Method for automatic identification of pipe weld defects based on double-wall and double-projection transillumination images

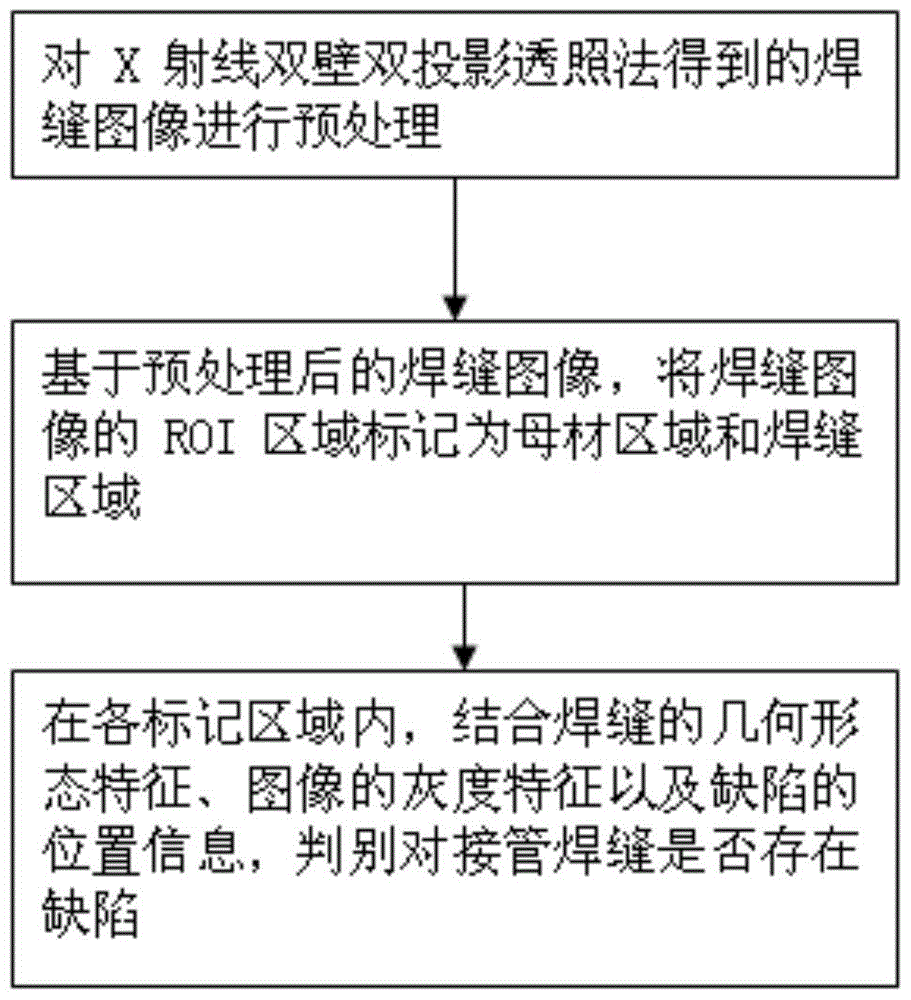

A double-wall, double-projection, automatic identification technology, applied in the field of image processing, can solve problems such as the deviation of the circular weld area from the actual value, the large error of the judgment result, and the complexity of the judgment method, so as to overcome the differences in technical quality and experience, improve The effect of work efficiency and objectivity of evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] In order to prove the feasibility of the scheme of the present invention, in this example, 20,000 images of butt pipe welds on the actual production line are used as detection and judgment objects. These 20,000 images of butt pipe welds contain normal samples and various common defects.

[0094] In this example, the above-mentioned 20,000 weld images are processed as follows:

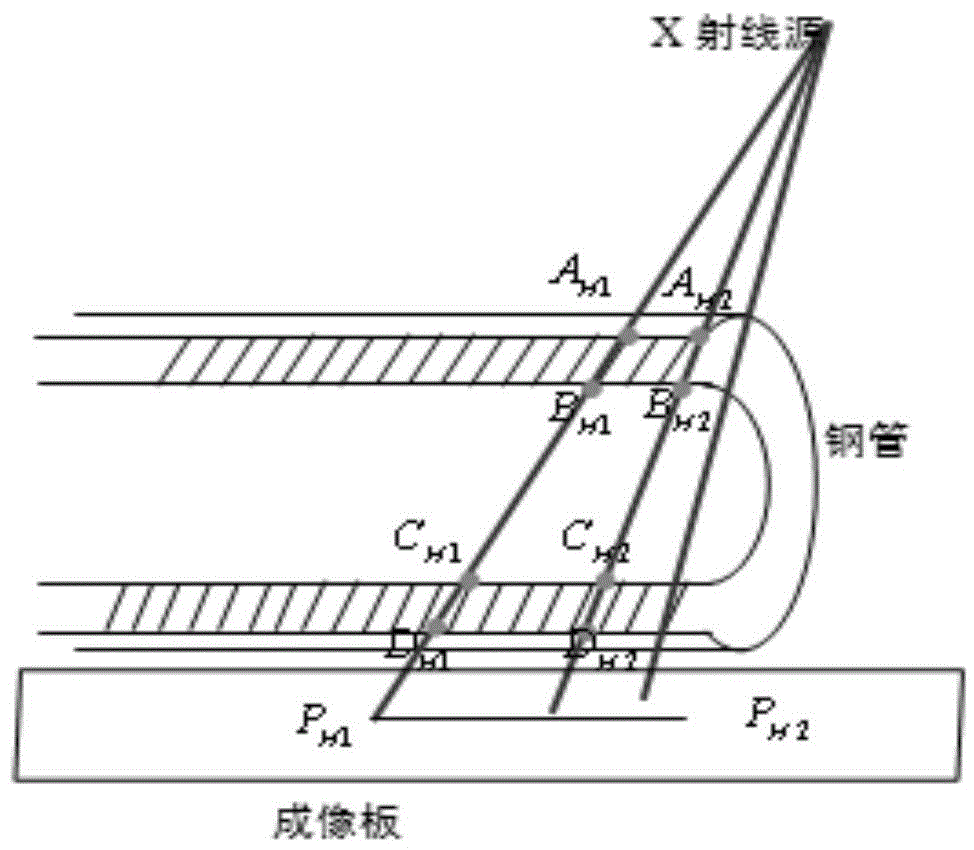

[0095] 1) Rotation correction:

[0096] In order to accurately determine the inclination angle of the steel pipe, a point is selected from the upper and lower regions of the image. In the experiment, the coordinates of two points A and B in the image are:

[0097] A(x 1 =0.5×width,y 1 =0.1×height),

[0098] B(x 2 =0.5×width,y 2 =0.9×height);

[0099] Where width is the width of the image and height is the height of the image.

[0100] The slope obtained by calculating the minimum variance of the pixels passed by the straight line beam indicates the degree of inclination of the steel pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com