Deep learning-based tire defect intelligent detection method

A deep learning and intelligent detection technology, applied in image data processing, instruments, calculations, etc., can solve the problems of recognition efficiency and accuracy not meeting production requirements, unsatisfactory detection results, and easy formation of occupational diseases, etc., to reduce the probability of tire defects , save labor costs, good detection ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] For the system equipment acquisition scheme, see figure 1

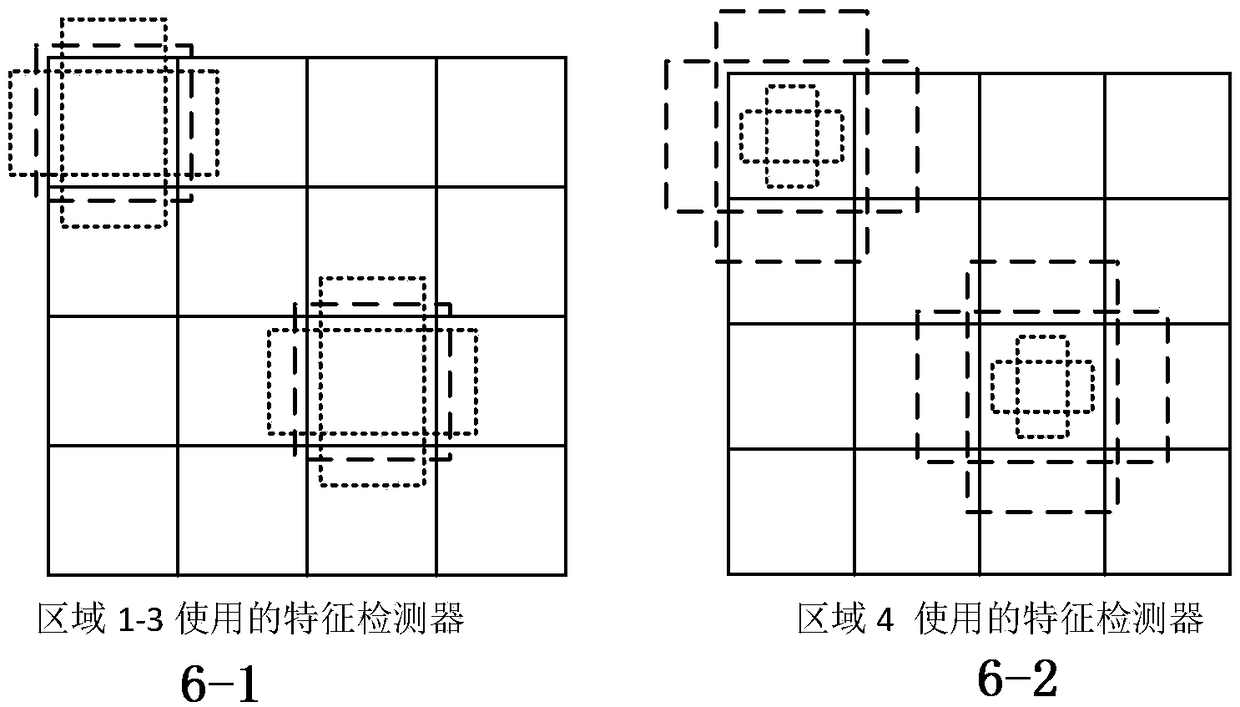

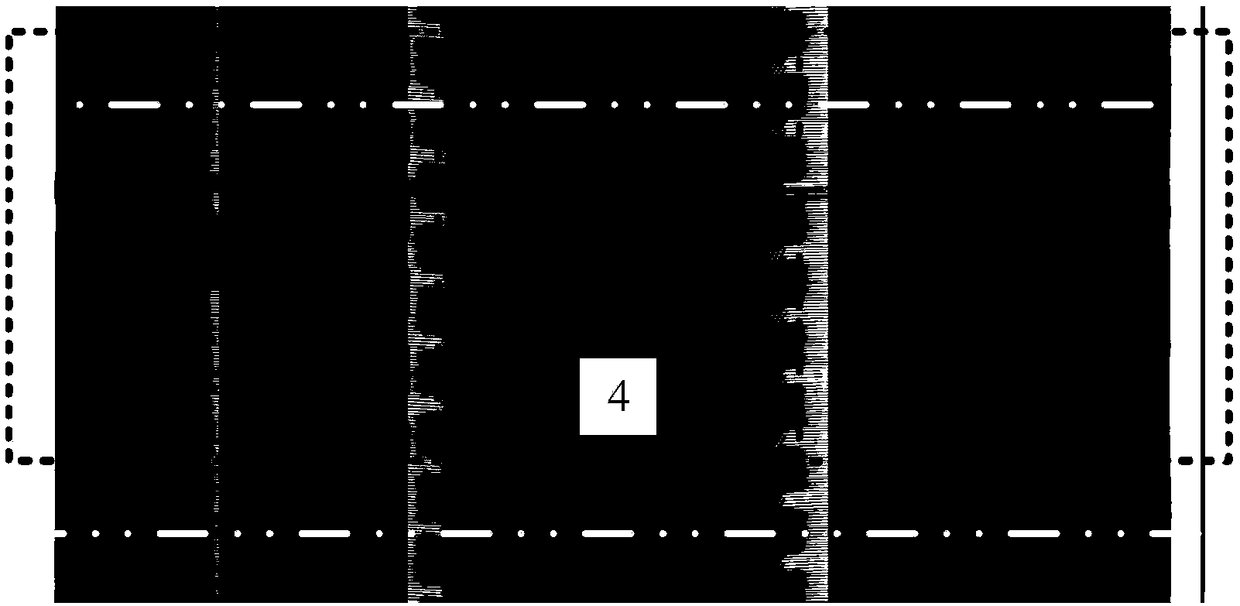

[0066] The identification system transforms the original X-ray, and divides the original video into two channels through the video distributor, one for the operator to monitor and use, and the other for the identification system, and the identification system collects the video into the management server through a high-speed acquisition card, After the management server stitches the images together, it generates a complete image of the tire, and then divides the image into left, middle and right regions according to the crown, sidewall and other regions. Each region has a side length of 0.4×b w (X-ray image width) square, and press b w ×0.4b w The intercepted overall situation forms four recognition regions. After division by area, the divided data is sent to the computing unit group, identified by the identification algorithm and the identification result is sent back to the management server. Each tire de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com