Device for adjusting fluid distribution in pipeline and method thereof

A pipeline, gas-liquid distribution technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of unfavorable fluid transportation, large pressure drop, etc., and achieve the effect of good rectification effect, reduced loss, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

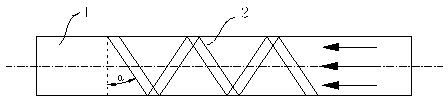

[0020] Such as figure 1 As shown, the spiral plate is installed in the horizontal pipeline to adjust the gas-liquid distribution in the pipeline. Among them, the diameter of the pipe is 882 mm and the length is 2000 mm; the starting point of the spiral plate is located at the lower part of the horizontal pipe where the liquid accumulates; the angle α between the line segment representing the spiral plate and the pipe diameter is 25°; the width W of the spiral plate is 50 mm , the angle θ between the surface where it is located and the tube wall surface is 45°; the spiral plate spirals forward counterclockwise relative to the fluid flow direction, and the number of rotations is 2.5. The experiment was carried out with air and water as the simulated medium, the gas flow rate was 12 m / s, and the mole fraction of water was 8%. When the spiral plate is not installed, the pressure drop between the inlet and outlet of the pipeline is 1060 Pa, and the variation coefficient of liquid ...

Embodiment 2

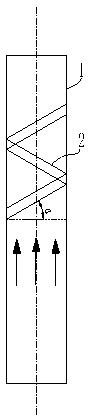

[0022] Such as figure 2 As shown in Fig. 1, a spiral plate is installed in a vertical pipeline to adjust the gas-liquid distribution in the pipeline. Among them, the diameter of the pipe is 882 mm, and the length is 2000 mm; the starting point of the spiral plate is located on the side of the pipe wall where the liquid accumulates; the angle α between the line segment representing the spiral plate and the pipe diameter is 30°; the width W of the spiral plate is 50 mm, the angle θ between the surface where it is located and the pipe wall surface is 60°; the spiral plate spirals forward clockwise relative to the direction of fluid flow, and the number of rotations is 1.5. The experiment was carried out with air and water as the simulated medium, the gas flow rate was 12 m / s, and the mole fraction of water was 8%. When the spiral plate is not installed, the pressure drop between the inlet and outlet of the pipeline is 1140 Pa, and the variation coefficient of liquid content on ...

Embodiment 3

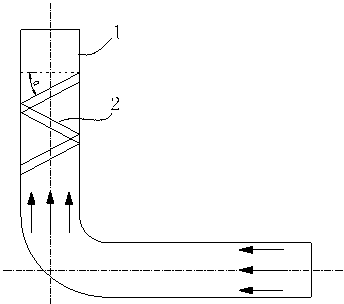

[0024] Such as image 3 As shown, a spiral plate is installed in the vertical pipeline behind the elbow to adjust the gas-liquid distribution in the pipeline. Among them, the diameter of the pipe is 882 mm, the length of the horizontal pipe is 1000 mm, the length of the vertical pipe is 2000 mm, and the elbow is a standard 90° elbow. The starting point of the spiral plate is located outside the vertical pipe where the liquid gathers downstream of the elbow; the angle α between the line segment of the spiral plate and the pipe diameter is 45°; the width W of the spiral plate is 45 mm, and the distance between the surface where it is located and the pipe wall surface The included angle θ is 30°; the spiral plate spirals forward clockwise relative to the fluid flow direction, and the number of rotations is 1.5. The experiment was carried out with air and water as the simulated medium, the gas flow rate was 14 m / s, and the mole fraction of water was 10%. When the spiral plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com