Method for preventing longitudinal ship mooring rope from fracturing when dock gate of ship lift opens

A technology for ship lifts and lying doors, applied in vertical lifting of ship machinery, ship lifting devices, force/torque/power measuring instruments, etc., can solve problems such as complex measurement and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

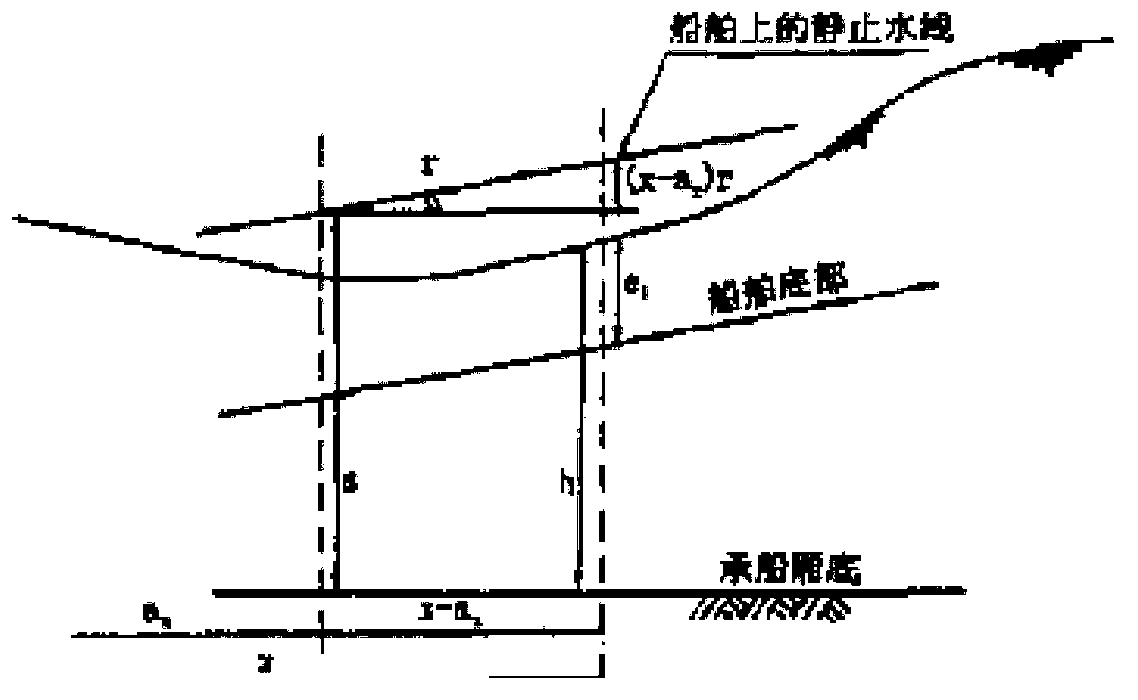

[0071] In a certain area, the effective water area size of a certain ship lift compartment is 59.0m×12m×2.5m (length×width×water depth), the design water depth of the ship-bearing compartment is 2.5m, and the allowable overload and underload ±0.2m. Constructed according to the 500-ton ship type standard, the ship size (total length×width×draft) is 55m×10.8m×1.6m, the midship section coefficient is 0.907, and the displacement is 637.27m 3 .

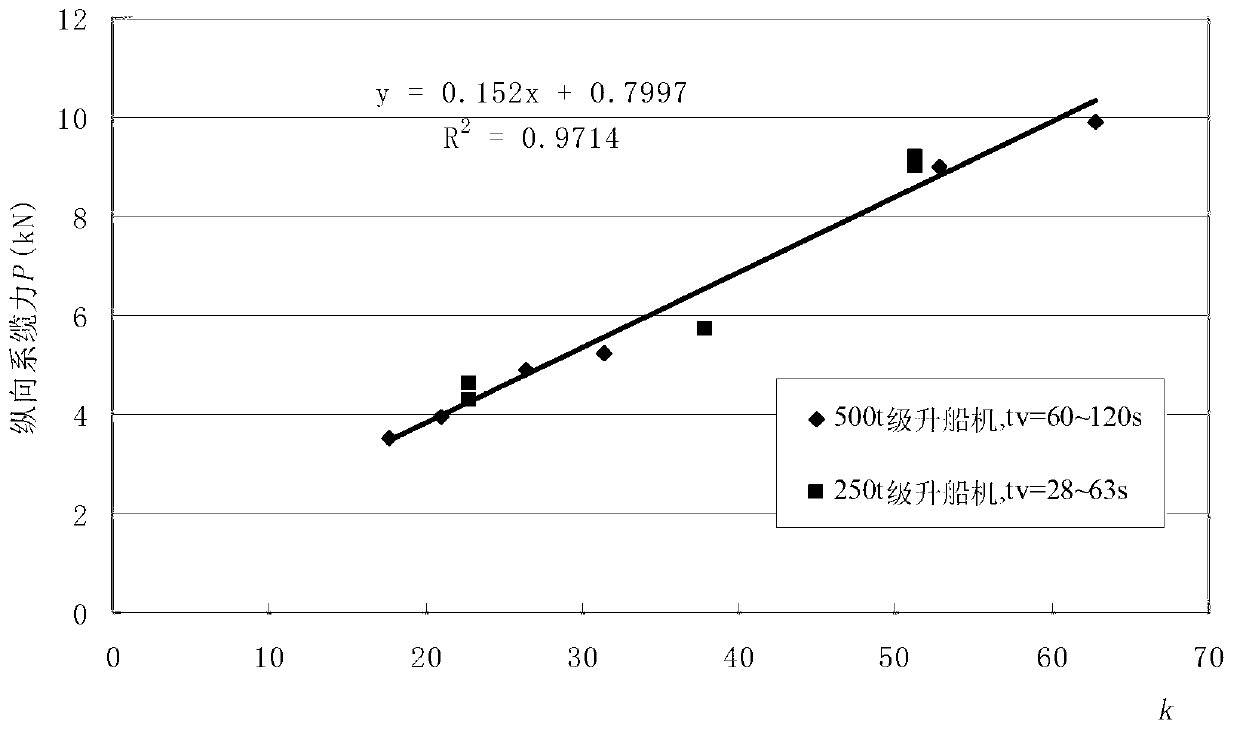

[0072] According to the above engineering data, use the following formula (3) to calculate the maximum longitudinal mooring force on the berthed ship in the cabin when the water depth of the cabin is 2.5m and 2.3m respectively, when the recumbent door is opened under flat water conditions. And a physical model was made to measure the maximum longitudinal mooring force of the ship when the recumbent door was opened and closed. The calculation results and the measured values of the physical model are shown in Table 1.

[0073] When △h≥0: ...

Embodiment 2

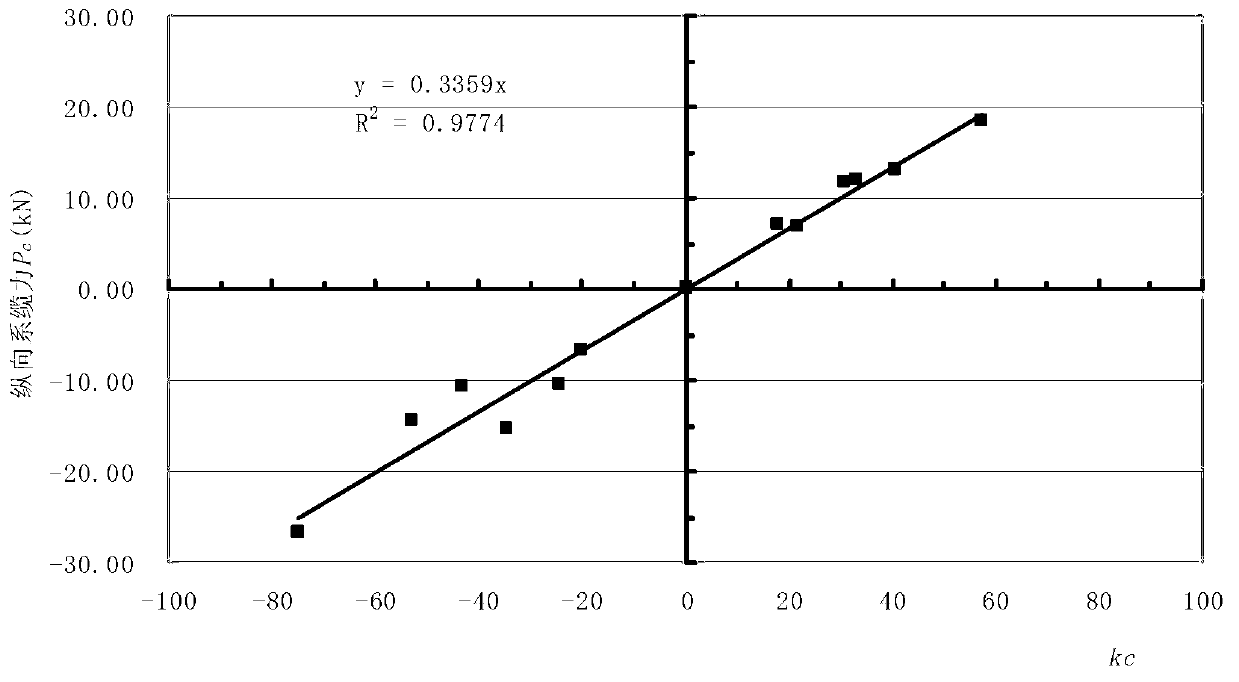

[0079] According to the data of embodiment one, when using formula (3) and (4) to calculate the water depth of the ship compartment to be 2.5m, the water level difference inside and outside the ship compartment is respectively 0.1, 0.2, -0.1, -0.2m when the recumbent door is opened. Subject to maximum longitudinal mooring force. The calculation results of formulas ⑶ and ⑷ and the measured values of the physical model are shown in Table 2.

[0080] When △h≥0:

[0081] P z = 0.334 WΔhb A k - A m gh t v + 0.152 Wbh 2 ( A k - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com