Buffer type weighing sensor module

A technology of load cells and sensors, applied in the field of load cells, can solve the problems of life and accuracy of load cells, and achieve the effect of small and exquisite design, convenient replacement and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

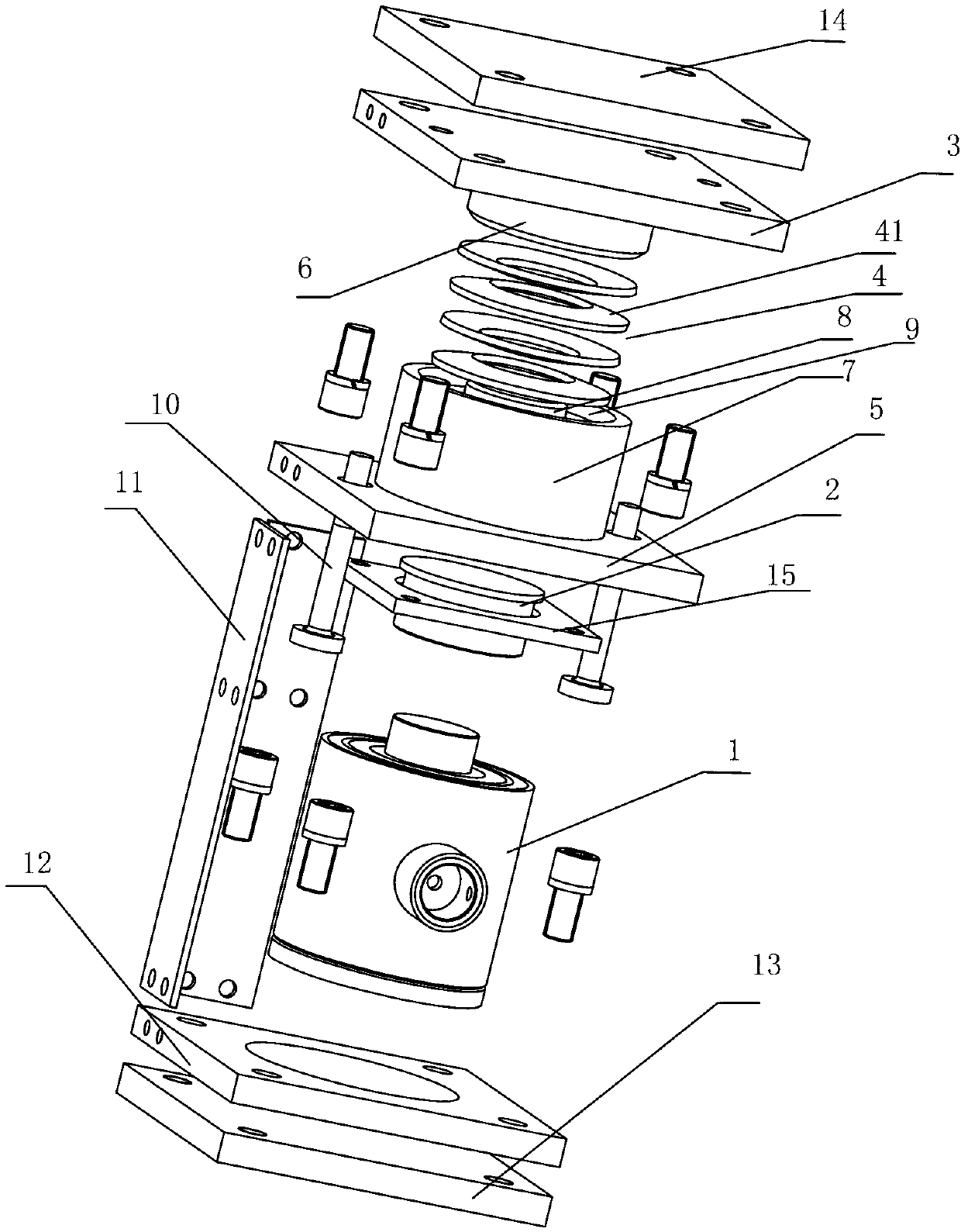

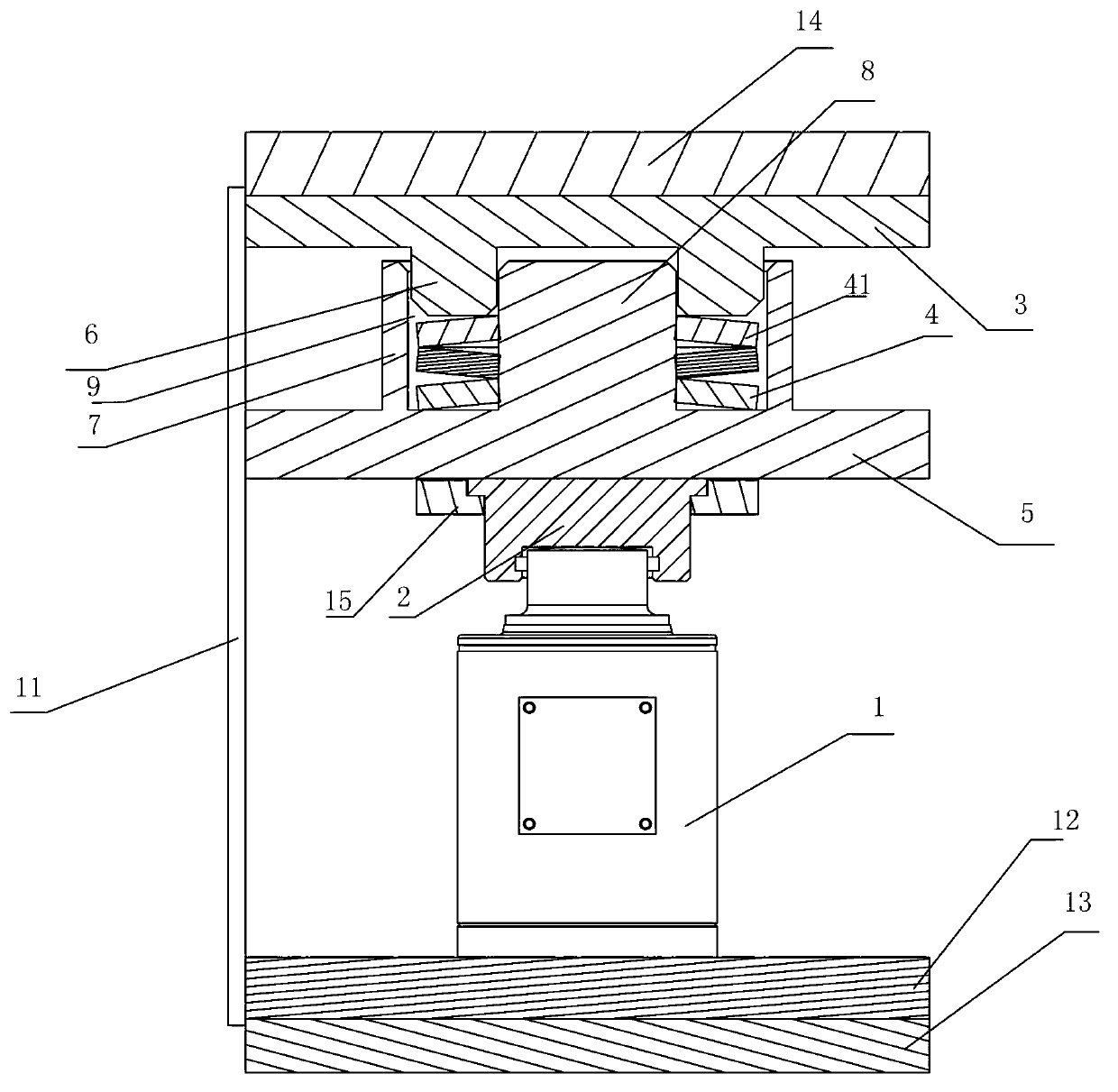

[0015] A buffer type load cell module, comprising a load cell 1 and a sensor pressure head 2, the sensor pressure head 2 is arranged on the load cell 1, a buffer mechanism is arranged above the sensor pressure head 2, the buffer mechanism includes an upper substrate 3, a plate Type reed set 4 and the lower base plate 5 located above the sensor pressure head 2, the disc type reed set 4 is located between the upper base plate 3 and the lower base plate 5, and a reverse limit mechanism is arranged between the upper base plate 3 and the lower base plate 5 .

[0016] A buffer indenter 6 is arranged below the upper base plate 3, and an outer cylinder 7 with an opening facing upward is arranged above the lower base plate 3. The disc spring set 4 is placed in the outer cylinder 7, and the lower end of the buffer indenter 6 is pressed against the disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com