Hydraulic automatic flushing system

An automatic flushing and hydraulic technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of power consumption, false triggering, waste of water resources, etc., and achieve good social and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

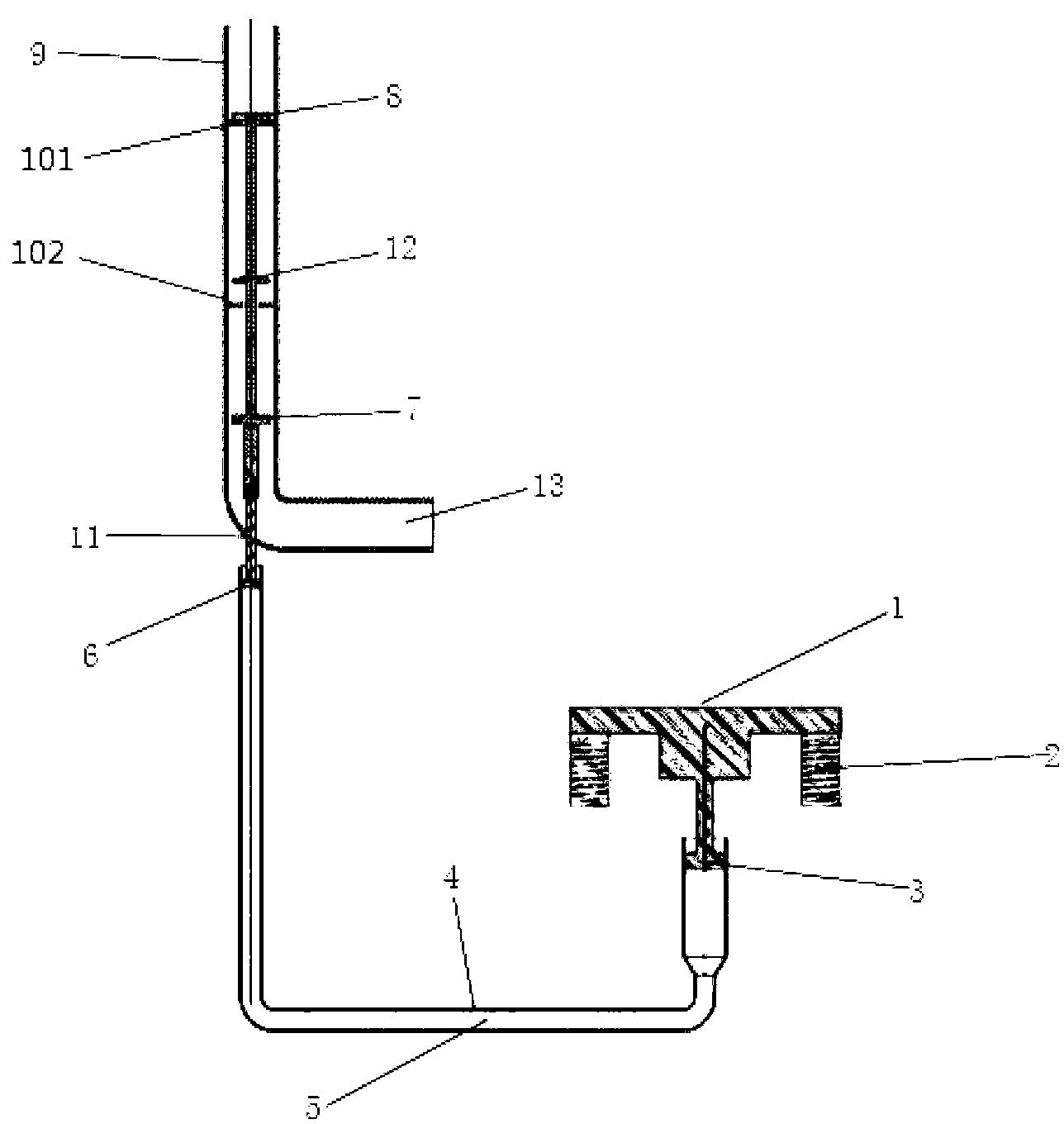

[0015] Such as figure 1 As shown, the present embodiment invention includes a pedal 1, a spring 2 arranged on the ground and installed on the lower surface of the pedal, a hydraulic cylinder and a water storage device. The water storage device includes a water pipe 9, and an upper throttle valve 8, an upper throttle plate 101, a drain piston 12, a lower throttle plate 102, and a lower throttle valve 7 arranged sequentially in the water pipe 9 along the flow direction. , wherein, the lower throttle valve 7, the drain piston 12 and the upper throttle valve 8 are rigidly connected through connecting rods, and can move up and down as a whole, and the upper throttle plate 101 and the lower throttle plate 102 are rigidly fixed in the water pipe 9 at intervals; The hydraulic cylinder includes a U-shaped tube connector 4, hydraulic oil 5 filled in the U-shaped tube connector, and a first hydraulic cylinder piston 3 installed on the pedal 1 side of the U-shaped tube connector 4 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com