High-performance, high-temperature and high-pressure safety valve

A high-temperature, high-pressure, safety valve technology, applied in the direction of safety valves, functional valve types, lift valves, etc., can solve the problem of affecting the sealing performance of the elastic valve disc and the valve seat, the weakening of the lift force of the elastic valve disc, and the inability of the elastic valve disc to quickly reach the opening height and other problems, to achieve the effect of easy processing, return seat pressure and opening height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

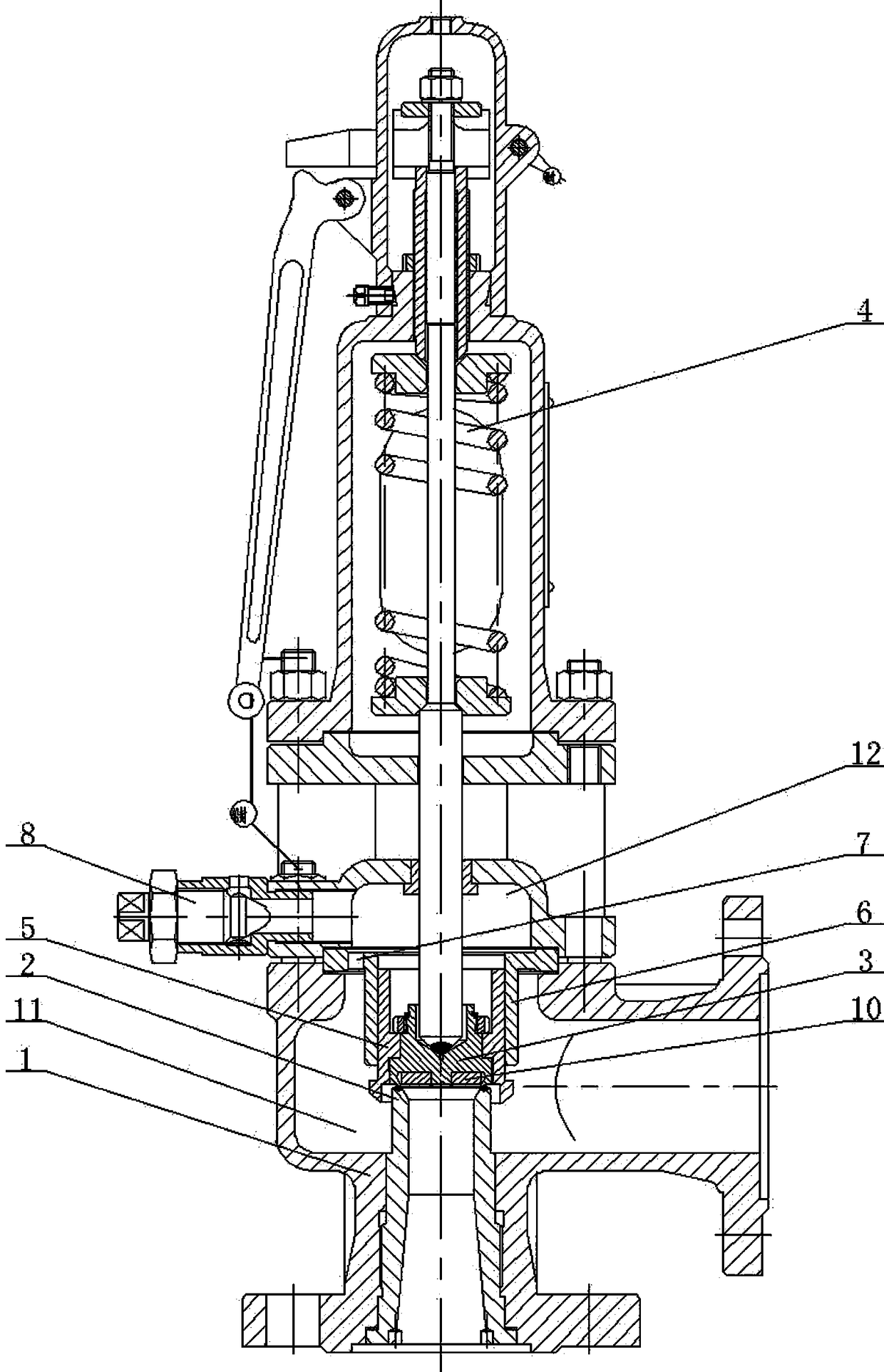

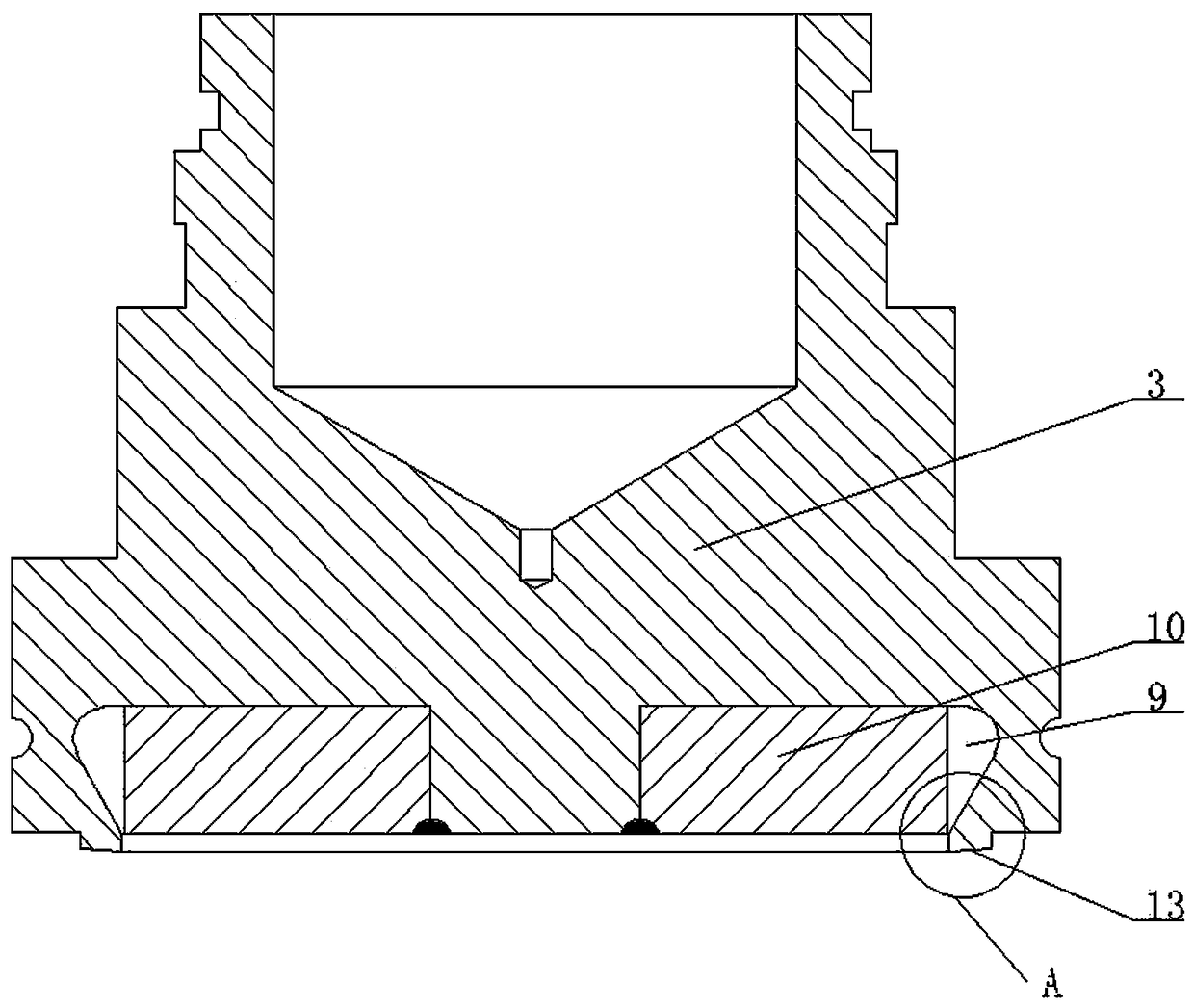

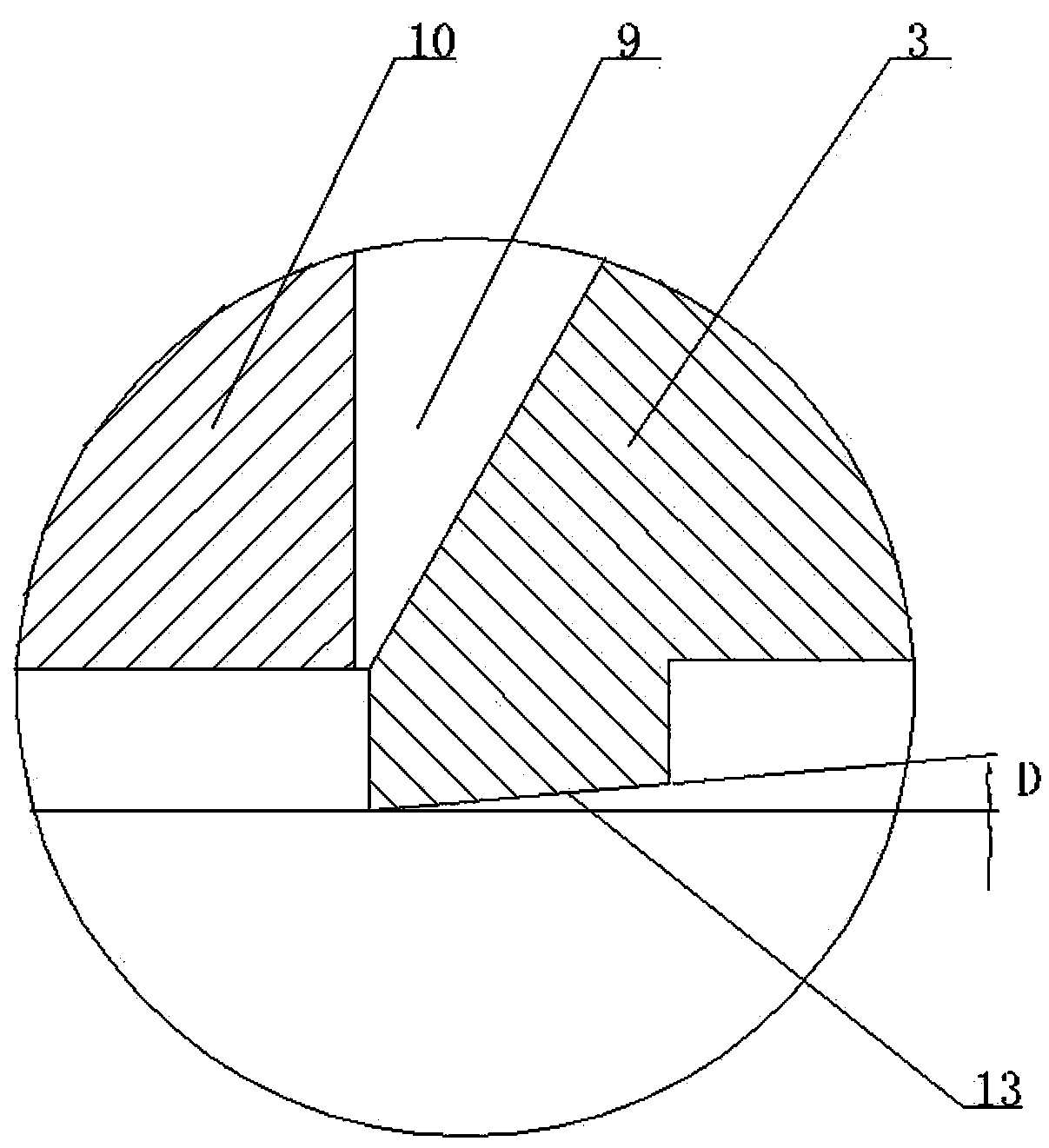

[0015] Depend on Figure 1 ~ Figure 3 As shown, the high-performance high-temperature and high-pressure safety valve includes a valve body 1, a valve seat 2, an elastic disc 3, a spring 4, a recoil disc 5 and a guide sleeve 6, and the upper part of the recoil disc 5 is located in the guide sleeve 6 and reversed. The flush plate 5 can slide up and down along the guide sleeve 6, and the elastic disc 3 is installed in the recoil disc 5. The upper end of the guide sleeve 6 is provided with a vent hole 7, and the vent hole 7 communicates with the valve chamber 11 and the elastic disc 3 The upper chamber 12, the side wall of the chamber 12 above the elastic valve disc 3 is provided with a regulating valve 8, and the chamber above the elastic valve disc 3 communicates with the outside world through the regulating valve 8; the lower end of the elastic valve disc 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com