Patents

Literature

44results about How to "Overcome misjudgment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

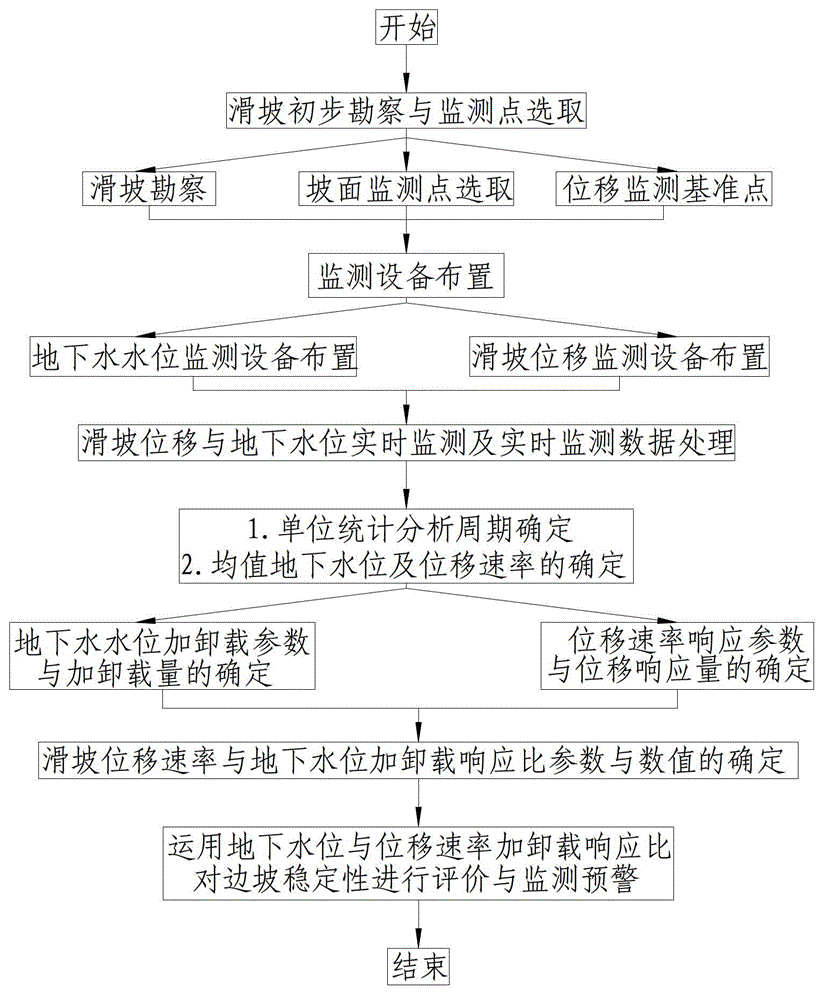

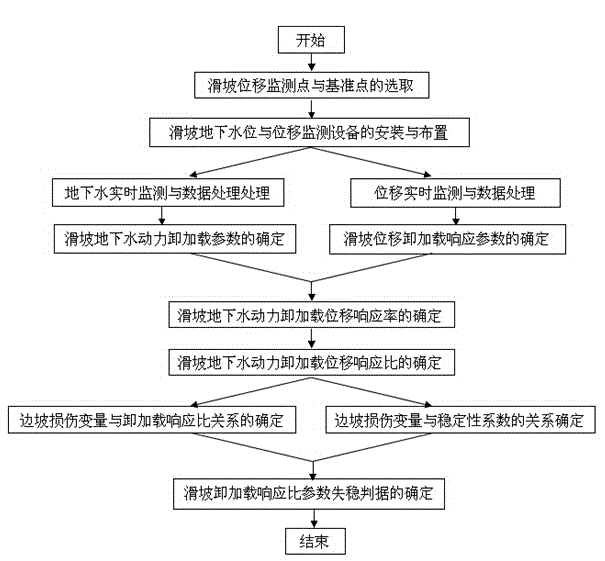

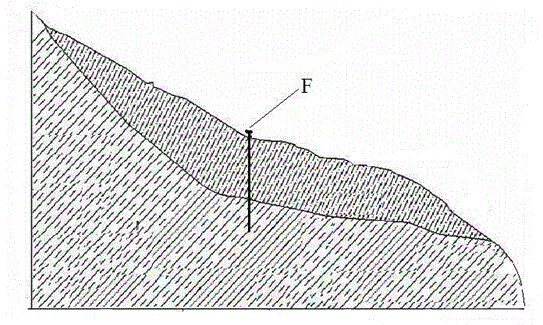

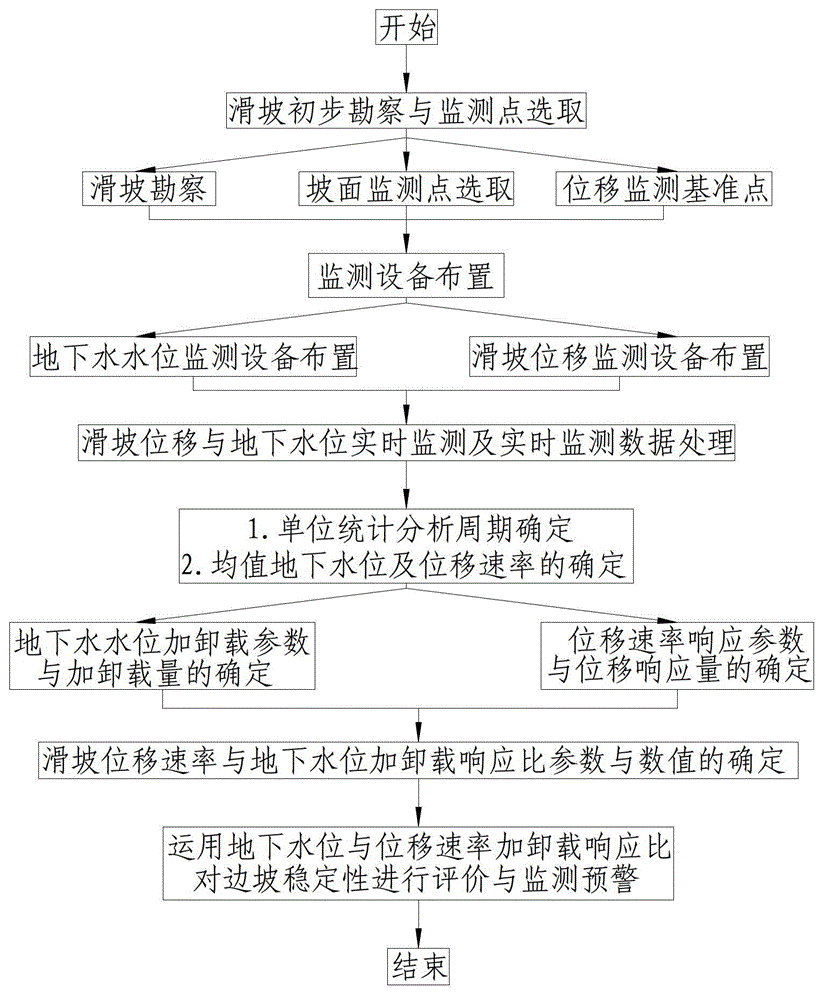

Landslide forecasting method capable of utilizing underground water levels and displacement real-time monitoring

InactiveCN103150871AOvercome the inability to analyzeOvercome limitationsAlarmsHazard monitoringPredictive methods

The invention belongs to the slope stability estimation and landslide hazard monitoring and early warning technologies. A landslide forecasting method capable of utilizing underground water levels and displacement real-time monitoring includes the following steps: (1) landslide preliminary reconnaissance and monitoring point selection; (2) monitoring arrangement and installation of equipment; (3) monitoring the landslide displacement and the underground water levels in real time and processing real-time monitoring data; (4) statistical analysis period by unit and confirming mean-value underground water level HO and a displacement speed VO; (5) confirming underground water level loading and unloading parameters and loading and unloading quantities; (6) confirming displacement speed response parameters and displacement response quantities; (7) confirming the landslide displacement speed and underground water level loading and unloading response ratio parameters and numbers; (8) applying the underground water levels and displacement speed loading and unloading response ratio to carrying out evaluating slope stability and monitoring and early warning. According to the landslide forecasting method capable of utilizing the underground water levels and the displacement real-time monitoring, produced erroneous judgement or mistake judgement that landslide physics mechanical parameters, boundary conditions and the like can not be confirmed difficultly and accurately by the transitional ultimate equilibrium mechanics appraisal method can be overcome effectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

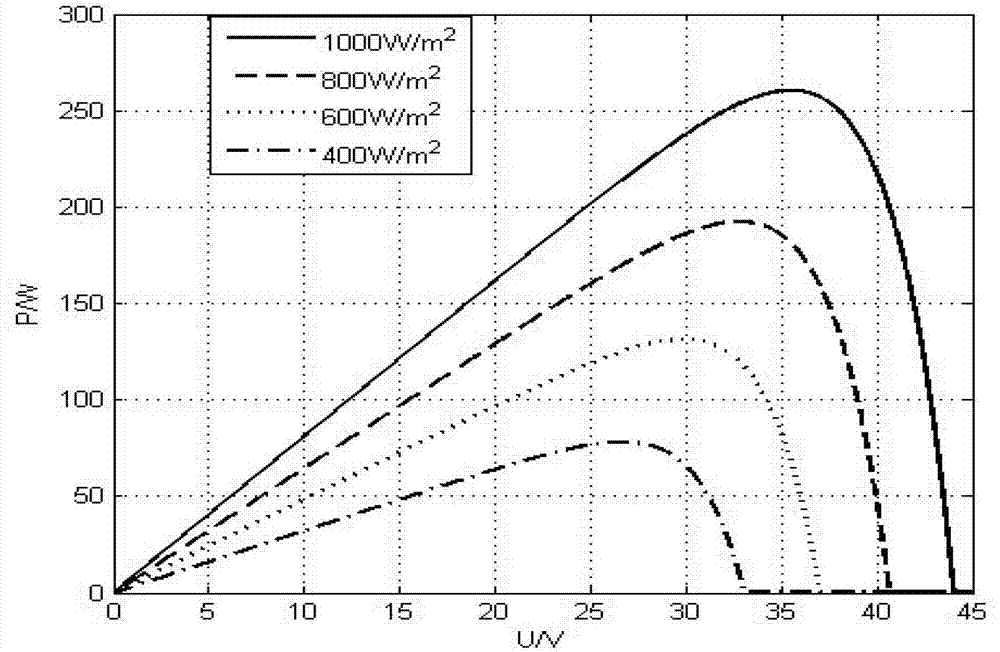

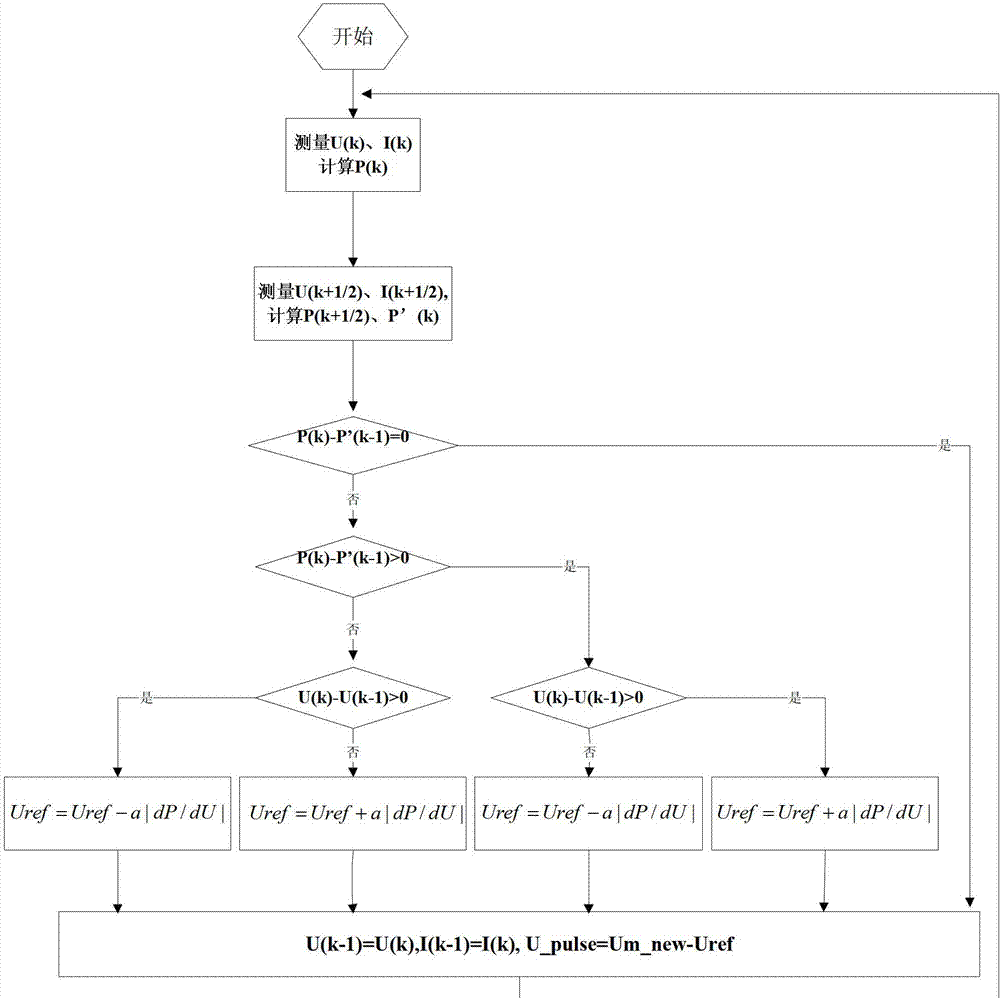

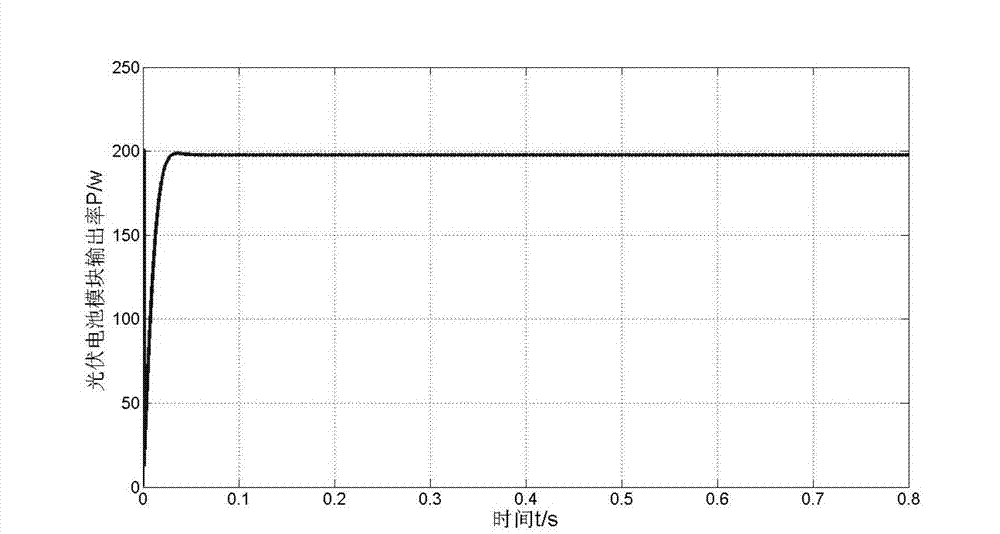

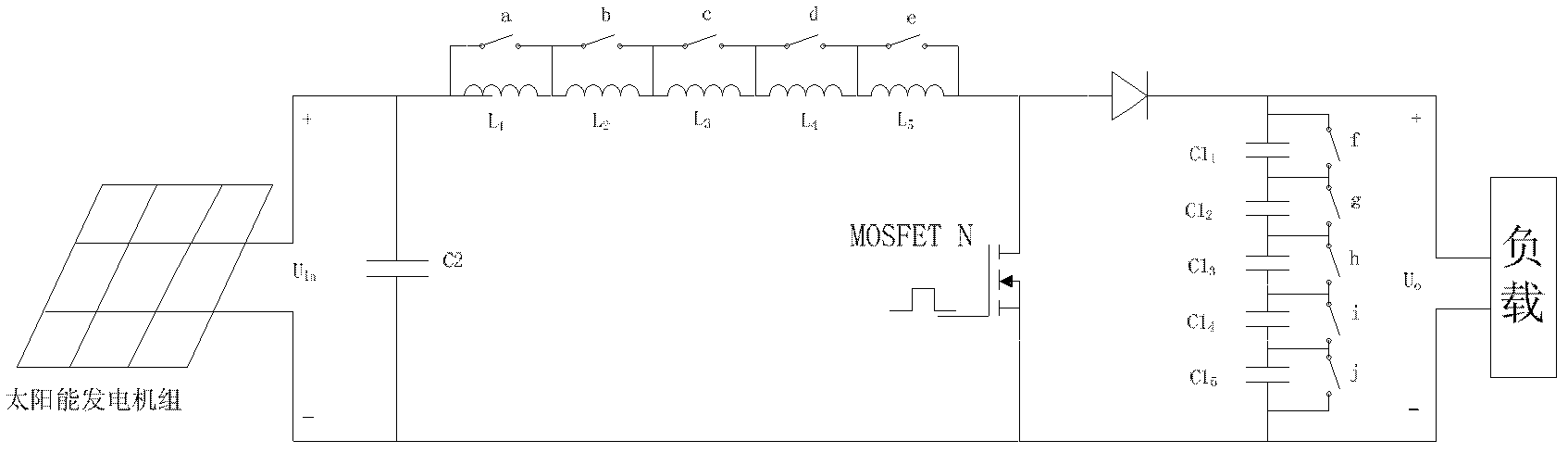

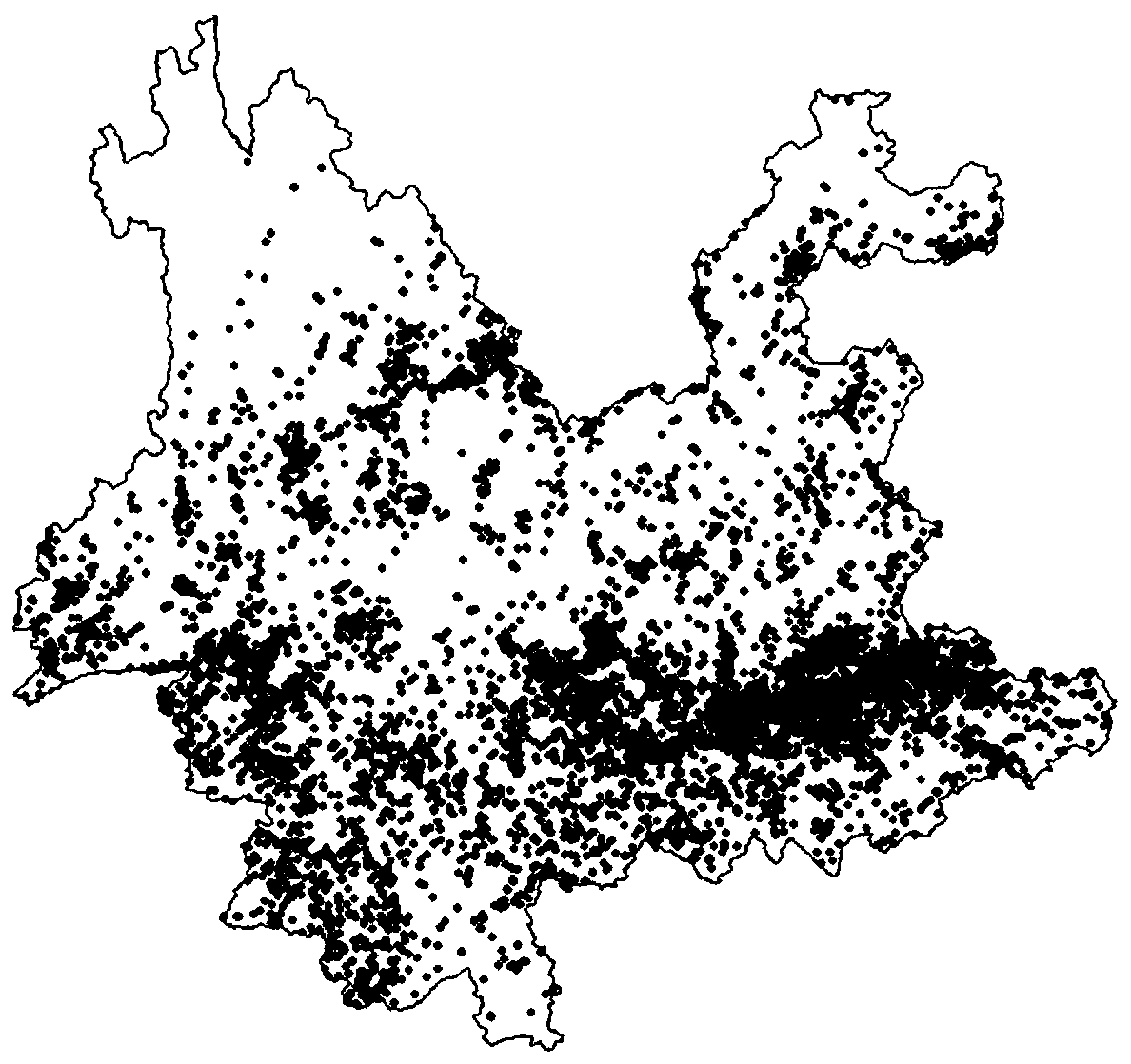

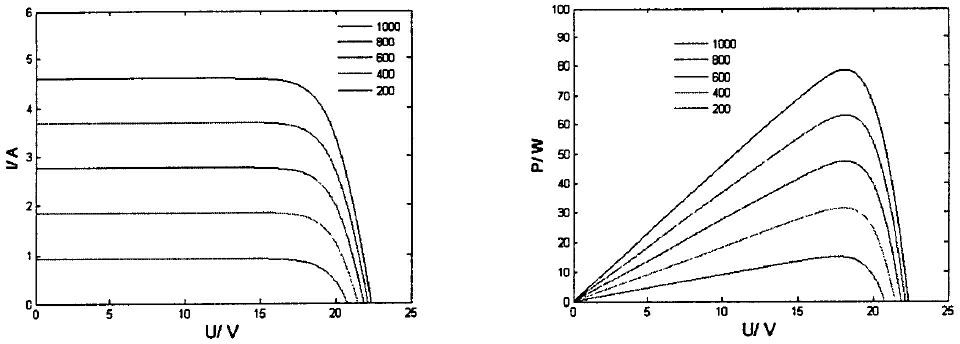

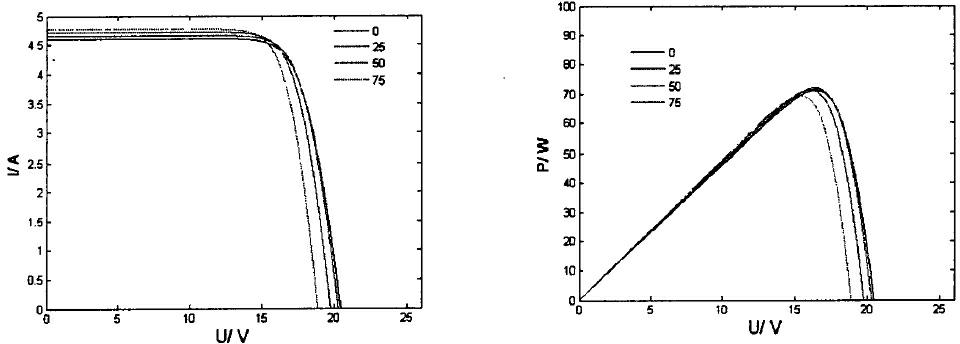

Variable step size disturbance maximum power point tracking method based on power forecating

InactiveCN103049034AOvercome misjudgmentOvercoming tracking failuresPhotovoltaic energy generationElectric variable regulationGeneration processEngineering

The invention discloses a variable step size disturbance maximum power point tracking method based on power forecasting. The control method combines a power forecasting method and a variable step size method, leads the voltage value of the theoretical maximum power point of a photovoltaic cell at the current time into a modulating pulse generation process to perform maximum power tracking of the photovoltaic cell through dual-functions of the two methods. By means of the control method, the problem of erroneous judgment and tracking failure when the external environment changes remarkably can be solved, the contradiction existing between the maximum power tracking speed and accuracy can be effectively solved, the maximum power point can be tracked fast, and the theoretical maximum power point voltage can be ensured when the actual working pressure changes along with the environment factors.

Owner:SOUTHWEST JIAOTONG UNIV

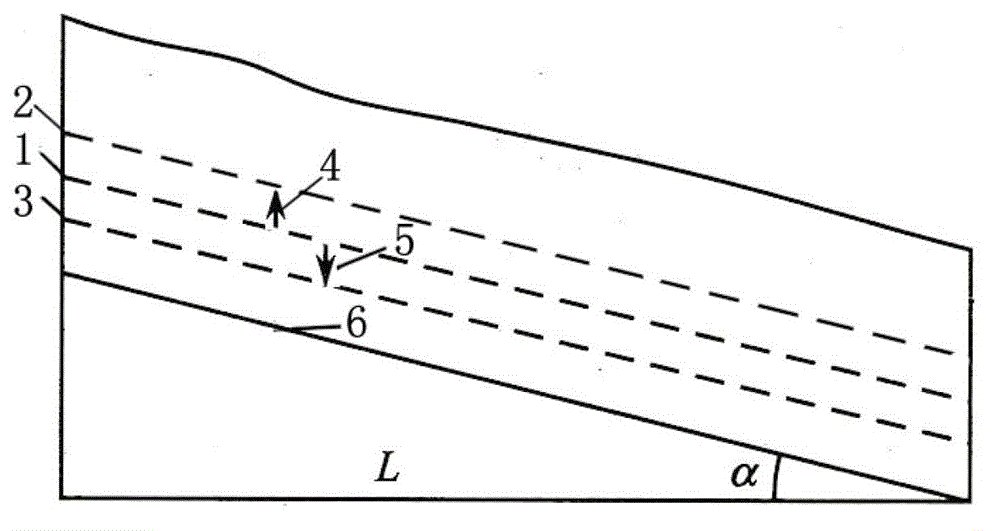

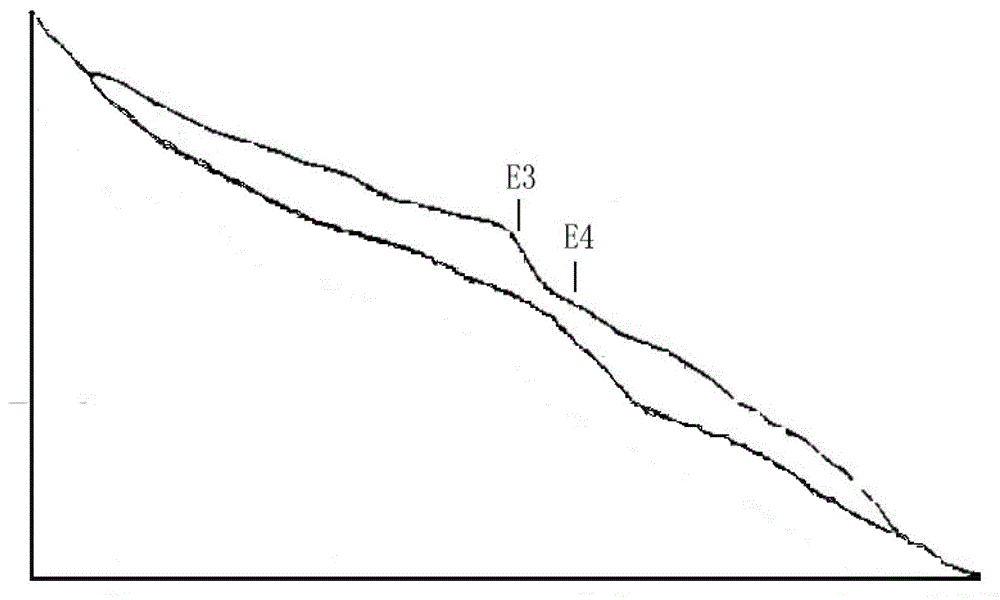

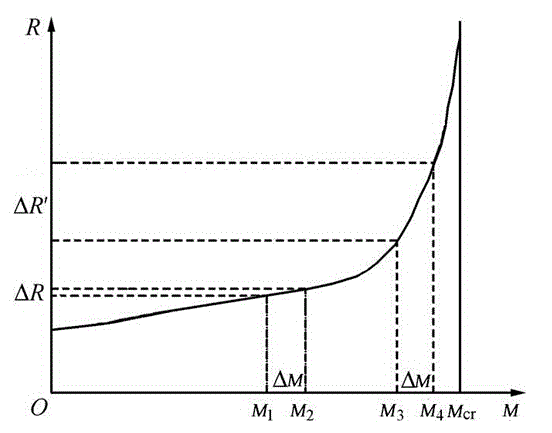

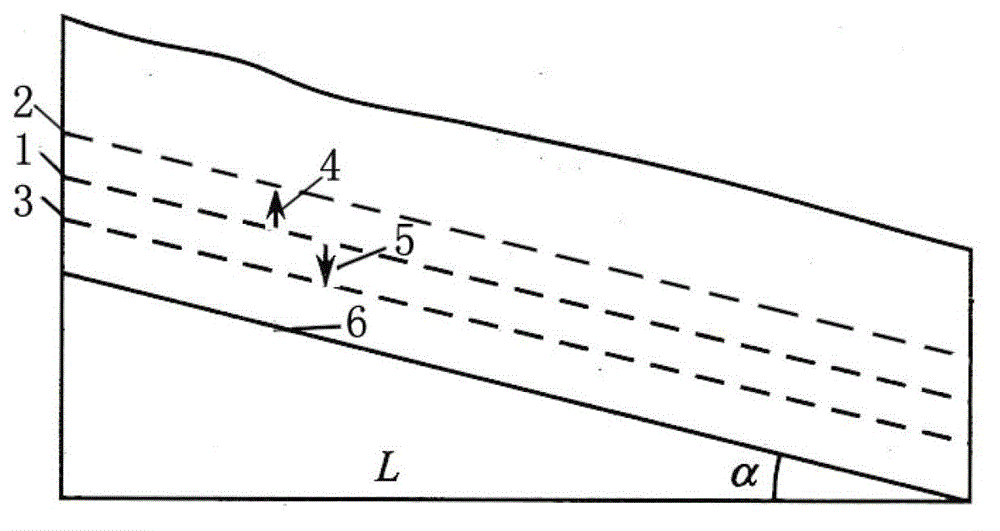

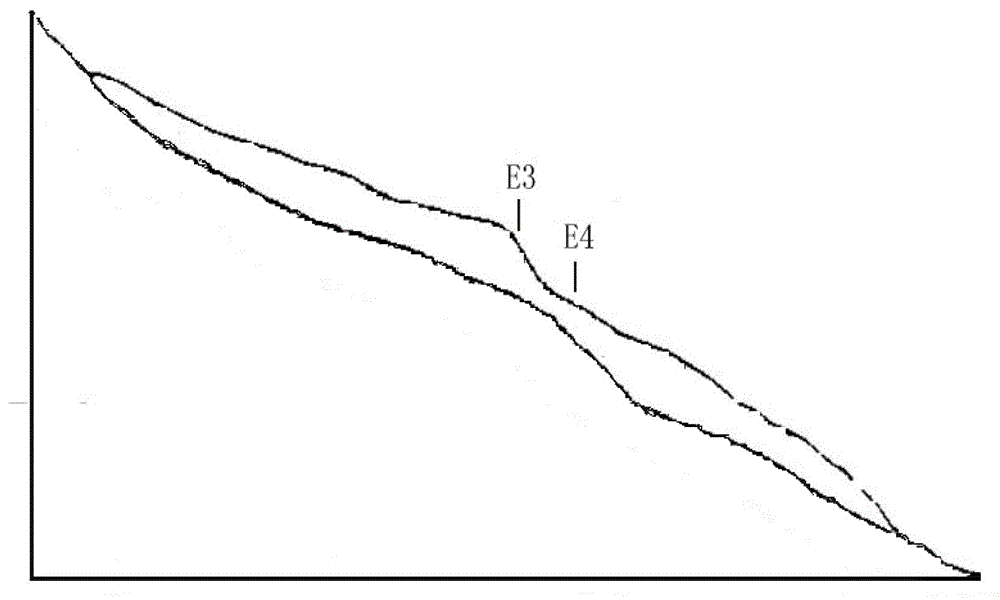

Side slope dynamic stability coefficient determination method based on underground water level and displacement monitoring

The invention discloses a side slope dynamic stability coefficient determination method and technology based on underground water level change and displacement monitoring data. The landslide formation motivation and mechanism are cross coupled with displacement response information change and an evaluation method thereof. A nonlinear unload and load response ratio parameter prediction model is established so that the side slope stability coefficient determination method based on underground water level and displacement change is established. According to the landslide displacement prediction method, the idea of a conventional displacement time sequence prediction method that only landslide displacement or displacement rate is selected to act as monitoring and evaluation parameters is changed, and simultaneous monitoring and integration of landslide underground water level and displacement or displacement rate are put forward so that the coupling integration power prediction parameter and evaluation method of landslide underground water level and displacement or displacement rate is confirmed. The limitation that a static limit mechanics evaluation method cannot analyze and evaluate the change rule of side slope stability along with time can be overcome by the method, and a defect that the conventional displacement time sequence prediction method cannot analyze and evaluate the landslide formation mechanism and motivation can also be overcome by the method.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

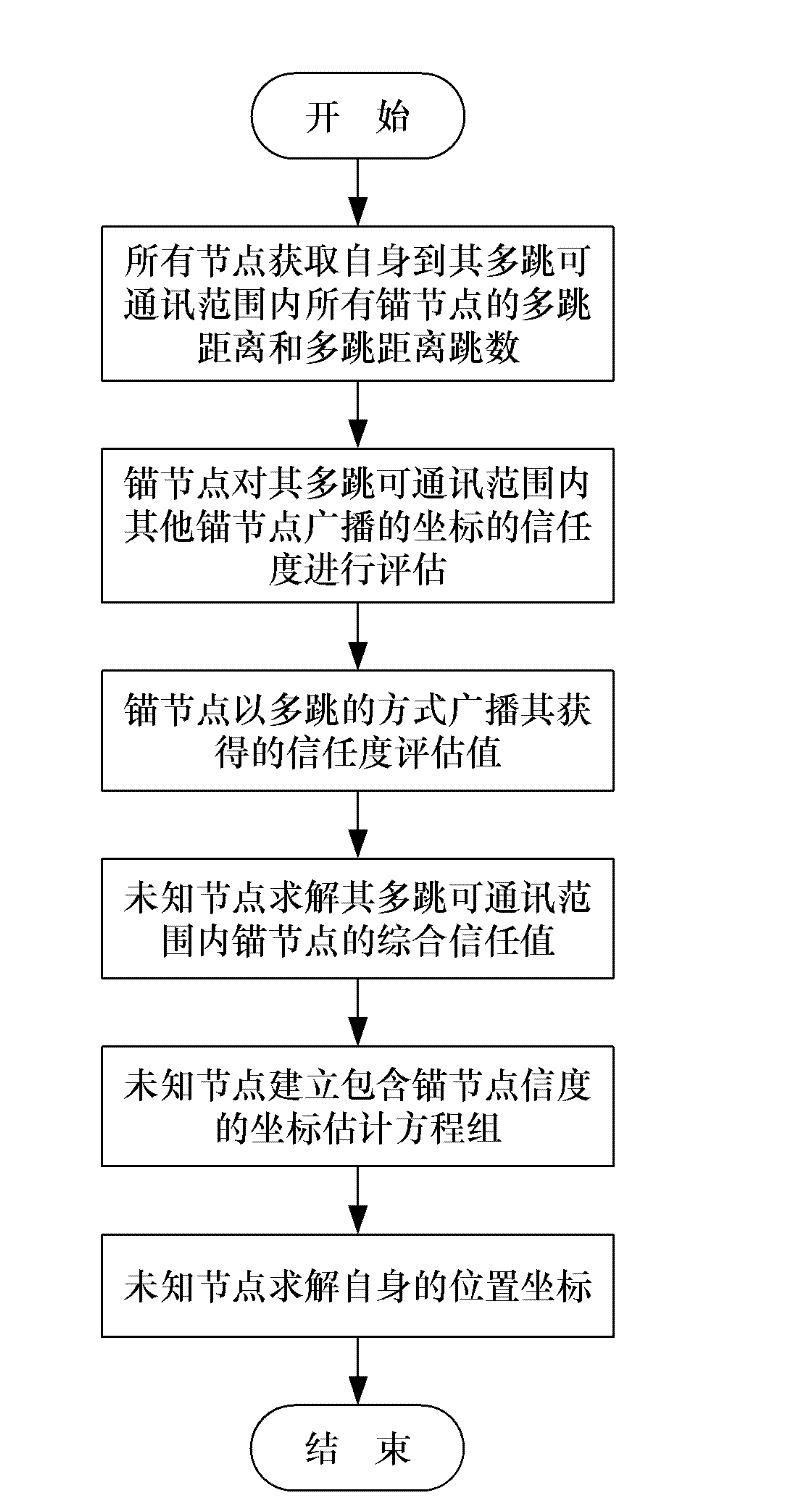

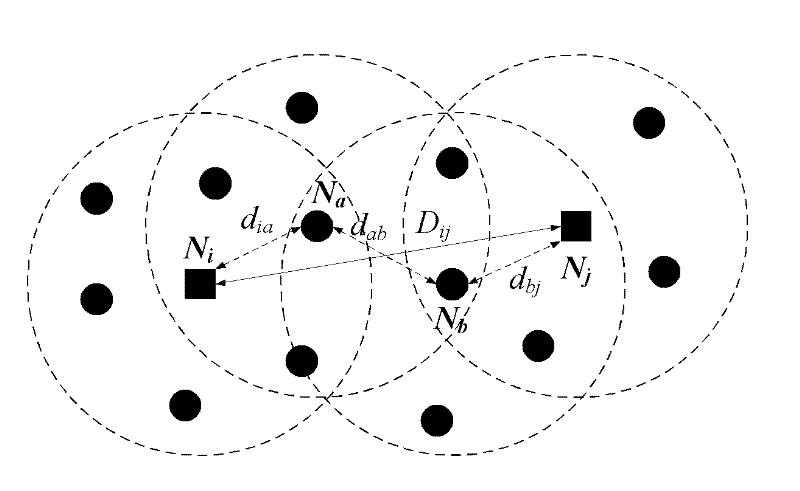

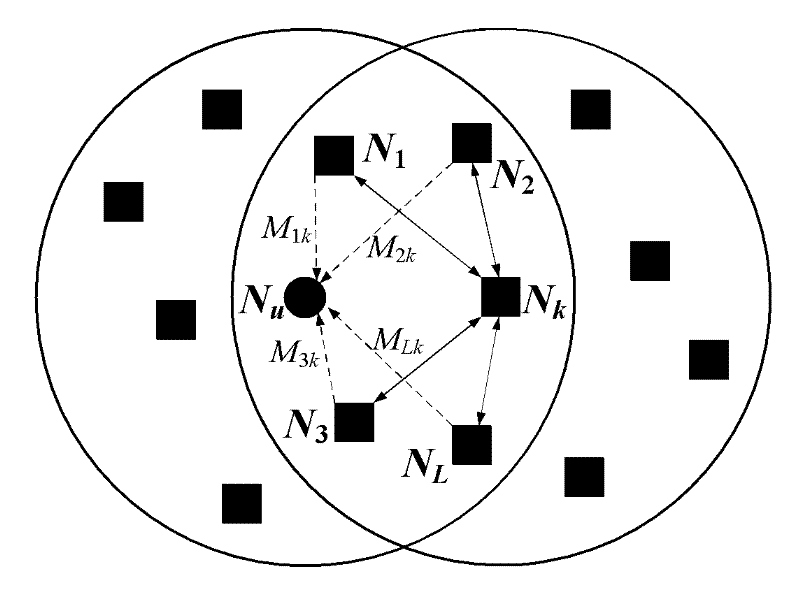

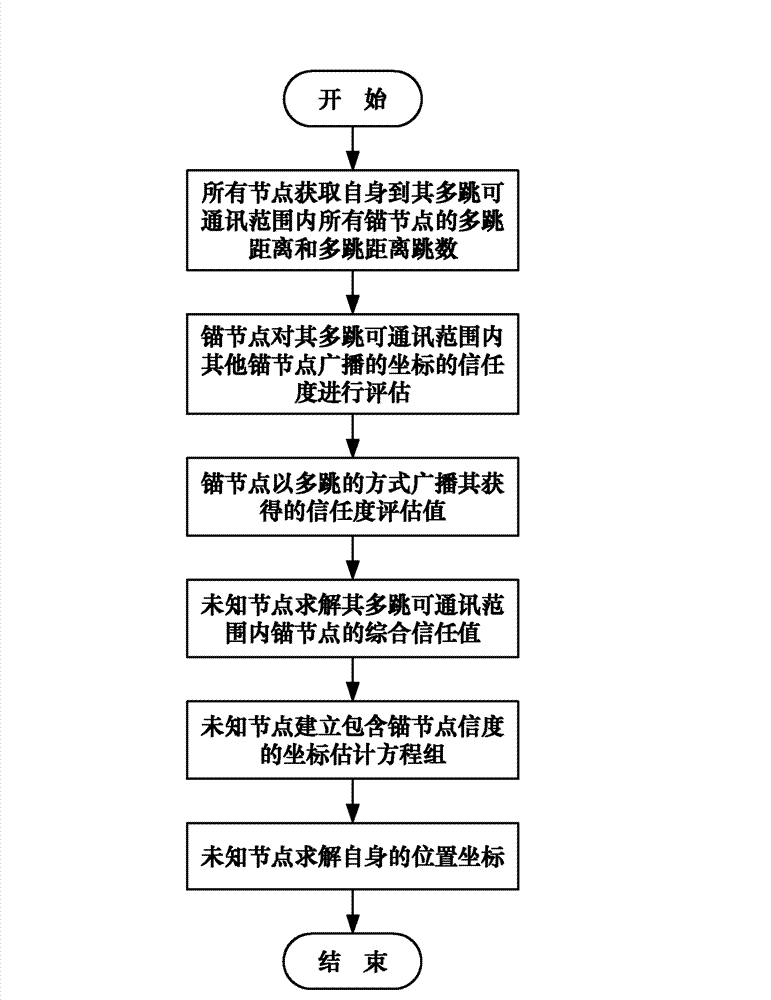

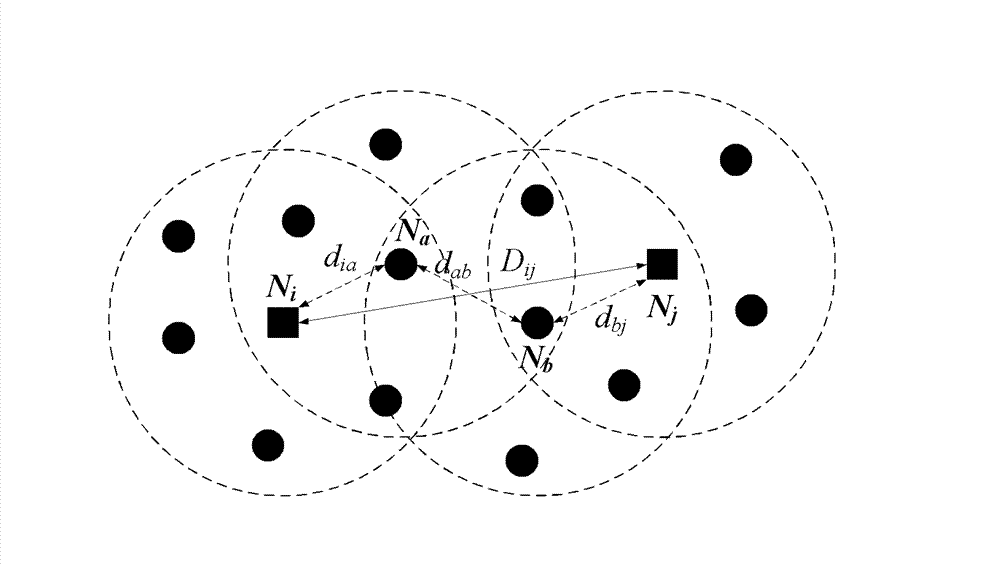

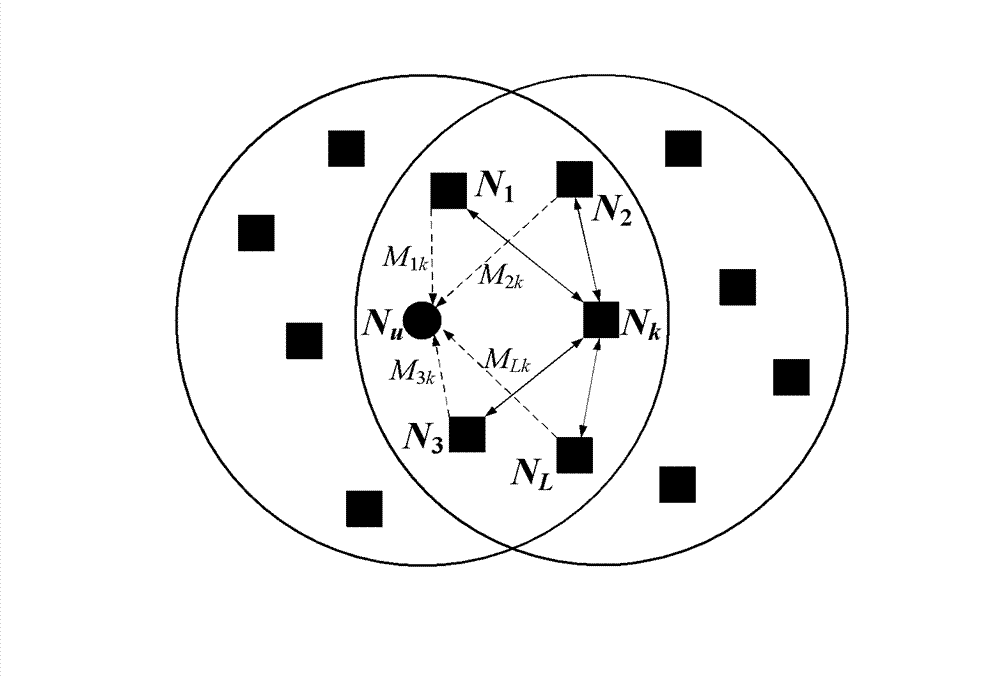

A secure multi-hop positioning method for wireless sensor networks

InactiveCN102300209AEvaluation results are reliableOvercome misjudgmentNetwork topologiesSecurity arrangementWireless sensor networkingPositioning technology

The invention, which belongs to the wireless sensor network positioning technology field, discloses a wireless sensor network safety multi-hop positioning method. The method comprises the following steps that: step 1. all nodes acquire multi-hop distances and multi-hop distance hop counts of all anchor nodes in a ranged of from the nodes to a multi-hop communication scope; step 2. the anchor nodecarries out assessment to a trust degree of other anchor node broadcast coordinates in the multi-hop communication scope; step 3. the anchor nodes use a multi-hop mode to broadcast an obtained trust degree assessment value; step 4. an unknown node solves a comprehensive trust value of the anchor nodes in the multi-hop communication scope; step 5. the unknown node establishes a coordinate estimateequation set which includes anchor node reliability; step 6. the unknown node solves the position coordinate of its own. In the invention, through the mutual trust assessment and comprehensive trust value calculation of the nodes in the multi-hop communication scope, negative influence of non-trusted anchor nodes to wireless sensor network multi-hop positioning can be reduced; system security andreliability can be enhanced; positioning precision of the wireless sensor network can be raised.

Owner:BEIHANG UNIV

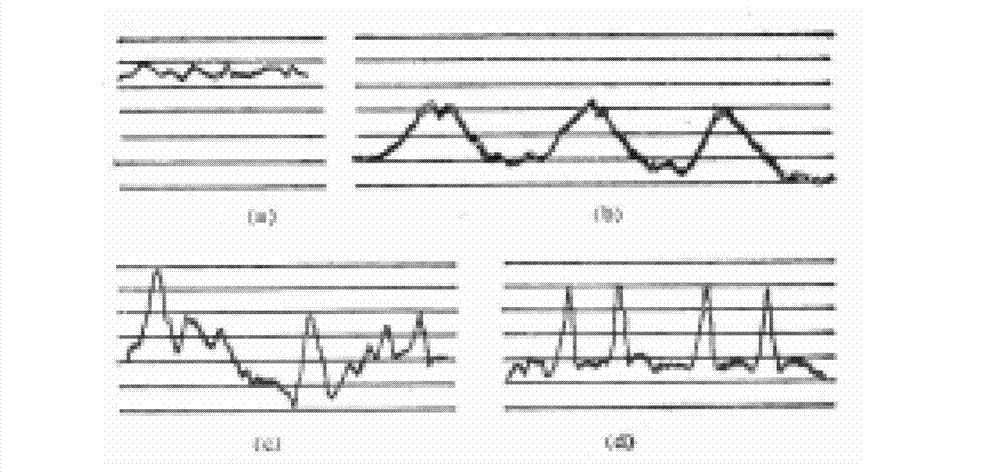

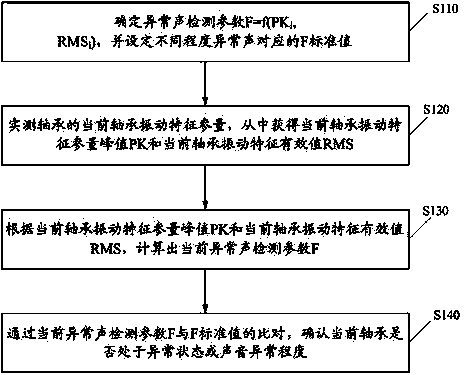

Bearing abnormal sound detection control method and bearing vibration measuring instrument

ActiveCN102243143AOvercome misjudgmentSubsonic/sonic/ultrasonic wave measurementMachine bearings testingPhysicsSound detection

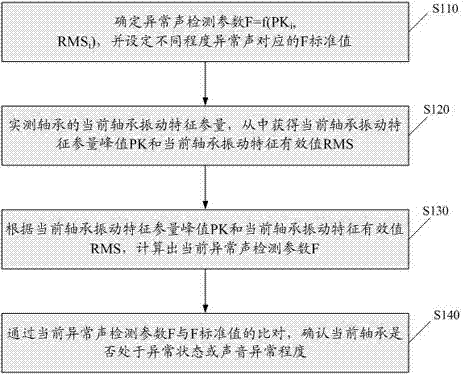

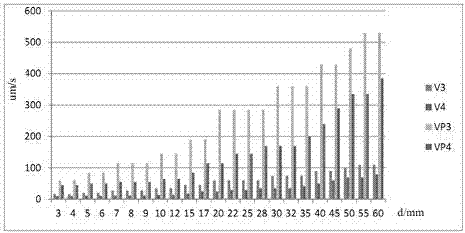

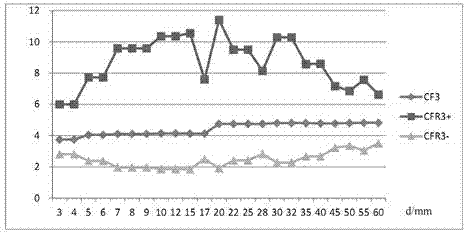

The invention discloses a bearing abnormal sound detection control method, comprising the following steps of: (1) determining an abnormal sound detection parameter F = f (PK i, RMS i), and setting F standard values corresponding to the abnormal sound of different degrees, wherein f (PK i, RMS i) refers to a function using the PK i and the RMS i as variables, the PK i is a bearing vibration characteristic parameter peak value, and the RMS i is a bearing vibration characteristic parameter effective value; (2) actually measuring the current vibration of the bearing, and obtaining a current bearing vibration characteristic parameter peak value PK and a current bearing vibration characteristic effective value RMS through the actual measurement; (3) calculating a current abnormal sound detection parameter F according to the current bearing vibration characteristic parameter peak value PK and the current bearing vibration characteristic effective value RMS; and (4) comparing the current abnormal sound detection parameter F with the F standard value to confirm whether the bearing is in abnormal state and confirm the abnormal degree of the sound. The method and the instrument provided by the invention solve the defect of mistake and omission in determination on the bearing abnormal sound caused by using the peak value for detection control in the current bearing vibration measuring instrument, and have very important significance in the filed of detection control of bearing abnormal sound.

Owner:SHANGHAI F&S BEARING TECH

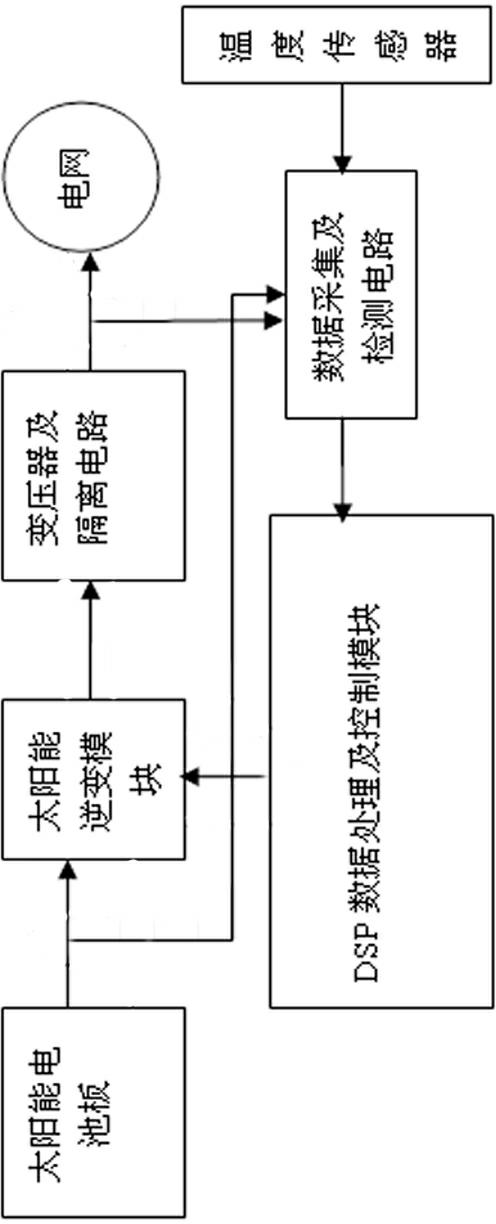

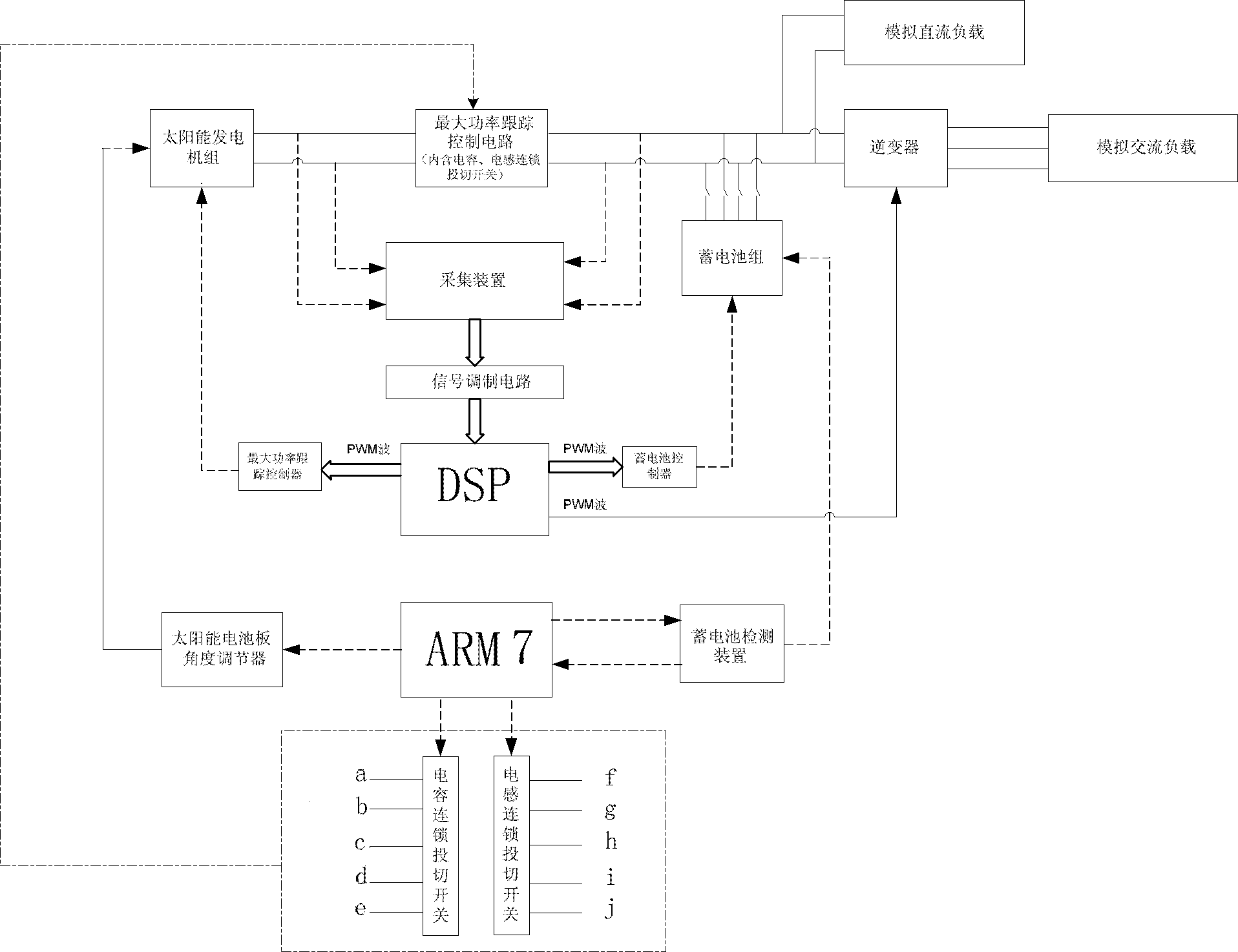

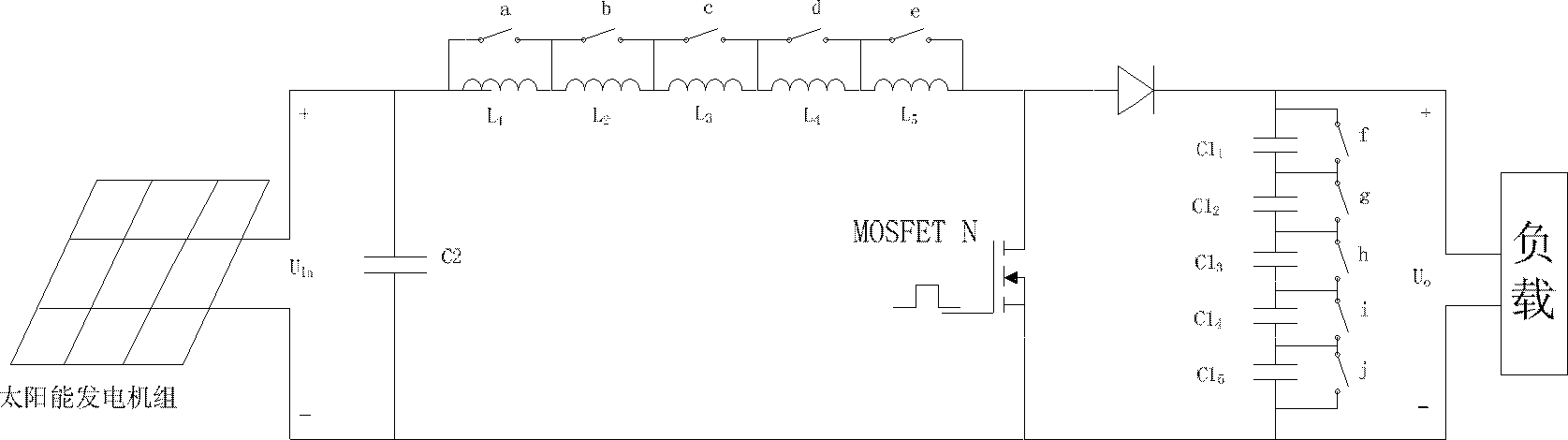

Solar energy generating system control device and method

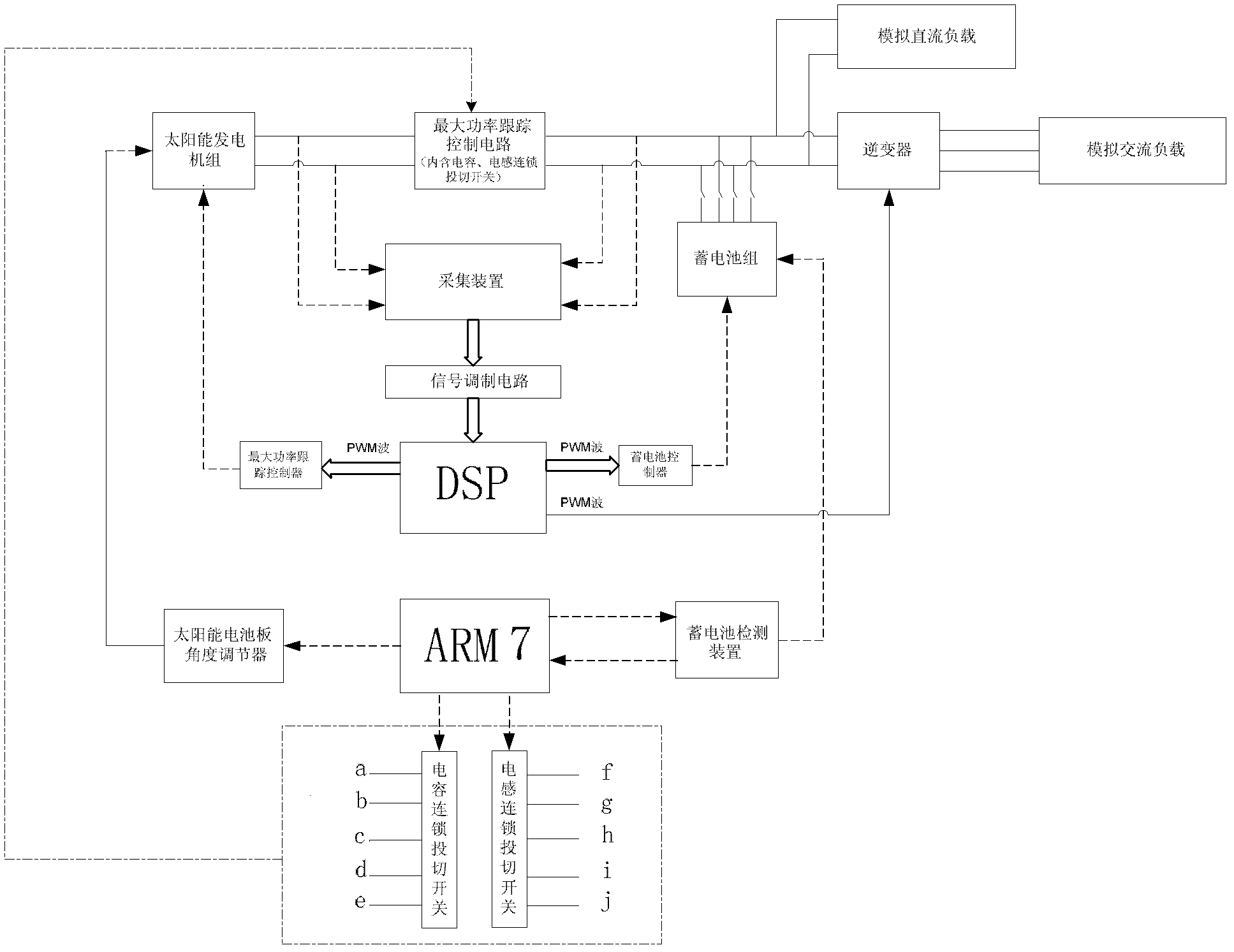

InactiveCN102638195AImprove utilization efficiencyImprove uninterrupted power supply timeBatteries circuit arrangementsPhotovoltaicsSolar generatorDsp processor

The invention relates to solar energy generating system control device and method. The device comprises a generating module, an inversion module, a master control module and a debugging module, wherein the generating module comprises a solar energy generating set, a maximum power tracking control circuit and a storage battery pack; the inversion module comprises an inverter, an analog direct current load and an analog alternating current load; the master control module comprises a DSP (Digital Signal Processor), a maximum power tracking controller, a storage battery controller, a collecting device and a signal modulation circuit; and the debugging module comprises an ARM7 processor, a solar cell panel angle regulator and a storage battery detector. By monitoring running states under a plurality of groups of working parameters in real time, electric energy utilization rate is maximum and while ensuring the normal work of the load, so that the running stability of the system is improved. A variable step size perturbation and observation method is adopted to conduct maximum power tracking so as to ensure the practical effect of MPPT (Maximum Power Point Tracking). The capacity of a storage battery and uninterrupted power supply time can be calculated by combining the longest continuous overcast and rainy days, ambient temperature and duration, and the service life of the storage battery is prolonged.

Owner:NORTHEASTERN UNIV

Optimal cutting method for wood surface defects

ActiveCN108943179AAvoid it happening againMaximize yieldProfiling/shaping machinesEconomic benefitsWaste material

The invention discloses an optimal cutting method for wood surface defects, and relates to the technical field of wood processing. The cutting method specifically comprises the following steps that S1, firstly, rubber wood undergoes manual blind cutting from raw material, transverse polishing and vertical polishing, then a wood block with the length of about 300 mm, the width of about 80 mm and the thickness of about 25 mm is cut, the wood usually has the defects such as black knots, white joints, tree centers, missing edges, cracks, inclined heads and damage, the wood is cut according to thedistribution rule of the defects, and the cut wood is divided into four types namely, an AA material, an AB material, a C material and a waste material. According to the optimal cutting method for thewood surface defects, the effects that a deep learning analysis algorithm is adopted to accomplish the defection on the surface detects of the wood, the yield of the wood can reach the maximum economic benefit, the labor cost is greatly saved, the production efficiency is improved, the utilization value of the wood is improved, and the problems that the cutting position is prone to be misjudged manually and the manual line drawing efficiency is low are solved can be achieved.

Owner:慧泉智能科技(苏州)有限公司

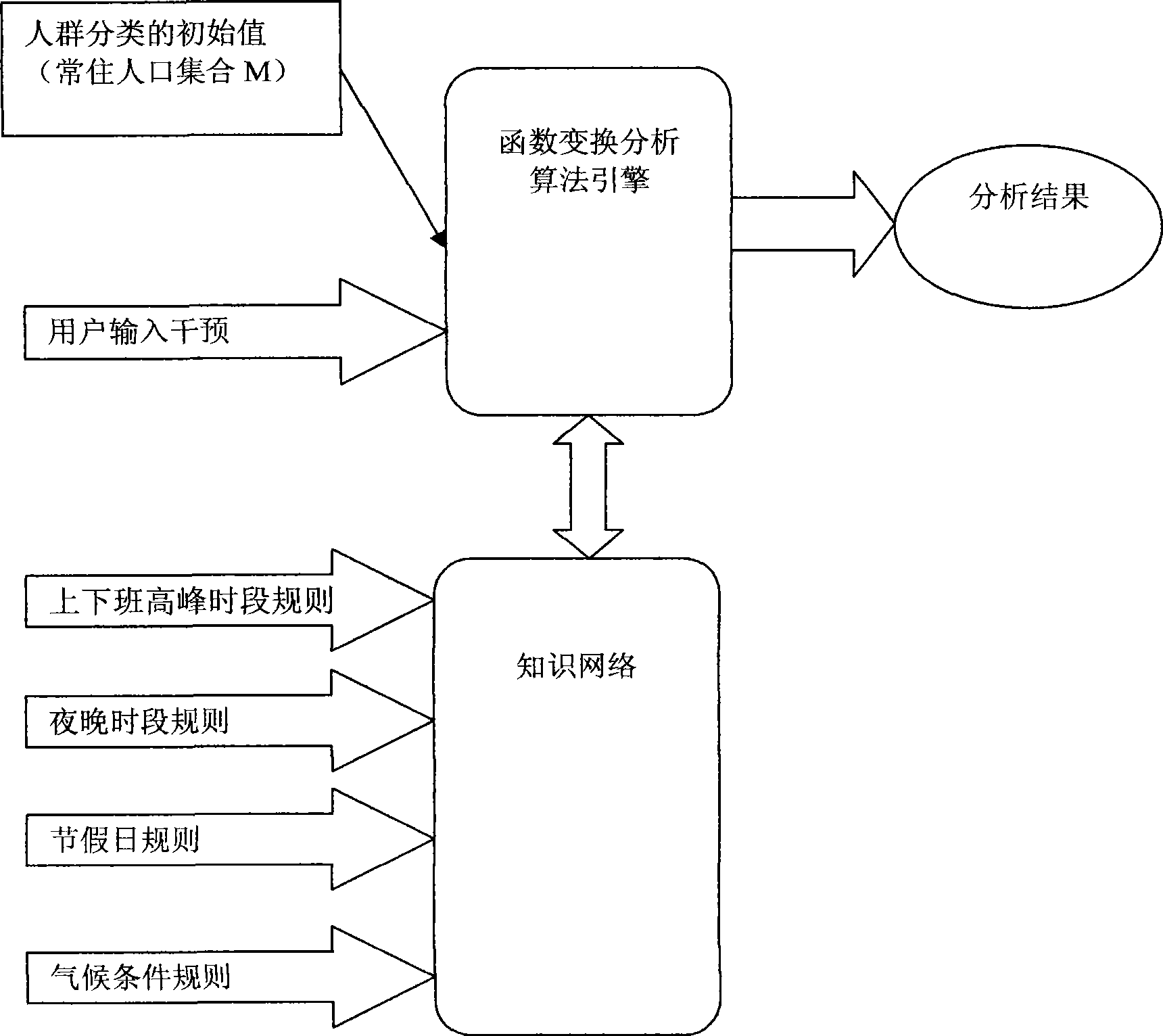

Permanent resident population analysis method based on operator network data

ActiveCN104217087AOvercome misjudgmentOvercome the disadvantages of missed judgmentSpecial data processing applicationsCrowding inPopulation

The invention relates to a permanent resident population analysis method based on operator network data. According to the method, statistics is carried out on the network data of user crowds in a certain area on the basis of the collected operator network data by utilizing the main idea of an ant colony algorithm, classification is carried out on the data according to the appearance positions and time indexes of the user crowds, calculation is carried out on the results obtained through statistics and analysis the factors according to given functional transformation, the calculation result serves as a judging basis of population classification, iteration correction is carried out on the characteristic values (the permanent resident population) of the crowds, and new judging results are fed back. According to the permanent resident population analysis method based on the operator network data, the defects that an original statistical classification method is poor in regression, slow in convergence, abnormally sensitive to abnormal data, and prone to causing misjudgment and neglected judgment are overcome; the method has the advantages that the number of requested sample data is small, requirements for an initial value are not accurate, and correction can be carried out at any time according to data; the partition of the permanent resident population in the area can reflect the current situations more truly.

Owner:SHANGHAI ZAIDE INFORMATION SCI & TECH

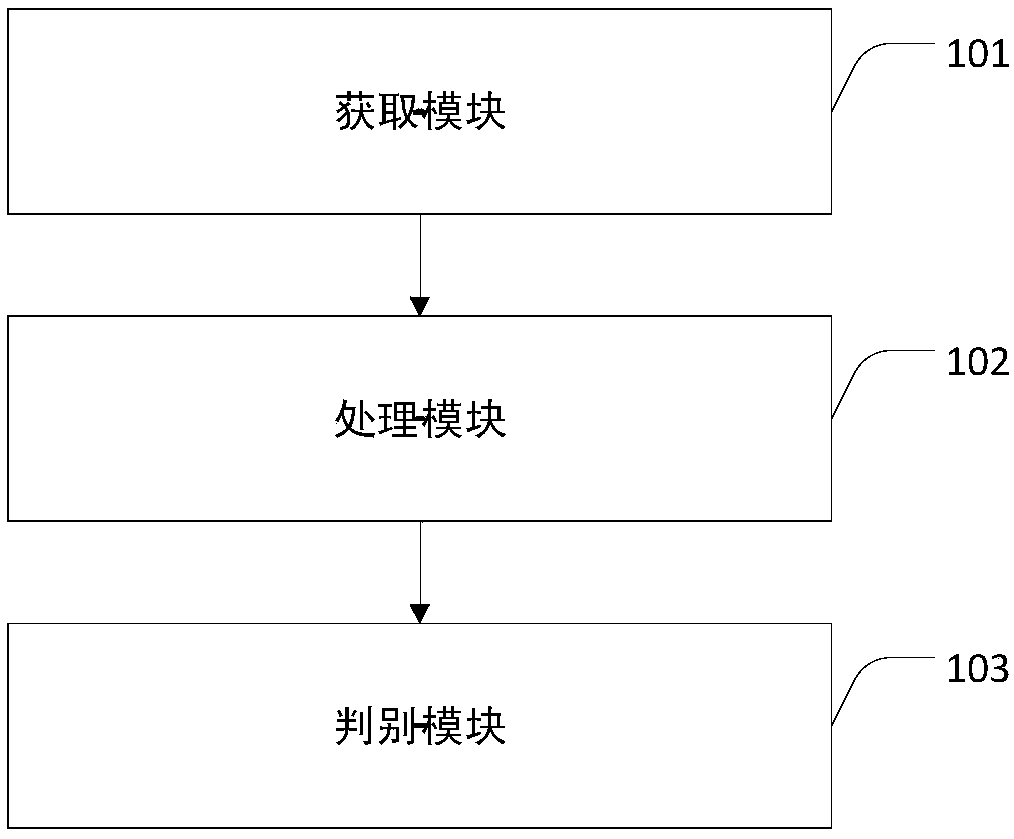

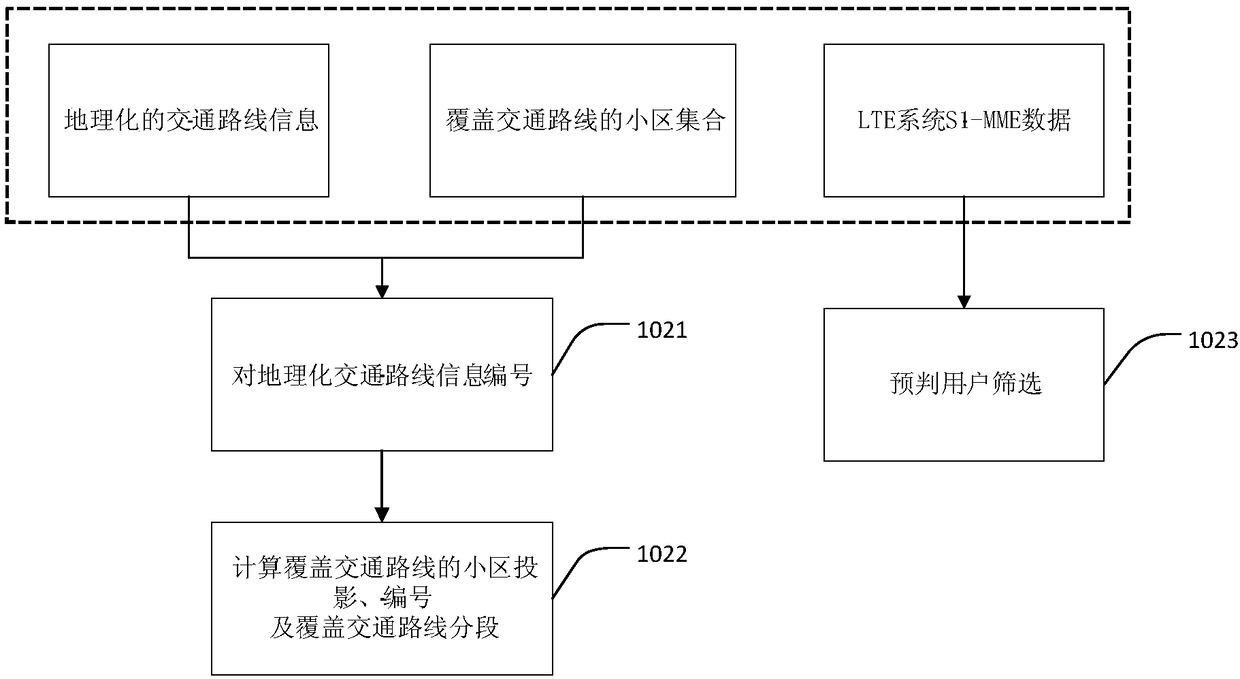

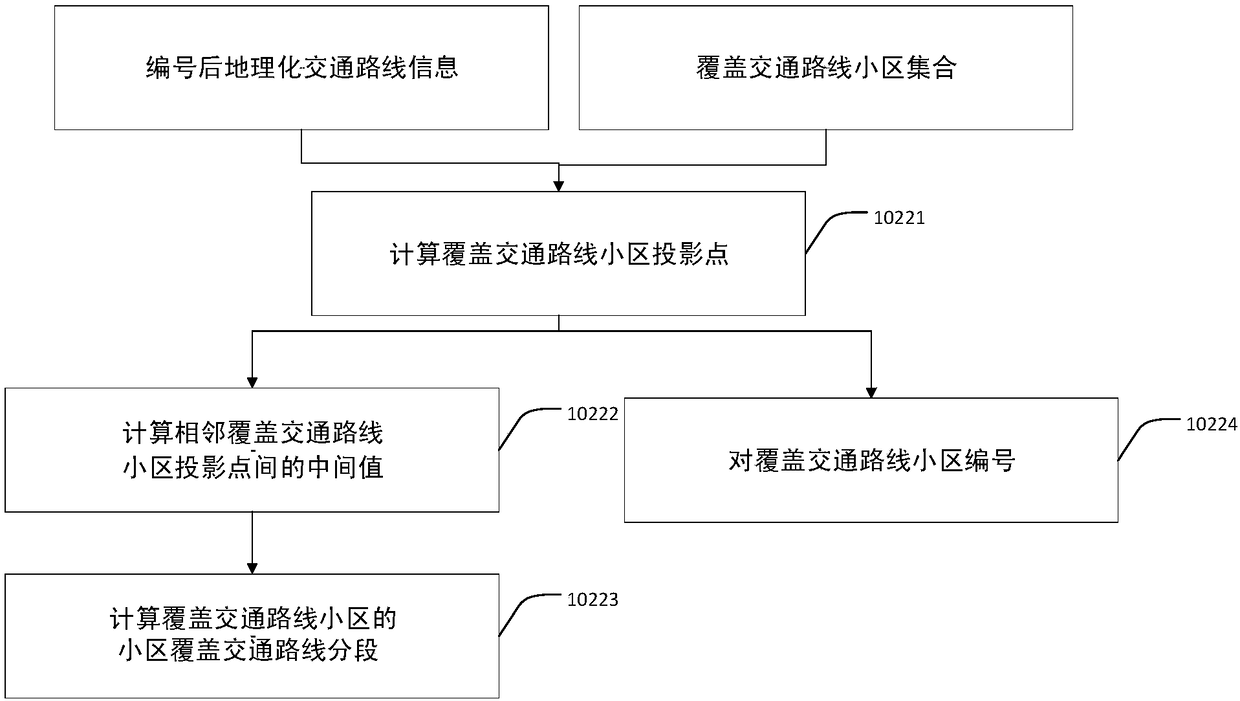

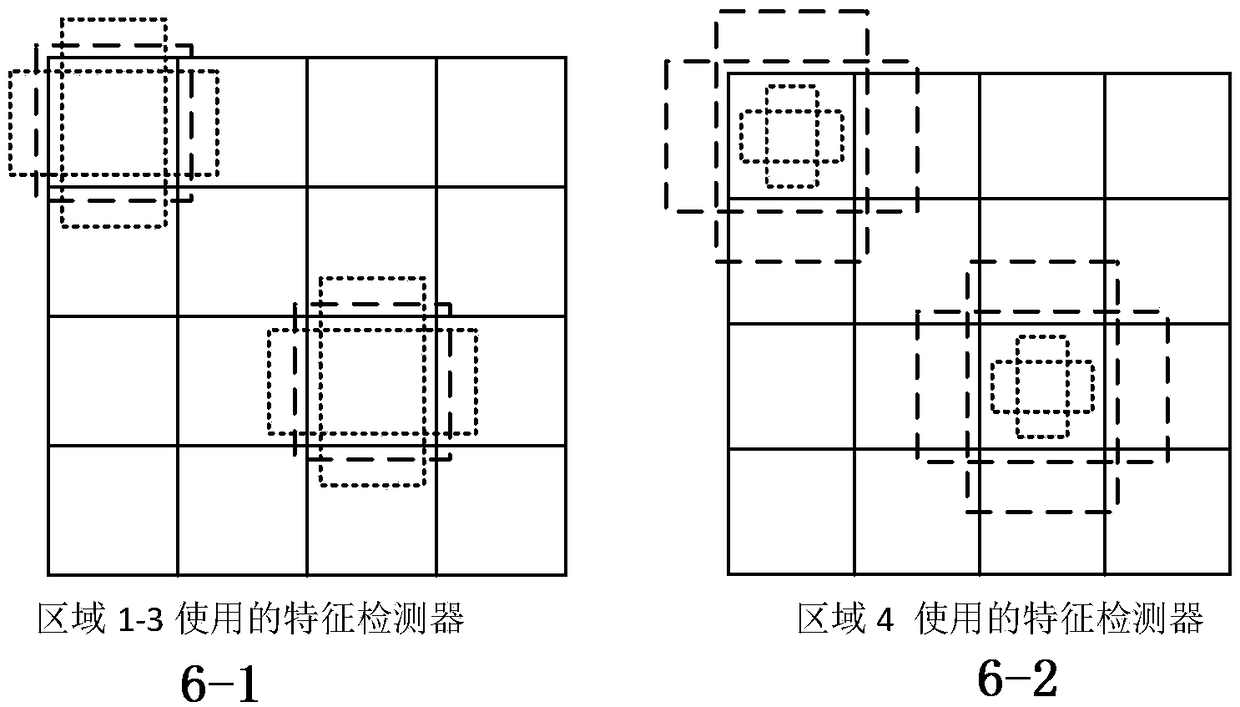

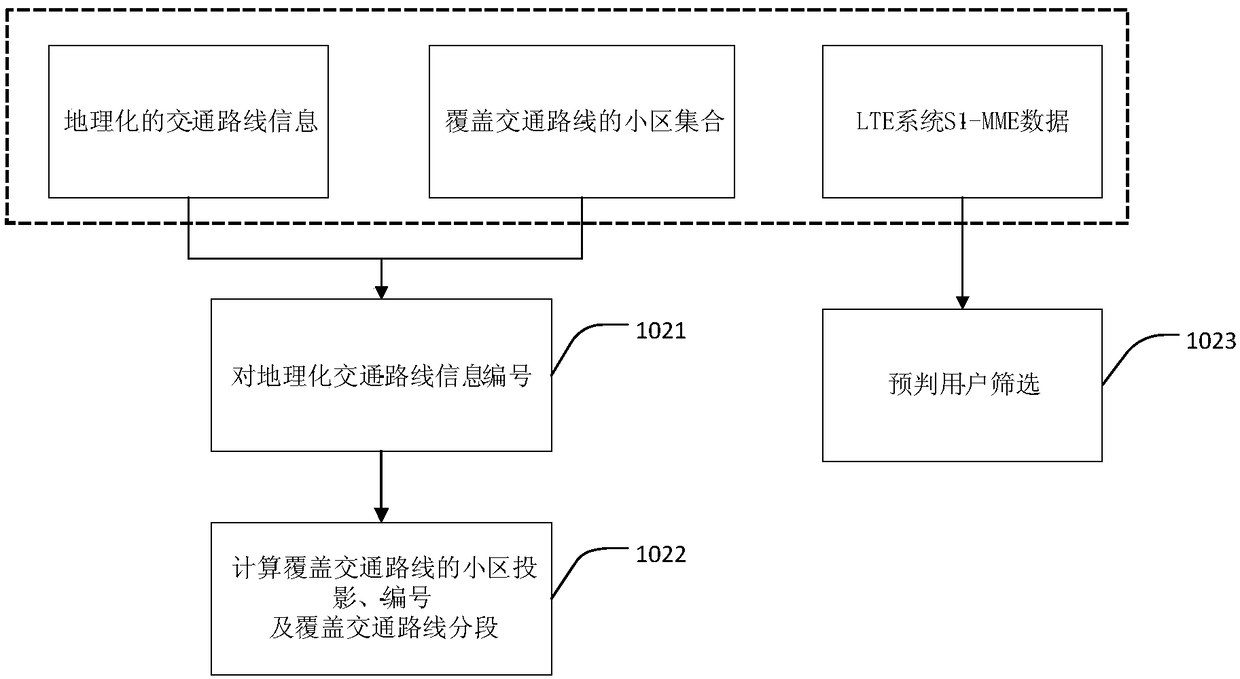

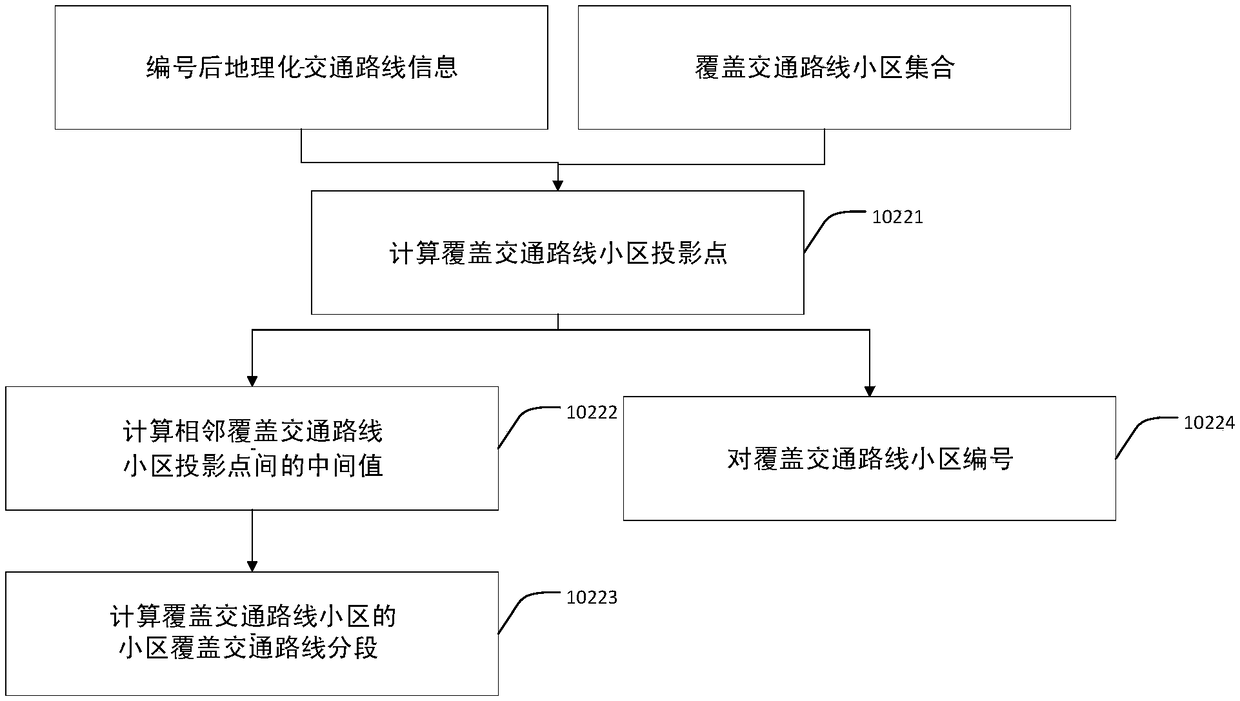

S1-MME data-based method of determining mobile user rapidly and accurately

ActiveCN108307316AHigh discrimination accuracyImprove discrimination accuracyParticular environment based servicesLocation information based serviceProjection algorithmsSlide window

The invention discloses an S1-MME data-based method of determining mobile user rapidly and accurately, belonging to the technical field of data analysis. According to the method, a pre-determined useris screened out by collecting S1-MME interface data in an LTE mobile communication network, and a practical traffic route and a travel distance of the user are simulated and calculated by combining an algorithm calculating a projection of a base station cell set covering the traffic route on a geographic traffic route and a cell coverage track segmentation algorithm. The method replaces a mannerof calculating a user movement speed by using cell space in the prior art, so that the movement distance and speed are determined more accurately; and the user is determined by using both a maximum span determining method and a reverse slide window determining method, so that the determining accuracy is improved, manual intervention factors are reduced, and false negative and false positive problems resulting from the fact that fewer cells cover the traffic route or traffic routes of different mobile attributes are adjacent are solved.

Owner:CHINA TELECOM CORP LTD

Deep learning-based tire defect intelligent detection method

ActiveCN108711148AImprove production efficiencyReduce labor costsImage enhancementImage analysisPattern recognitionProduction rate

The invention discloses a deep learning-based tire defect intelligent detection method. According to the method, based on an original X-ray detection device, an original video is divided into two channels through a video distributor; one channel is used for an operator to perform manual judgment, and the other channel is used for collecting an X-ray image through a high-speed video collection cardand transmitting the X-ray image to an identification system; and automation is realized by utilizing an artificial intelligence technology, so that the productivity is improved and the labor cost isreduced.

Owner:SHENYANG LIGONG UNIV

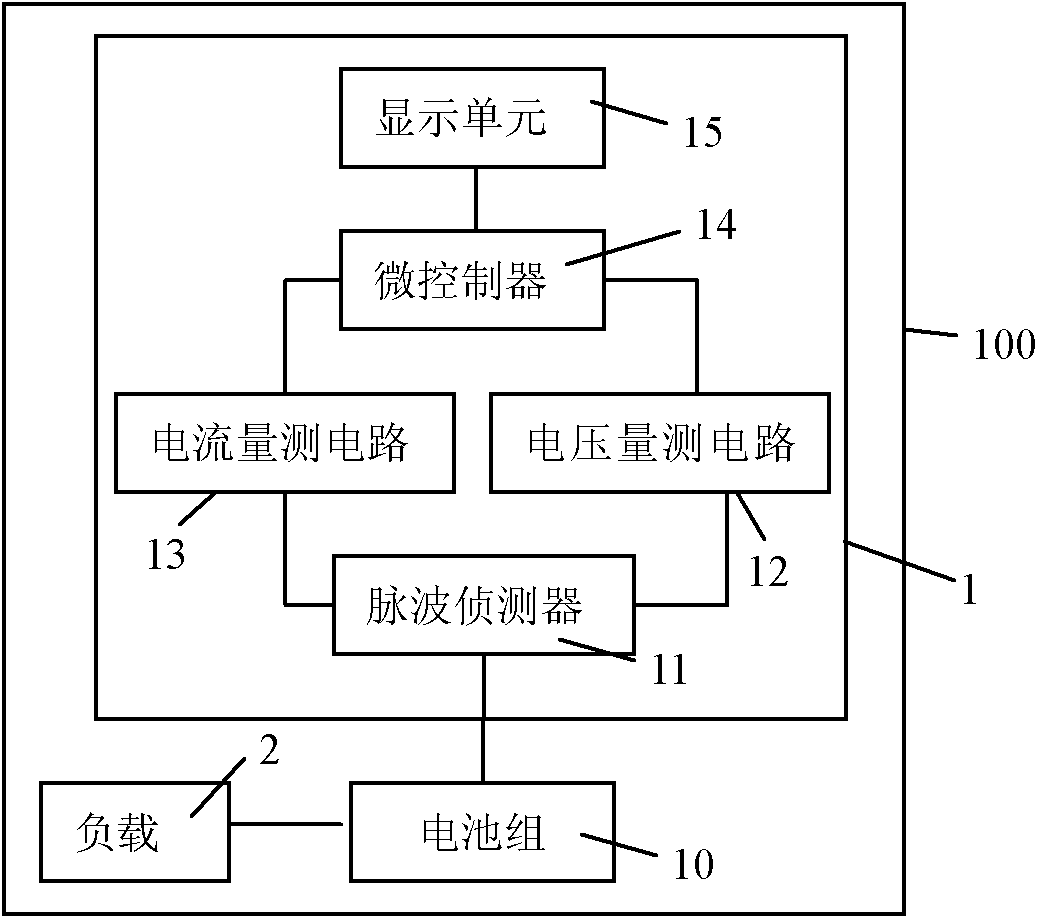

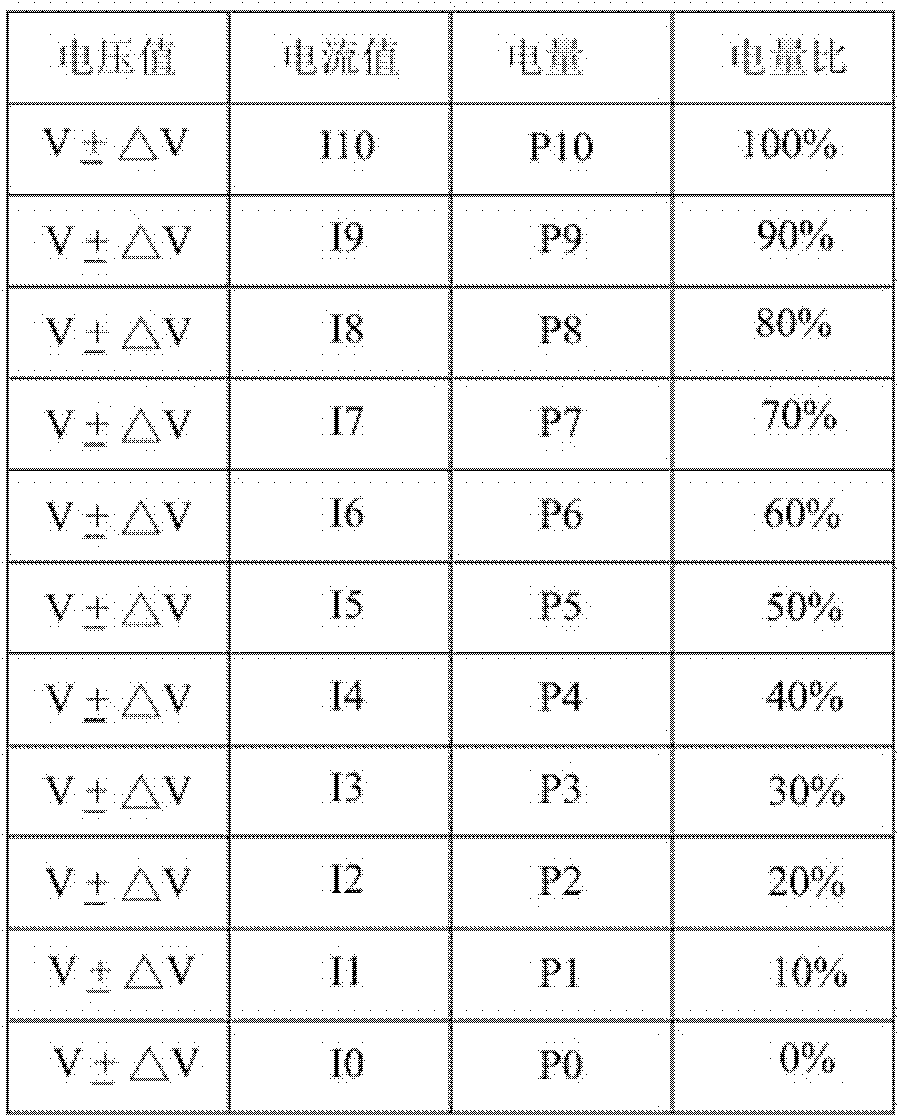

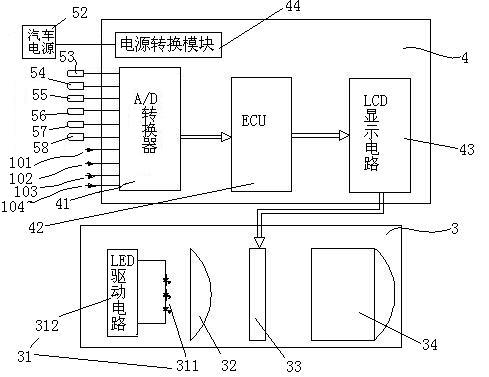

Electric quantity detection and display device and method thereof

InactiveCN102837620AOvercome misjudgmentAccurately grasp the power statusElectrical testingVehicular energy storageElectric vehicleElectricity

The invention provides an electric quantity detection and display device and a method thereof. The device is arranged in an electric vehicle which is provided with a battery unit, and comprises a pulse wave detector, a voltage measuring circuit, an electric quantity measuring circuit, a microcontroller and a display unit, wherein the pulse wave detector is used for detecting a voltage value and a current valve fed back by the battery unit; the voltage measuring circuit and the current measuring circuit are electrically connected to the pulse wave detector, and are used for measuring the voltage value and the current value of the battery unit; an electric quantity mapping table is built in the microcontroller according to the power characteristic of the battery unit; and the electric quantity value of the battery unit is acquired by matching the electric quantity mapping table with the measured voltage value and current value.

Owner:ALL WIN GREEN POWER TECH CORP

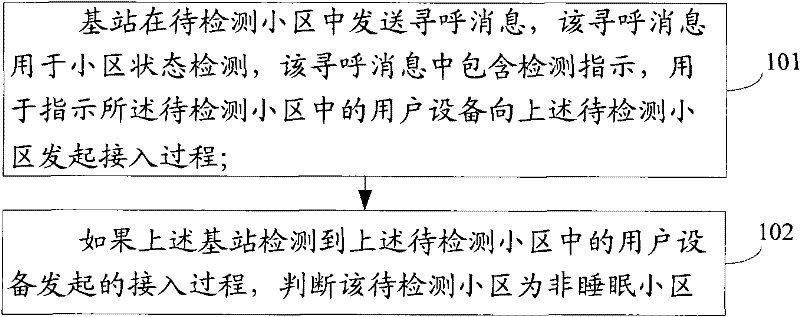

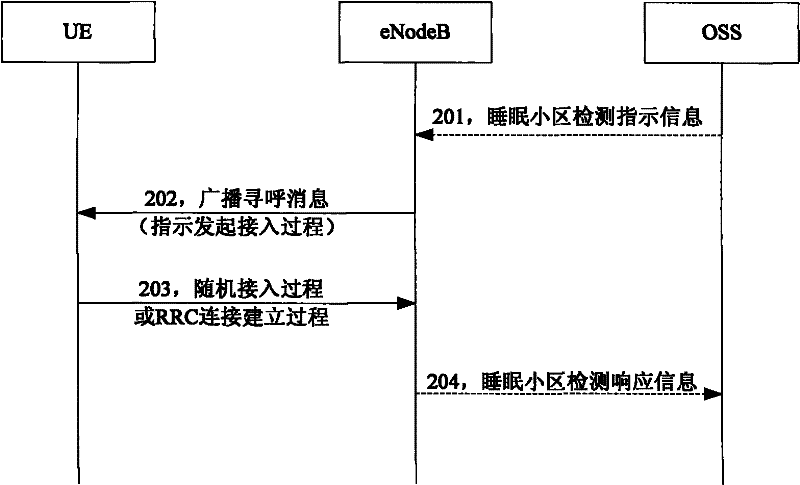

Method, device and system for cell detection

A method, device and system for cell detection are disclosed. The method for cell detection comprises: transmitting, by a base station, a paging message in a cell to be detected, wherein the paging message is used for detecting a state of the cell and the paging message comprises a detection indicator which is used for indicating a user equipment in the cell to be detected to initiate an access process to the cell to be detected; determining, by the base station, that the cell to be detected is a non-sleep cell if the base station detects the access process initiated by the user equipment in the cell to be detected. The above technical solution can detect whether a cell is a sleep cell more precisely.

Owner:HONOR DEVICE CO LTD

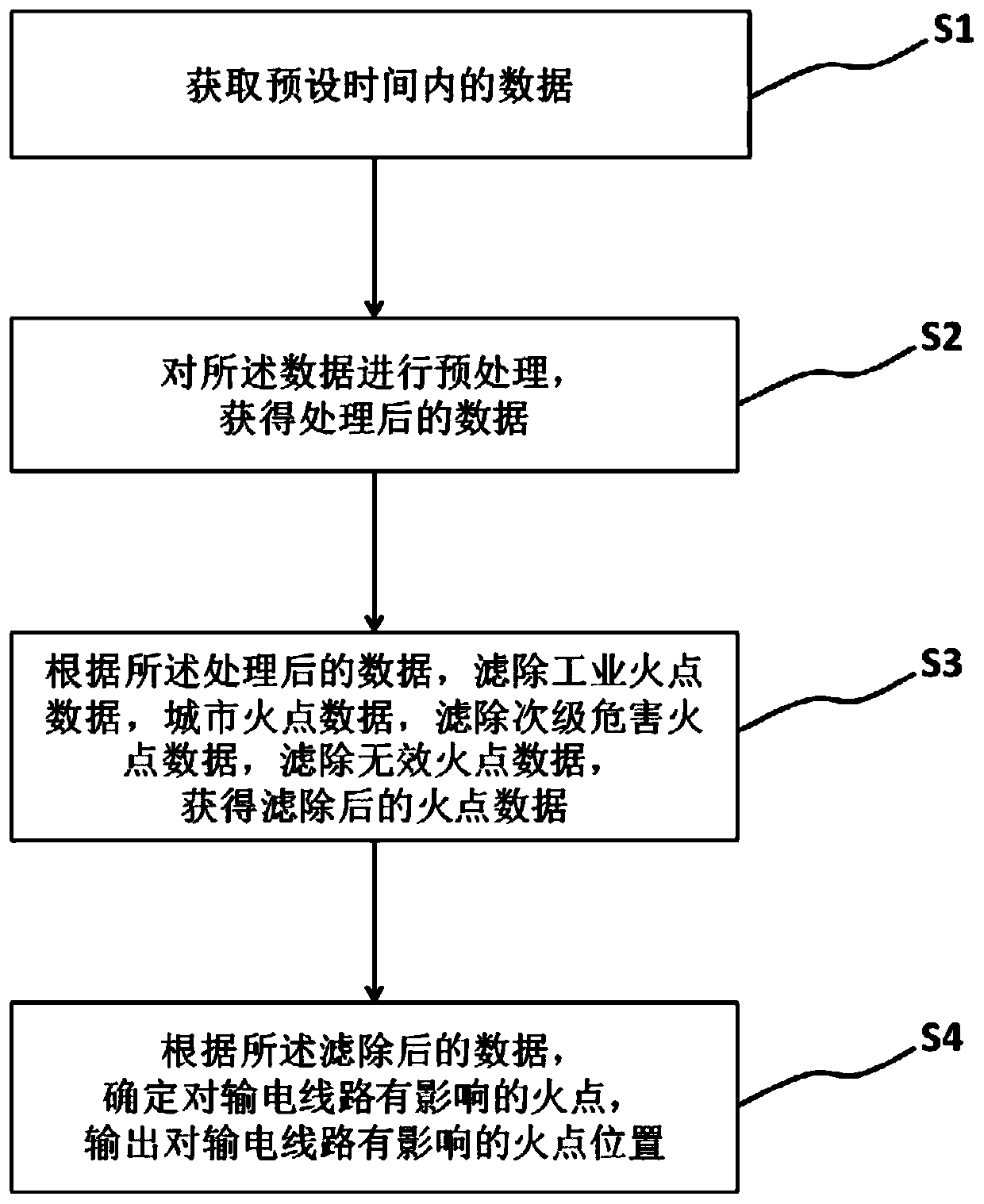

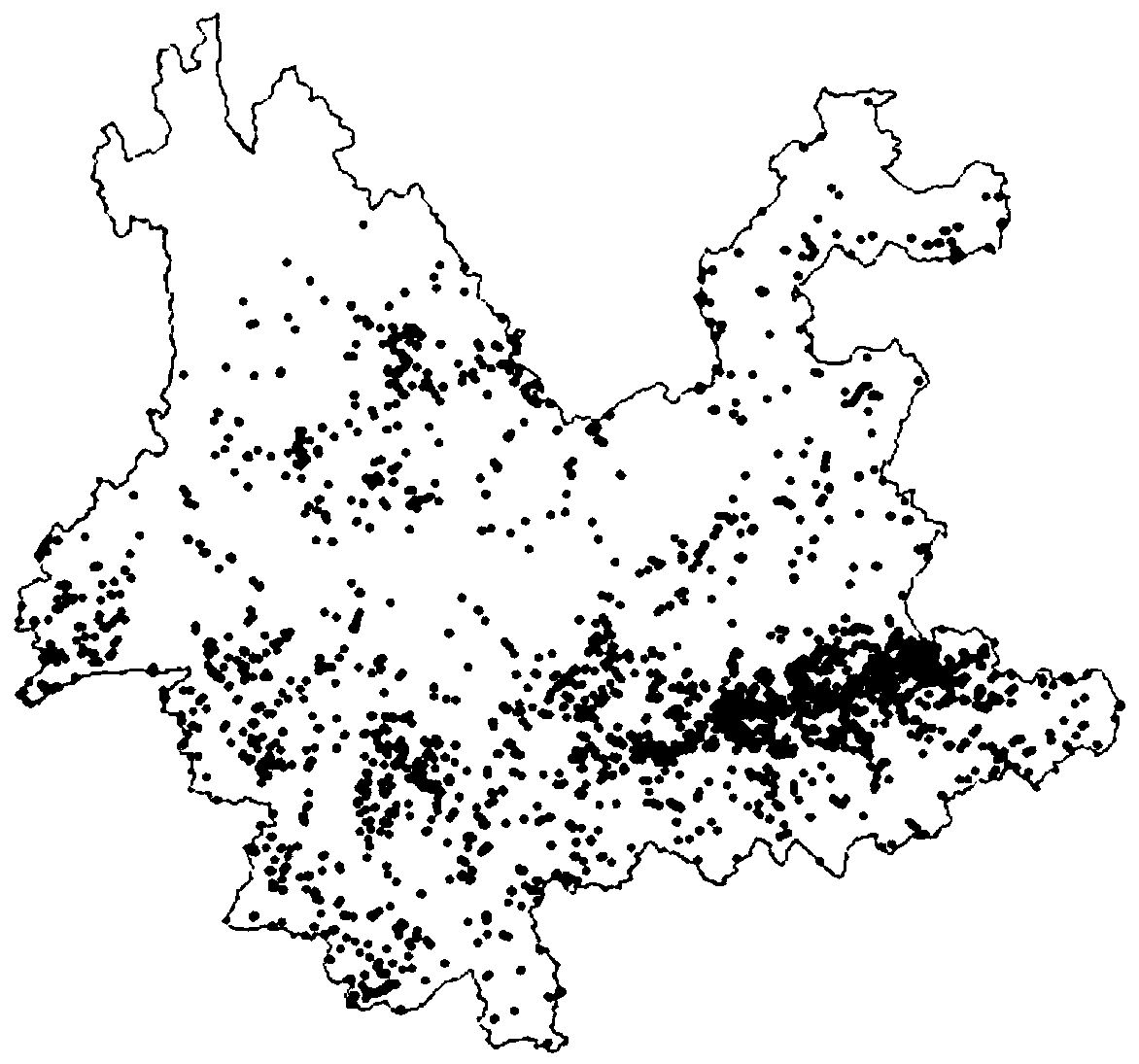

Satellite mountain fire point secondary screening method based on multi-source remote sensing data

PendingCN110009031AImprove fire detection rateImprove recognition accuracyCharacter and pattern recognitionDesign optimisation/simulationSensing dataFire point

The embodiment of the invention discloses a satellite mountain fire point secondary screening method based on multi-source remote sensing data, and the method comprises the steps: obtaining fire pointdata in a preset time through a remote sensing satellite, carrying out the preprocessing of combination, intersection and the like on the original data, and obtaining the fire point data of a research region; and after the industrial fire point, the urban fire point, the secondary hazard fire point and the invalid fire point are filtered out, obtaining effective fire points of a research area; and finally, judging a fire point having influence on the power transmission line, and outputting a fire point verification result. According to the satellite mountain fire point secondary screening method, the fire point judgment rate is increased, the problem that many misjudgments exist in an existing satellite mountain fire recognition method is solved, the problem of mountain fire point secondary screening is solved in a targeted mode, the mountain fire point recognition accuracy is improved, and the mountain fire early warning accuracy of a power transmission line is improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Improved MPPT (Maximum Power Point Tracking) algorithm and LED (Light Emitting Diode) street lamp system based on algorithm

ActiveCN102665314AFast trackAccurate trackingElectric light circuit arrangementMppt algorithmEngineering

The invention relates to a solar LED (Light Emitting Diode) street lamp system. The invention comprises an improved MPPT (Maximum Power Point Tracking) algorithm and an LED street lamp system based on the algorithm. The improved MPPT algorithm comprises the steps of: step 1: setting a maximum power point tracking starting scope as from Vmin to Vmax according to current environmental temperature T and the open-circuit voltage Voc; step 2: measuring the output voltage and the input current of a solar battery panel; step 3: judging whether VPN meets the condition that Vmin is smaller than or equal to VPN which is smaller than or equal to Vmax or not, if so, starting to search for the maximum power point from the midpoint from the Vmax to Vmin; step 4: judging whether the VPN is located in the maximum power point or not in a shorter period of time; step 5: judging whether the VPN is located in the maximum power point or not in a longer period of time, if so, calculating the reference voltage of a PI controller and making the system operate at the maximum power point stably by performing PI adjustment for Vset and VPN, or continuously searching for the maximum power point; and step 6: inquiring whether the VPN is located at the maximum power point or not for a long period of time, if not, returning to the step 2 to continuously track the maximum power point.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

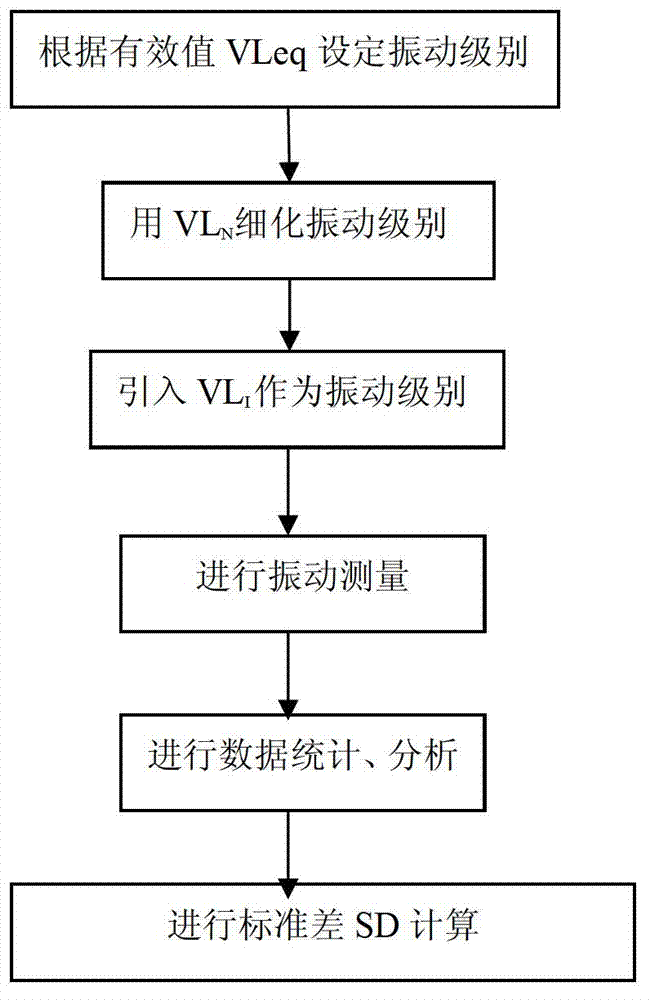

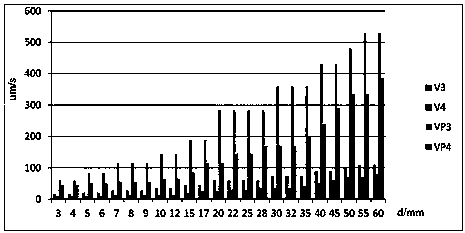

Measuring method for vibration state of antifriction bearing

ActiveCN103033257AThe process is simpleAccurate measurementSubsonic/sonic/ultrasonic wave measurementUsing electrical meansEngineeringRolling-element bearing

The invention belongs to the technical field of vibration measurement of an antifriction bearing, and particularly relates to a measuring method for a vibration state of the antifriction bearing. Firstly, an effective value VLeq of the bearing is set to four vibration levels. Then, setting of N cumulative percentage vibration level VLN of the bearing is conducted on the different vibration levels, in the setting process of the bearing vibration level, a vibration index VL I is led in, and generalization and summarization are conducted on vibration data. Then, the vibration state of the bearing is measured through a bearing vibration measuring instrument, all vibration data in the measuring process are recorded and classified, and the proportion of each class in general measuring data is calculated. The proportion of the vibration mean effective value VLeq and the proportion of the VLNs is calculated, and the proportions are compared with a standard set VLN level. At last, a standard deviation is calculated, a degree that the bearing deviates from the standard deviation is confirmed, and measurement on vibration state of the antifriction bearing is finished. The measuring method for the vibration state of the antifriction bearing is easy in manufacturing process, scientific, reasonable, accurate in measuring result and capable of being widely applied to measurement and judgment of vibration of various bearings.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

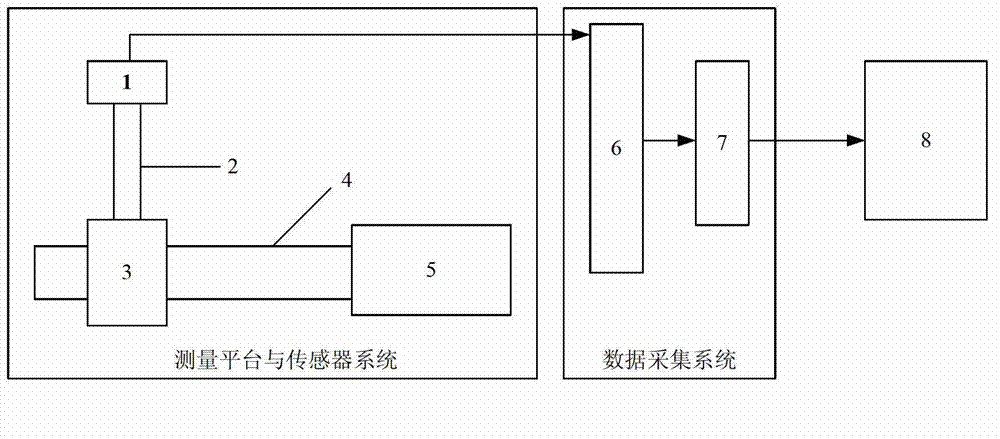

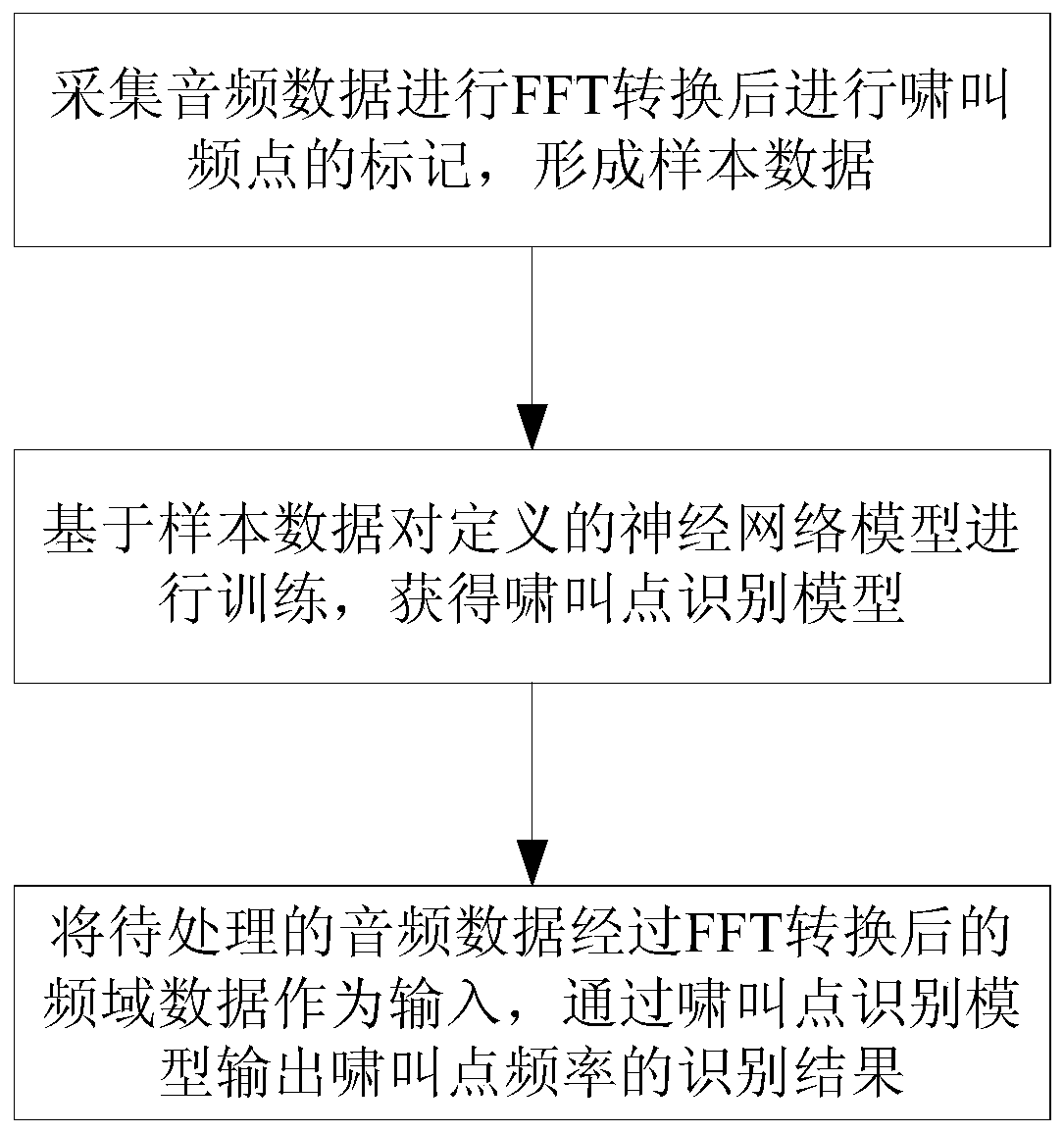

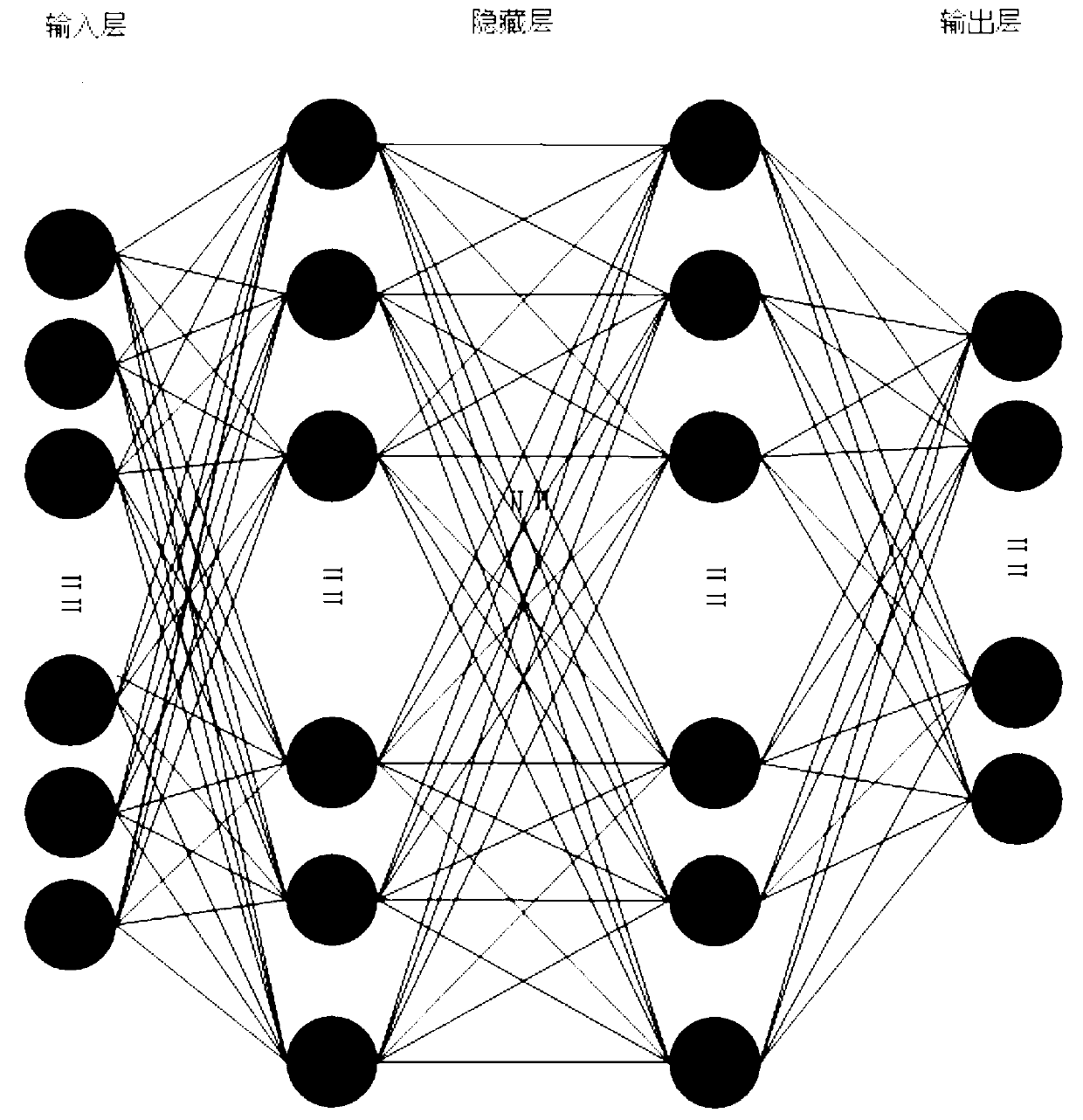

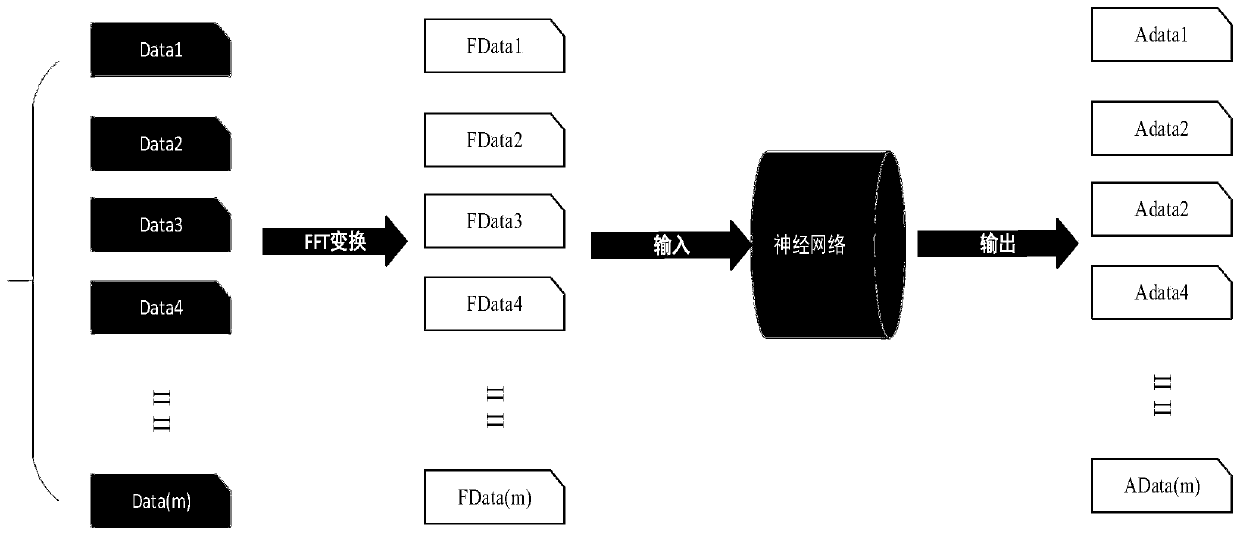

Acoustic amplification system howling point detection method based on neural network

InactiveCN111526469AStrong self-learning functionOvercome misjudgmentElectrical apparatusSpeech analysisNetwork modelAudio frequency

The invention relates to an audio signal processing technology, discloses a sound amplification system howling point detection method based on a neural network, and solves the problems of misjudgmentand missed judgment of a howling point and incapability of accurately tracking and detecting the howling point in the traditional technology. The method comprises the following steps: a, acquiring audio data, performing FFT conversion, and marking howling frequency points to form sample data; b, training a defined neural network model based on the sample data to obtain a howling point recognitionmodel; c, in practical application, taking the frequency domain data of the audio data to be processed after FFT conversion as input, and outputting a howling point frequency identification result through a howling point identification model.

Owner:成都千立网络科技有限公司

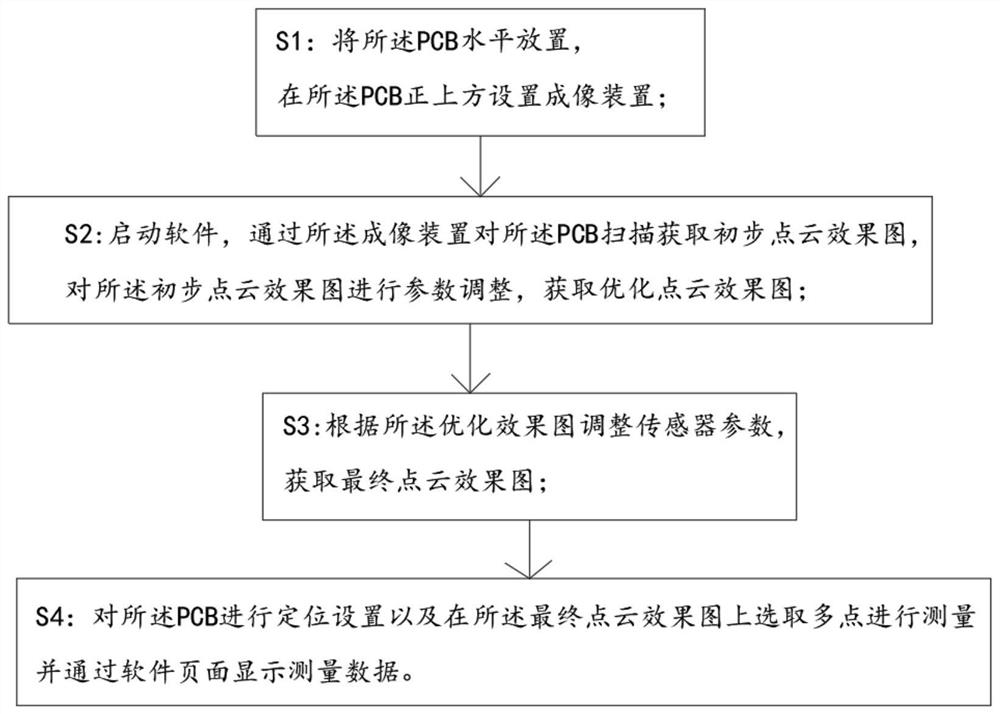

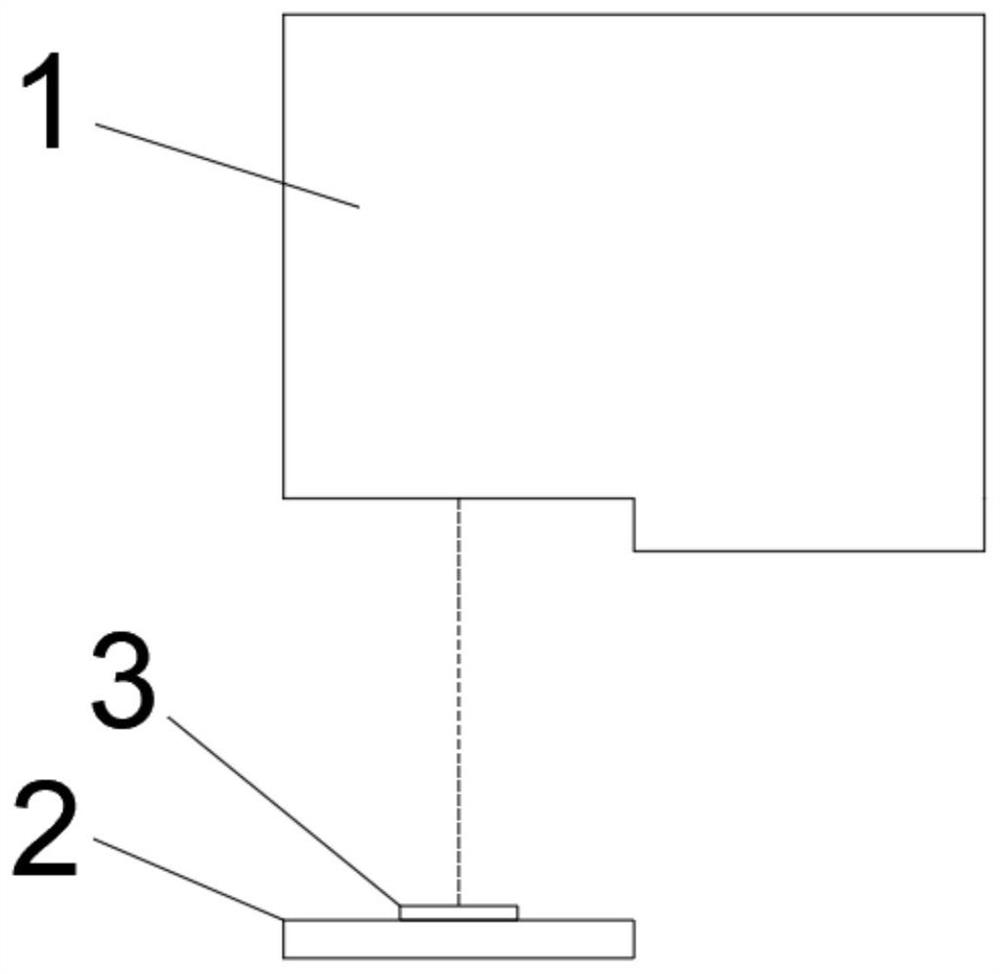

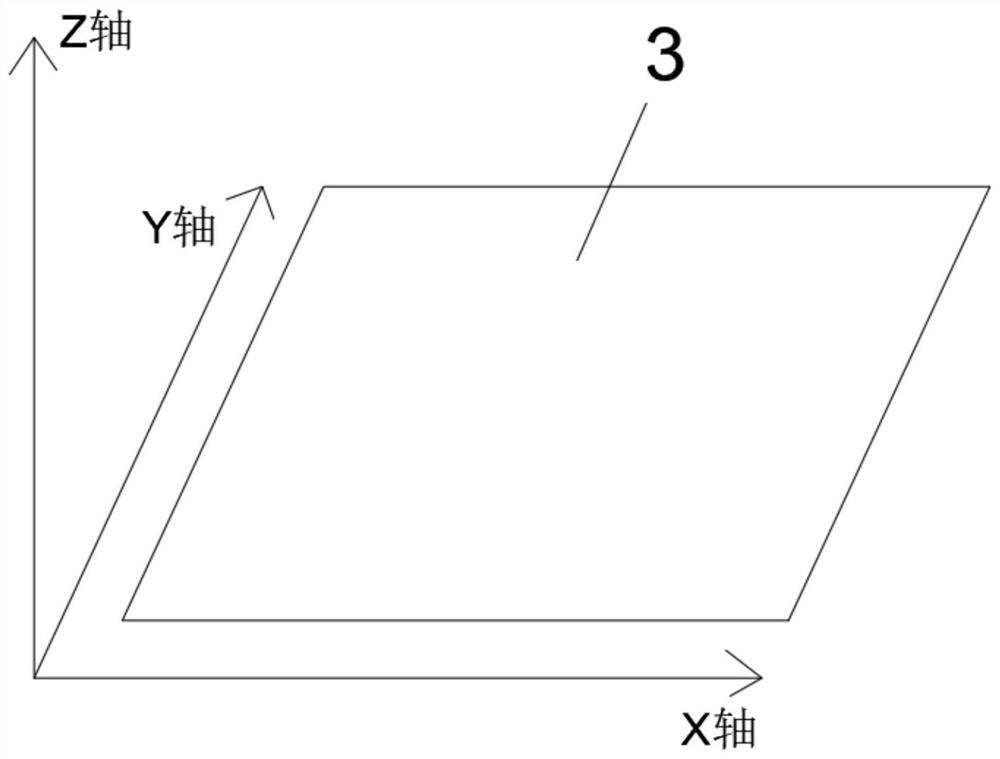

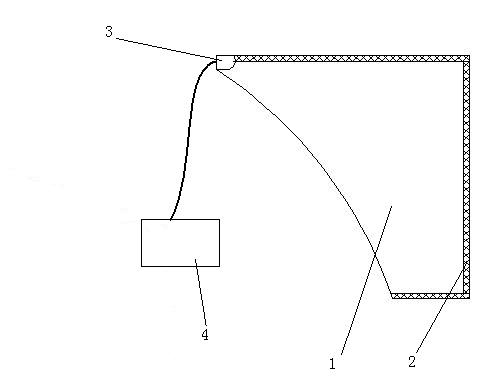

PCB flatness measuring method and measuring device

PendingCN114184143AOvercome misjudgmentOvercoming problems such as missed judgmentsMaterial analysis by optical meansUsing optical meansPoint cloudEngineering

The invention relates to the technical field of PCB detection, in particular to a PCB flatness measuring method and device, and the method comprises the steps: horizontally placing a PCB, arranging a 3D camera right above the PCB, scanning the PCB below through the 3D camera to obtain a point cloud image, carrying out the parameter adjustment of the scanned image to cut off a flying spot or a noisy spot of the image, and carrying out the measurement of the flatness of the PCB. Multi-point measurement is carried out on the surface of a PCB through a measurement operator, the PCB is positioned through the measurement operator so as to ensure that the measurement positions of the PCB are consistent, the invention provides a measurement device for detecting the flatness of the PCB, and the measurement device comprises a placement platform for placing the PCB, an imaging device for scanning the surface of the PCB and an industrial computer with built-in analysis processing software. Multi-point comprehensive measurement is selected for the surface of the PCB, and the measurement accuracy and the measurement efficiency are improved.

Owner:HUIZHOU GAOSHENGDA TECH CO LTD

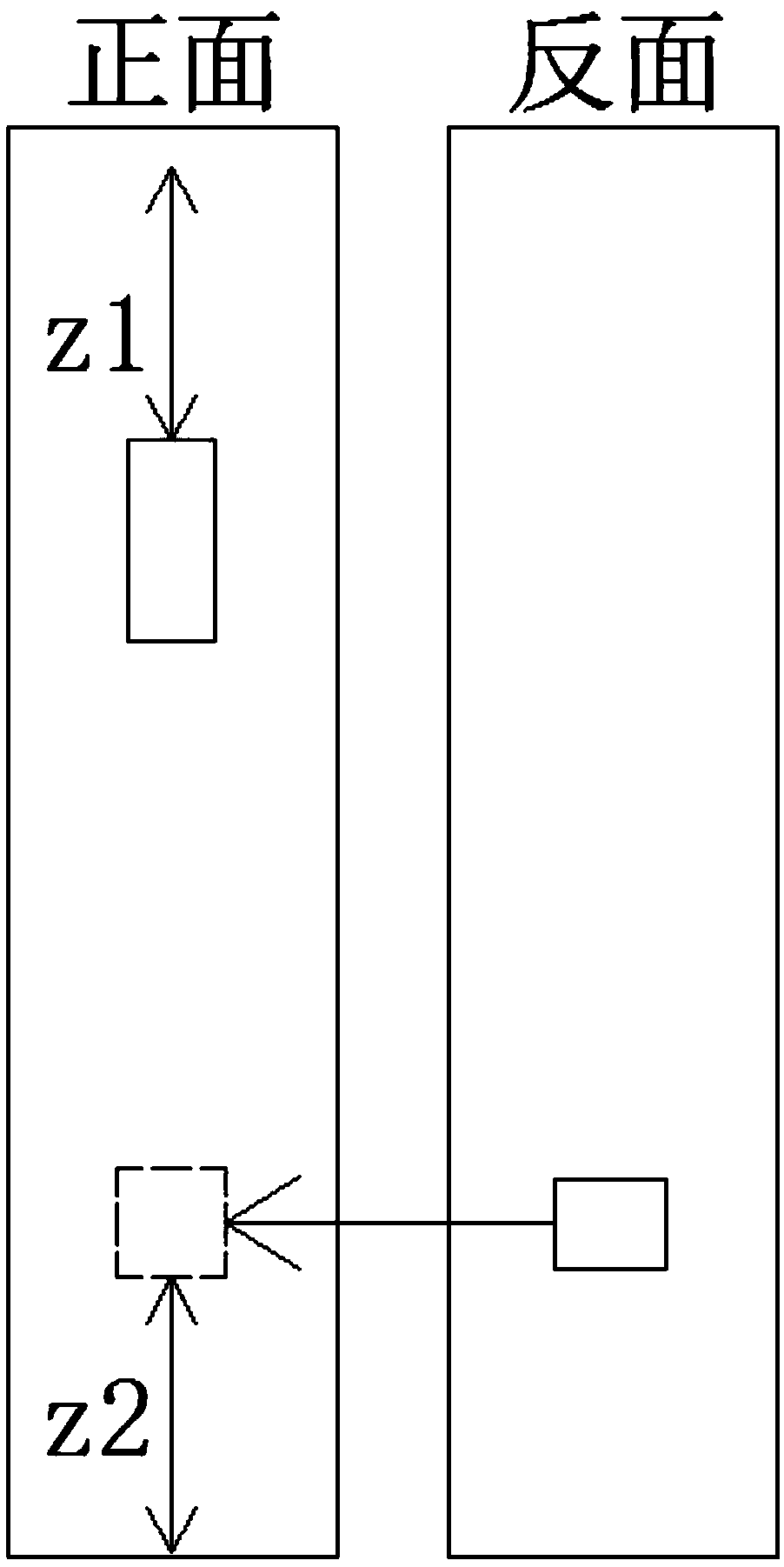

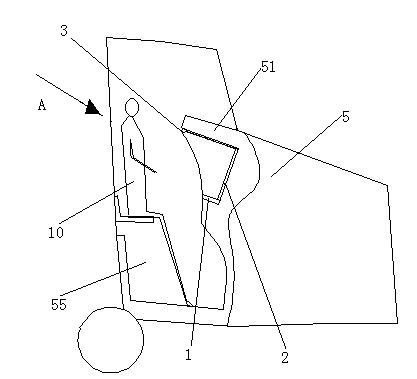

Phantom-type combined automobile instrument

InactiveCN102642470AGood misjudgmentObservation effect is goodPrintersProjectorsElectricityEngineering

The invention relates to an automobile instrument, in particular to a phantom-type combined automobile instrument. The phantom-type combined automobile instrument comprises a shell body; a projection screen is arranged at one end of the shell body; a projection light head for projecting towards the projection screen is arranged at the other end of the shell body; the projection light head is electrically connected with a signal processing device; the signal processing device is used for converting signals input by electrical elements, which are used for detecting and controlling the state of an automobile, into digital image data signals; and the projection light head is used for projecting the digital image data signals output by the signal processing device onto the projection screen in the form of an image. The phantom-type combined automobile instrument provided by the invention has the advantages that the misjudgment difficultly occurs, the observation effect is good, and the problems that the misjudgment occurs and the observation effect is not good enough due to the fact that the existing instrument is read through a face shield are solved.

Owner:LANZHOU GEELY AUTOMOBILE IND +1

Landslide prediction method based on real-time monitoring of groundwater level and displacement

InactiveCN103150871BOvercome misjudgmentIt has the function of medium and long-term forecastingAlarmsHazard monitoringStatistical analysis

The invention belongs to the slope stability estimation and landslide hazard monitoring and early warning technologies. A landslide forecasting method capable of utilizing underground water levels and displacement real-time monitoring includes the following steps: (1) landslide preliminary reconnaissance and monitoring point selection; (2) monitoring arrangement and installation of equipment; (3) monitoring the landslide displacement and the underground water levels in real time and processing real-time monitoring data; (4) statistical analysis period by unit and confirming mean-value underground water level HO and a displacement speed VO; (5) confirming underground water level loading and unloading parameters and loading and unloading quantities; (6) confirming displacement speed response parameters and displacement response quantities; (7) confirming the landslide displacement speed and underground water level loading and unloading response ratio parameters and numbers; (8) applying the underground water levels and displacement speed loading and unloading response ratio to carrying out evaluating slope stability and monitoring and early warning. According to the landslide forecasting method capable of utilizing the underground water levels and the displacement real-time monitoring, produced erroneous judgement or mistake judgement that landslide physics mechanical parameters, boundary conditions and the like can not be confirmed difficultly and accurately by the transitional ultimate equilibrium mechanics appraisal method can be overcome effectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Wireless sensor network safety multi-hop positioning method

InactiveCN102300209BEvaluation results are reliableOvercome misjudgmentNetwork topologiesSecurity arrangementWireless sensor networkingPositioning technology

The invention, which belongs to the wireless sensor network positioning technology field, discloses a wireless sensor network safety multi-hop positioning method. The method comprises the following steps that: step 1. all nodes acquire multi-hop distances and multi-hop distance hop counts of all anchor nodes in a ranged of from the nodes to a multi-hop communication scope; step 2. the anchor nodecarries out assessment to a trust degree of other anchor node broadcast coordinates in the multi-hop communication scope; step 3. the anchor nodes use a multi-hop mode to broadcast an obtained trust degree assessment value; step 4. an unknown node solves a comprehensive trust value of the anchor nodes in the multi-hop communication scope; step 5. the unknown node establishes a coordinate estimateequation set which includes anchor node reliability; step 6. the unknown node solves the position coordinate of its own. In the invention, through the mutual trust assessment and comprehensive trust value calculation of the nodes in the multi-hop communication scope, negative influence of non-trusted anchor nodes to wireless sensor network multi-hop positioning can be reduced; system security andreliability can be enhanced; positioning precision of the wireless sensor network can be raised.

Owner:BEIHANG UNIV

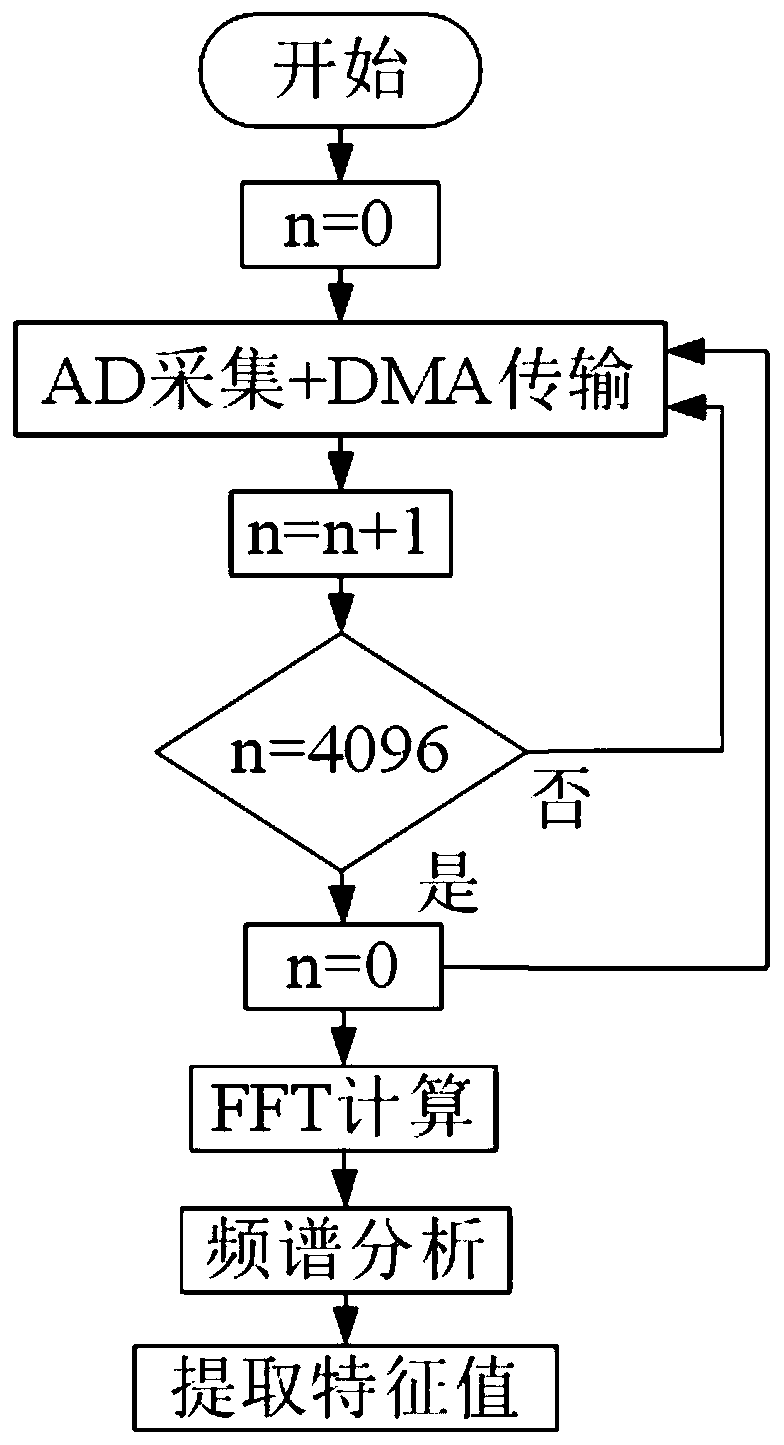

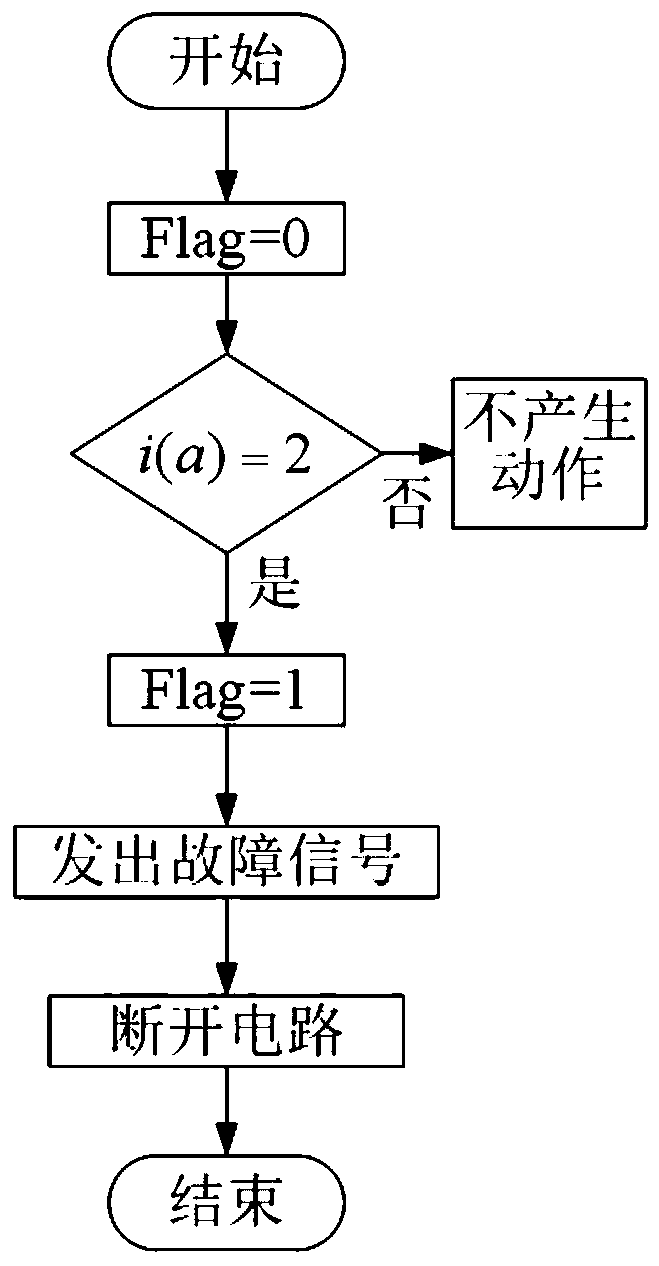

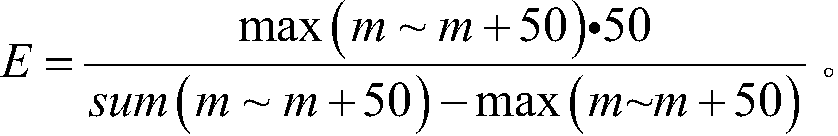

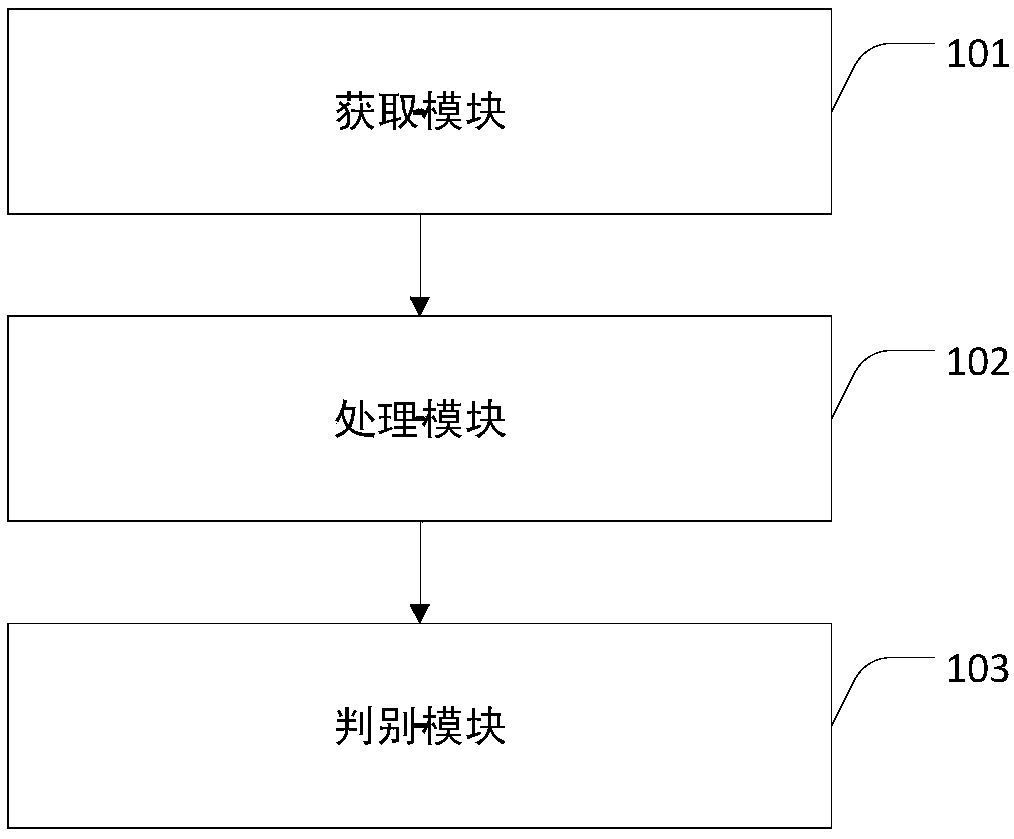

Method for judging DC series arc fault based on frequency domain sage specific value

ActiveCN110441663AOvercome misjudgmentMeet real-time detection requirementsTesting dielectric strengthFrequency bandCollections data

The invention discloses a method for judging DC series arc fault based on a frequency domain sage specific value, and belongs to the technical field of the DC arc fault detection. The method comprisesthe following steps: computing amplitude sum of each of 12 frequency bands in a DC power supply loop current spectrum, forming six groups of specific value relations as characteristic values Rarc1-Rarc4, S_Rarc1, S_Rarc2, and finding out the maximum amplitude in 51 points from the 75th to the 125th in the loop current spectrum, and computing the specific value of the 50 times of the maximum valueto other 50 points, and serving the specific value as the characteristic value E. when a threshold condition is satisfied twice or more in quartic data collection cycles of seven groups of characteristic values, the DC series arc fault in the DC power supply system can be confirmed. The method disclosed by the invention can be applied to the DC series arc fault detection in the DC power supply system.

Owner:HARBIN INST OF TECH

High-precision discrimination method for fast-moving users based on s1-mme data

ActiveCN108307316BHigh discrimination accuracyImprove discrimination accuracyParticular environment based servicesLocation information based serviceSlide windowProjection algorithms

The invention discloses an S1-MME data-based method of determining mobile user rapidly and accurately, belonging to the technical field of data analysis. According to the method, a pre-determined useris screened out by collecting S1-MME interface data in an LTE mobile communication network, and a practical traffic route and a travel distance of the user are simulated and calculated by combining an algorithm calculating a projection of a base station cell set covering the traffic route on a geographic traffic route and a cell coverage track segmentation algorithm. The method replaces a mannerof calculating a user movement speed by using cell space in the prior art, so that the movement distance and speed are determined more accurately; and the user is determined by using both a maximum span determining method and a reverse slide window determining method, so that the determining accuracy is improved, manual intervention factors are reduced, and false negative and false positive problems resulting from the fact that fewer cells cover the traffic route or traffic routes of different mobile attributes are adjacent are solved.

Owner:CHINA TELECOM CORP LTD

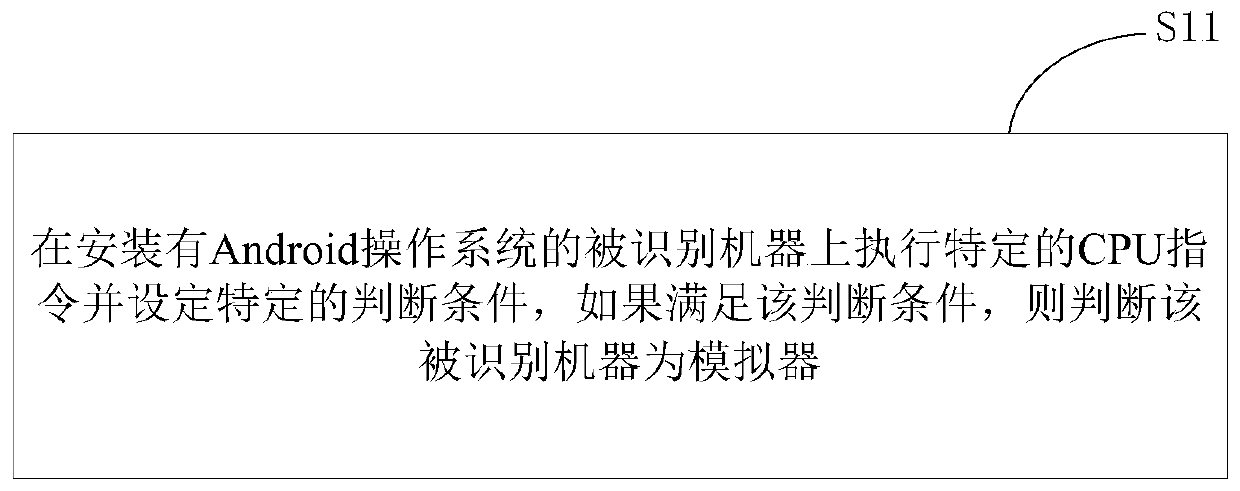

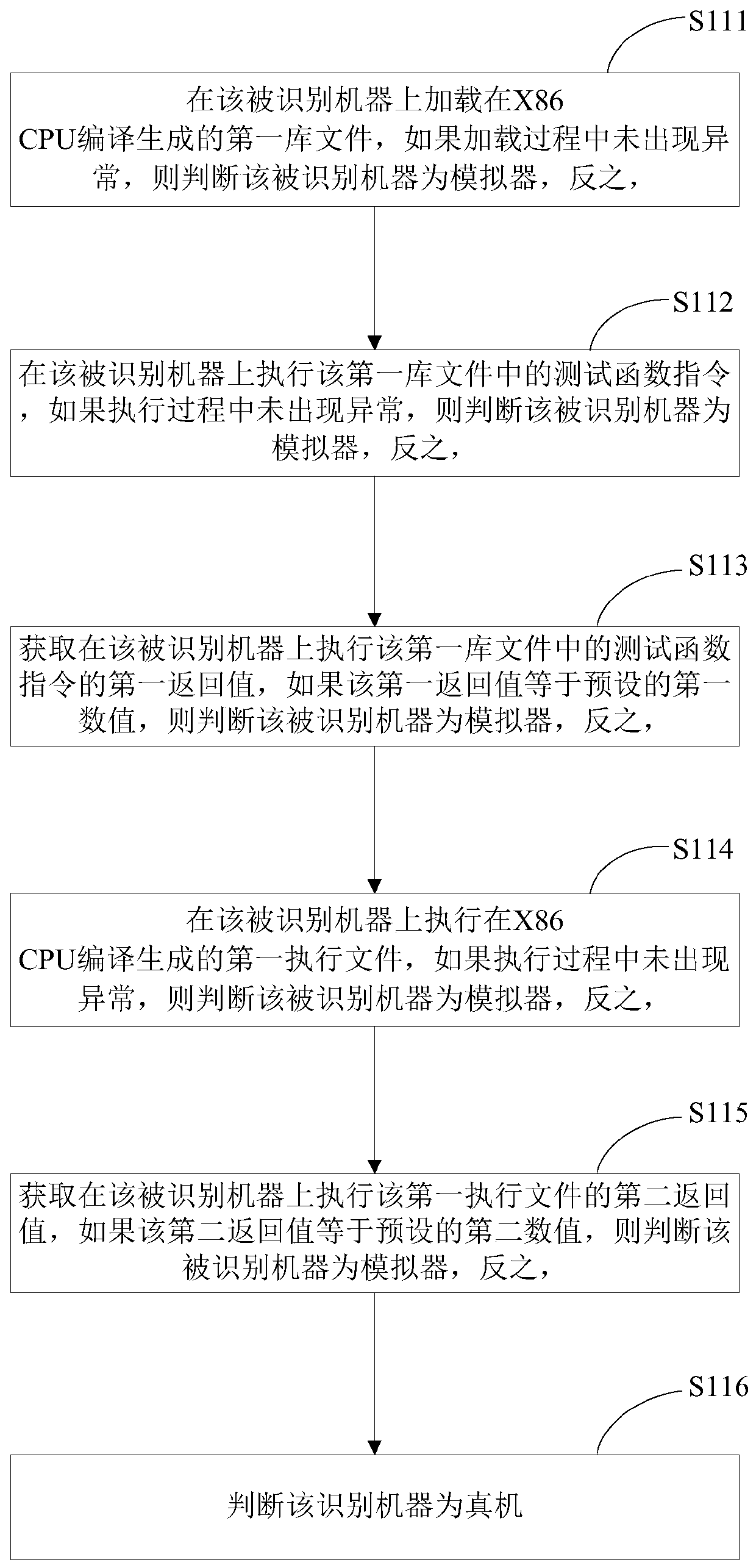

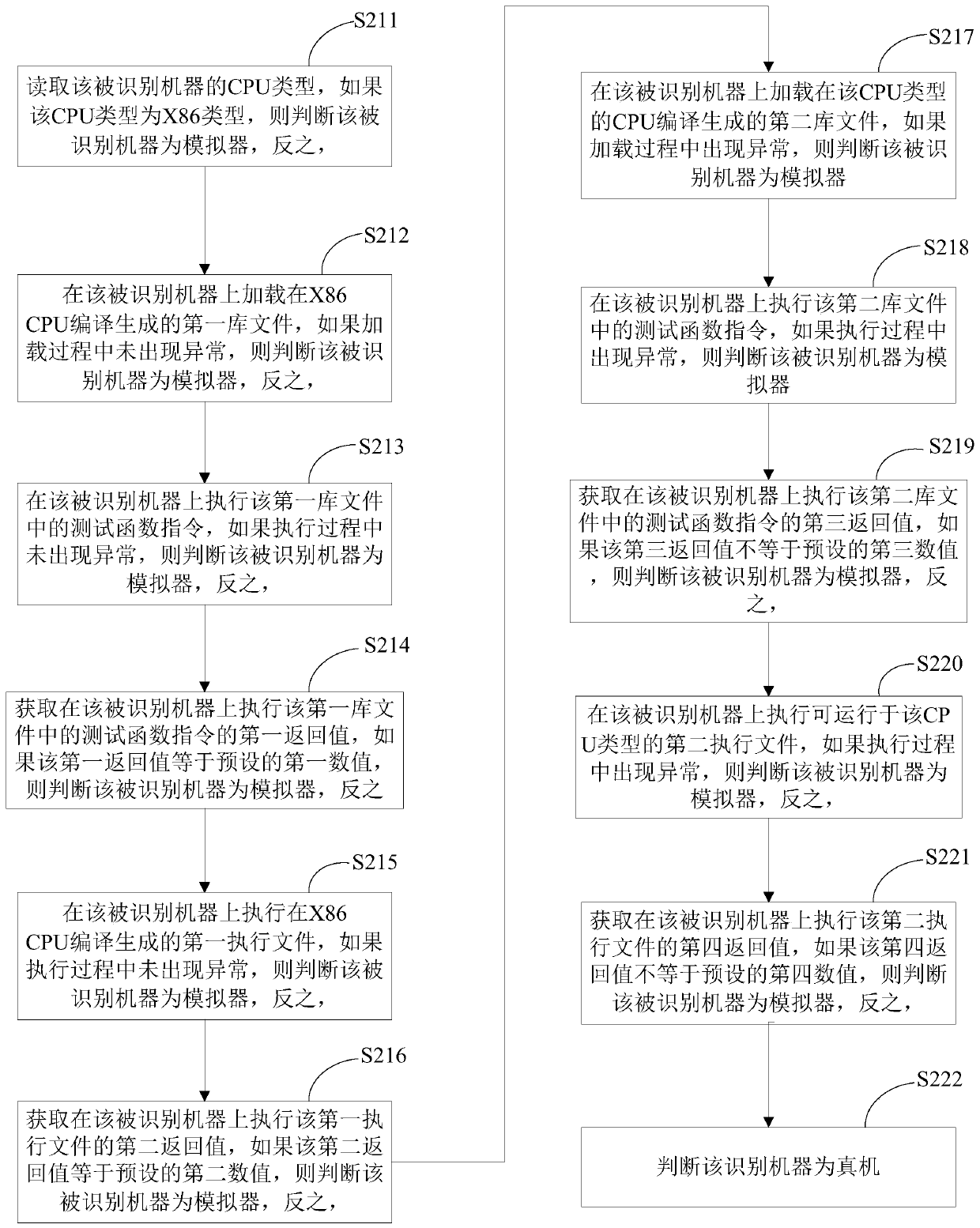

Method and device for identifying Android real machine and simulator and storage medium

ActiveCN111367752AOvercome misjudgmentImprove reliabilityHardware monitoringFunctional testingComputer hardwareSimulation

The invention discloses a method and device for identifying an Android real machine and a simulator and a storage medium. The identification method comprises the following steps: executing a specificCPU instruction on an identified machine provided with an Android operating system, setting a specific judgment condition, and if the judgment condition is met, judging the identified machine as a simulator. According to the method and the device, the problem that in the prior art, specific parameters and functions are modified in an operating system and a system bottom layer framework, so that anapplication layer reads false parameters or false function results, and misjudgment of identifying a real machine and a simulator is caused is solved.

Owner:卓望数码技术(深圳)有限公司

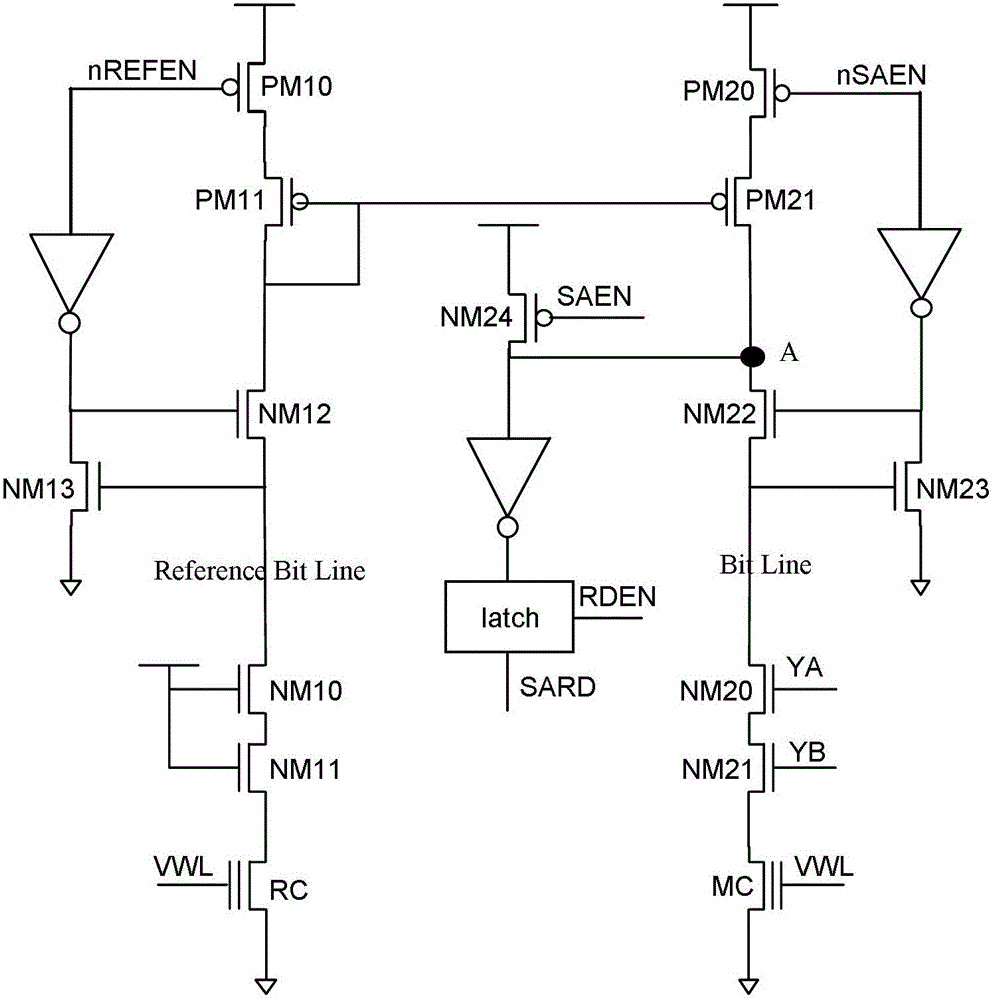

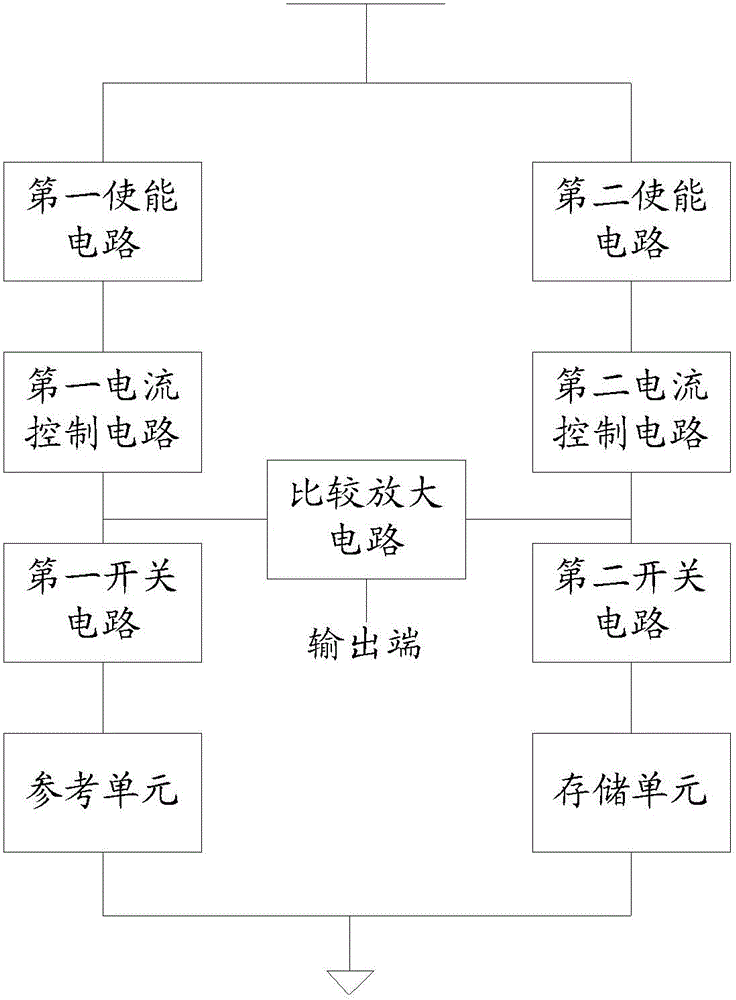

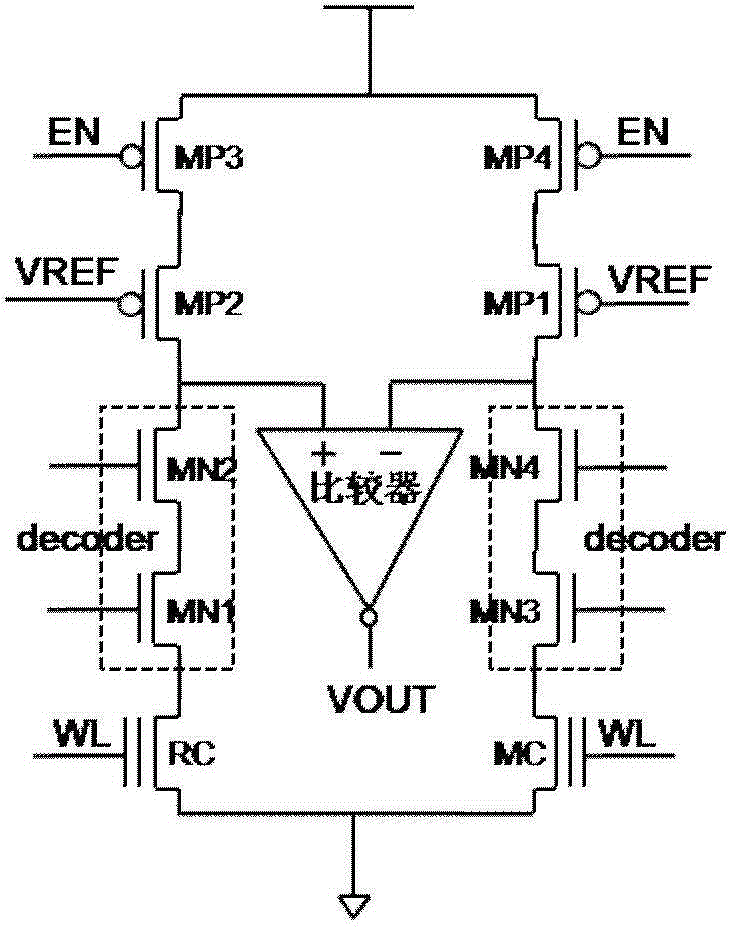

Sensitive Amplifier Circuit

ActiveCN103383857BImprove accuracyOvercome misjudgmentDigital storageAudio power amplifierPower flow

A provided sensitive amplifier circuit comprises a parallel circuit and a comparison amplification circuit; the parallel circuit comprises a first branch circuit and a second branch circuit; the first branch circuit comprises a first enablement circuit, a first current control circuit, a first switch circuit and a reference cell; the second branch circuit comprises a second enablement circuit, a second current control circuit, a second switch circuit and a storage cell; the current controlled by the first current control circuit and the current controlled by the second current control circuit are equal in intensity; and the comparison amplification circuit is used to compare the voltage at the joint of a comparator and the first switch circuit with the voltage at the joint of the comparator and the second switch circuit, wherein the cell corresponding to the joint with a larger voltage is a programmed cell, and the cell corresponding to the joint with a smaller voltage is an erased cell.

Owner:GIGADEVICE SEMICON (BEIJING) INC

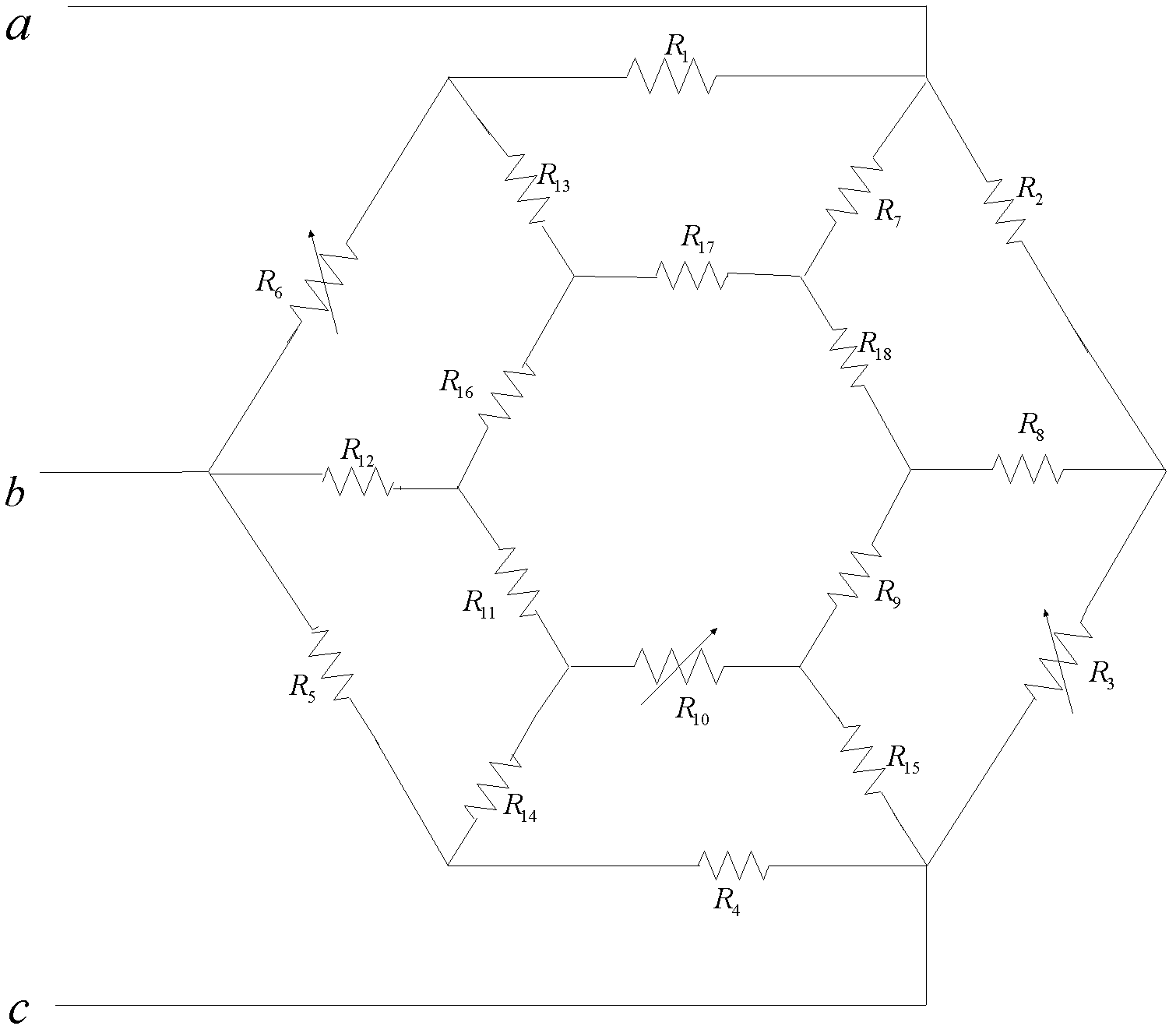

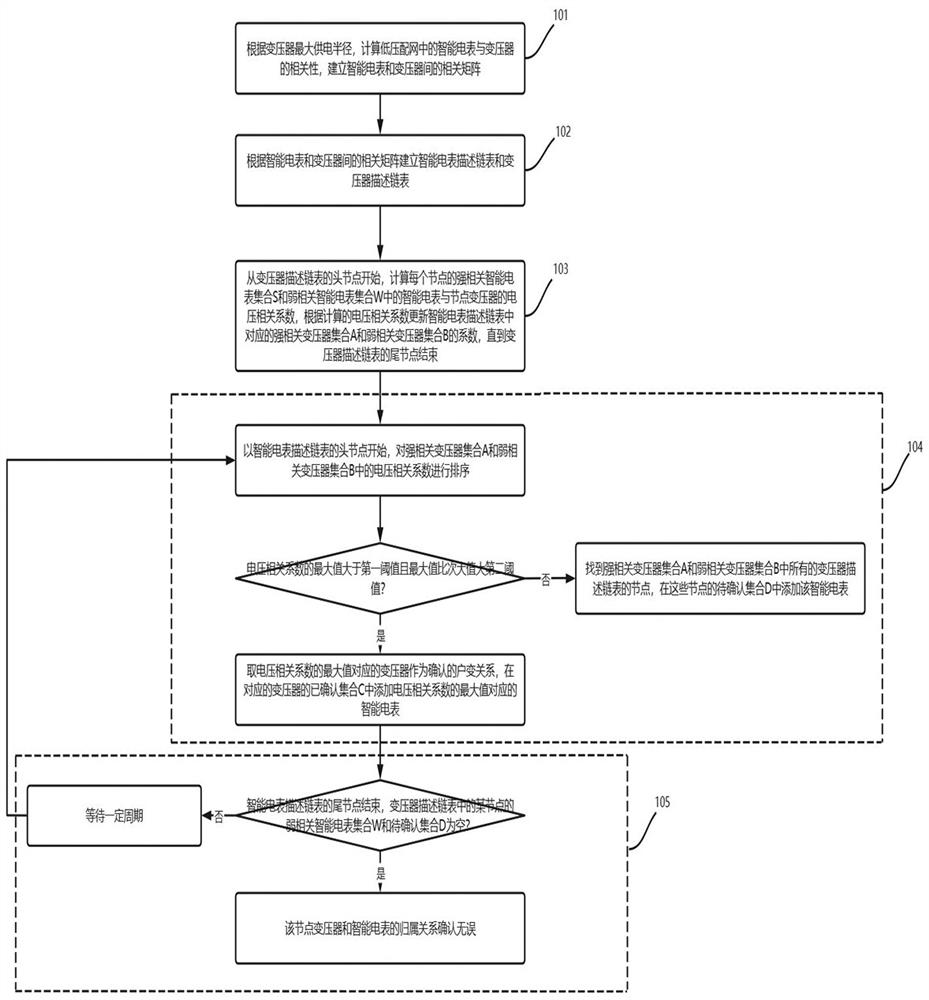

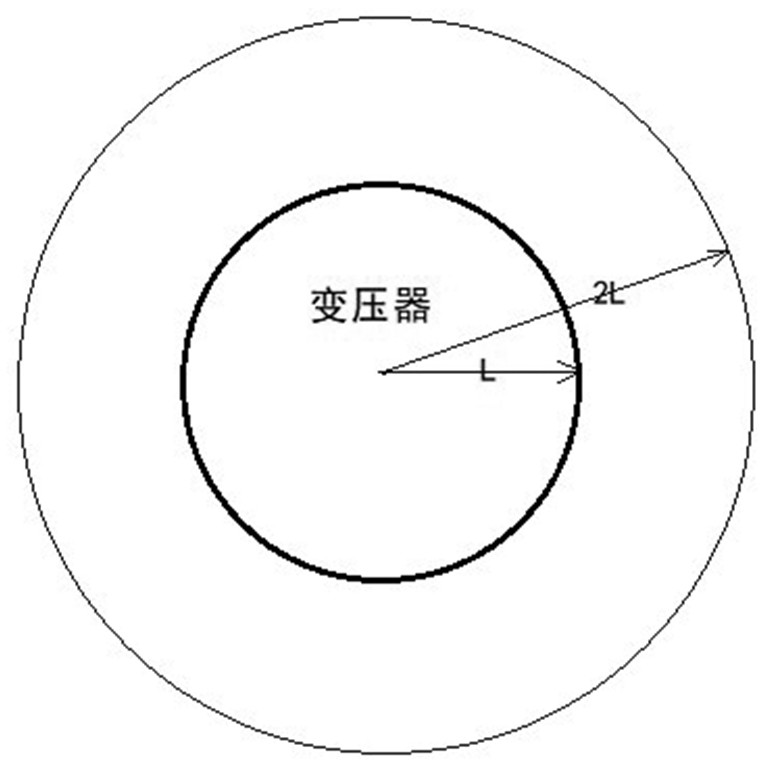

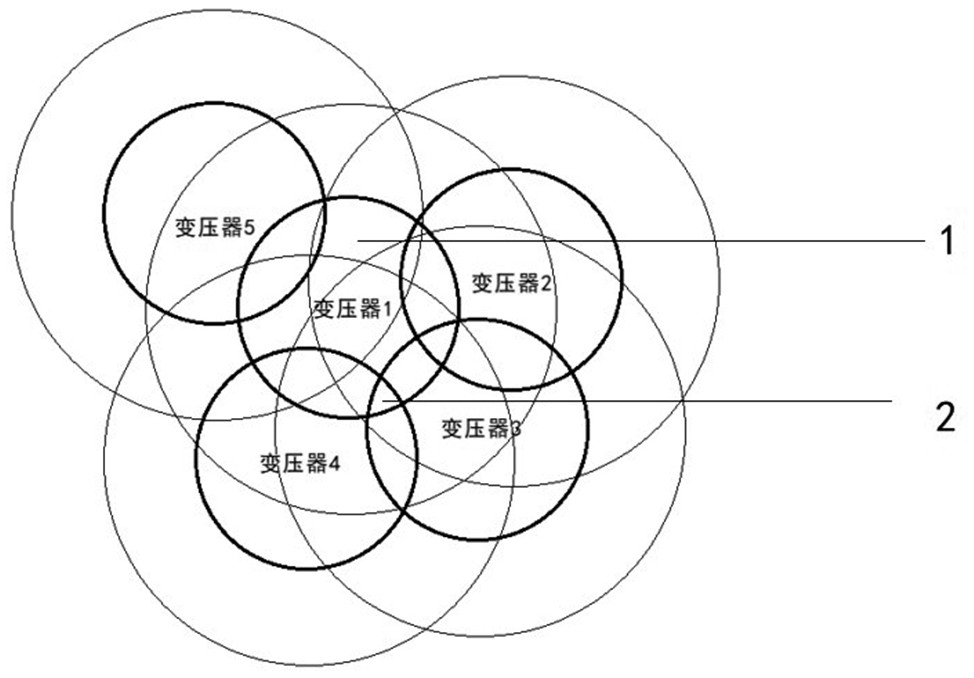

A low-voltage power distribution topology identification method and system

ActiveCN114123201BOvercome misjudgmentReduce construction difficultyComplex mathematical operationsAc network circuit arrangementsTopology identificationLow voltage

The invention discloses a low-voltage distribution topology identification method and system, which relate to the technical field of low-voltage distribution topology identification. The location information of the smart meter is used to delineate the geographical location of the smart meter and the transformer in combination with the maximum power supply radius of the transformer, and the smart meter and the transformer are established. The correlation matrix between transformers, and then establish the smart meter description linked list and the transformer description linked list. The smart meter description linked list describes the smart meter and its related transformer set, including a strong related transformer set and a weak related transformer set. The transformer description linked list describes the transformer and its related The collection of smart meters includes a collection of strongly correlated smart meters and a collection of weakly correlated smart meters. According to the voltage correlation between smart meters and transformers, the household transformer relationship can be determined, which can not only overcome the problem of misjudgment caused by simply using electrical quantity identification, but also does not require additional Adding equipment will not cause interference to the power grid and will not increase the difficulty of construction.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Improved MPPT (Maximum Power Point Tracking) algorithm and LED (Light Emitting Diode) street lamp system based on algorithm

ActiveCN102665314BFast trackAccurate trackingElectric light circuit arrangementEnergy efficient lightingMppt algorithmEngineering

The invention relates to a solar LED (Light Emitting Diode) street lamp system. The invention comprises an improved MPPT (Maximum Power Point Tracking) algorithm and an LED street lamp system based on the algorithm. The improved MPPT algorithm comprises the steps of: step 1: setting a maximum power point tracking starting scope as from Vmin to Vmax according to current environmental temperature T and the open-circuit voltage Voc; step 2: measuring the output voltage and the input current of a solar battery panel; step 3: judging whether VPN meets the condition that Vmin is smaller than or equal to VPN which is smaller than or equal to Vmax or not, if so, starting to search for the maximum power point from the midpoint from the Vmax to Vmin; step 4: judging whether the VPN is located in the maximum power point or not in a shorter period of time; step 5: judging whether the VPN is located in the maximum power point or not in a longer period of time, if so, calculating the reference voltage of a PI controller and making the system operate at the maximum power point stably by performing PI adjustment for Vset and VPN, or continuously searching for the maximum power point; and step 6: inquiring whether the VPN is located at the maximum power point or not for a long period of time, if not, returning to the step 2 to continuously track the maximum power point.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

A kind of solar power generation system control method

InactiveCN102638195BImprove utilization efficiencyImprove uninterrupted power supply timeBatteries circuit arrangementsPhotovoltaicsPerturbation and observationAlternating current

A solar power generation system control device and method. The device includes a power generation module, an inverter module, a main control module and a debugging module; the power generation module includes a solar generator set, a maximum power tracking control circuit and a battery pack; the inverter module includes an inverter, Simulate DC load and simulate AC load; the main control module includes DSP processor, maximum power tracking controller, battery controller, acquisition device and signal modulation circuit; the debugging module includes ARM7 processor, solar panel angle regulator and battery detection device . By monitoring the operating status of multiple sets of working parameters in real time, it is ensured that the power utilization rate is the highest while the load is working normally, and the stability of the system operation is improved. The variable step size perturbation observation method is used for maximum power tracking to ensure the actual effect of MPPT. Calculate the battery capacity and uninterrupted power supply time by combining the longest continuous rainy days, ambient temperature, and usage time to extend the battery life.

Owner:NORTHEASTERN UNIV LIAONING

Bearing abnormal sound detection control method and bearing vibration measuring instrument

ActiveCN102243143BOvercome misjudgmentSubsonic/sonic/ultrasonic wave measurementMachine bearings testingSound detectionAbnormal voice

The invention discloses a bearing abnormal sound detection control method, comprising the following steps of: (1) determining an abnormal sound detection parameter F = f (PK i, RMS i), and setting F standard values corresponding to the abnormal sound of different degrees, wherein f (PK i, RMS i) refers to a function using the PK i and the RMS i as variables, the PK i is a bearing vibration characteristic parameter peak value, and the RMS i is a bearing vibration characteristic parameter effective value; (2) actually measuring the current vibration of the bearing, and obtaining a current bearing vibration characteristic parameter peak value PK and a current bearing vibration characteristic effective value RMS through the actual measurement; (3) calculating a current abnormal sound detection parameter F according to the current bearing vibration characteristic parameter peak value PK and the current bearing vibration characteristic effective value RMS; and (4) comparing the current abnormal sound detection parameter F with the F standard value to confirm whether the bearing is in abnormal state and confirm the abnormal degree of the sound. The method and the instrument provided by the invention solve the defect of mistake and omission in determination on the bearing abnormal sound caused by using the peak value for detection control in the current bearing vibration measuring instrument, and have very important significance in the filed of detection control of bearing abnormal sound.

Owner:SHANGHAI F&S BEARING TECH

Beam scintillation spatio-temporal evolution monitoring device for ion electric thruster

ActiveCN114428264AWith precise positioningPositionedX/gamma/cosmic radiation measurmentEngineeringMechanical engineering

The invention discloses a beam flicker spatio-temporal evolution monitoring device of an ion electric thruster. The device comprises a vacuum chamber, a first support structure for fixing a thruster on the vacuum chamber, an ion thruster, a shell of the thruster, a screen gate electrode, an acceleration gate electrode, a deceleration gate electrode, a lead for connecting the electrodes, a signal line and a flange which are arranged on the wall of the vacuum chamber and are used for transmitting diagnosis information, and a monitoring device for loop volt-ampere characteristic measurement, the high-speed camera array is used for monitoring time-space characteristics of beam flicker; and the second supporting structure is used for fixing and mounting cameras. According to the invention, the problems of precise positioning and time evolution characteristic tracking of the beam flicker space position of the ion electric thruster in a closed and high-vacuum environment are solved, and the problem that the beam flicker generation position and flicker type identification are difficult to determine only by monitoring the volt-ampere characteristics of a loop in the prior art is solved. And secondly, the device can comprehensively monitor the spatial characteristics and the time evolution characteristics of beam flicker.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

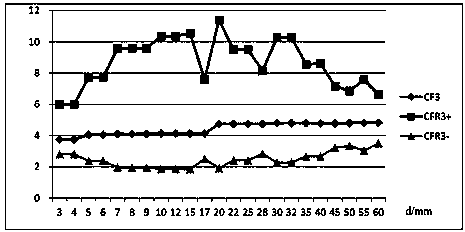

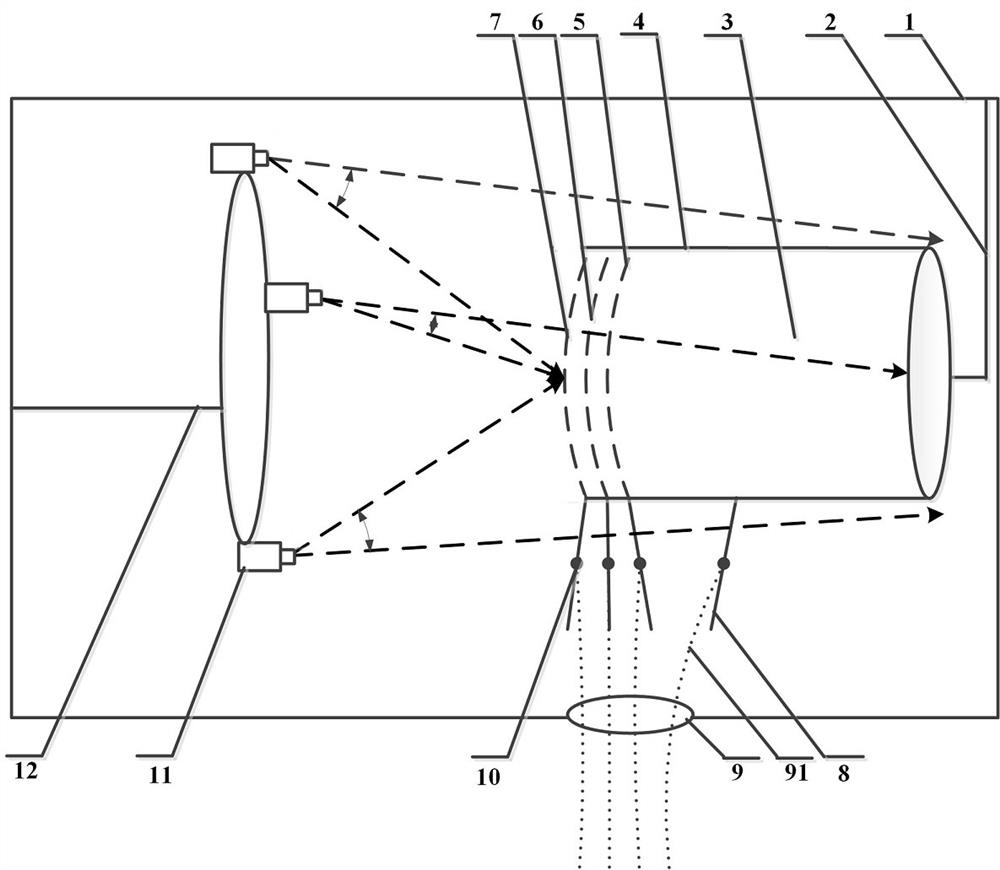

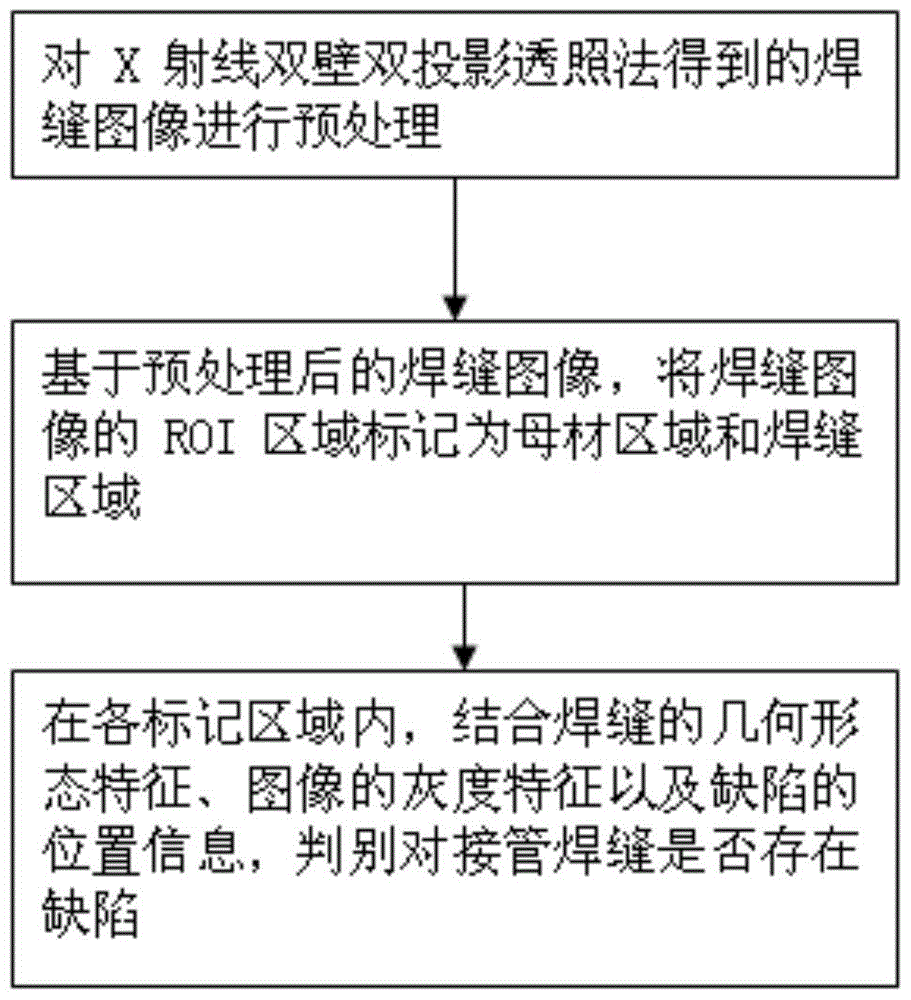

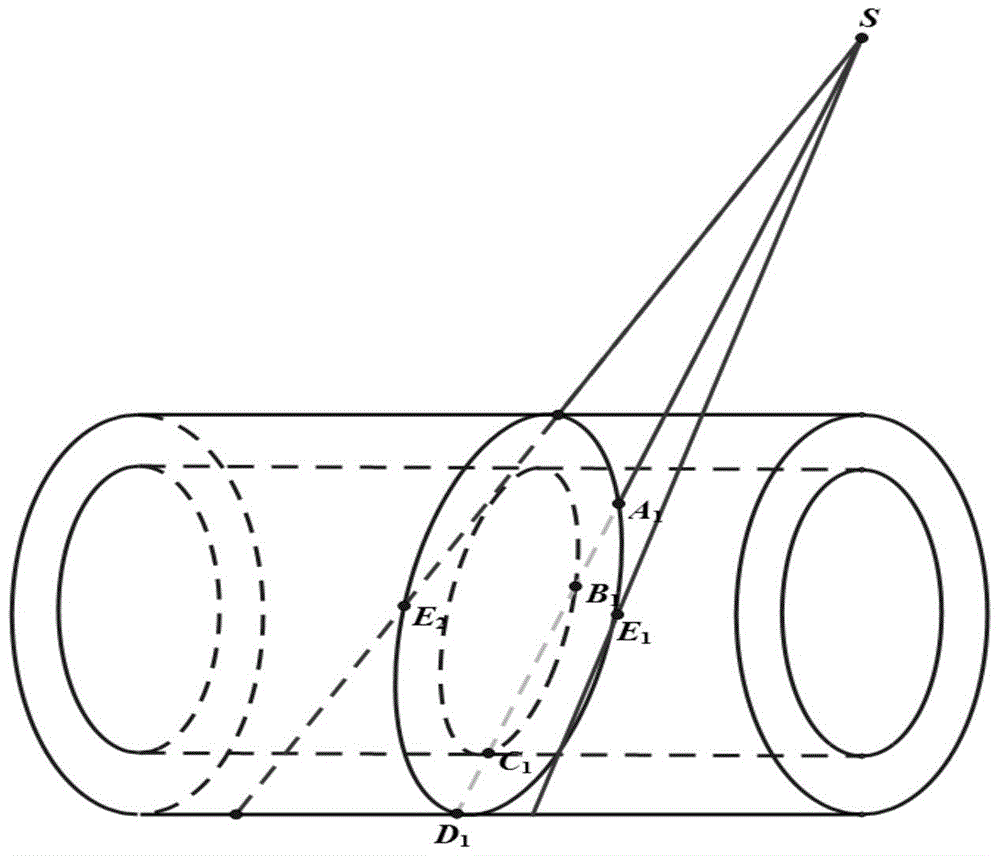

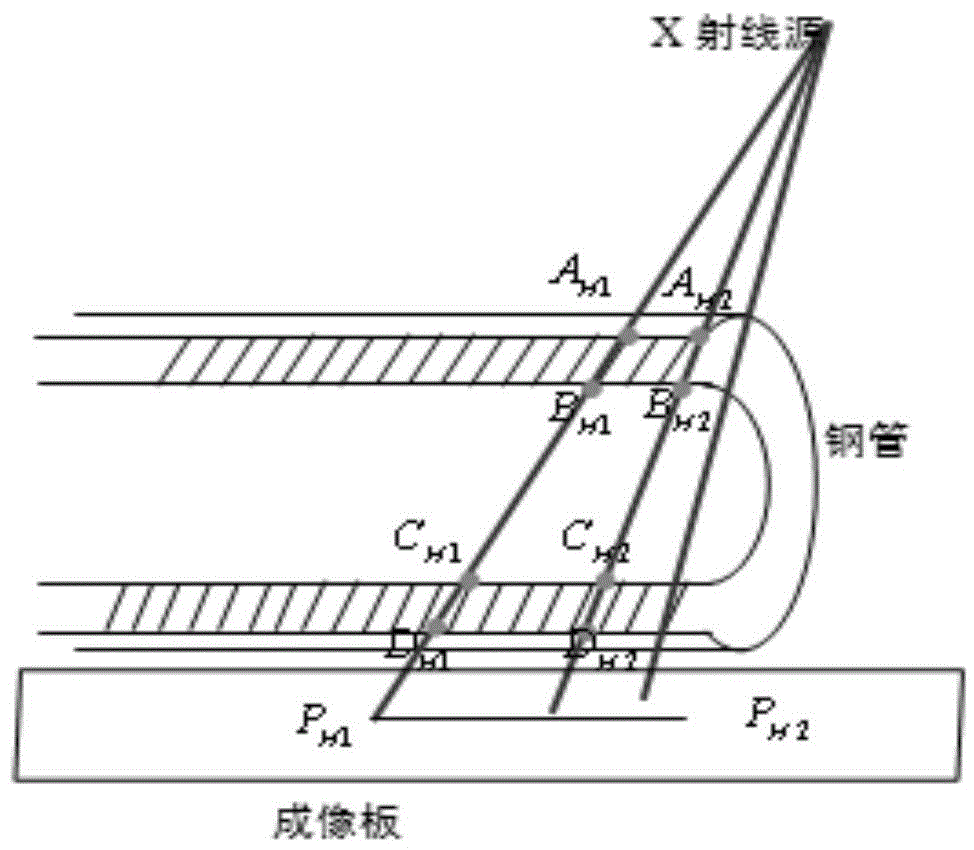

Method for automatic identification of pipe weld defects based on double-wall and double-projection transillumination images

InactiveCN104865277BImprove work efficiencyOvercome misjudgmentImage analysisCharacter and pattern recognitionImaging processingButt joint

The invention relates to the image processing techniques, and discloses a method for automatically identifying a pipe weld defect based on a double-wall double-projection transillumination image so as to accurately extract a circumferential weld zone of a butt joint pipe and realize an accurate judgment of whether a butt welded seam has a defect. The method comprises the following steps: A. carrying out pretreatment to a weld joint image obtained by an X-ray double-wall double-projection transillumination method; B. based on the weld joint image subjected to the pretreatment, marking the ROI zone of the weld joint image as a base metal zone and a weld joint zone; and C. in each marking zone, in combination with the geometrical morphology characteristics of the weld joint, the gray characteristics of the image and the position information of the defect, judging whether the weld joint of the butt joint pipe has an defect. The method for automatically identifying the pipe weld defect based on the double-wall double-projection transillumination image is suitable for defect detection of the weld joint of the butt joint pipe.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com