Measuring method for vibration state of antifriction bearing

A bearing vibration and rolling bearing technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as abnormal fluctuations of bearing vibration, misjudgment, etc., and achieve accurate measurement results and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

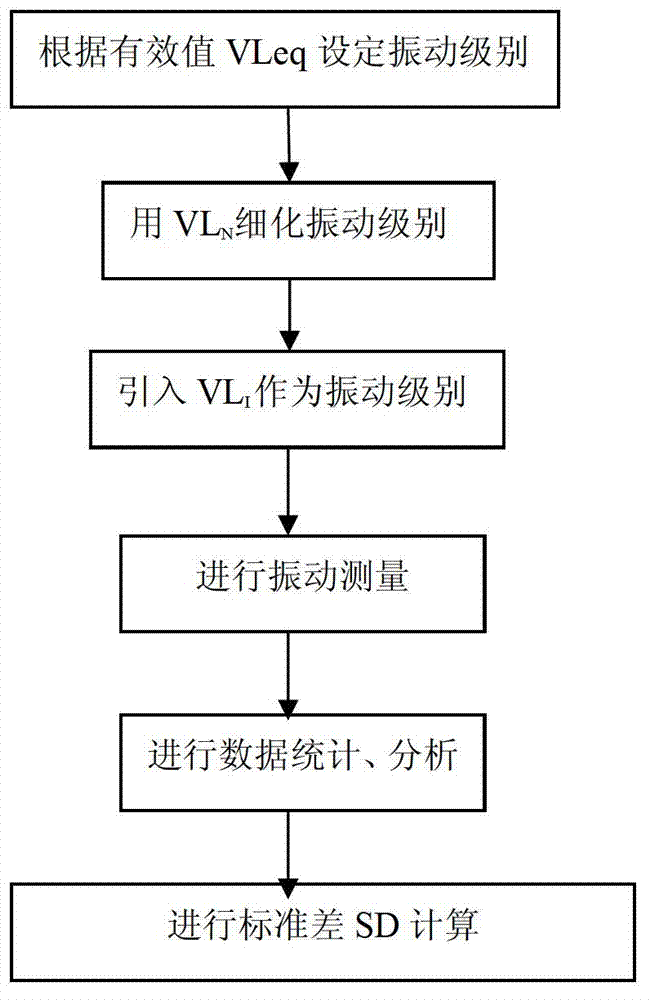

[0021] The concrete processing steps of the present embodiment are as follows:

[0022] (1) Select a commercially available bearing vibration measuring instrument, and first calculate the effective value of bearing vibration VL according to the different requirements for bearing quietness eq The different vibration levels of ZV1, ZV2, ZV3 and ZV4 are set in advance; according to the human perception of noise, the noise level of the bearing is determined, and then the allowable level of bearing vibration is finally determined according to the noise requirements of the bearing; For vibration measurement, to judge the magnitude of vibration in a period, VL eq is the most commonly used and effective value, so in the bearing vibration measurement, VL is introduced according to the current measurement and evaluation methods in the field of vibration measurement. eq As a basic parameter for bearing vibration evaluation; VL eq Setting of values or referring to values set by curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com