Product appearance defect detection method based on multi-core learning with fuzzy relaxation constraints

A multi-core learning and appearance defect technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve the problem of no effective real-time detection standard for industrial production, and achieve both detection accuracy and detection time, Detect a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

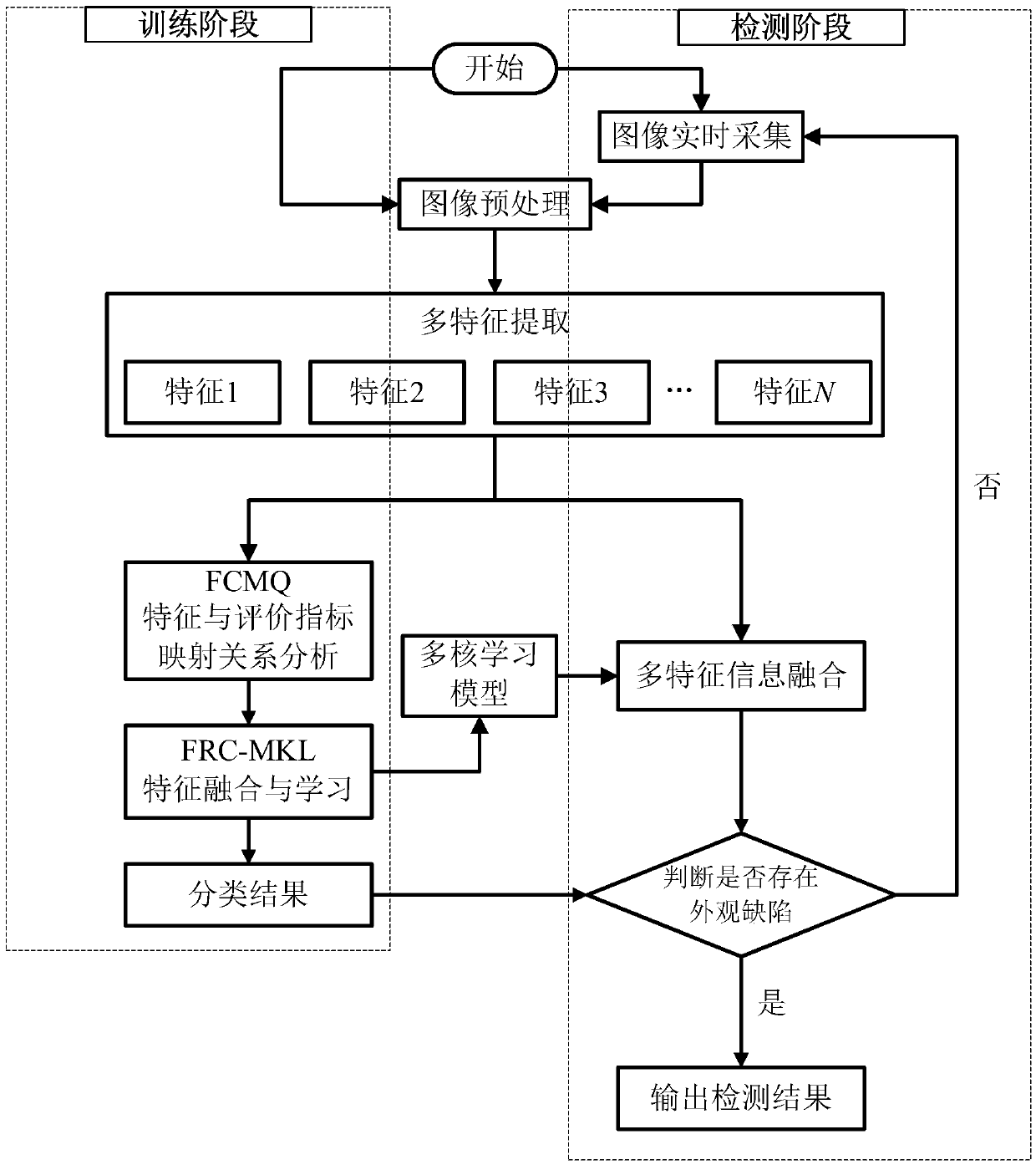

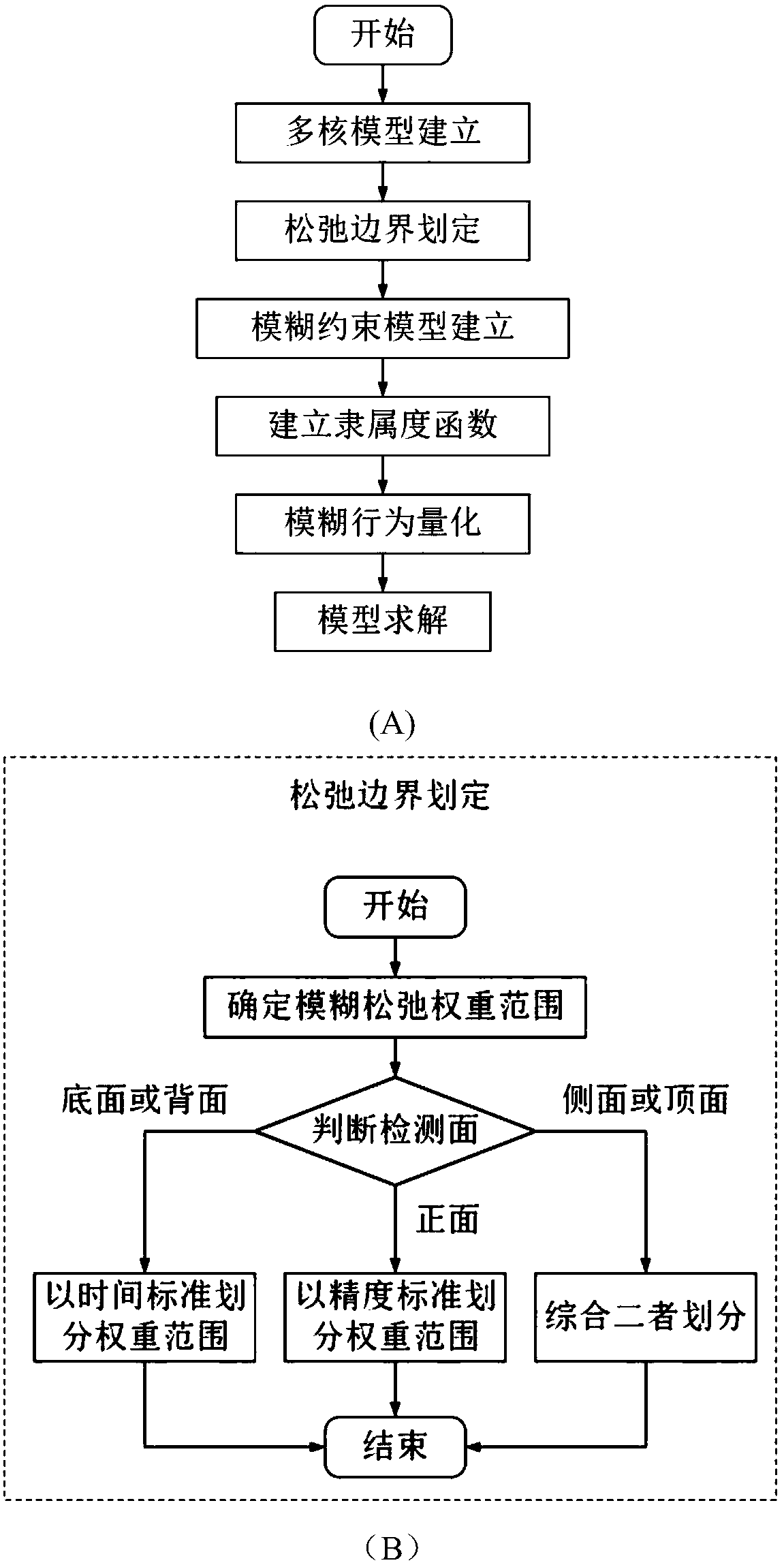

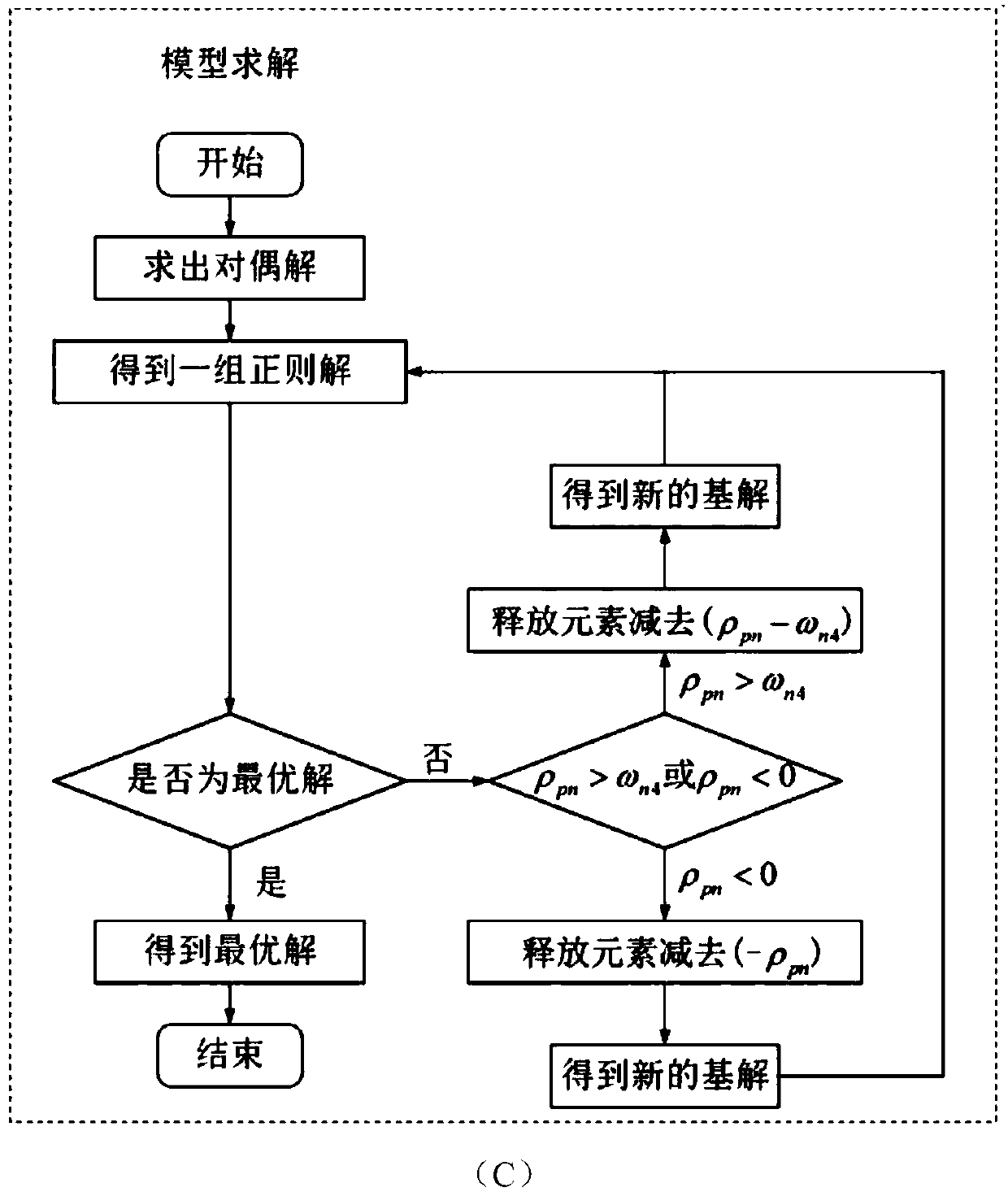

[0053] The purpose of the present invention is to provide a method for detecting appearance defects of large-scale industrial products. Different surfaces of products have different requirements for detection accuracy and time. The present invention uses multi-scale windows to obtain product appearance images. Usually, the front side has higher requirements for detection accuracy, and small-scale windows are used to extract images; the bottom surface and the back surface have higher requirements for detection accuracy. Low, in order to improve efficiency and shorten detection time, large-scale windows are used to extract images; side and top surfaces are extracted with medium-scale windows. After the image is acquired, the method of the invention extracts several features, and uses a fuzzy constraint method to quantitatively analyze the mapping relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com