A marine boiler safety valve

A technology for marine boilers and safety valves, which is applied in the direction of safety valves, valve details, balance valves, etc., can solve problems such as inability to release pressure in time and inflexible work of safety valves, and achieve increased discharge, rapid pressure relief, and increased opening height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

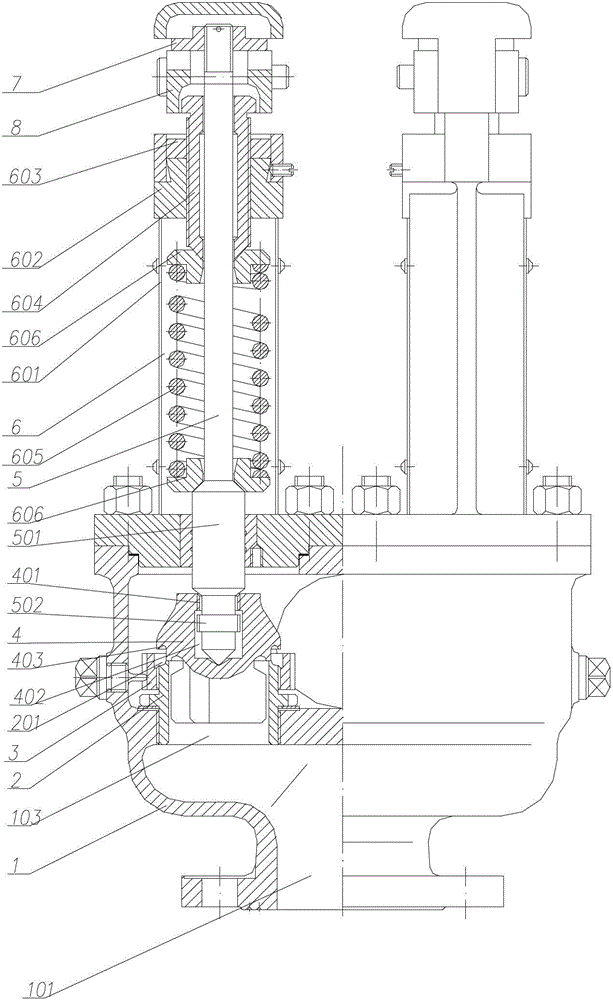

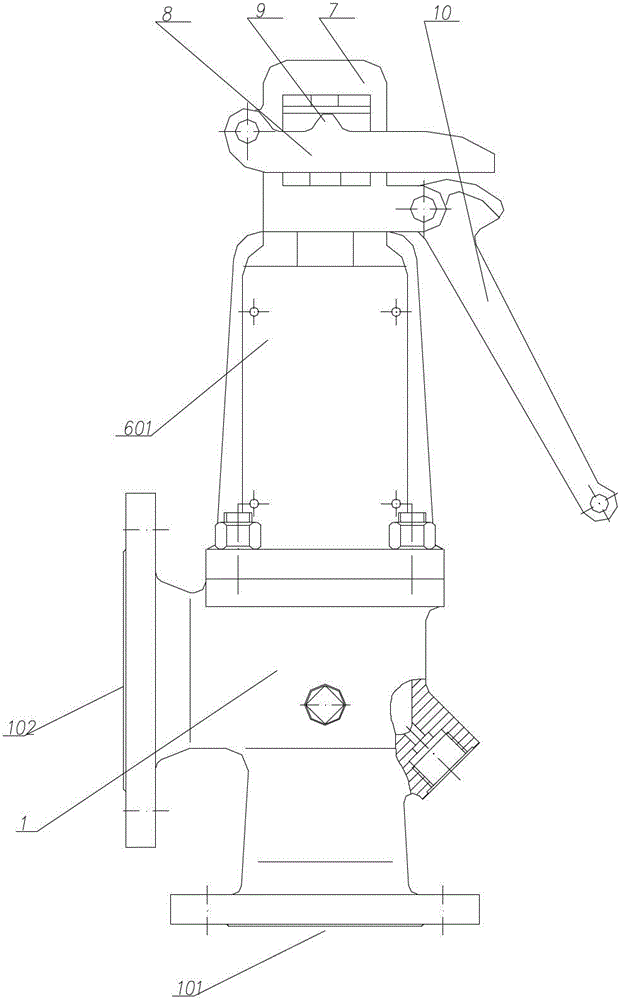

[0018] Such as Figure 1-2 As shown, a marine boiler safety valve includes a valve body 1, on which a liquid inlet 101, a liquid outlet 102, and two valve core 4 holes 103 are arranged. The spool 4 holes 103 communicate with each other, the spool 4 holes 103 are provided with a spool 4 seat 2, and the outside of the spool 4 seat 2 top is threadedly connected with an adjusting ring 3. The valve core 4 seat 2 is provided with a movable valve core 4 mechanism, and the valve core 4 mechanism includes a valve core 4 , a valve stem 5 disposed on the valve core 4 and a pressure control device 6 disposed on the valve stem 5 .

[0019] The valve core 4 is provided with stepped holes, including a threaded hole 401 with a smaller diameter on the upper part and a round hole 402 with a larger diameter on the lower part. Platform 502, the distance from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com