Parallel shaft speed reducer adjustable in center distance

A technology of reducer and center distance, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of expensive reducers and unusable reducers, and achieve simple structure, stable operation, and low impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

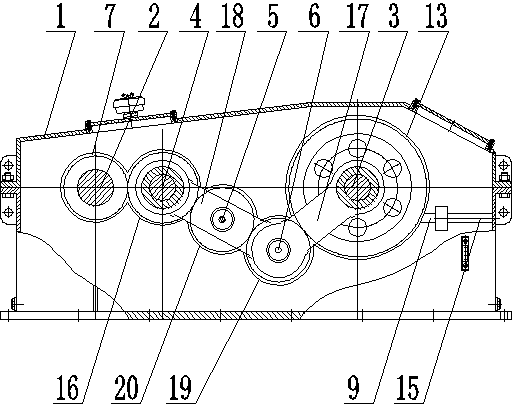

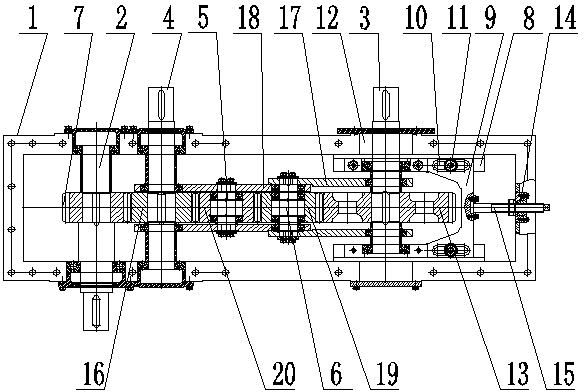

[0012] The parallel shaft reducer with adjustable center distance is composed of a reducer housing 1, an input shaft 2, an output shaft A3, an output shaft B4, a spindle A5 and a spindle B6. One end of the reducer housing 1 is installed with an input shaft 2 through a ball bearing, and the input shaft 2 is equipped with a transmission gear A7. The other end of the reducer housing 1 is symmetrically fixed and fixed with a slide rail 8, and a Bottom plate9. Sliding holes 10 are symmetrically arranged on the bottom plate 9 , and the bottom plate 9 is slidably connected to the slide rail 8 through the sliding holes 10 through fixing bolts 11 . One end of the reducer housing 1 is provided with a screw nut 14 , and a transmission screw 15 is housed in the screw nut 14 , and one end of the transmission screw 15 is movably connected with the base plate 9 .

[0013] The upper surface of the bottom plate 9 is fixed with the output shaft A3 through the ball bearing, and the reducer hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com