Artificial intelligent image recognizing based detection system for printed circuit board

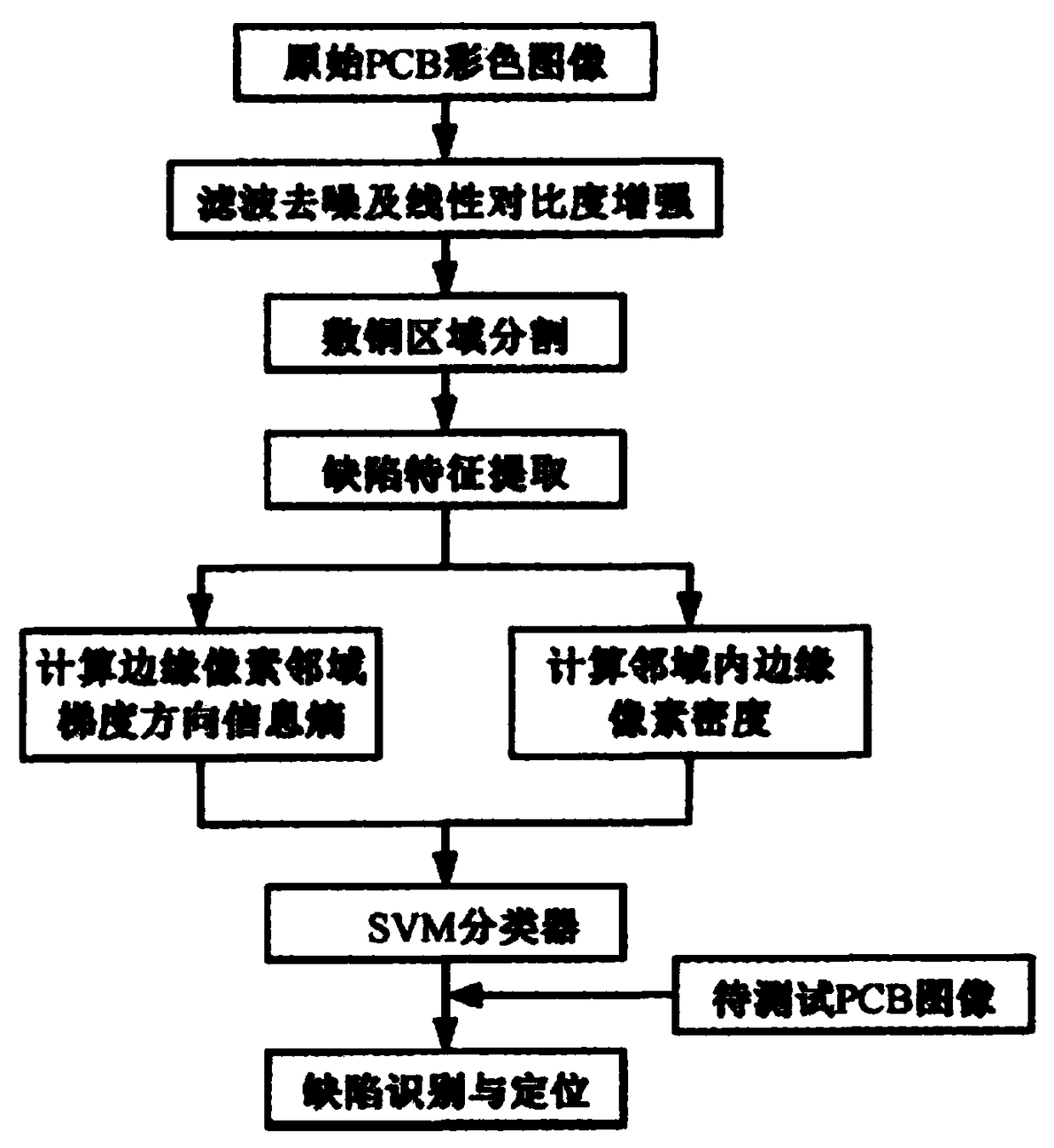

A printed circuit board and image recognition technology, applied in the fields of artificial intelligence and image recognition, can solve the problems of detection accuracy and detection speed to be further improved, and achieve the effect of fast speed, high detection accuracy, convenient and accurate segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

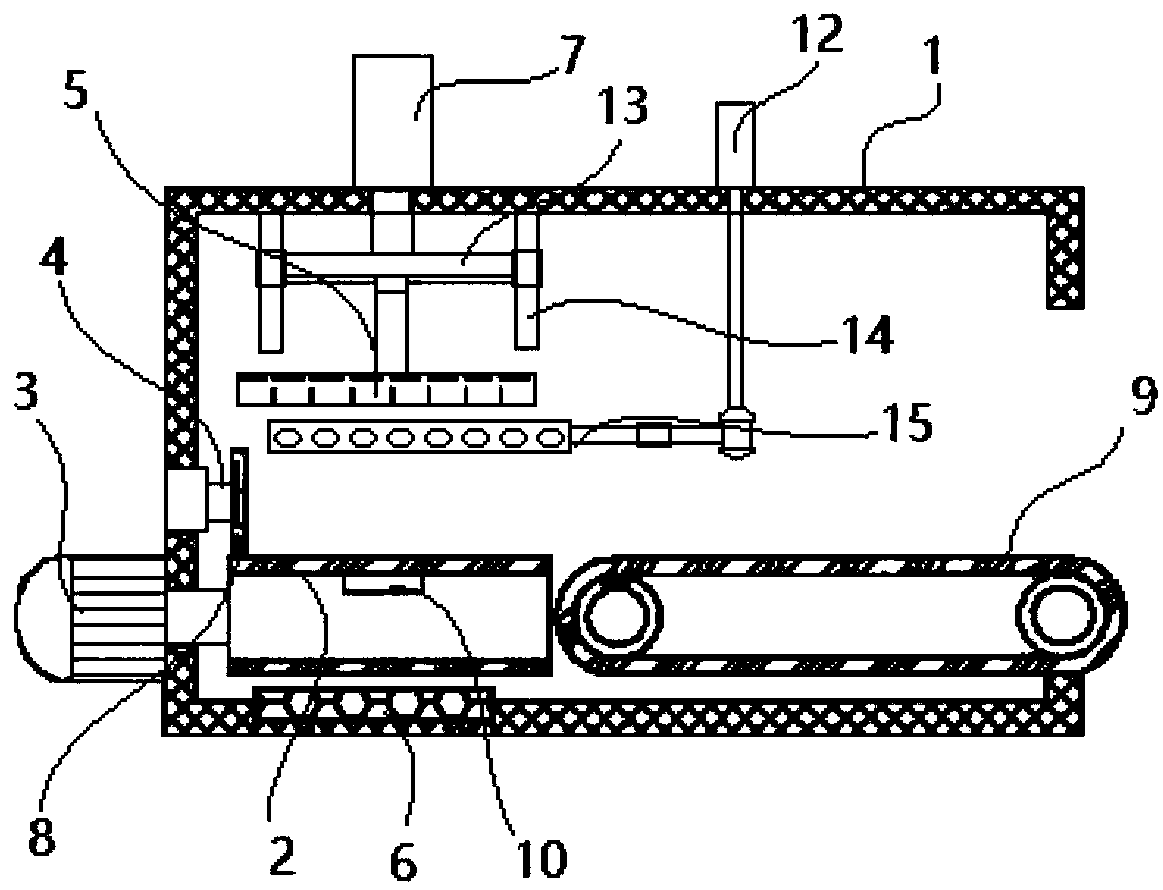

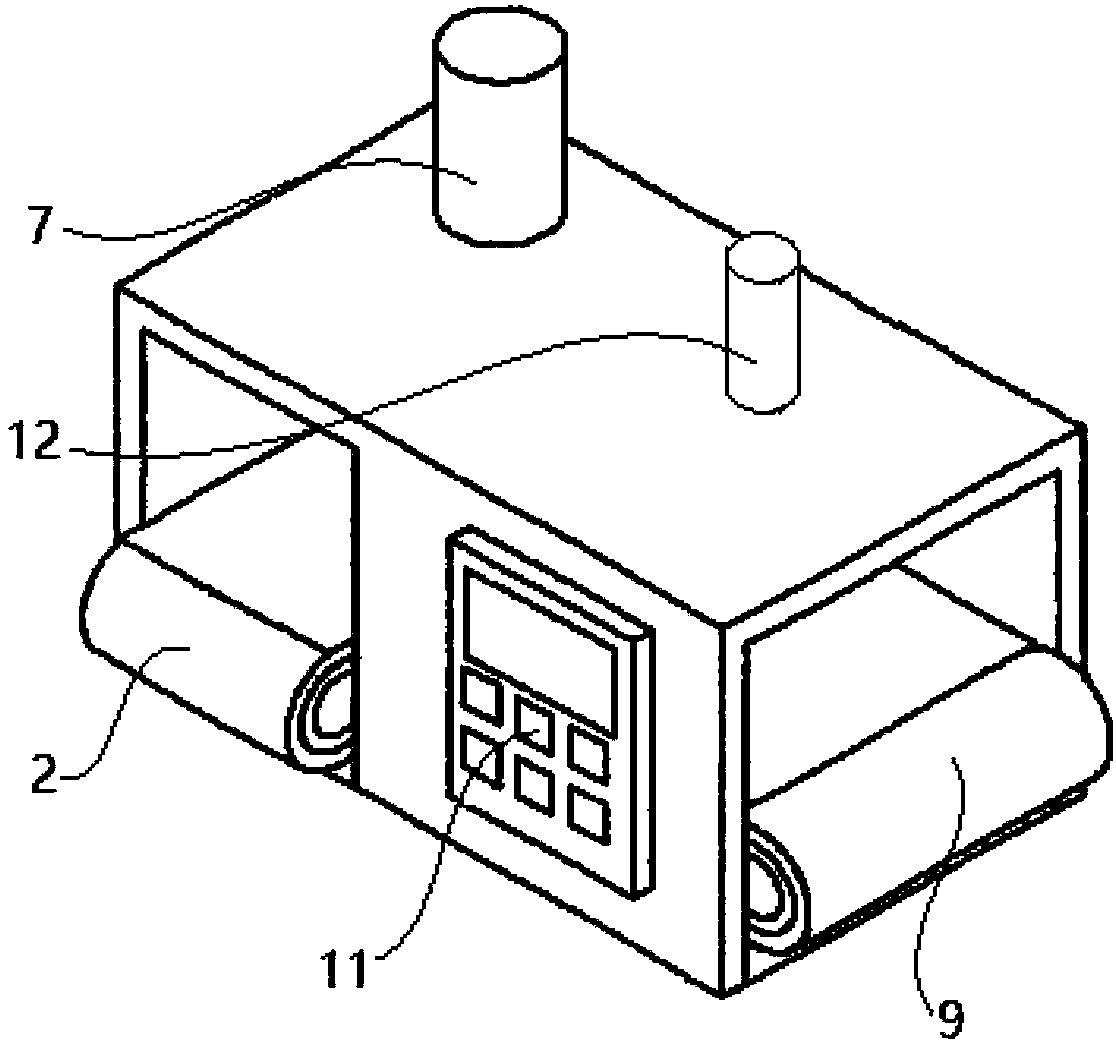

[0028] like figure 1 As shown, a printed circuit board inspection system based on artificial intelligence image recognition includes a housing 1, conveyor belts 2, 9, air pumps 7, 12, motor 3, telescopic rod 4, push plate 8, detector 5, receiver 6, Sensor 10, controller 11; the front and back of the shell are respectively provided with a feed port and a discharge port, the left end and the right end of the shell are respectively provided with a motor and a defective product outlet, the top of the shell is fixed with an air pump, and the outer surface of the shell is fixed There are controllers.

[0029] like figure 2 As shown, the conveyor belt includes an X conveyor belt 2 and a Y conveyor belt 9, and its transmission movement direction is vertical, and its power source is a motor; the starting point of the X conveyor belt is the feed port, and the end point is the discharge port; Exit for rejects; X-belt is located between detector and receiver, with sensors attached to i...

Embodiment 2

[0033] A printed circuit board inspection system based on artificial intelligence image recognition, including housing 1, conveyor belts 2, 9, air pumps 7, 12, motor 3, telescopic rod 4, push plate 8, detector 5, receiver 6, sensor 10, Controller 11; the front and back of the shell are respectively provided with a feed port and a discharge port, the left end and the right end of the shell are respectively provided with a motor and a defective product outlet, the top of the shell is fixed with an air pump, and the outer surface of the shell is fixed with a controller .

[0034] The controller includes a data processing module, an input module, an output module, a communication module, a display module and a key module; the data processing module adopts TMS320L2812; the input module is electrically connected with the detector and the receiver, and inputs digital image signals; the input module is electrically connected with the sensor , the input pressure signal; the output modu...

Embodiment 3

[0041] A printed circuit board inspection system based on artificial intelligence image recognition, including housing 1, conveyor belts 2, 9, air pumps 7, 12, motor 3, telescopic rod 4, push plate 8, detector 5, receiver 6, sensor 10, Controller 11; the front and back of the shell are respectively provided with a feed port and a discharge port, the left end and the right end of the shell are respectively provided with a motor and a defective product outlet, the top of the shell is fixed with an air pump, and the outer surface of the shell is fixed with a controller .

[0042]The controller includes a data processing module, an input module, an output module, a communication module, a display module and a key module; the data processing module adopts TMS320L2812; the input module is electrically connected with the detector and the receiver, and inputs digital image signals; the input module is electrically connected with the sensor , the input pressure signal; the output modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com