PCB flatness measuring method and measuring device

A measurement method and flatness technology, applied in the field of PCB flatness measurement methods and measurement devices, can solve the problems of fuzzy qualitative judgment, missed judgment, and high efficiency of manual measurement, so as to improve the measurement accuracy and overcome misjudgment or missed judgment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

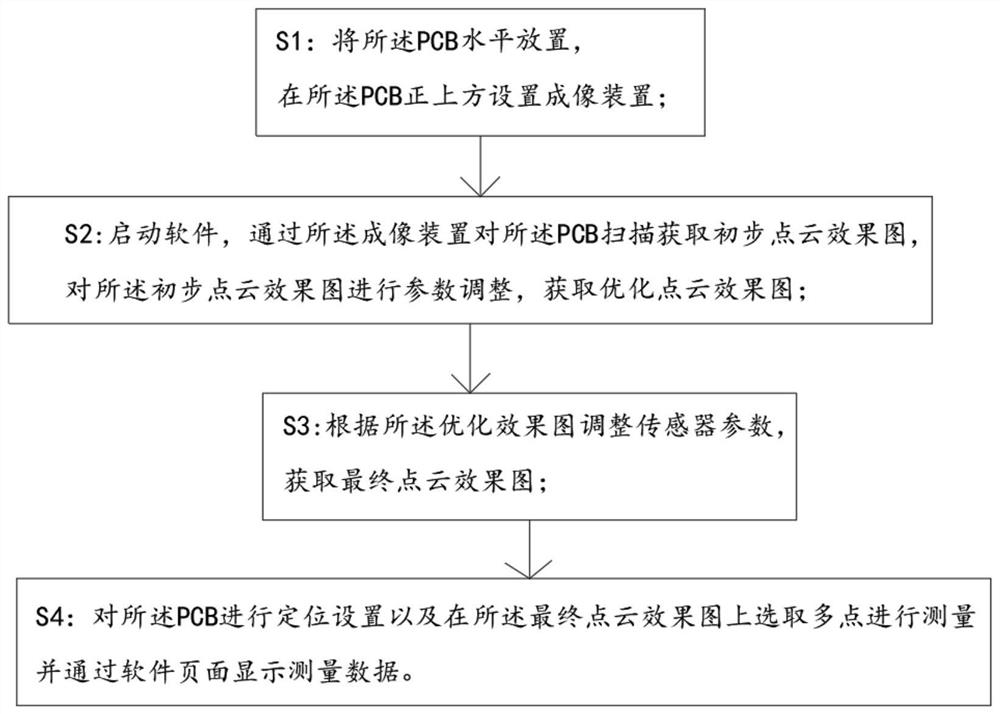

[0046] A method for measuring PCB flatness, comprising the following steps:

[0047] The following steps are described in combination with software operation.

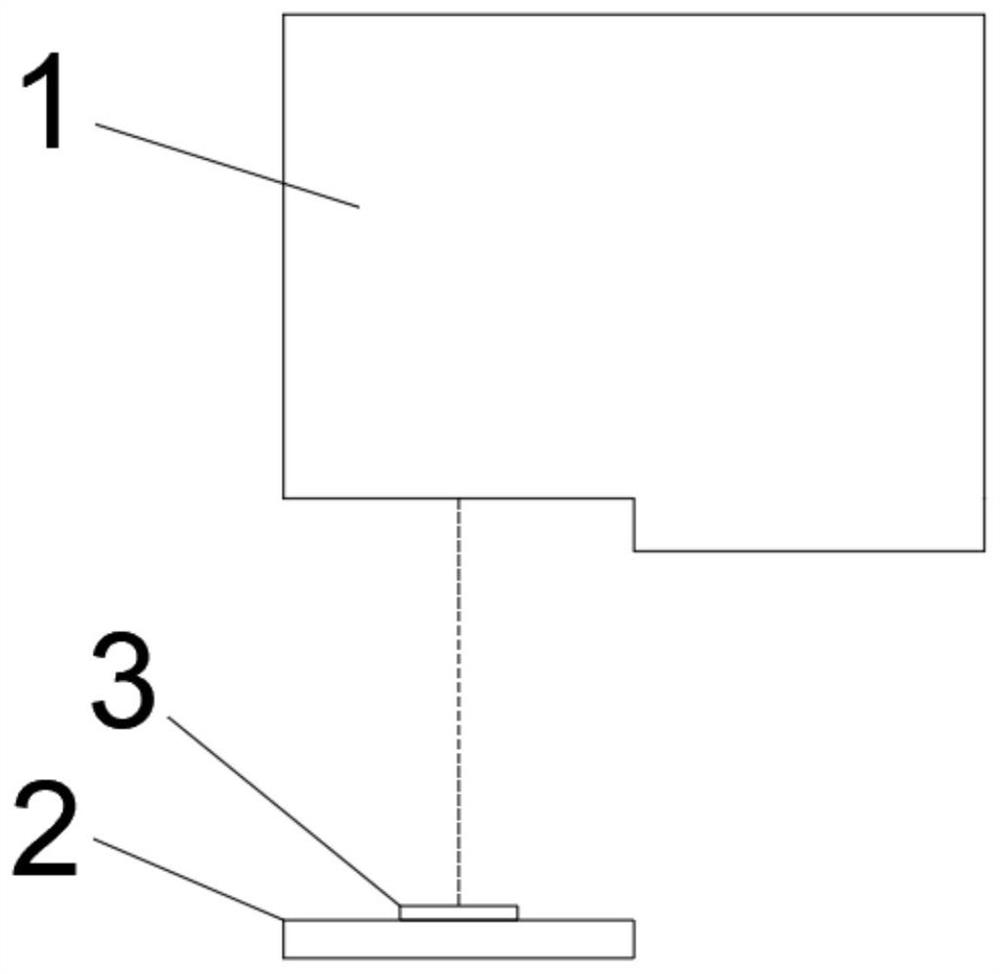

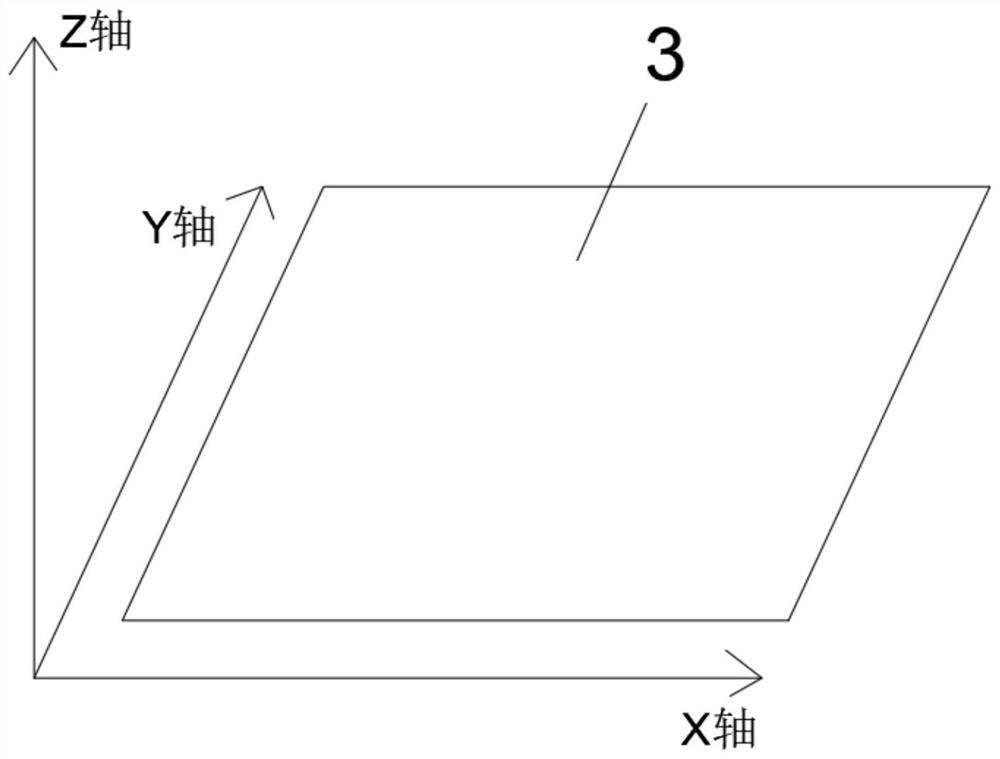

[0048] Such as figure 1 As shown, the first step is to place the PCB-3 horizontally, and set the imaging device directly above the PCB-3. The imaging device is located at 140mm±10mm directly above the PCB-3, and the optimal height distance is 140mm. The distance between the bottom and the surface of PCB-3, the imaging device is 3D camera-1.

[0049]The second step is to start the software and scan the PCB-3 through the imaging device to obtain the preliminary point cloud rendering. The specific operation is to operate the measurement software, click Settings, switch to the setting interface, open the hardware parameter list, and open the "2D preview function". Use the imaging device to preview the planar image of PCB-3, adjust the position of PCB-3 according to the planar image preview, so that PCB-3 is located in th...

Embodiment 2

[0069] A measuring device includes: a placing platform, an imaging device and an industrial computer.

[0070] Placement platform-2: for placing the PCB-3 horizontally and fixing the imaging device directly above the PCB-3;

[0071] Imaging device: used to scan the PCB-3 and provide scanning images for the measurement software; the imaging device is provided with a lifting support, and the lower end of the lifting support is installed around the placement platform-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com