Bearing abnormal sound detection control method and bearing vibration measuring instrument

A bearing vibration, detection and control technology, applied in mechanical bearing testing, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as misjudgment and missed judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

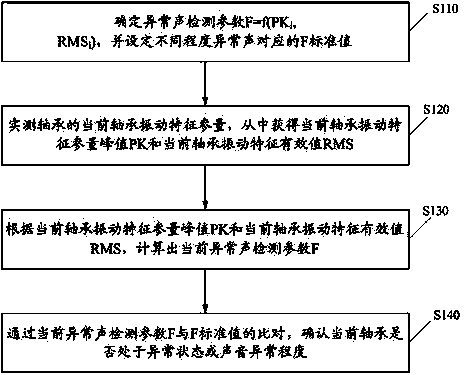

[0050] see figure 1 , which is a flow chart of a method for detecting and controlling abnormal bearing noise of the present invention. It includes the following steps:

[0051] S110: determine the abnormal sound detection parameter F=f(PK i , RMS i ), and set F standard values corresponding to different degrees of abnormal sound, where f(PK i , RMS i ) means PK i , RMS i As a function of variables, PK i is the peak value of the characteristic parameter of bearing vibration, RMS i is the effective value of the characteristic parameter of bearing vibration.

[0052] Applicants have found that it is very inaccurate to judge the sound condition of a bearing considering only peaks. For this reason, the applicant has found out that when judging the current state of the bearing sound, if the peak value of the current characteristic parameter of bearing vibration and the effective value of the characteristic parameter of bearing vibration can be considered at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com