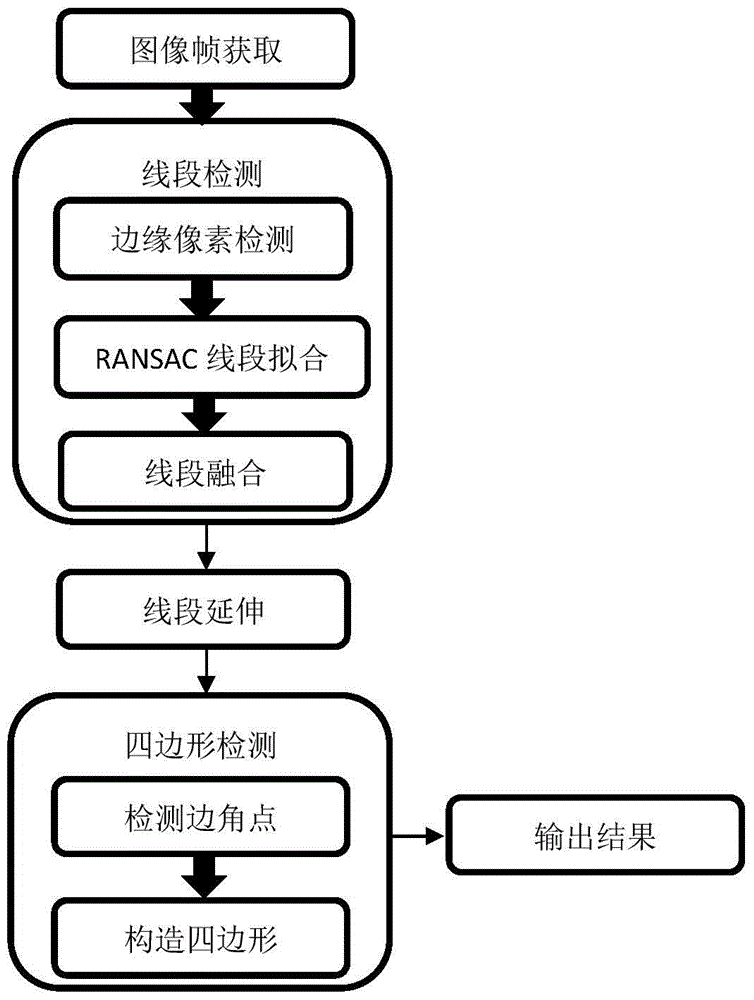

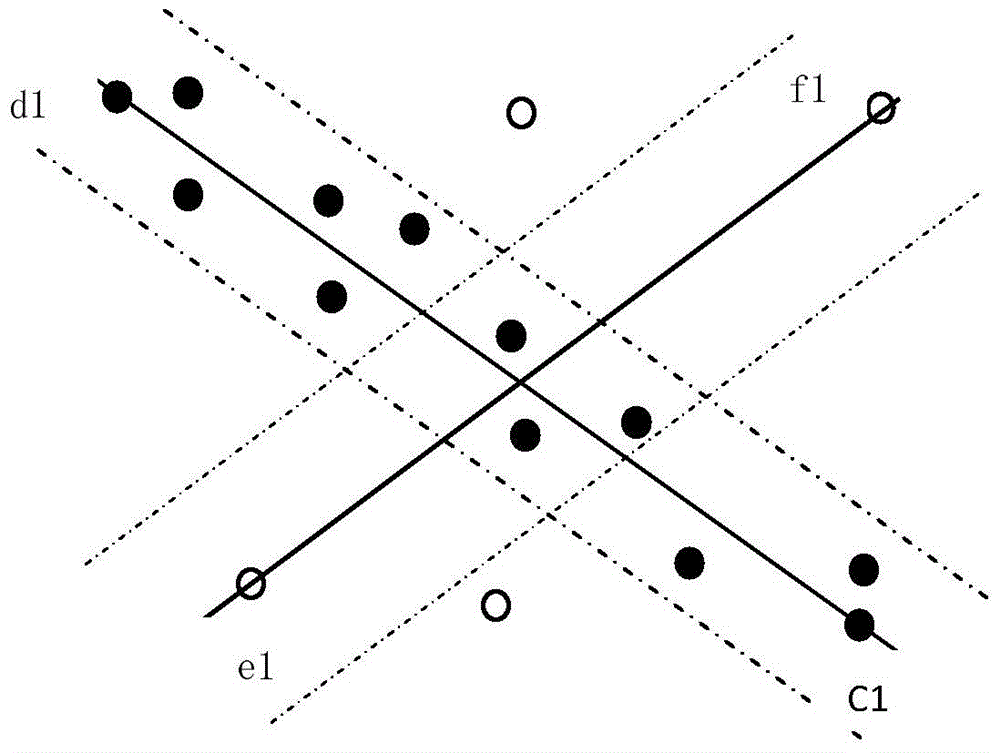

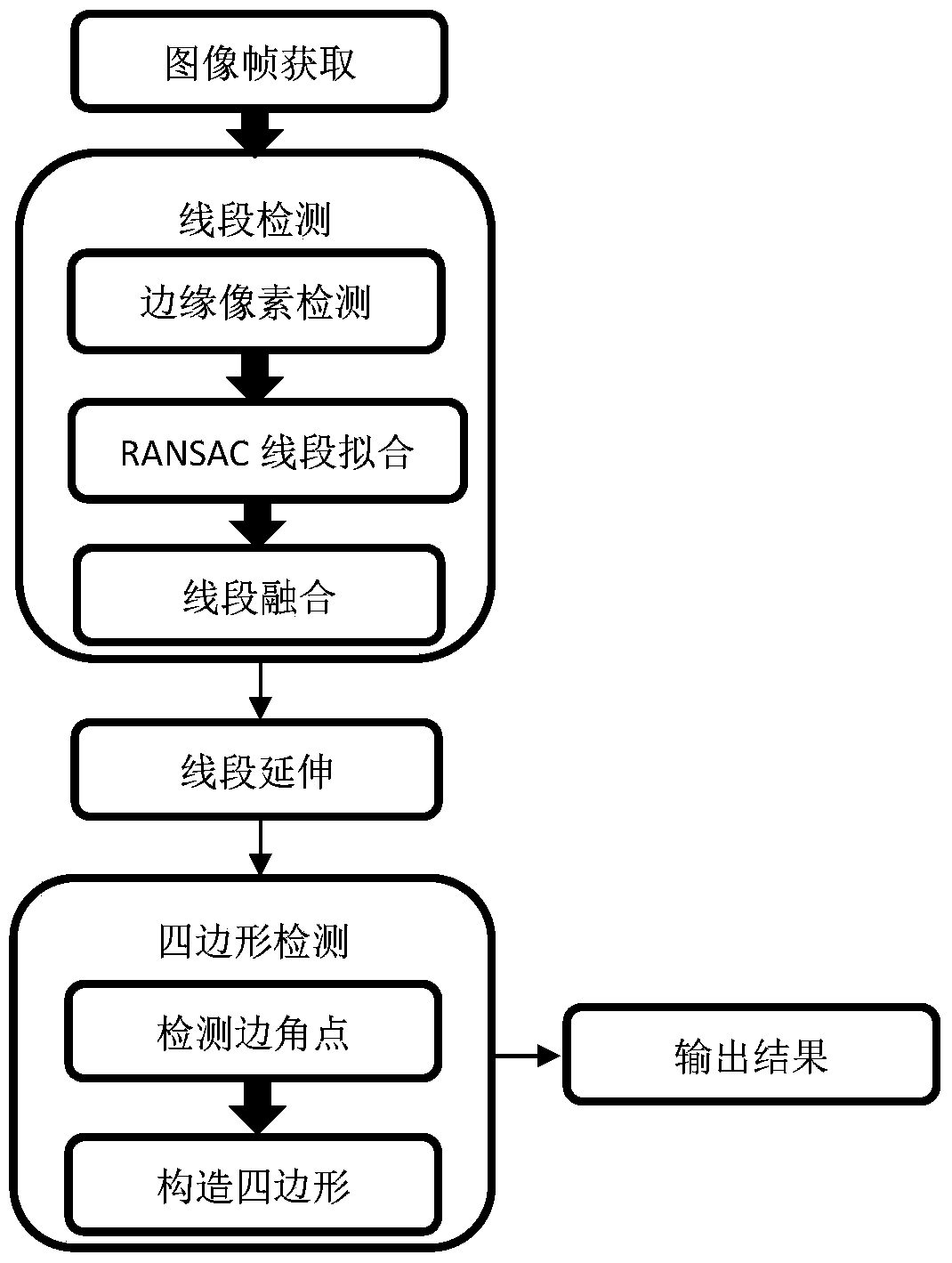

Artificial mark detection method applied to augmented reality

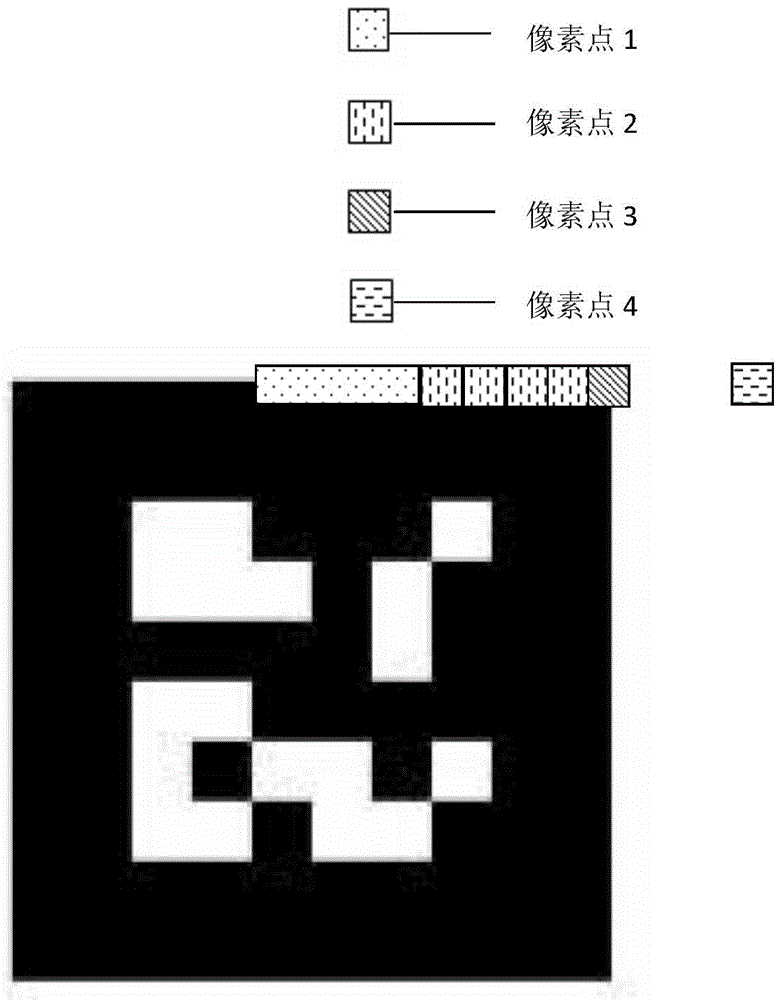

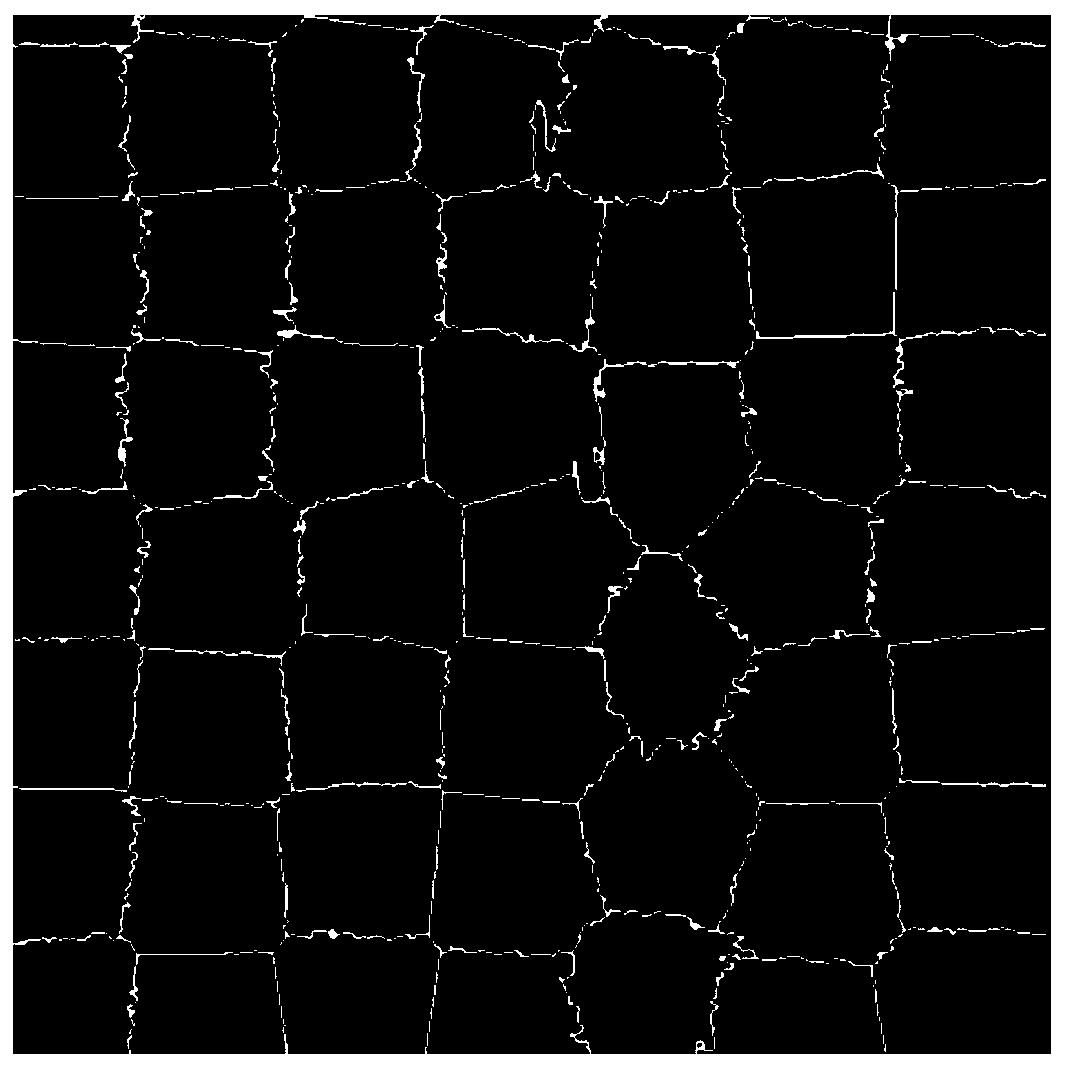

ActiveCN105740818AFast recognitionImprove anti-interference abilityImage analysisCharacter and pattern recognitionEdge basedLine segment

The invention relates to an artificial mark detection method applied to augmented reality. The method comprises the specific steps of S1: acquiring a frame image, roughly sampling the frame image, performing slant grid scanning, and performing detection to obtain edge pixels of the frame image; S2: based on an RANSAC algorithm, performing detection to obtain edge line segments in the frame image; S3: fusing the edge line segments; S4: extending and screening the edge line segments; and S5: detecting edge corner points of a quadrangle and constructing the quadrangle according to the edge corner points of the quadrangle. According to the method, the frame image is preprocessed before calculation, rough grid sampling is performed, and each grid region is subjected to edge detection, so that the program operation time is greatly shortened, the detection speed is increased, the real-time property is good, and the real-time detection requirement is met; and by adopting an edge-based detection method, line segment testing is performed at first and then a quadrilateral frame of a mark is reconstructed according to the line segments obtained by the line segment testing, so that the method has very good robustness for the illumination change and the occlusion condition.

Owner:SHANDONG UNIV

On-orbit satellite remote sensing image ship detection method

ActiveCN110414343AMeet real-time detection requirementsAccurate detectionScene recognitionOrbitComputer science

The invention discloses an on-orbit satellite remote sensing image ship detection method. According to the method, a high-resolution remote sensing image is segmented and target pre-positioning is realized by using super pixels on the premise of ensuring the integrity of a target, and a target detection algorithm is realized by using local features and variable threshold neighbor check in a pre-positioning area. Under the performance constraint and real-time performance requirements of a satellite-borne platform, the operation efficiency of the algorithm can meet the real-time detection requirements of the satellite-borne platform, and a large ship target in a high-resolution remote sensing image can be accurately detected.

Owner:XIDIAN UNIV

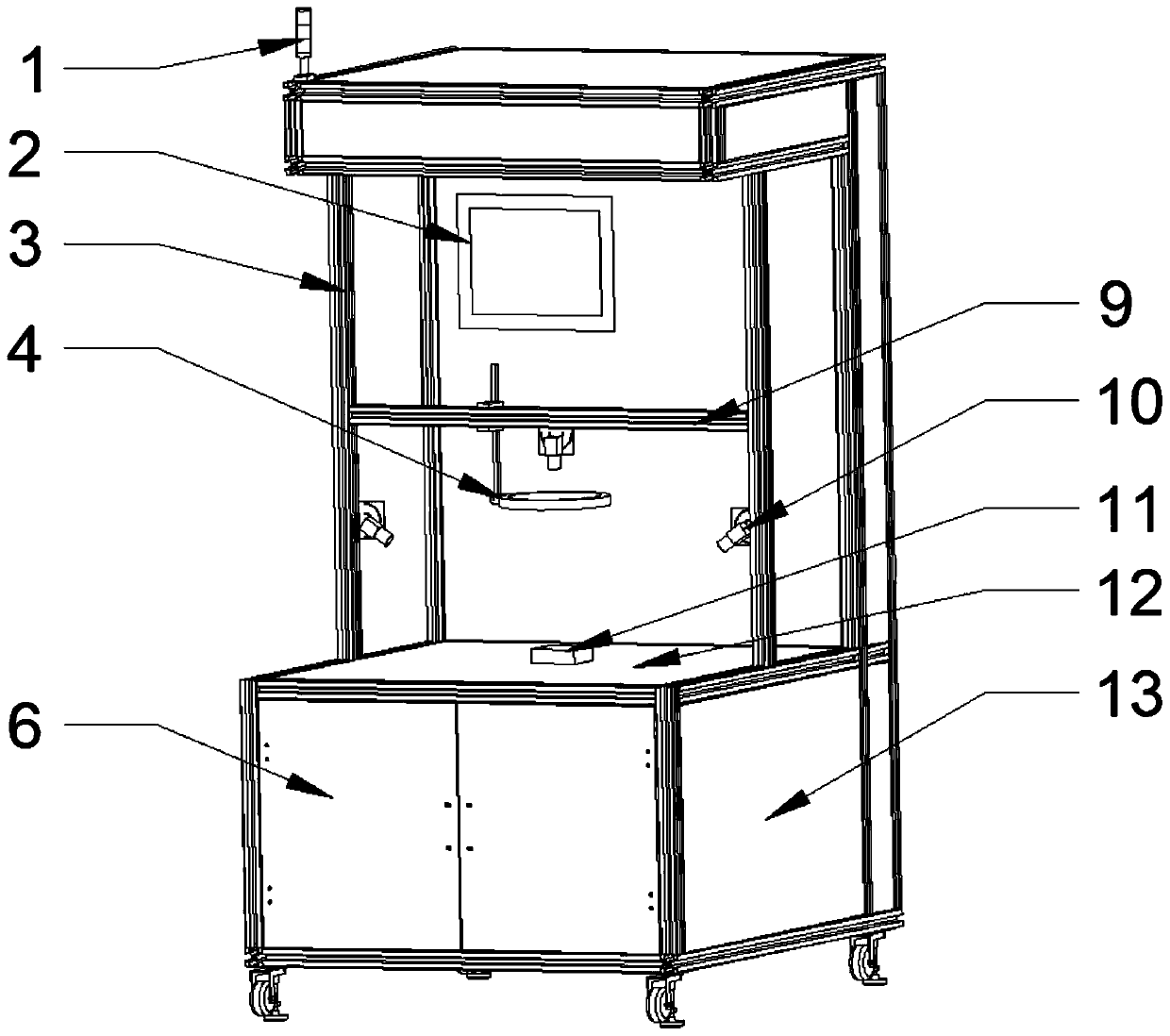

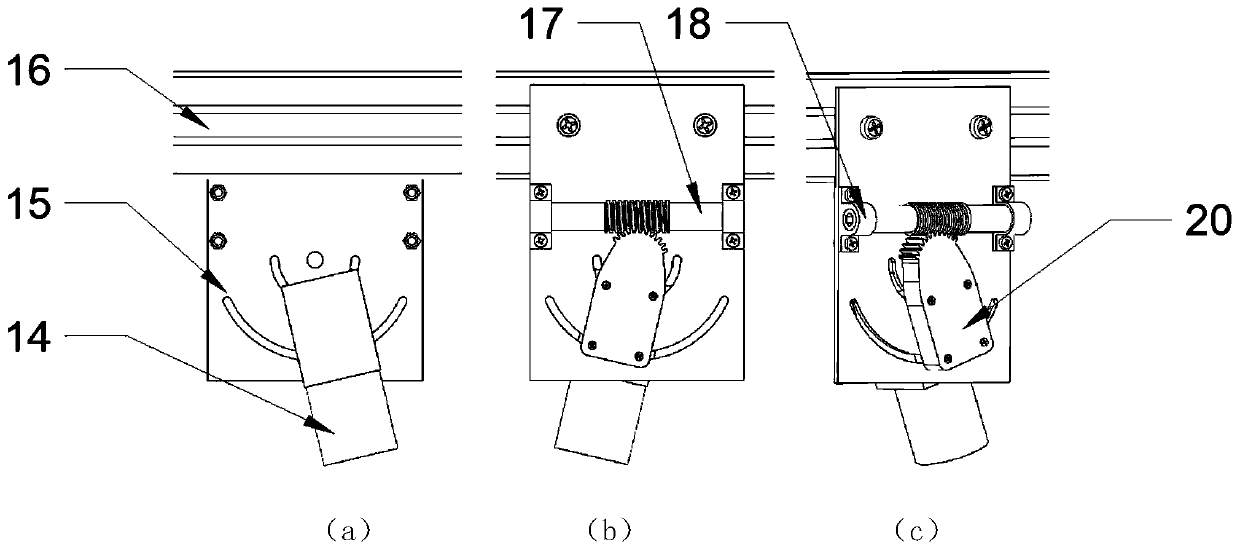

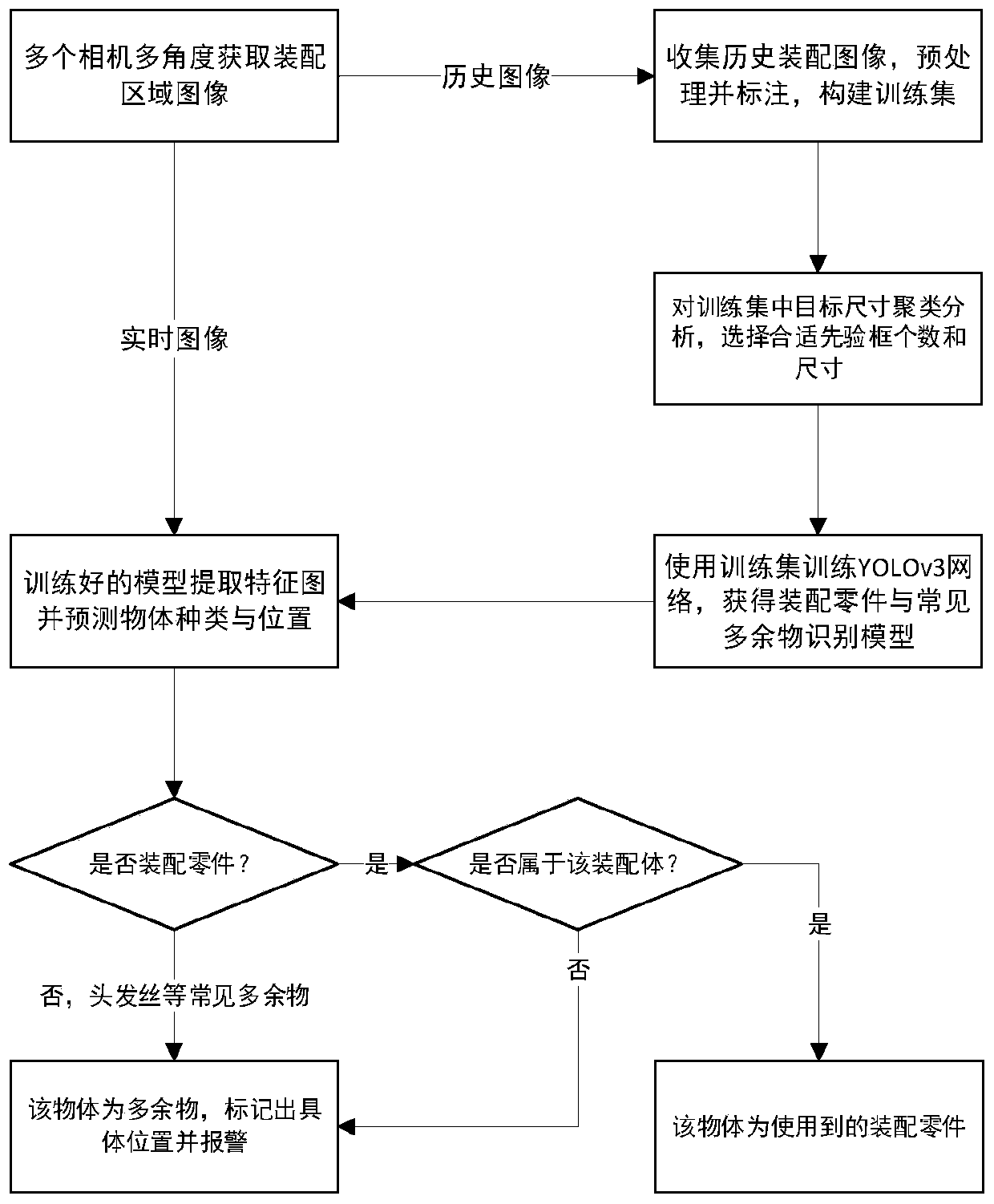

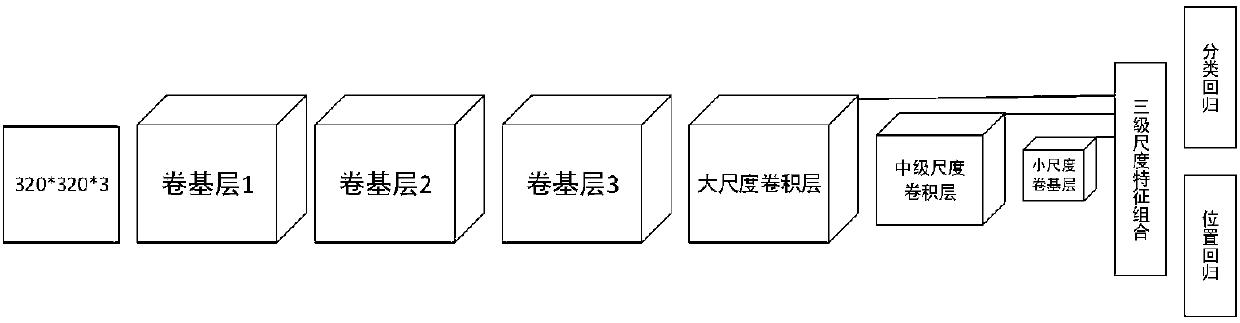

Deep learning-based redundant object visual detection system and method in mechanical assembly

ActiveCN110385282AStrong applicability in application scenariosImprove robustnessNeural architecturesAquisition of 3D object measurementsFeature extractionNetwork model

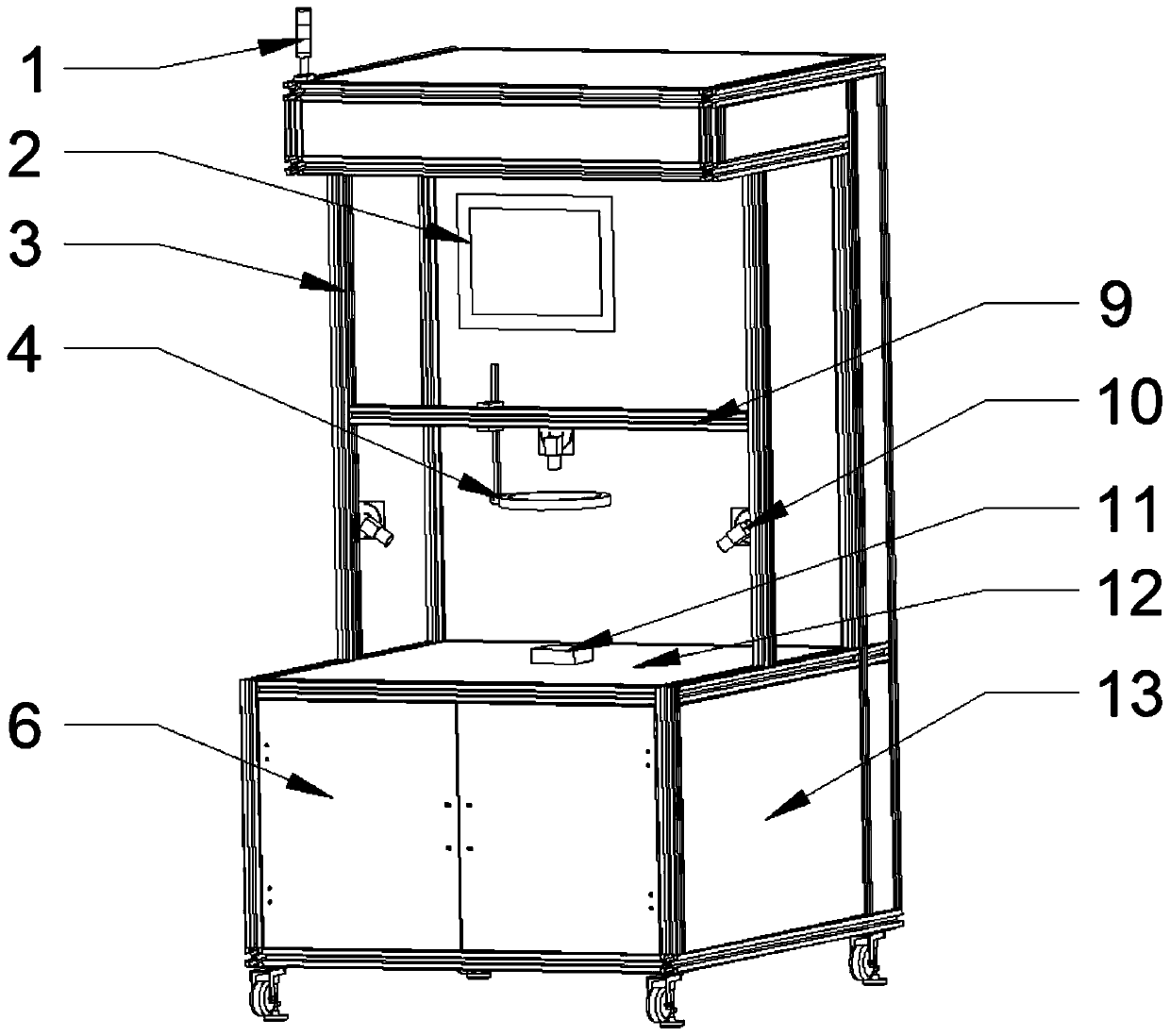

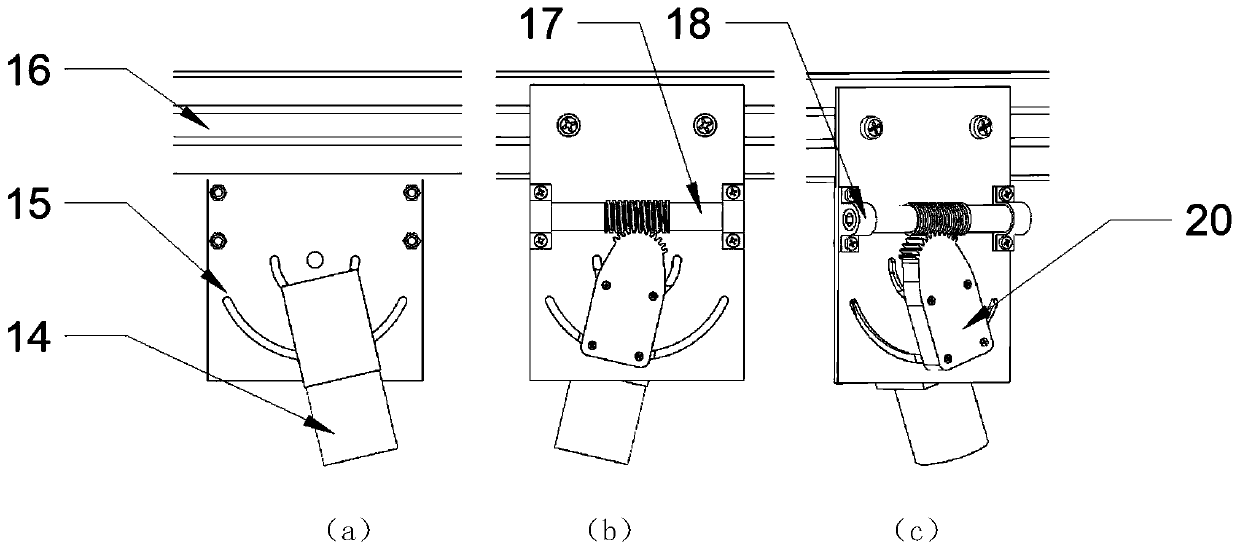

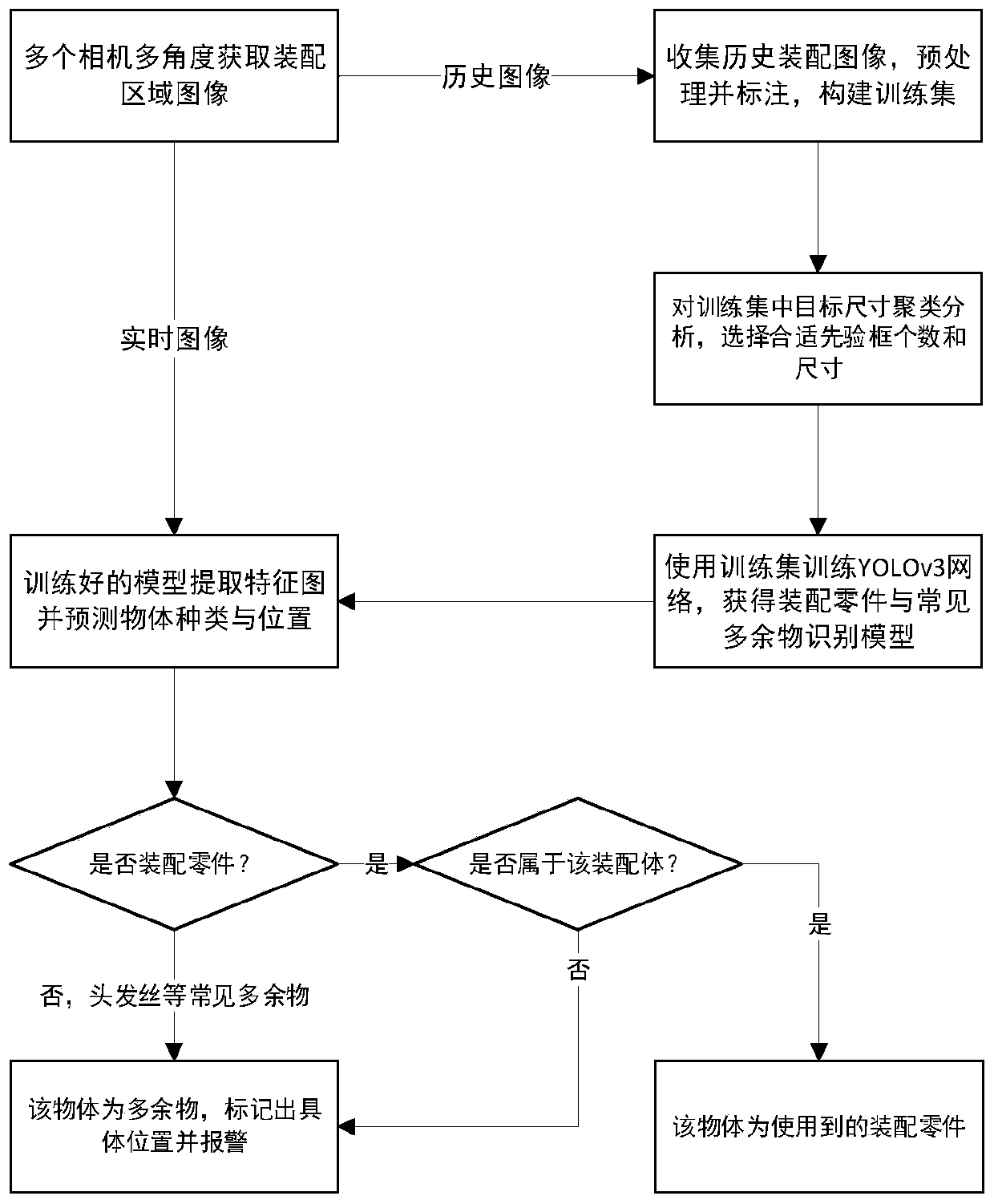

The invention discloses a deep learning-based redundant object visual detection system and method in mechanical assembly. The detection system involves a worktable, an angle-adjustable camera, a lightsource, a visual controller and the like, wherein by processing and analyzing images acquired from the camera, the visual controller is used for identifying objects in the images and then distinguishing assembly parts and redundant objects. The detection method comprises the following steps of acquiring the images in a multi-angle assembly area, preprocessing the images, inputting the images intoa trained target detection network model for feature extraction to predict the positions and the types of the objects, then judging whether the objects belong to redundant objects, and marking the positions of the redundant objects and giving an alarm. The system and method can be used for assisting people with real time and multi-angle detection on the redundant objects in the specific area in the assembling process; the system and the method have the advantages of being high in detection accuracy, high in real-time performance, flexible in use and the like; and the introduction of the redundant objects in the assembling process can be reduced, and the product reliability is enhanced.

Owner:ZHEJIANG UNIV

Television station logo detection and recognition method

InactiveCN108509953AStrong complexityStrong interferenceCharacter and pattern recognitionNeural architecturesImage detectionTelevision station

The invention relates to a television station logo detection and recognition method, and belongs to the technical field of image detection and recognition. The method comprises the following steps: (1) collecting station logo picture samples, carrying out labeling on corresponding station logo positions of pictures, and carrying out size normalization processing on all the images of object detection; (2) setting parameters of a learning rate, an iteration number and the like of TB-Net network training; (3) sending the normalized images into a TB-Net network for training, extracting primary features and abstract features of the images, sending the same into a position regression layer and a classification layer, and obtaining a best station logo detection model after training; and (4) loading the station logo detection model and network by a test program, sending a to-be-detected picture into the network, and outputting a result of whether the image contains a station logo and a position where the station logo is located. According to the method, station logos in video pictures can be more accurately detected, and accuracy of station logo recognition can be improved.

Owner:南京烽火天地通信科技有限公司

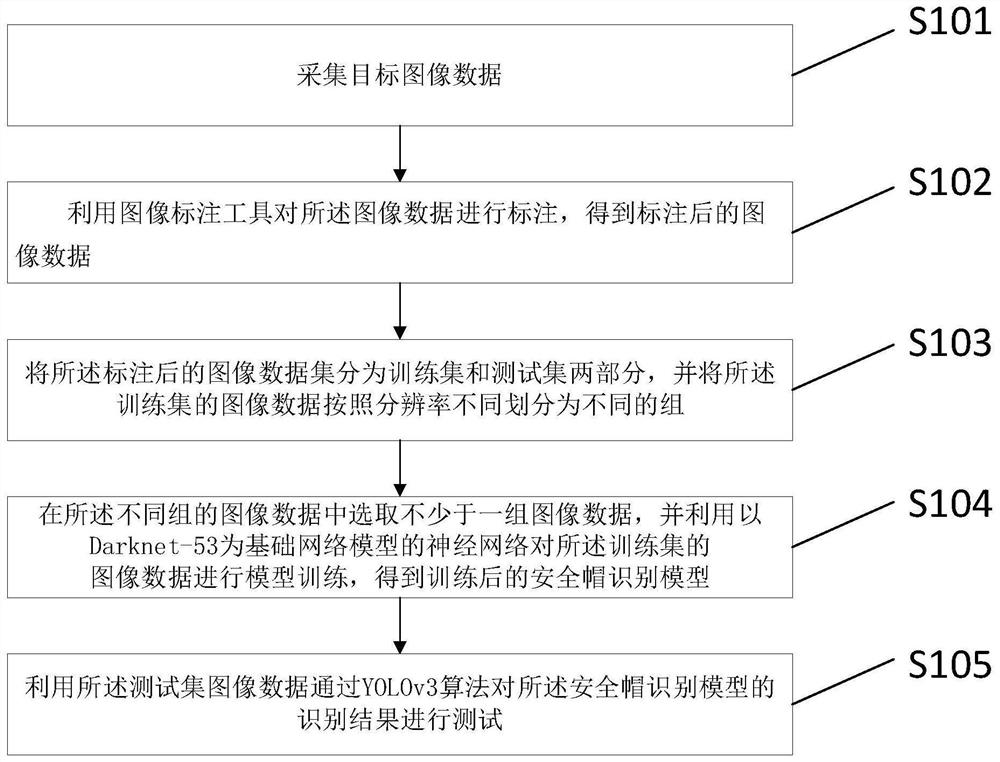

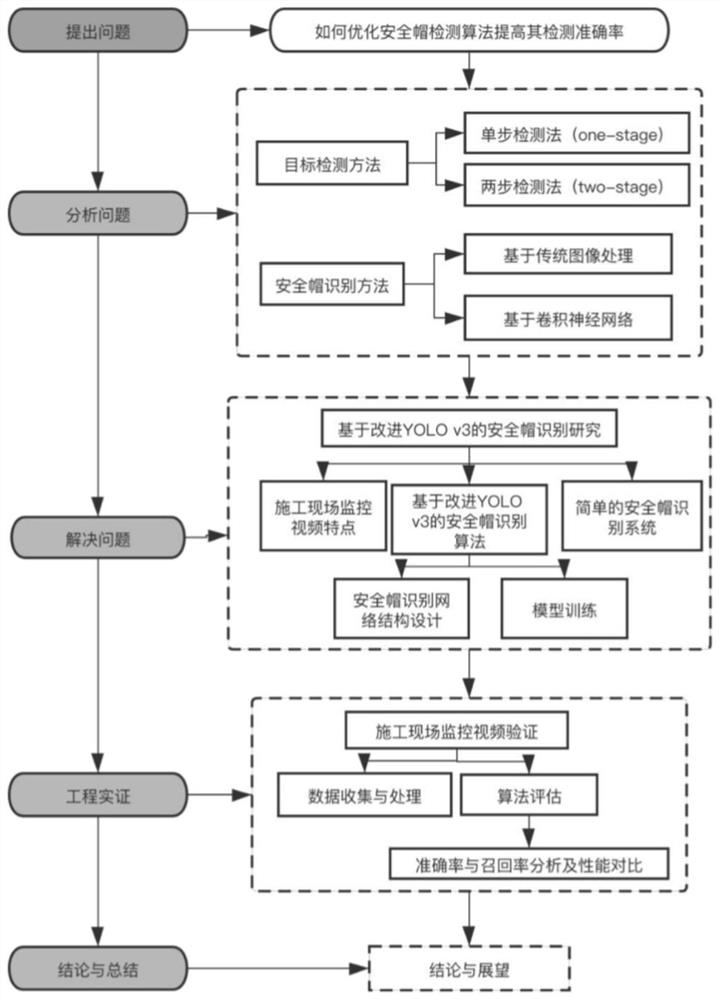

Safety helmet identification method and device based on YOLOv3, medium and equipment

PendingCN113052133AImprove accuracySolve the detection speed is slowCharacter and pattern recognitionNeural architecturesData setImage resolution

The invention relates to the technical field of image recognition, and provides a safety helmet recognition method and device based on YOLOv3, a medium and equipment, and the method comprises the steps: collecting target image data; annotating the image data by using an image annotation tool to obtain annotated image data; dividing the marked image data set into a training set and a test set, and dividing the image data of the training set into different groups according to different resolutions; selecting at least one group of image data from the different groups of image data, and performing model training on the image data of the training set by using a neural network taking Darknet-53 as a basic network model to obtain a trained safety helmet recognition model; and testing an identification result of the safety helmet identification model by using the test set image data through a YOLOv3 algorithm. According to the method, data set classification and multi-scale and multi-level training are carried out, the accuracy and the detection speed of safety helmet detection are improved, and the real-time detection requirement is met.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

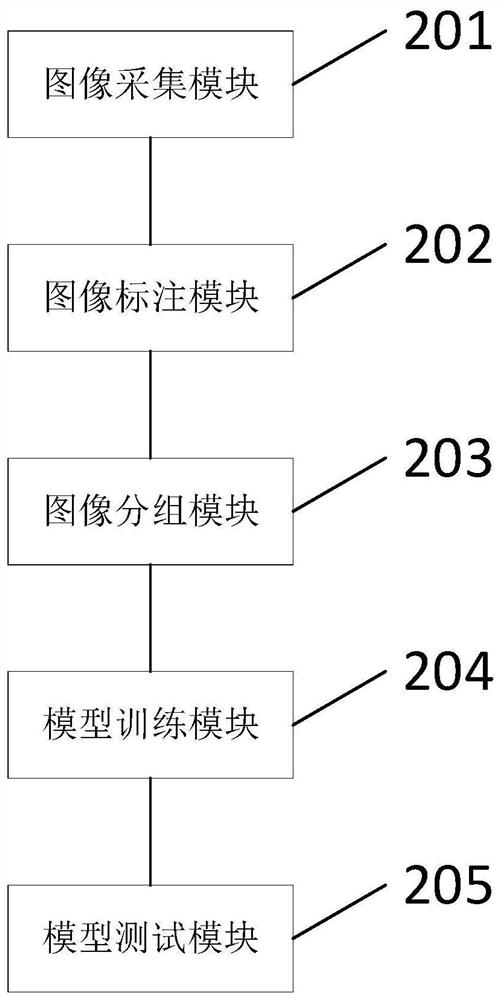

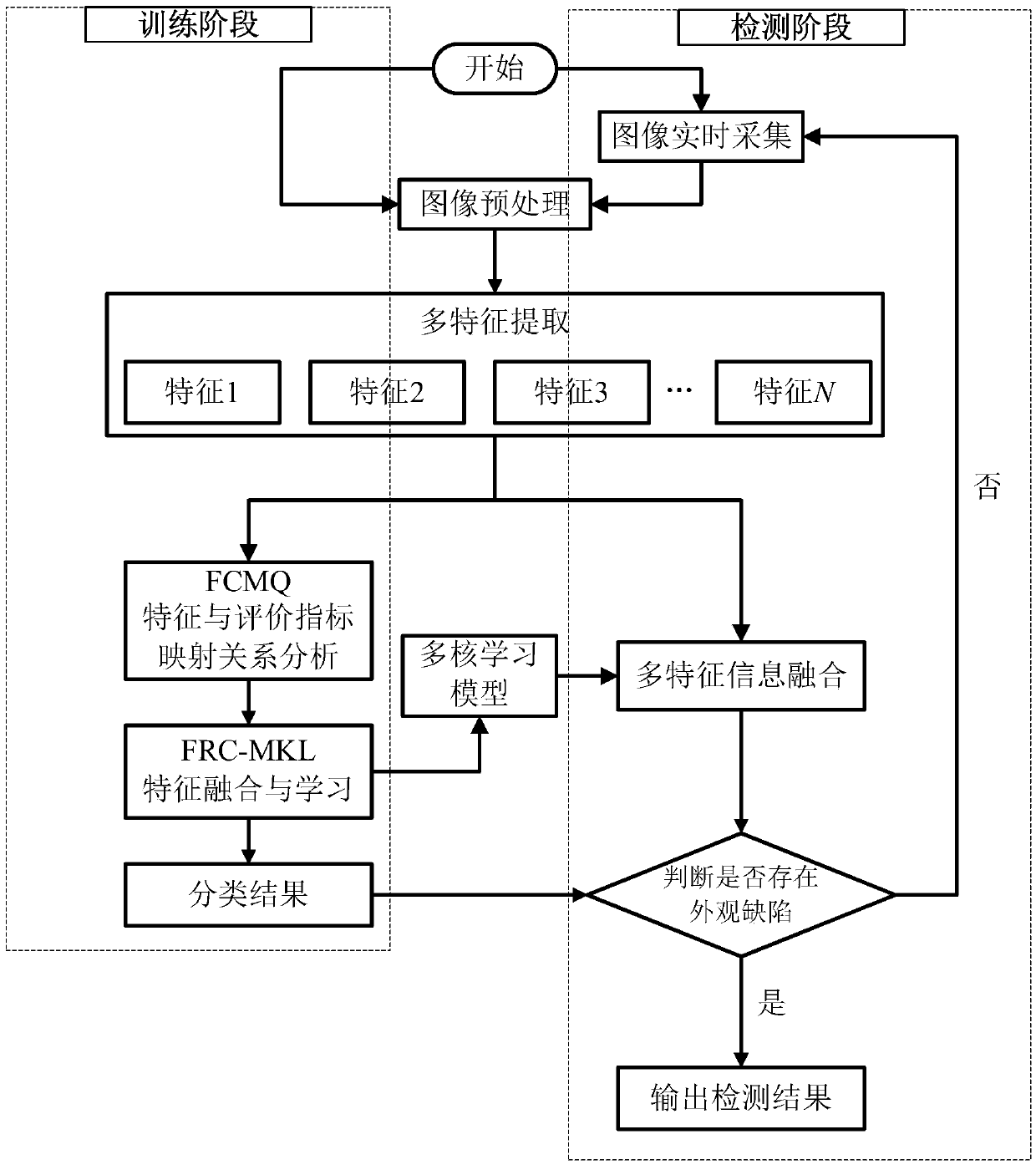

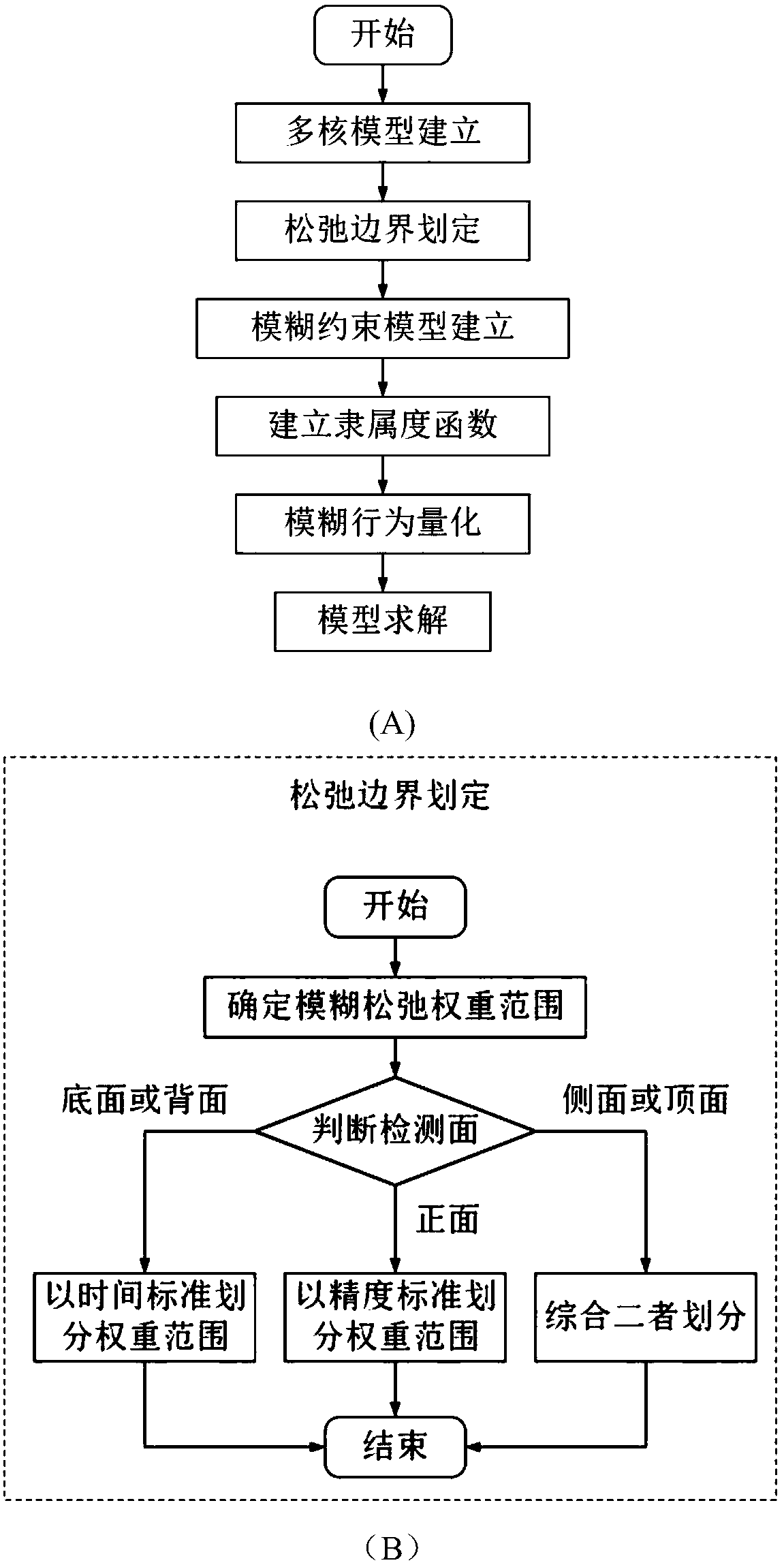

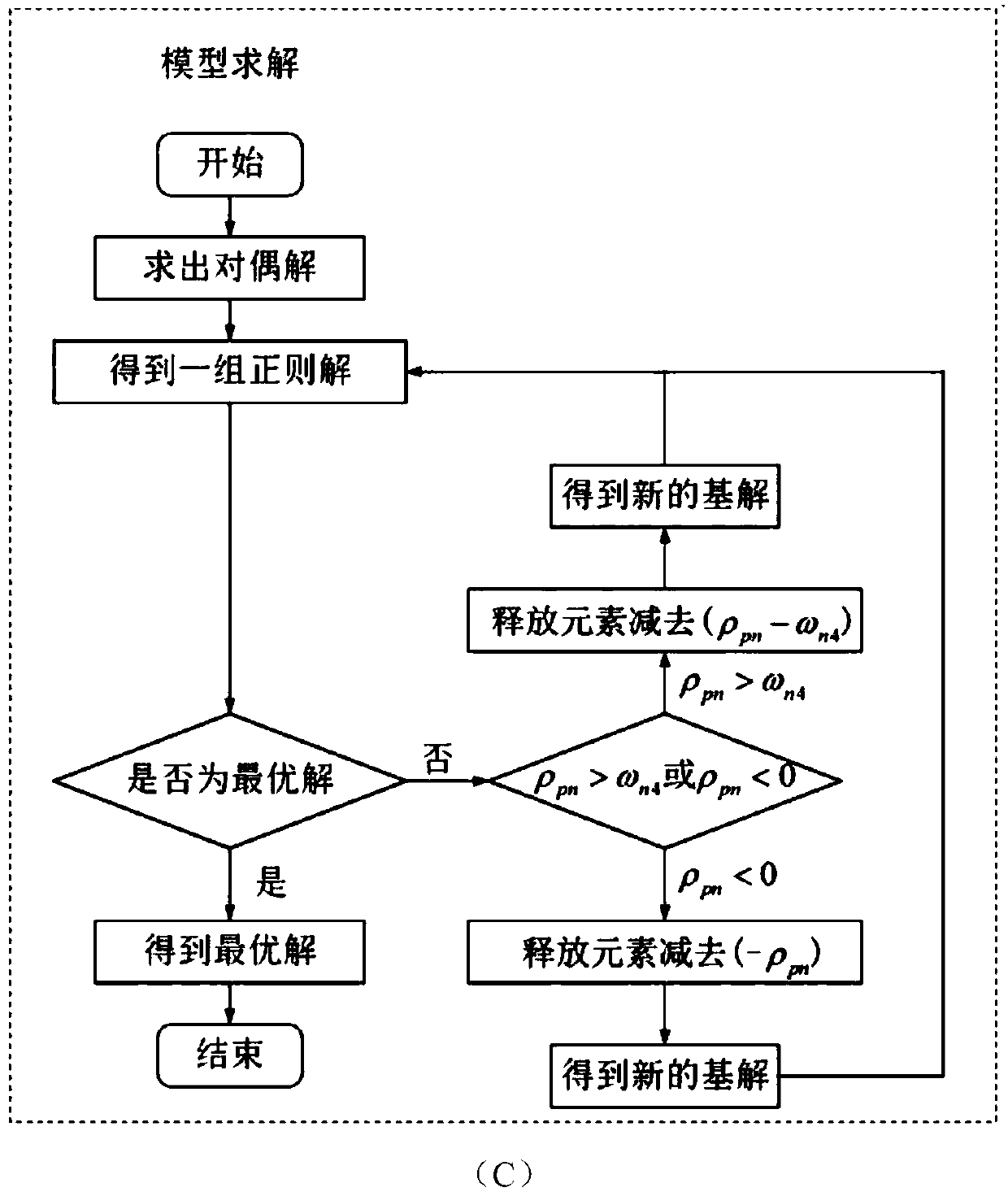

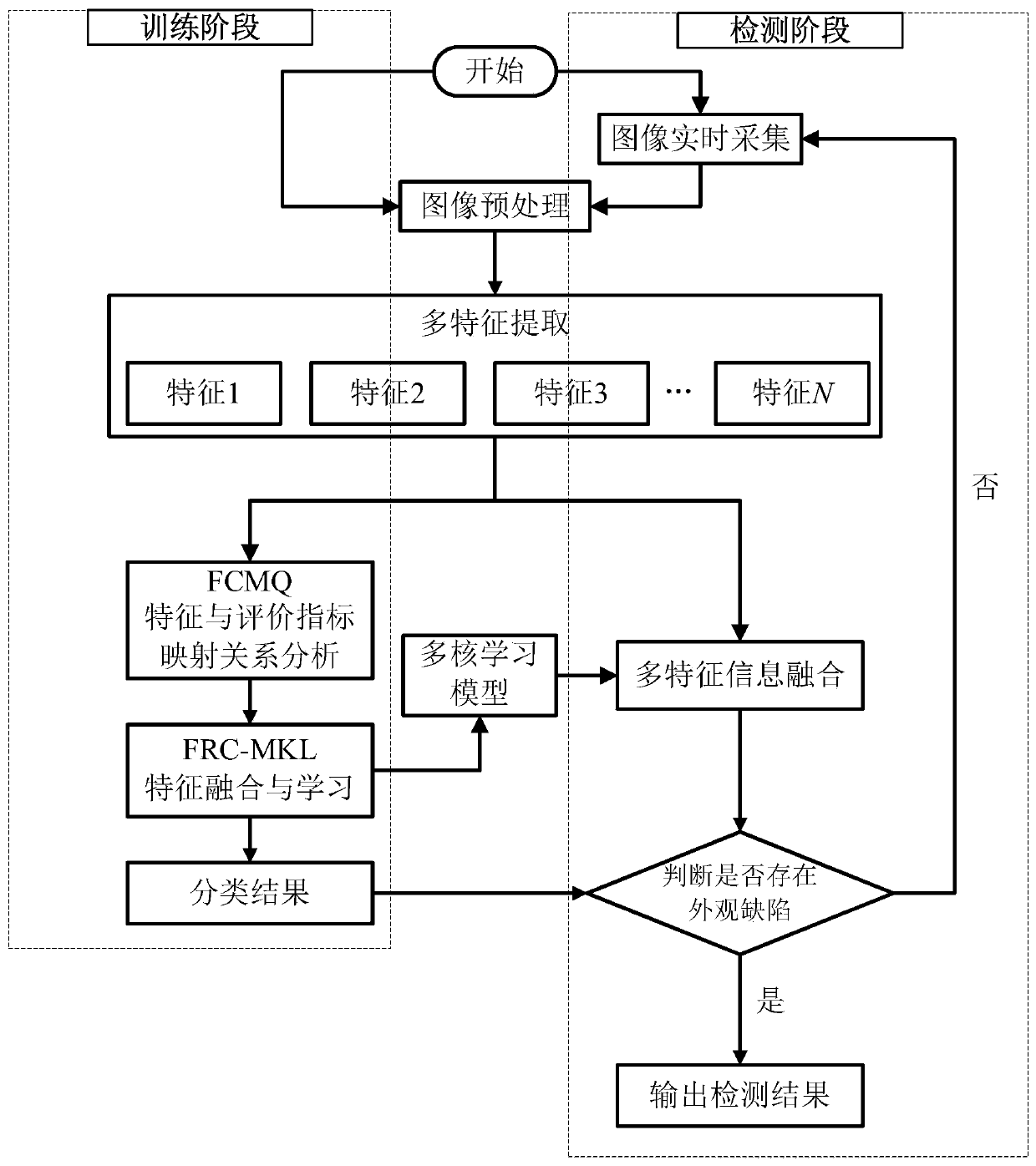

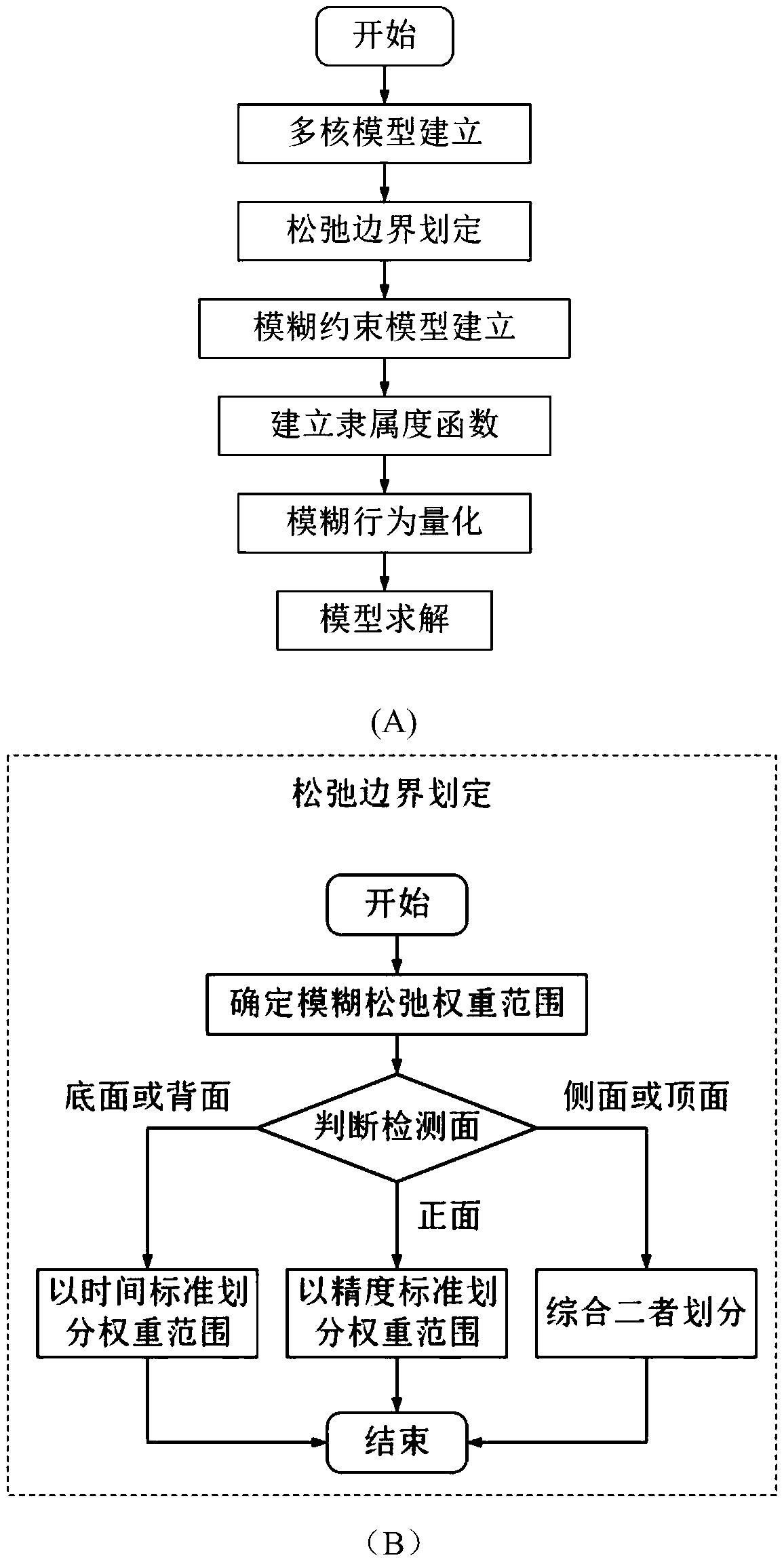

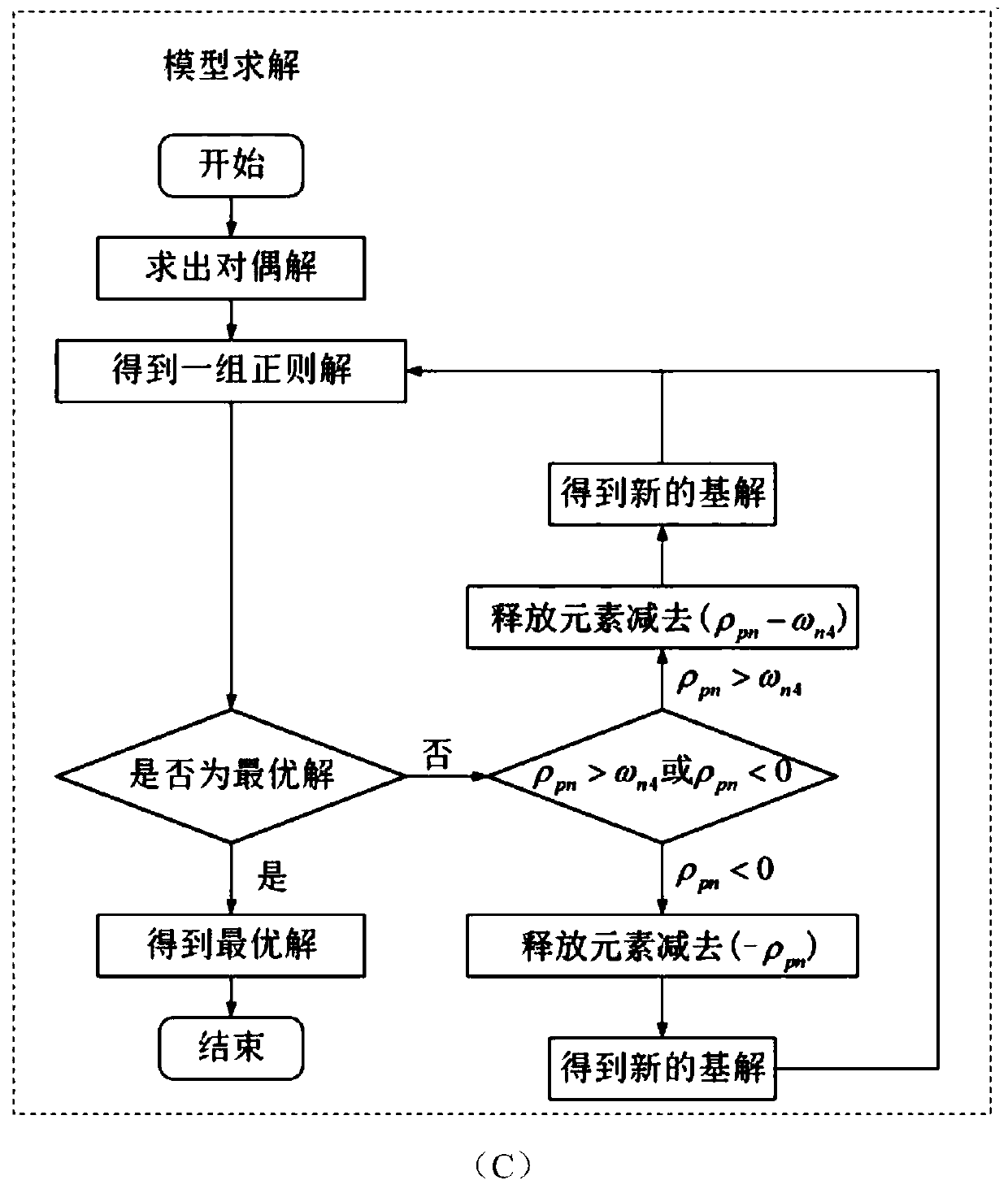

Product appearance defect detection method based on multi-core learning with fuzzy relaxation constraints

ActiveCN109034172AMeet detectionMeet real-time detection requirementsImage enhancementImage analysisMachine visionStudy methods

The invention provides a product appearance defect detection method based on fuzzy relaxation constraint multi-core learning, which belongs to the product quality detection field of machine vision. Firstly, some features of the real-time image are extracted. Then the fuzzy constraint theory is used to quantitatively analyze the mapping relationship between the characteristics and the evaluation indexes. A multi-core learning model is established to classify the appearance defects, and the fuzzy relaxation boundary of each kernel function weight is delineated by combining the mapping quantization relation. The fuzzy relaxation constraint (FRC) method is used to determine the weights of the multi-kernel model and the fuzzy range of the weights. At last, the multi-core learning model with different kinds of defects is obtained by calculating the weights of defects, and the defect detection results are obtained by using the multi-core learning model. The invention adopts the multi-featurefusion multi-core learning classification detection method, which makes the detection range wider, combines the fuzzy relaxation constraint to adapt to different detection requirements, can meet the real-time detection, and has high detection accuracy.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

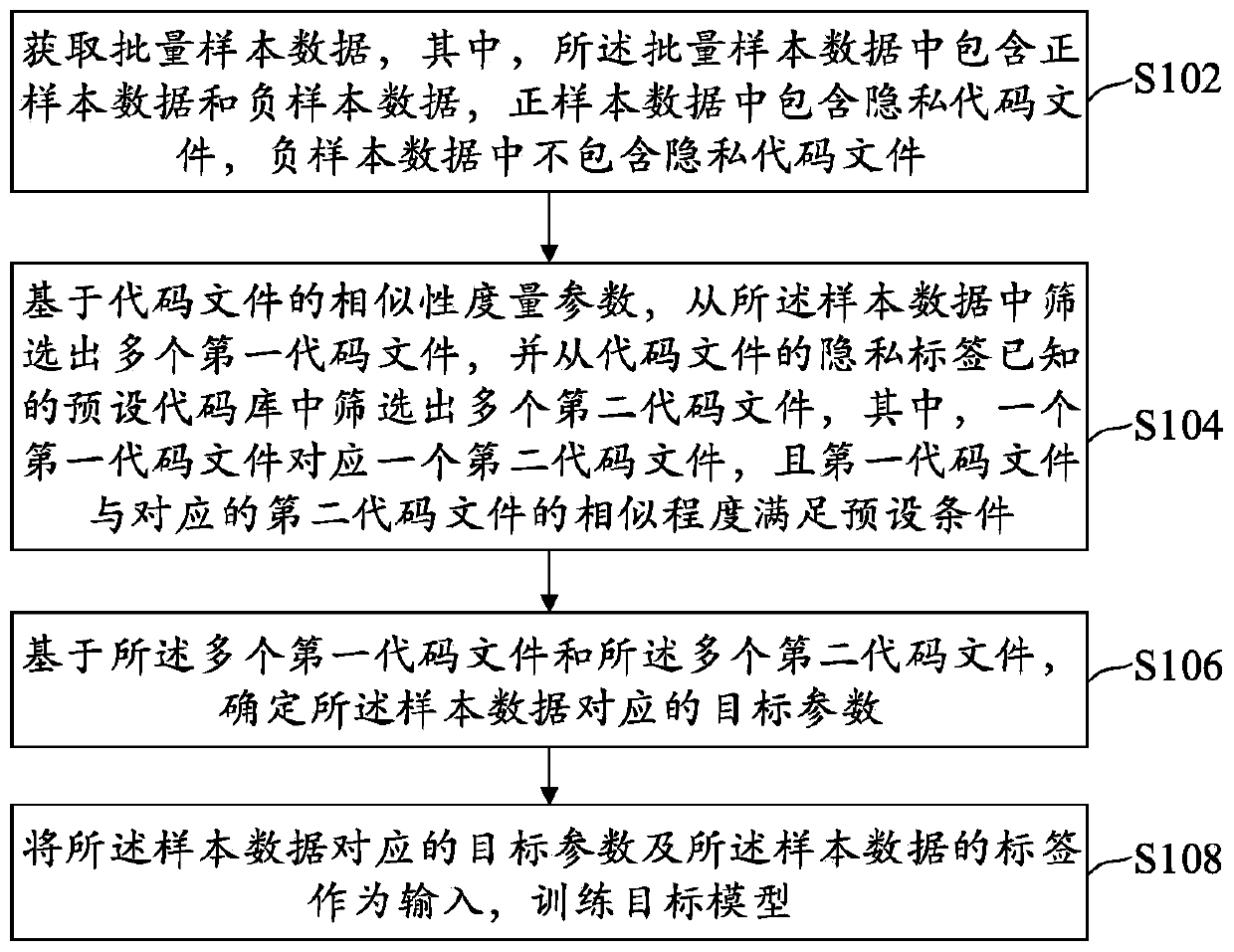

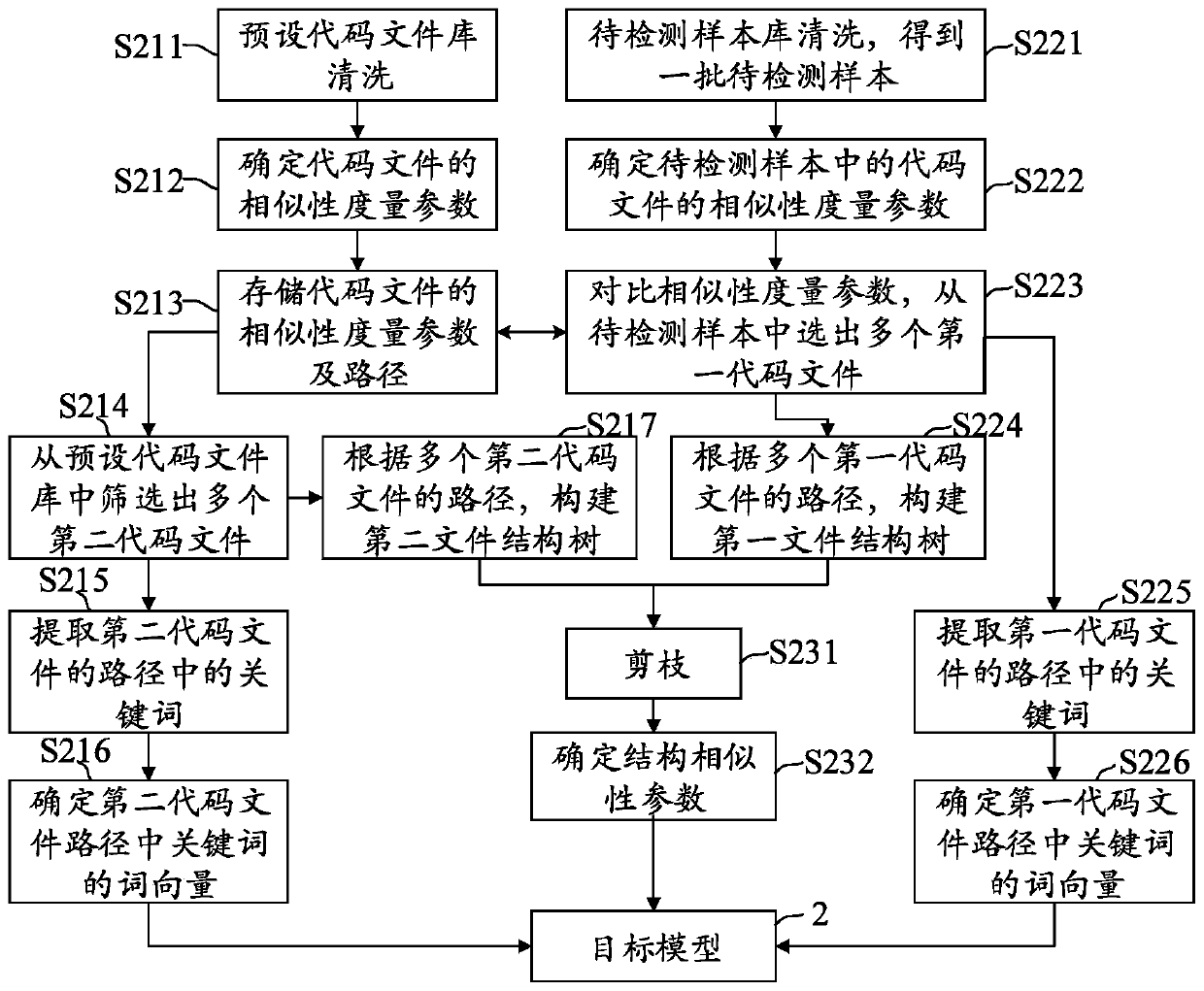

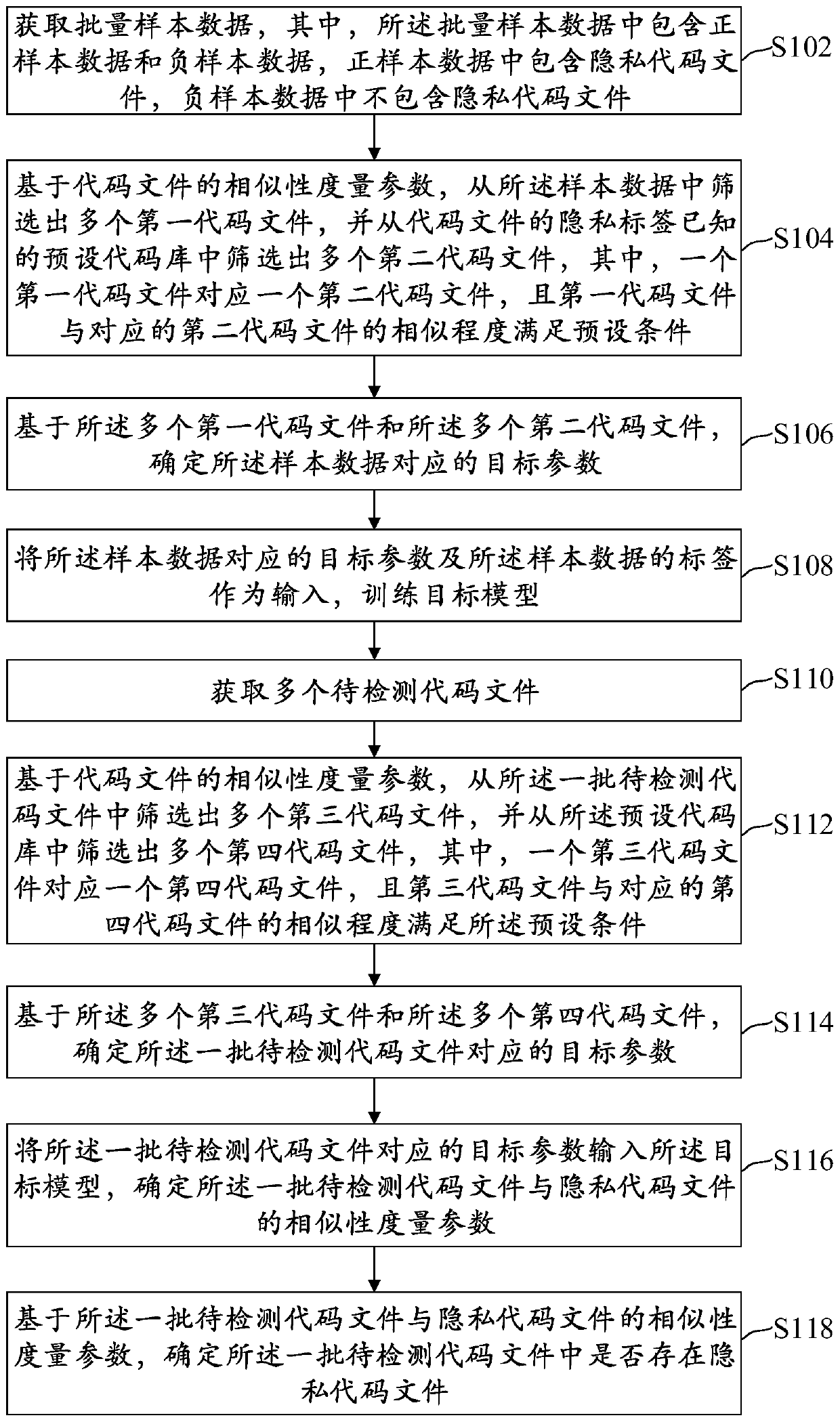

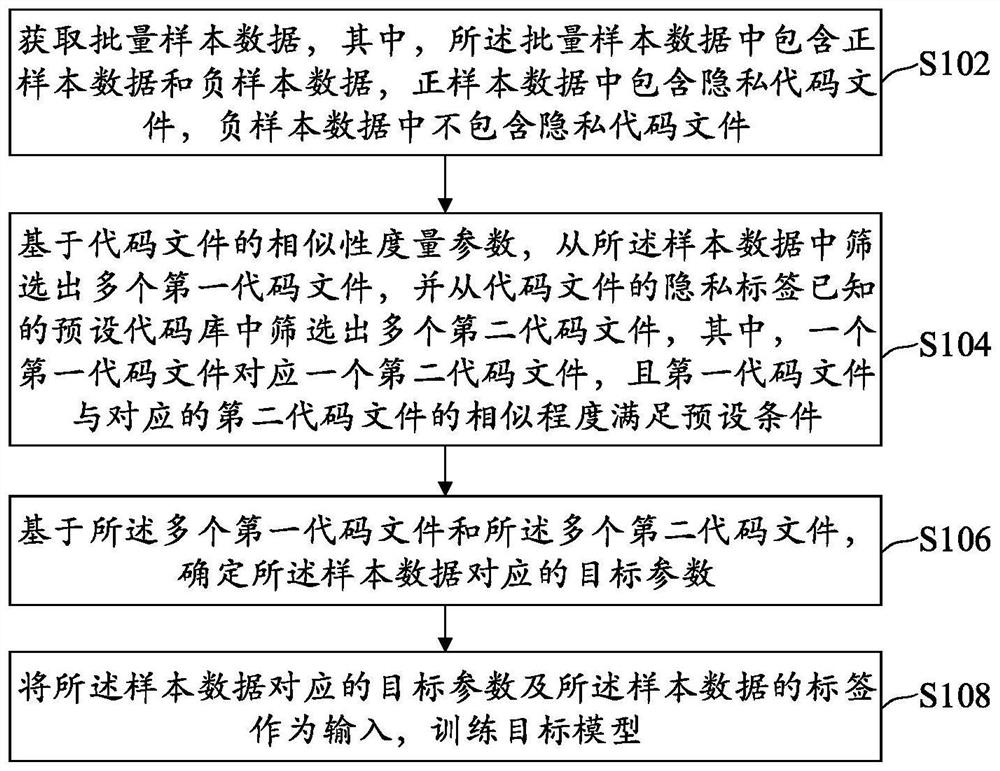

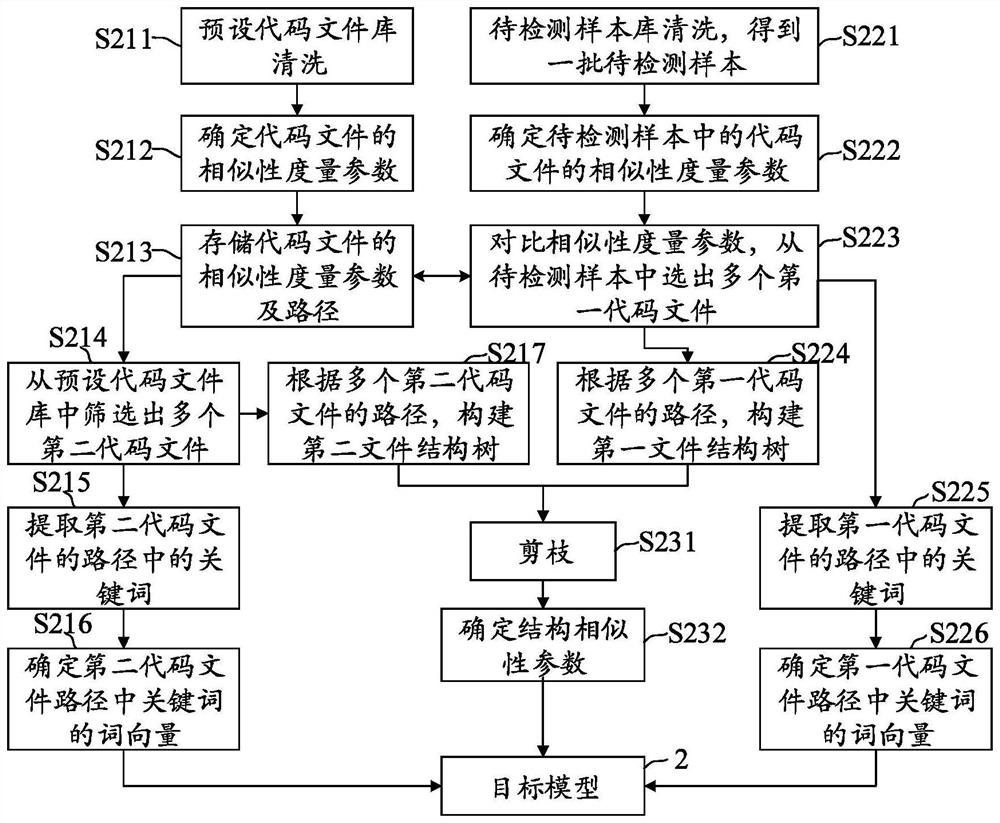

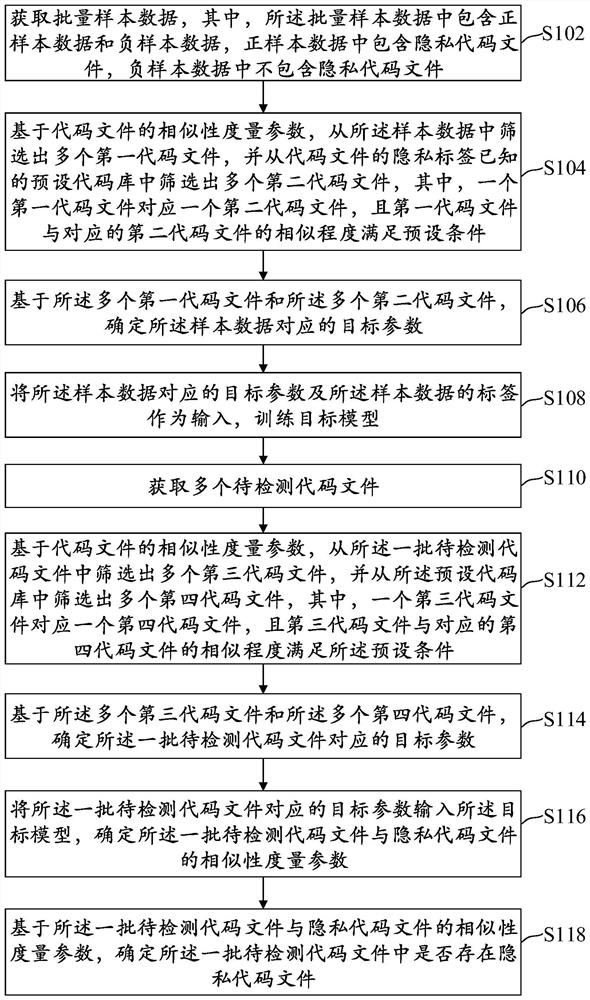

Machine learning method and device, privacy code determination method and device and electronic equipment

ActiveCN111143203AImprove detection efficiencyHigh speedSoftware testing/debuggingMachine learningPositive sampleTheoretical computer science

The embodiment of the invention discloses a machine learning method and device, a privacy code determination method and device and electronic equipment, the machine learning method includes: obtainingsample data containing positive and negative samples in batch, the positive sample data contains a privacy code file, and the negative sample data does not contain a privacy code file; screening outa plurality of first code files from the sample data based on similarity measurement parameters of the code files, and screening out a plurality of second code files from a preset code library with known privacy tags of the code files; determining a target parameter corresponding to the sample data based on the plurality of first code files and the plurality of second code files; and training a target model by taking the target parameters corresponding to the sample data and the labels of the sample data as input, the target model being used for determining similarity measurement parameters ofa batch of code files to be detected and private code files.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

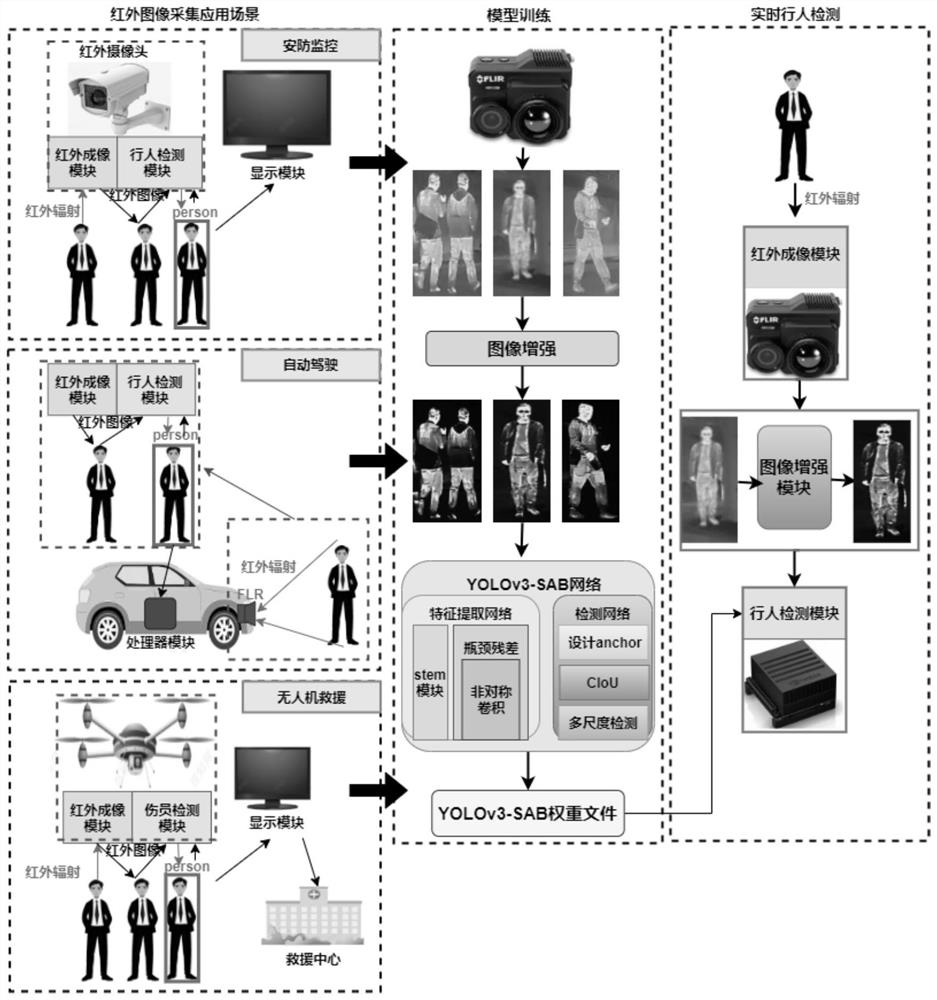

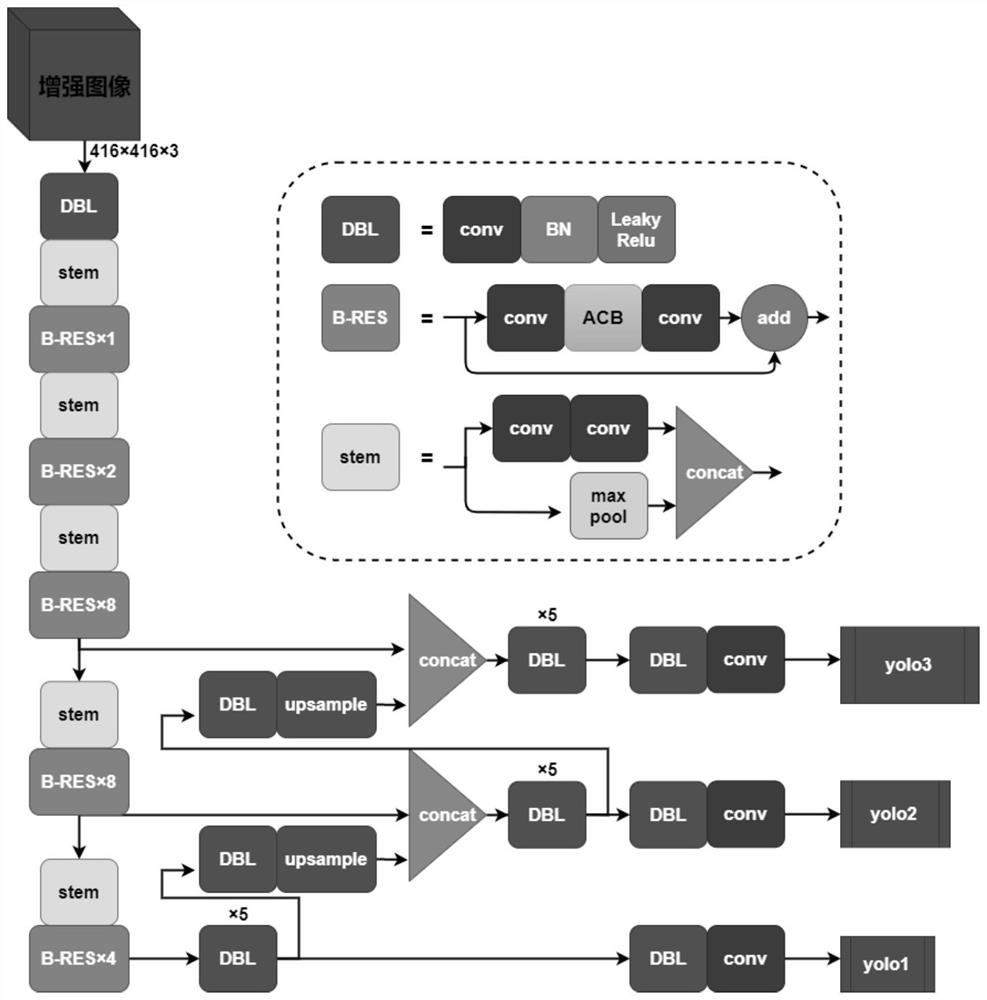

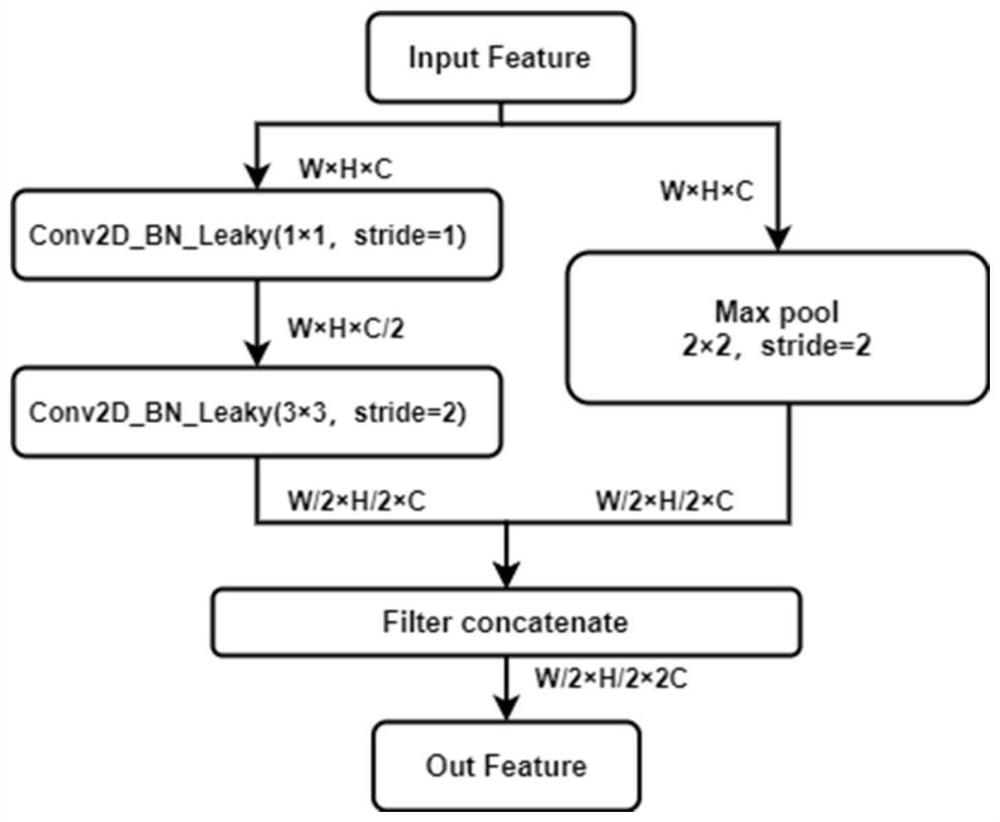

Night infrared pedestrian detection method and system based on improved YOLOv3

PendingCN114332942AThe detection model (YOLOv3) is efficient for infrared pedestrian detection at nightReal-time detectionBiometric pattern recognitionNeural architecturesFeature extractionData set

The invention discloses a night infrared pedestrian detection method and system based on improved YOLOv3, and the method comprises the steps: collecting a plurality of infrared pedestrian detection data sets through a plurality of infrared cameras, carrying out the pixel value contrast enhancement of the data sets, increasing the pedestrian pixel values, and reducing the background pixel values; a night infrared pedestrian detection network model YOLOv3-SAB is improved and constructed based on YOLOv3, a stem down-sampling module and asymmetric convolution are introduced to improve the network feature extraction capability and feature expression capability, calculation parameters in a bottleneck residual error reduction model are introduced, and the pedestrian detection speed of the model is improved; a specific prior aiming frame is generated through clustering by using a mean value clustering algorithm, and the model target positioning precision is improved; cIoU is used as a YOLOv3-SAB network bounding box regression loss function, so that model convergence is accelerated, and the accuracy of a prediction box is improved; a YOLOv3-SAB network is trained to generate a night infrared pedestrian detection model; and performing real-time infrared pedestrian detection at night by using the night infrared pedestrian detection model. According to the invention, the detection precision and the detection speed of pedestrians at night are effectively improved.

Owner:WUHAN UNIV OF TECH

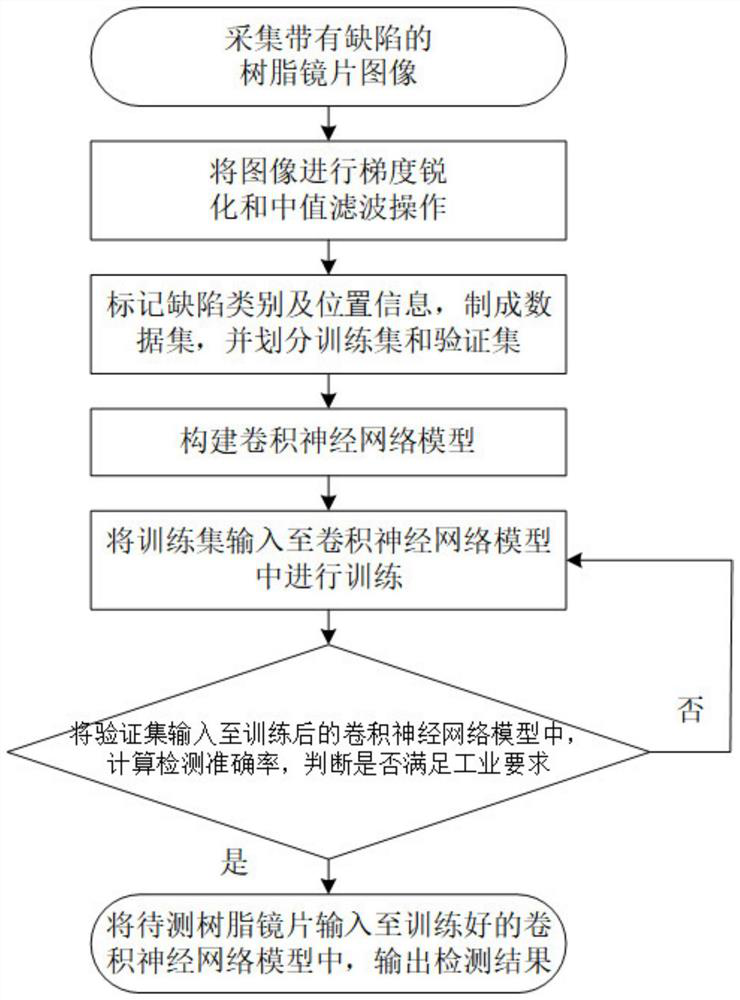

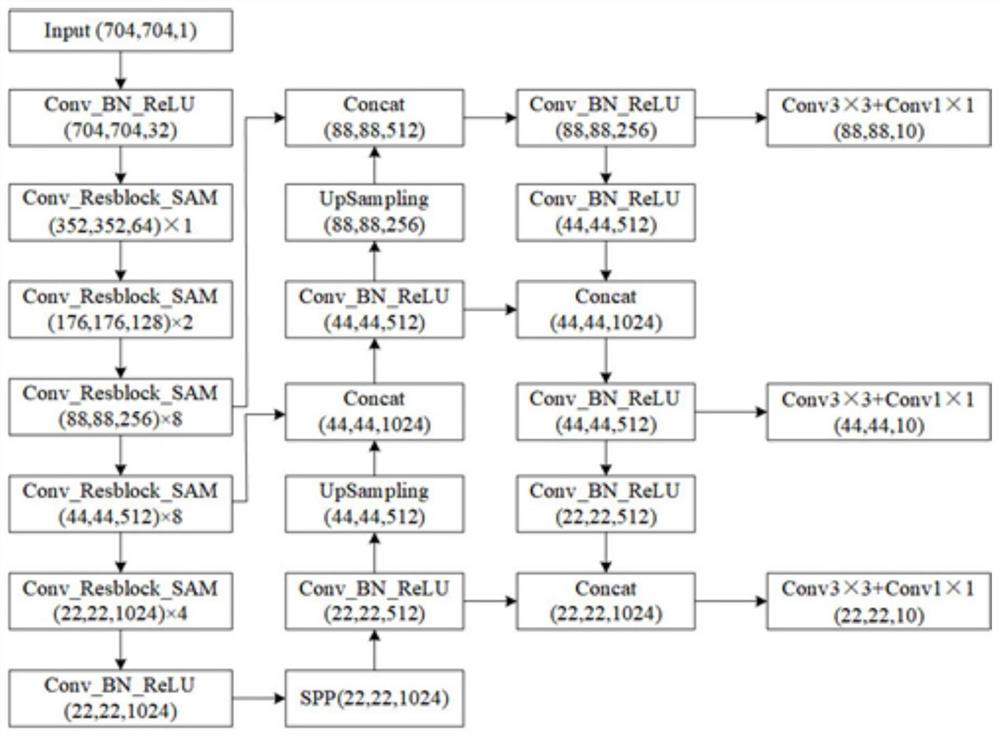

Resin lens defect detection method based on convolutional neural network

ActiveCN113393438AImprove feature extractionFully integratedImage enhancementImage analysisData setEngineering

The invention discloses a resin lens defect detection method based on a convolutional neural network. The method comprises the following steps: acquiring an image of a resin lens with defects; carrying out gradient sharpening and median filtering on the image to enhance detail information of the image; marking the position and category of the defect, and making a data set; constructing a convolutional neural network model, wherein the network model is based on an improved DarkNet53 as a backbone network, a multi-scale feature fused neck network and a multi-classification regression network as a detection head; inputting the data set into the network model for training; and inputting a to-be-detected picture into the trained network model for detection, and finally outputting information such as a defect category, a defect position and confidence, namely a final detection result. According to the invention, online detection of the defects of the resin lens can be realized, the generalization performance is good, and the detection efficiency and the detection precision are improved.

Owner:HARBIN UNIV OF SCI & TECH

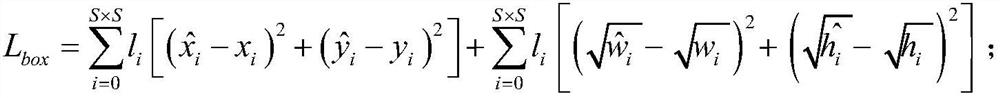

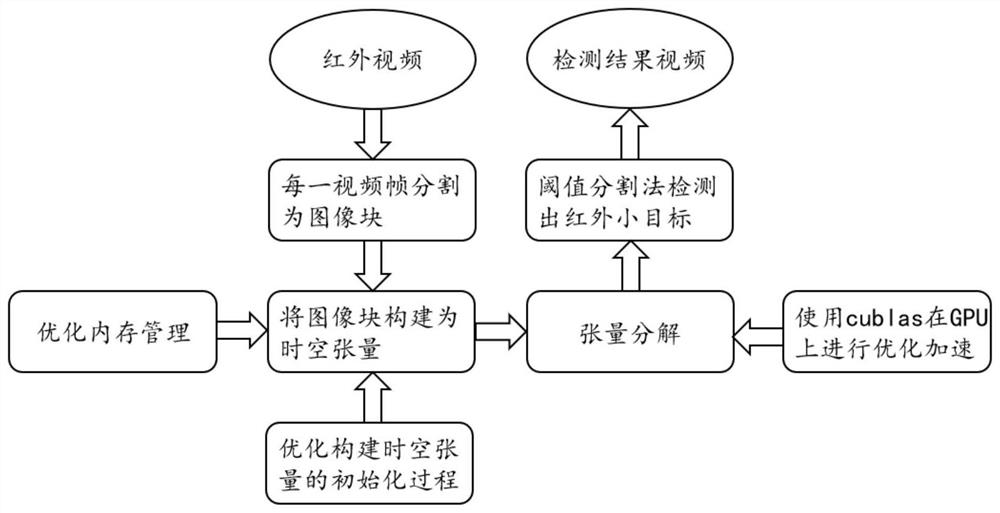

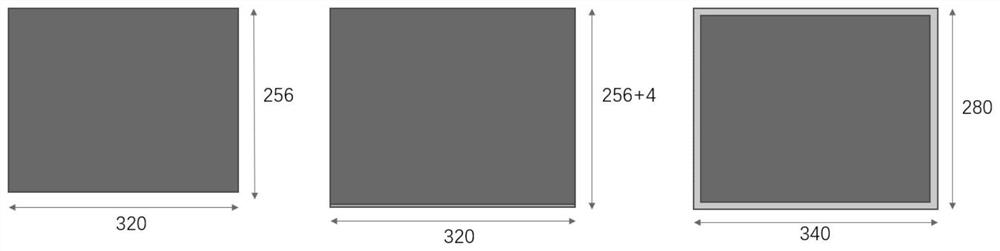

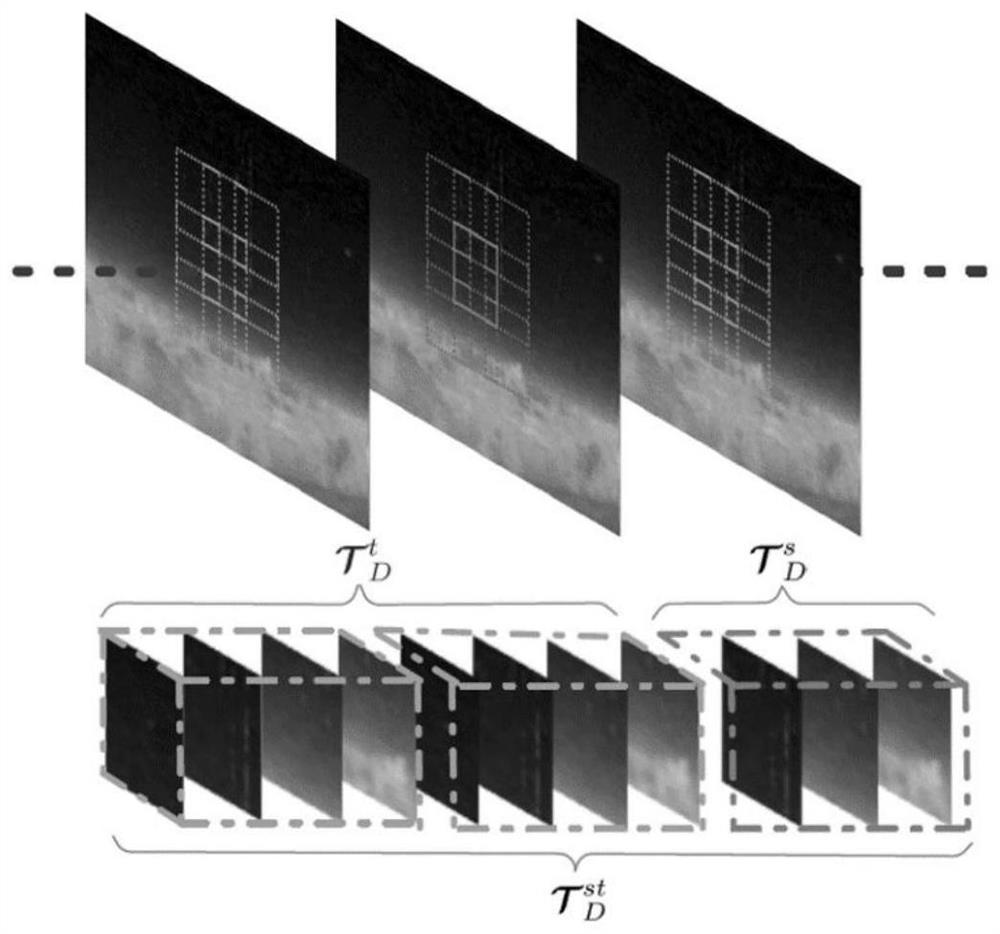

Infrared video moving small target real-time detection method based on space-time tensor decomposition

ActiveCN113256585AAvoid putting inEasy to detectImage enhancementImage analysisComputer graphics (images)Tensor decomposition

The invention discloses an infrared video moving small target real-time detection method based on space-time tensor decomposition, and belongs to the field of video processing and target detection. Each input video frame image is partitioned, the partitioning results of several adjacent frames of images are fully utilized, the three-dimensional matrix tensor is constructed, only the memory space of the key tensor in one three-dimensional matrix tensor is reserved, the memory allocation and release processes are omitted, each frame of target detection result picture is deleted, and memory management is optimized. The video frame required for constructing the space-time image block tensor for the first time is directly partitioned according to the size of the image block, so that the situation that the image blocks with overlapped information are merged into the process of constructing the three-dimensional matrix tensor is avoided, and the initialization process of constructing the space-time tensor is further optimized. The two-dimensional tensor of the target image is obtained through tensor decomposition. And according to the two-dimensional tensor of the target image obtained through tensor decomposition, the infrared small target is detected through a threshold segmentation method, namely, the real-time detection of the infrared video moving small target is achieved based on space-time tensor decomposition.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

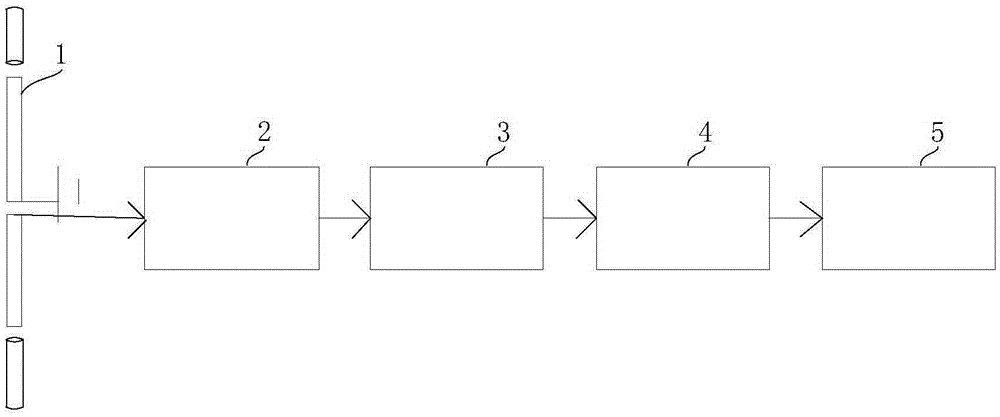

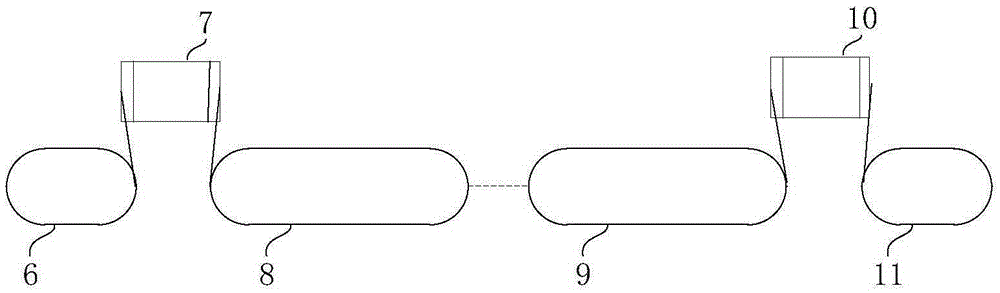

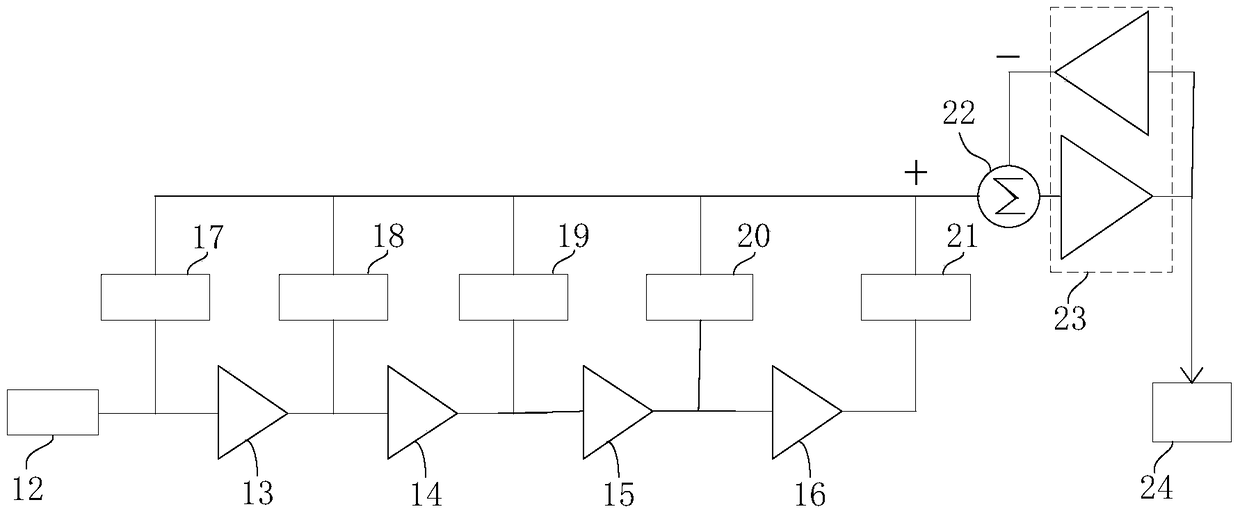

Wireless electromagnetic wave detection device

ActiveCN105353227AObvious linear follow effectAccurate measurementElectric devicesElectromagentic field characteristicsWave detectionPeak value

The invention relates to a wireless electromagnetic wave detection device, which solves the problems that the current electromagnetic wave detection device is narrow in the detection frequency band, low in the detection accuracy and high in the cost. The wireless electromagnetic wave detection device comprises an antenna, a logarithm power detection device, a filtering unit and a peak value demodulation unit; the output terminal of the antenna is connected to the input of the logarithm power detection device; the output terminal of the logarithm power detection device is connected to the peak value detection unit through the filtering unit. The invention is widely applicable to the radio wave detection technology field.

Owner:WEIHAI BEIYANG ELECTRIC GRP CO LTD BEIJING BRANCH

An Artificial Landmark Detection Method Applied to Augmented Reality

ActiveCN105740818BShorten operation timeDetection speedImage analysisCharacter and pattern recognitionAngular pointSign detection

The present invention relates to an artificial sign detection method applied to augmented reality, and the specific steps include: S1: collecting a frame image, sampling the frame image roughly, using oblique grid scanning, and detecting edge pixels of the frame image; S2: based on the RANSAC algorithm , to detect the edge segments in the frame image; S3: fuse the edge segments; S4: extend and filter the edge segments; S5: detect the corner points of the quadrilateral, and construct a quadrilateral according to the corner points of the quadrilateral. The invention preprocesses frame images before operation, performs coarse grid sampling, and performs edge detection on each grid area, greatly reduces program operation time, improves detection speed, has good real-time performance, and meets real-time detection requirements. The invention adopts an edge-based detection method, firstly performs a line segment test, and then reconstructs a quadrilateral frame of a sign according to the line segment obtained by the line segment test, and has good robustness to illumination changes and occlusion conditions.

Owner:SHANDONG UNIV

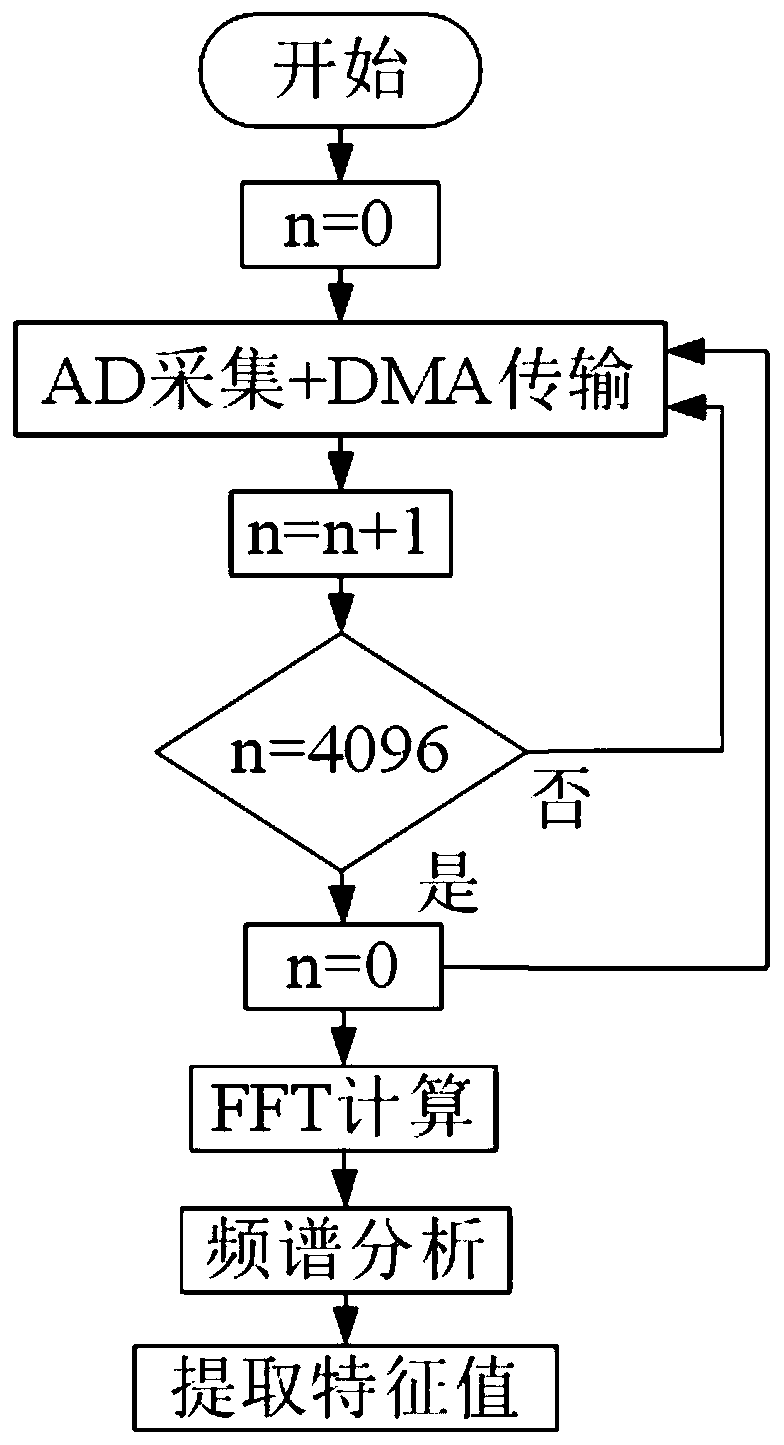

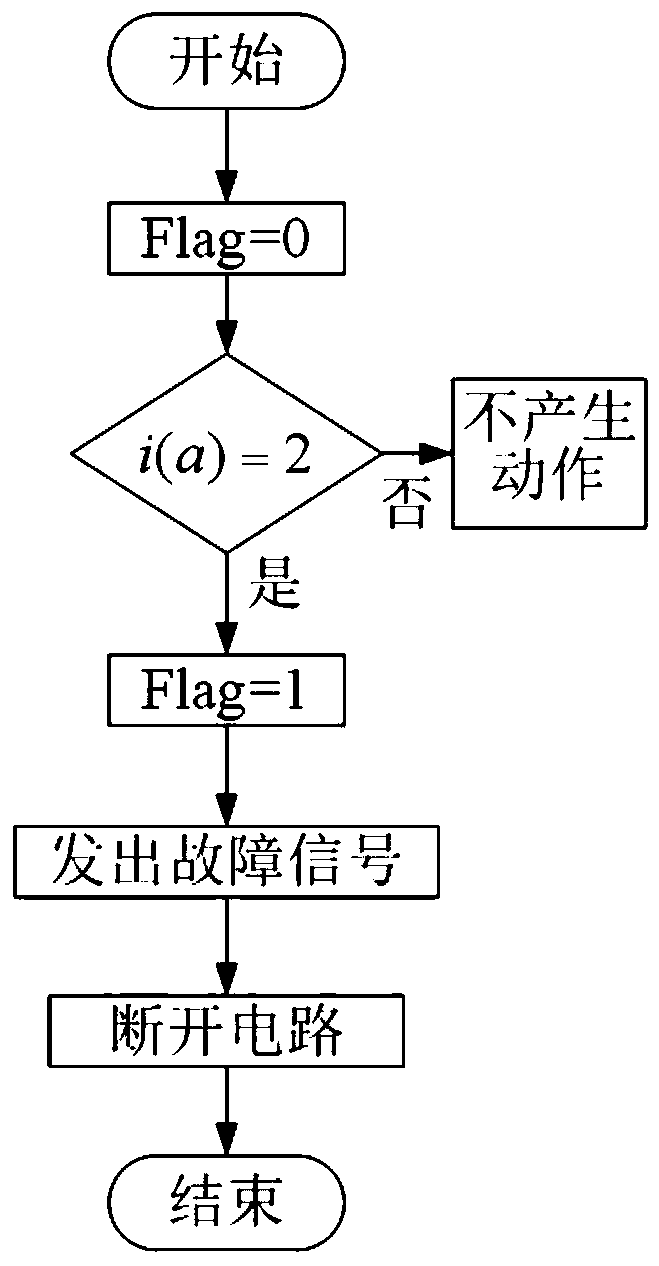

Method for judging DC series arc fault based on frequency domain sage specific value

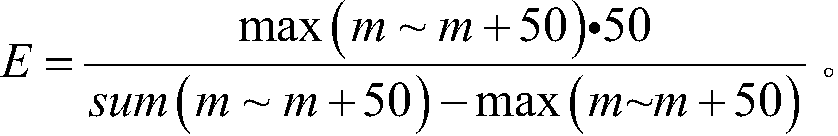

ActiveCN110441663AOvercome misjudgmentMeet real-time detection requirementsTesting dielectric strengthFrequency bandCollections data

The invention discloses a method for judging DC series arc fault based on a frequency domain sage specific value, and belongs to the technical field of the DC arc fault detection. The method comprisesthe following steps: computing amplitude sum of each of 12 frequency bands in a DC power supply loop current spectrum, forming six groups of specific value relations as characteristic values Rarc1-Rarc4, S_Rarc1, S_Rarc2, and finding out the maximum amplitude in 51 points from the 75th to the 125th in the loop current spectrum, and computing the specific value of the 50 times of the maximum valueto other 50 points, and serving the specific value as the characteristic value E. when a threshold condition is satisfied twice or more in quartic data collection cycles of seven groups of characteristic values, the DC series arc fault in the DC power supply system can be confirmed. The method disclosed by the invention can be applied to the DC series arc fault detection in the DC power supply system.

Owner:HARBIN INST OF TECH

A vehicle detection method based on multi-feature fusion

ActiveCN103295003BImprove reliabilityAccurate detectionCharacter and pattern recognitionAngular pointVehicle detection

Owner:BEIJING BOOSTIV TECH

Method and device for extracting the center of structured light strips for rut detection

ActiveCN108564621BAvoid disconnectionPrecise location of breakpointsImage analysisUsing optical meansEngineeringLaser light

A method and device for extracting the center of a structured light strip for rut detection, the method comprising: obtaining an image of the center of the light strip; selecting N columns of reference columns and N columns of search columns along the normal direction of the light strip in the image of the center of the light strip , to obtain N reference column laser light bar signals and N search column laser light bar signals respectively; use the signal correlation method to correlate the N search column laser light bar signals with the N reference column laser light bar signals one by one, and obtain the maximum correlation value and the signal offset corresponding to the maximum value; according to the signal offset, determine the center position of the light bar in the middle column of the N columns of search columns, and repeatedly select different search columns until the center position of the light bar of each search column is determined . The invention well solves the disconnection problem of the laser light bar, can quickly and efficiently extract the center of the light bar, and can meet the requirements of the system for real-time detection.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Machine learning, privacy code determination method, device and electronic equipment

ActiveCN111143203BImprove detection efficiencyHigh speedSoftware testing/debuggingMachine learningPositive sampleEngineering

The embodiment of this specification discloses a method, device, and electronic device for machine learning and privacy code determination, wherein, the machine learning method can acquire batches of sample data including positive and negative samples, the positive sample data includes privacy code files, and the negative The sample data does not contain privacy code files; based on the similarity measurement parameters of the code files, a plurality of first code files are screened out from the sample data, and the code files are screened out from a preset code library whose privacy labels are known A plurality of second code files; based on the plurality of first code files and the plurality of second code files, determine the target parameters corresponding to the sample data; combine the target parameters corresponding to the sample data and the sample data The label of is used as input to train the target model, and the target model is used to determine the similarity measurement parameters between a batch of code files to be detected and private code files.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

Wireless Electromagnetic Wave Detection Device

ActiveCN105353227BObvious linear follow effectAccurate measurementElectric devicesElectromagentic field characteristicsWave detectionPeak value

Owner:WEIHAI BEIYANG ELECTRIC GRP CO LTD BEIJING BRANCH

A Product Appearance Defect Detection Method Based on Fuzzy Relaxed Constrained Multi-kernel Learning

ActiveCN109034172BMeet detectionMeet real-time detection requirementsImage enhancementImage analysisPattern recognitionMachine vision

The invention proposes a product appearance defect detection method based on fuzzy relaxation constraint multi-core learning, which belongs to the field of product quality detection of machine vision. Firstly extract some features of real-time collected images; then use fuzzy constraint theory to quantitatively analyze the mapping relationship between features and evaluation indicators; establish a multi-kernel learning model, use multi-kernel learning methods to classify appearance defects, and delineate each kernel function in combination with the mapping quantitative relationship The fuzzy relaxation boundary of the weight; the weight of the multi-core model is determined by the method of fuzzy relaxation constraint (FRC), and the fuzzy range of the weight is determined; finally, the weight size is obtained to obtain the multi-core learning model of different defect types, and the defect detection is obtained by using the multi-core learning model. Test results. The invention adopts the multi-core learning and classification detection method of multi-feature fusion, so that the detection range is wider, combined with fuzzy relaxation constraints to adapt to different detection requirements, can meet the real-time performance of detection, and has high detection accuracy.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

An Ellipse Detection Method Based on Newton's Theorem in Object Shooting Images

The invention discloses a Newton's theorem-based method for detecting ellipses in shot object images. According to the method of the invention, in a pre-processing stage, invalid edge information is removed according to arc dimension constraints; edge gradient information is extracted, the slope of each edge point is calculated, and edges are divided into four categories according to the slope information; arcs which satisfy a condition of constituting an ellipse are aggregated according to the relative positional relationships of endpoints and Newton's theorem-based geometric constraints; theleast squares method is directly adopted to estimate the parameters of arcs belonging to the same set; and the validity of fitted ellipses is verified, ellipses that do not satisfy a verification condition are removed, and ellipses requiring repeated detection are aggregated. Since a large number of invalid edges are removed, dimensions, relative positions and Newton's theorem-based geometric constraints are adopted, the precision and speed of ellipse detection are significantly improved.

Owner:ZHEJIANG UNIV

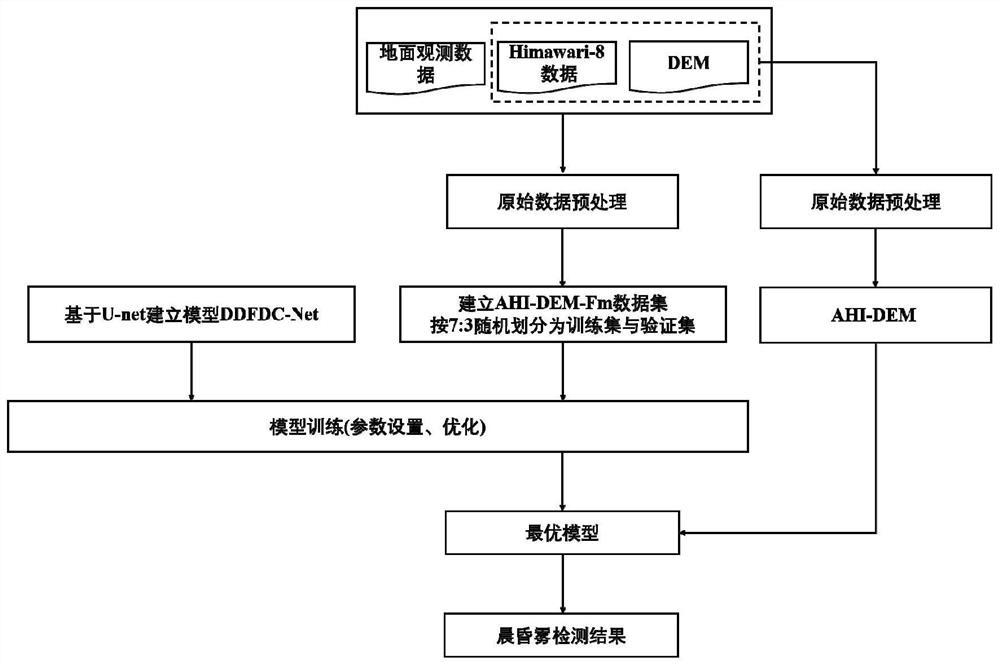

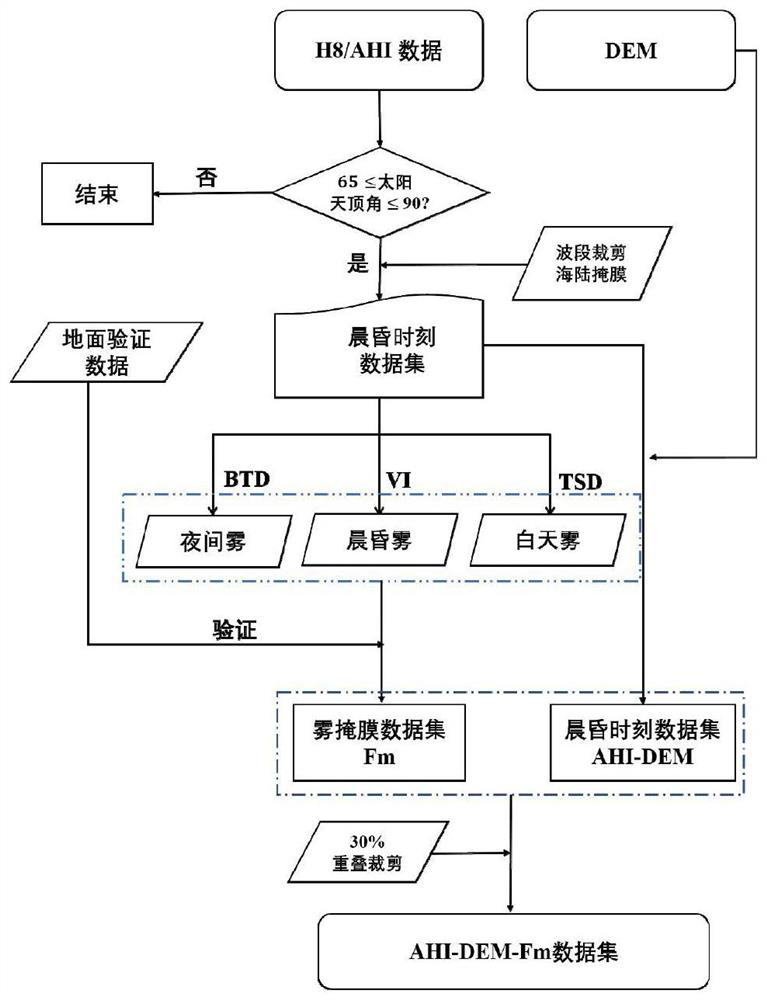

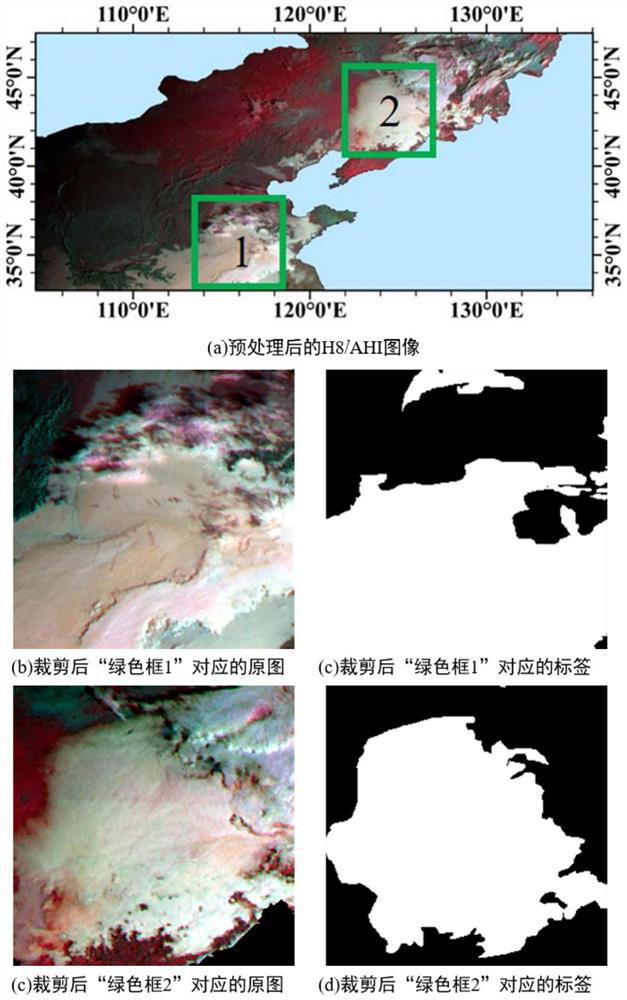

Terrain constraint and deep learning-based morning fog rapid detection method, apparatus and device, and medium

PendingCN114882013ARefinement of test resultsTest results are stableImage enhancementImage analysisAtmospheric sciencesLandform

The invention discloses a quick morning and night fog detection method, device and equipment based on terrain constraint and deep learning and a medium. The method comprises the following steps: step 1, acquiring DEM data of a research area and H8 / AHI data at morning and night moments; step 2, preprocessing the data obtained in the step 1: carrying out wave band cutting and useless wave band elimination on the H8 / AHI data, and then combining the reserved wave band data and DEM data according to channels to obtain fused AHI-DEM data; and step 3, inputting the AHI-DEM data into a pre-trained morning fog detection model based on deep learning, and outputting to obtain a morning fog detection result of the research area. The terrestrial fog detection method can accurately, efficiently and quickly realize terrestrial fog detection at morning and evening.

Owner:CENT SOUTH UNIV

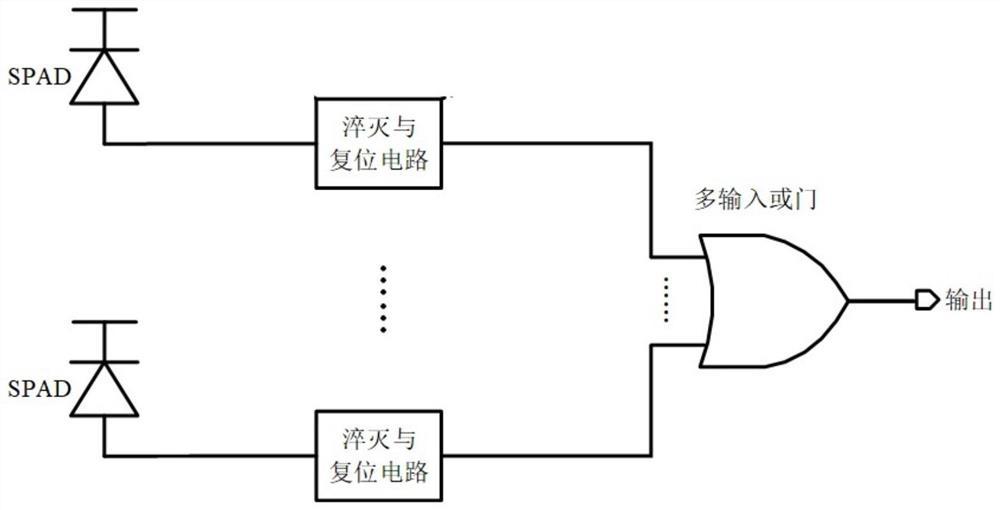

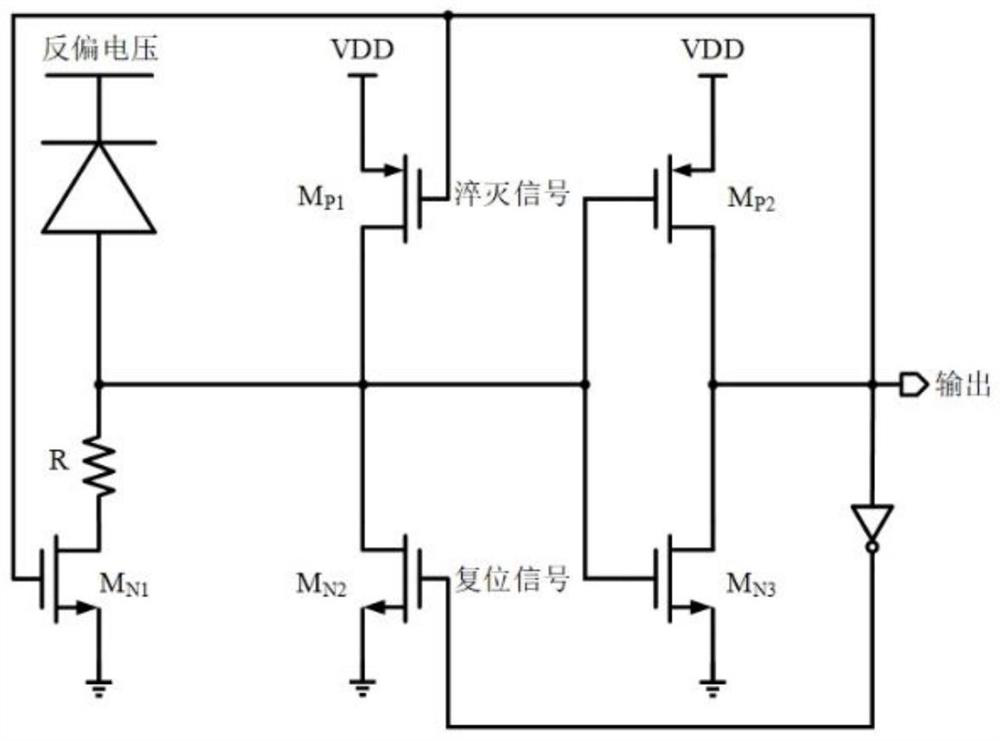

Single photon avalanche diode optical signal receiving circuit based on adaptive adjustment of ambient light intensity

ActiveCN114650092AHigh photoelectric conversion gainImprove signal-to-noise ratioWave based measurement systemsTime-division optical multiplex systemsHemt circuitsEngineering

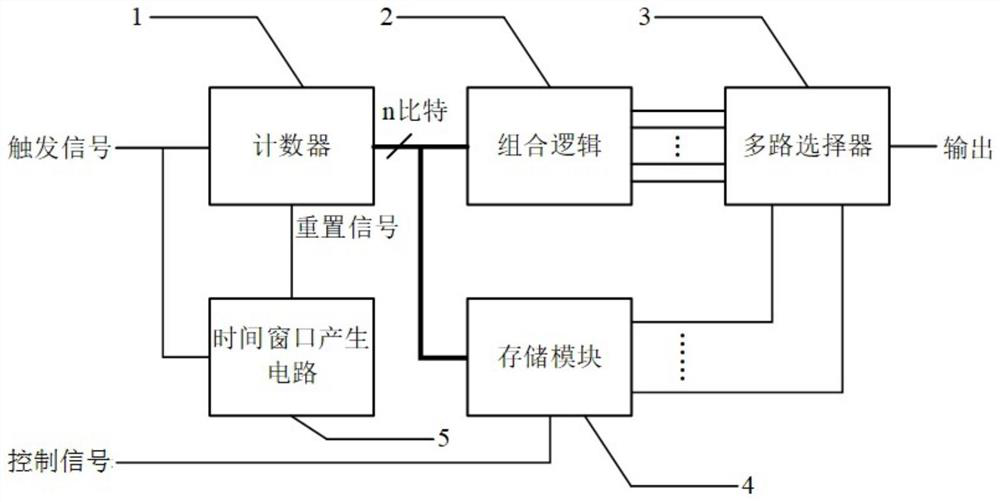

The invention discloses a single photon avalanche diode optical signal receiving circuit based on adaptive adjustment of ambient light intensity. The single photon avalanche diode optical signal receiving circuit comprises a counter, a combinational logic module circuit, a multiplexer, a storage module and a time window generation circuit, the time window generation circuit generates a time window; a counter collects and records the number of photon pulses in a time window; the storage module dynamically stores the count value of the photon pulse number in the ambient light detection mode as the reference value of the signal pulse detection threshold value in the signal detection mode, and controls the output of the multiplexer; the combinational logic module circuit combines binary output bit numbers of the counter to represent different count values; the multiplexer takes different count values in the combinational logic module circuit as input signals; the output of the storage module is connected with the gating control end of the multiplexer, and the count value, larger than or equal to the signal pulse detection threshold reference value, in the input signals of the multiplexer is controlled to serve as the output.

Owner:SUN YAT SEN UNIV

System and method for visual detection of redundant objects based on deep learning in mechanical assembly

ActiveCN110385282BStrong applicability in application scenariosImprove robustnessNeural architecturesAquisition of 3D object measurementsFeature extractionVisual inspection

The invention discloses a system and method for visual detection of redundant objects based on deep learning in mechanical assembly. The detection system includes a workbench, an adjustable angle camera, a light source, a vision controller, etc. The vision controller processes and analyzes the images obtained from the camera to identify the objects in it, and then distinguish the assembly parts and redundant objects; the detection methods include The steps are as follows: obtain the multi-angle assembly area image, preprocess the image and input it into the trained target detection network model for feature extraction to predict the position and type of the object, then judge whether each object is redundant, and mark the redundant object position and call the police. The invention can assist manual detection of redundant objects in a specific area from multiple angles in real-time during the assembly process, has the advantages of high detection accuracy, strong real-time performance, flexible use, etc., can reduce the introduction of redundant objects in the assembly process, and enhance product reliability sex.

Owner:ZHEJIANG UNIV

An automatic ship detection method for inland river bridge areas

ActiveCN110060508BImplement automatic detectionReduce workloadCharacter and pattern recognitionMarine craft traffic controlEngineeringComputer vision

The invention discloses an automatic detection method for ships in an inland bridge area, which includes: 1) collecting real traffic monitoring video in the water area of the inland bridge area to obtain original sampling picture data; 2) manually marking the original sampling picture data to form Mark the image; 3) use the deep convolutional neural network to learn the features of the marked image, classify the learned features, and obtain a trained deep learning model; 4) use the trained deep convolutional neural network model to The ship is detected, the position of the ship is framed by a rectangular frame, and the category of the ship is indicated. This method has good adaptability to different weather, different light conditions and dark conditions at night, can achieve a relatively high accuracy rate, and the processing speed meets the real-time requirements.

Owner:WUHAN UNIV OF TECH

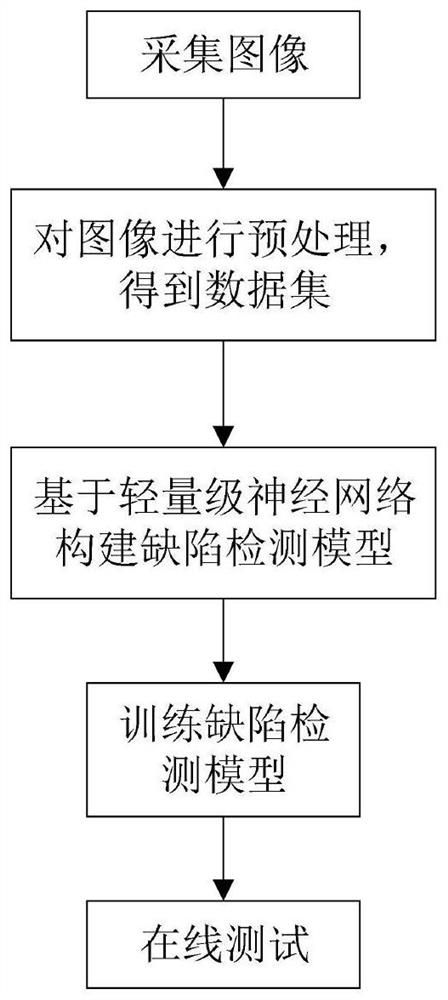

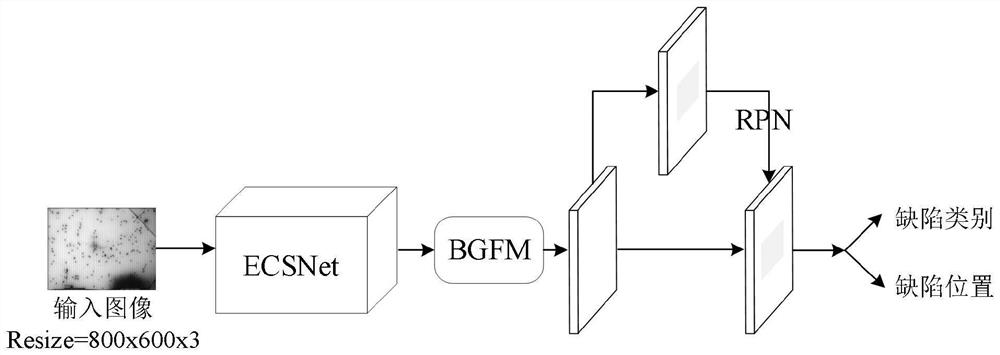

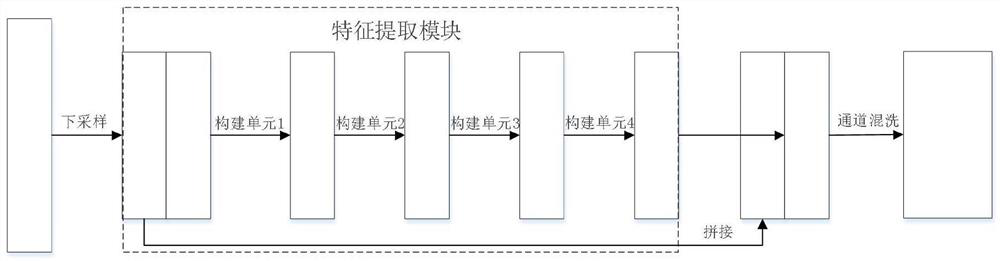

Battery defect detection method based on lightweight neural network

PendingCN113989267AOvercoming the Gradient Reuse ProblemMeet real-time detection requirementsImage enhancementImage analysisPattern recognitionAlgorithm

The invention relates to a battery defect detection method based on a lightweight neural network. The method comprises the following steps: constructing a defect detection model based on the lightweight neural network, wherein the defect detection model takes ShuffleNetV2 as a backbone network, a refined cross-stage local mechanism is fused into a ShuffleNetV2 network, a refined cross-stage local ShuffleNetV2 network is obtained, and a parallel grouping attention module is further fused into the refined cross-stage local ShuffleNetV2 network; and refining an output feature map of the cross-stage local ShuffleNetV2 network, inputting the output feature map into a recommended region in a region recommendation network after the output feature map passes through a fusion module guided by low-layer features, and classifying and regressing the recommended region to obtain a defect category and a defect position. A parallel grouping attention module realizes shallow-layer and deep-layer feature fusion, and a fusion module guided by the low-layer features expands the receptive field; and the method solves the problem that the lightweight network detection effect is not ideal.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com