Resin lens defect detection method based on convolutional neural network

A convolutional neural network and resin lens technology, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve the problems of inability to guarantee accuracy, low efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solution described in the present invention clearer, further description will be given below in conjunction with the accompanying drawings and specific implementation. The accompanying drawings are only for illustrative purposes and should not be construed as limitations on this patent.

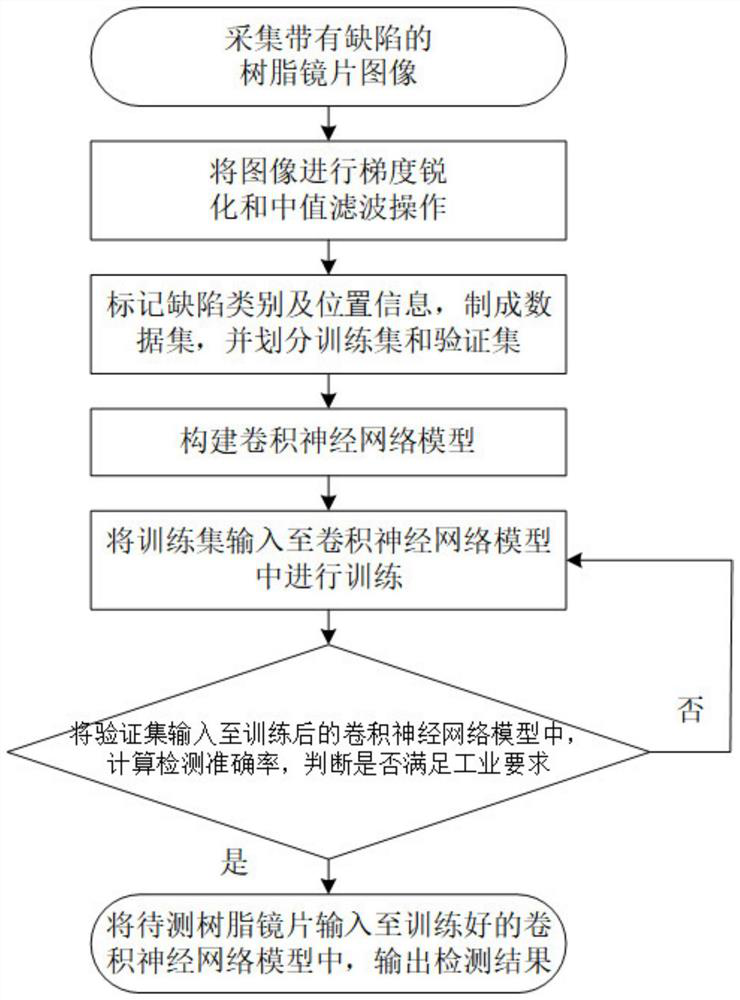

[0032] figure 1 A convolutional neural network-based defect detection method for resin lenses according to an embodiment of the present disclosure is shown. Such as figure 1 As shown, the method includes the following steps:

[0033] Step 1. Use a polarized black-and-white camera, use a white LED parallel light source, and use backlighting to obtain 2,000 images of resin lenses with 5 types of defects, such as pitting, scratches, bubbles, broken edges, and cracks, under dark field conditions. As the original image, the number of image pixels is 704×704;

[0034] Step 2. Carry out gradient sharpening and median filtering preprocessing operations to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com