Numerically controlled workshop automatic delivery vehicle scheduling method

A scheduling method and a technology for delivering vehicles, applied in data processing applications, instruments, logistics, etc., can solve problems such as low efficiency and single delivery method, achieve high convergence, achieve optimal scheduling, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and the distribution example in the numerical control workshop.

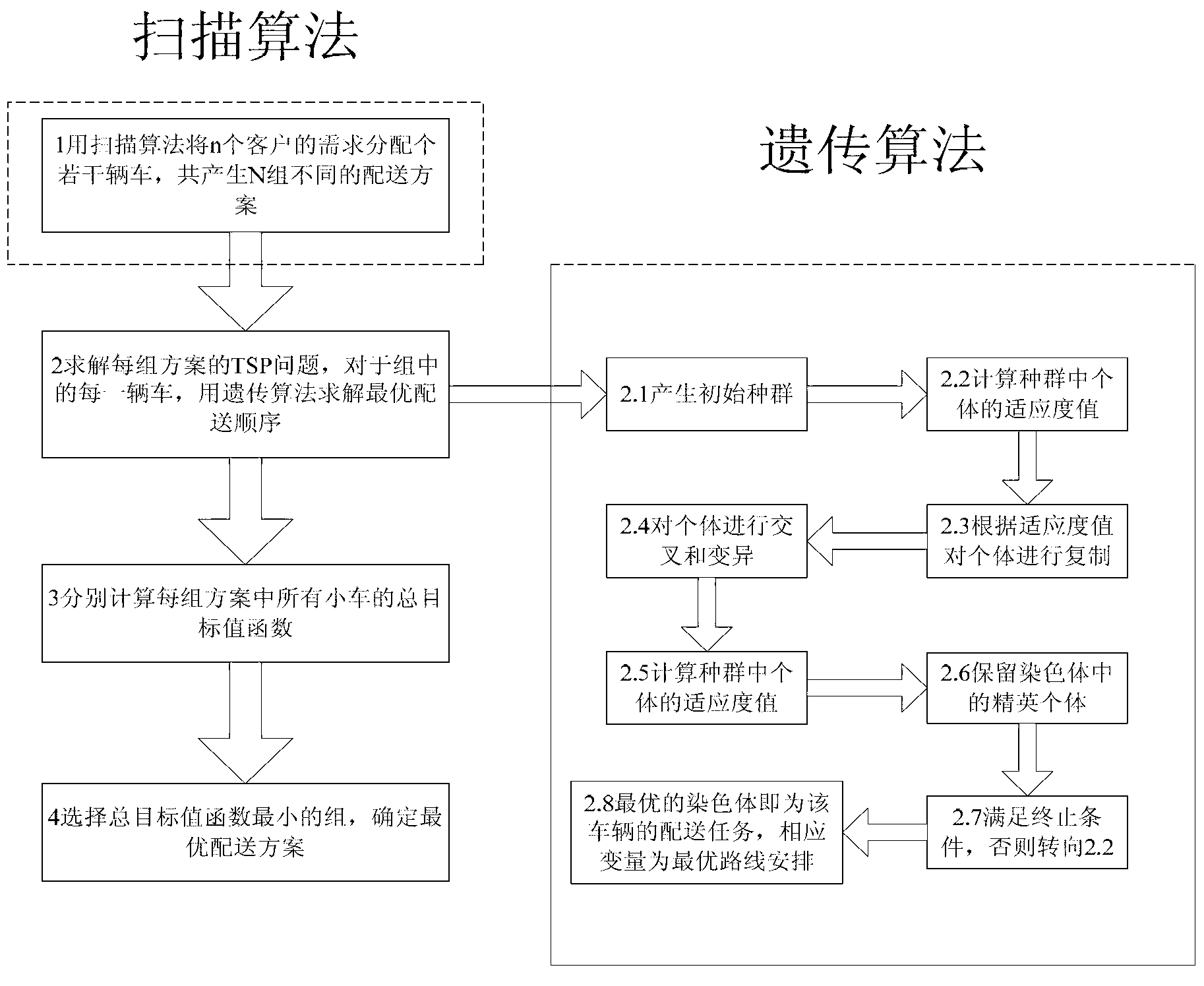

[0053] Such as figure 1 shown.

[0054] A method for scheduling automatic distribution vehicles in a numerical control workshop, comprising the following steps:

[0055] (1) The delivery center obtains the delivery instruction information. The delivery center refers to the place where materials are delivered in the CNC workshop. The delivery instruction information includes: user demand, user location, and delivery time window required by the user;

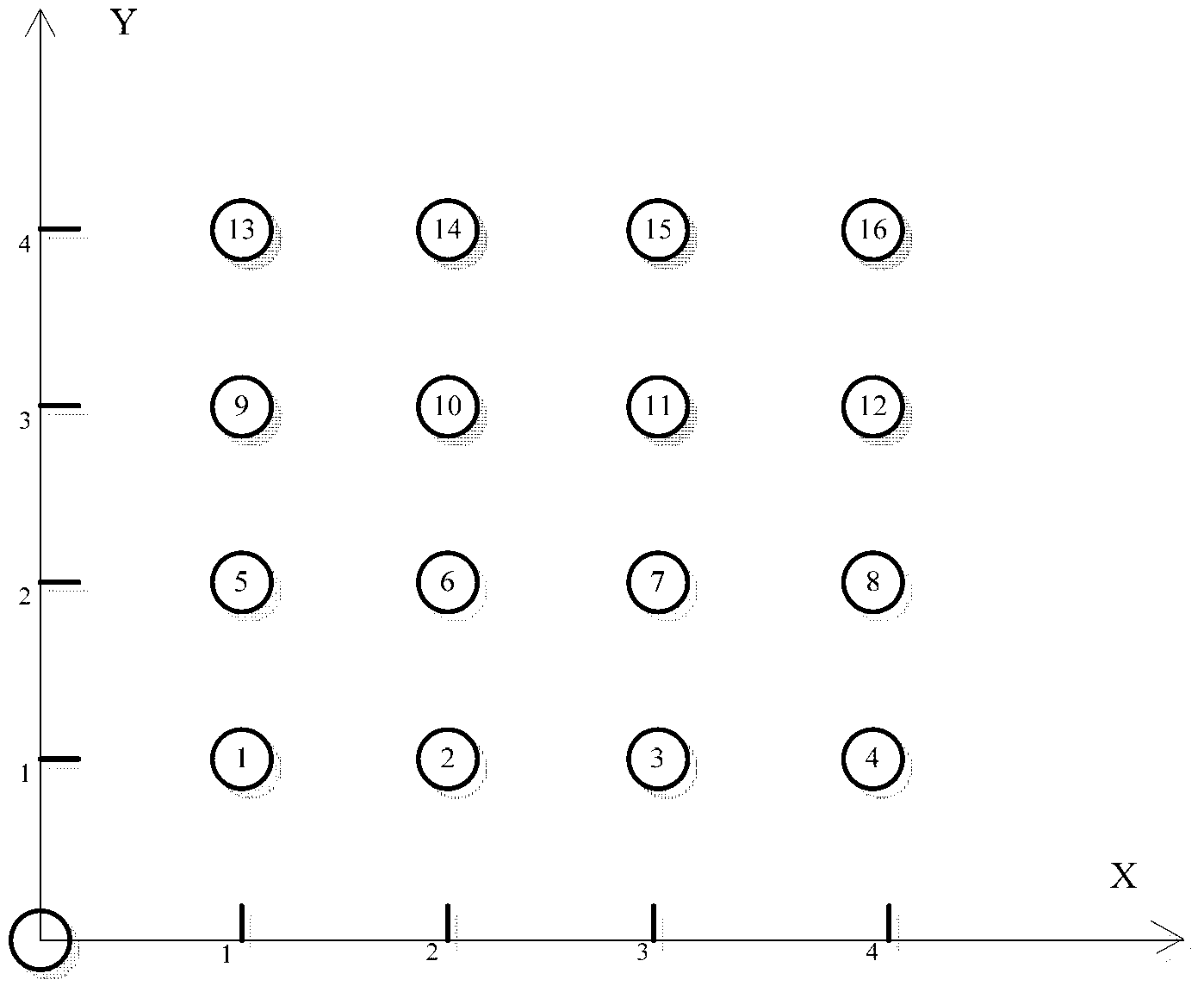

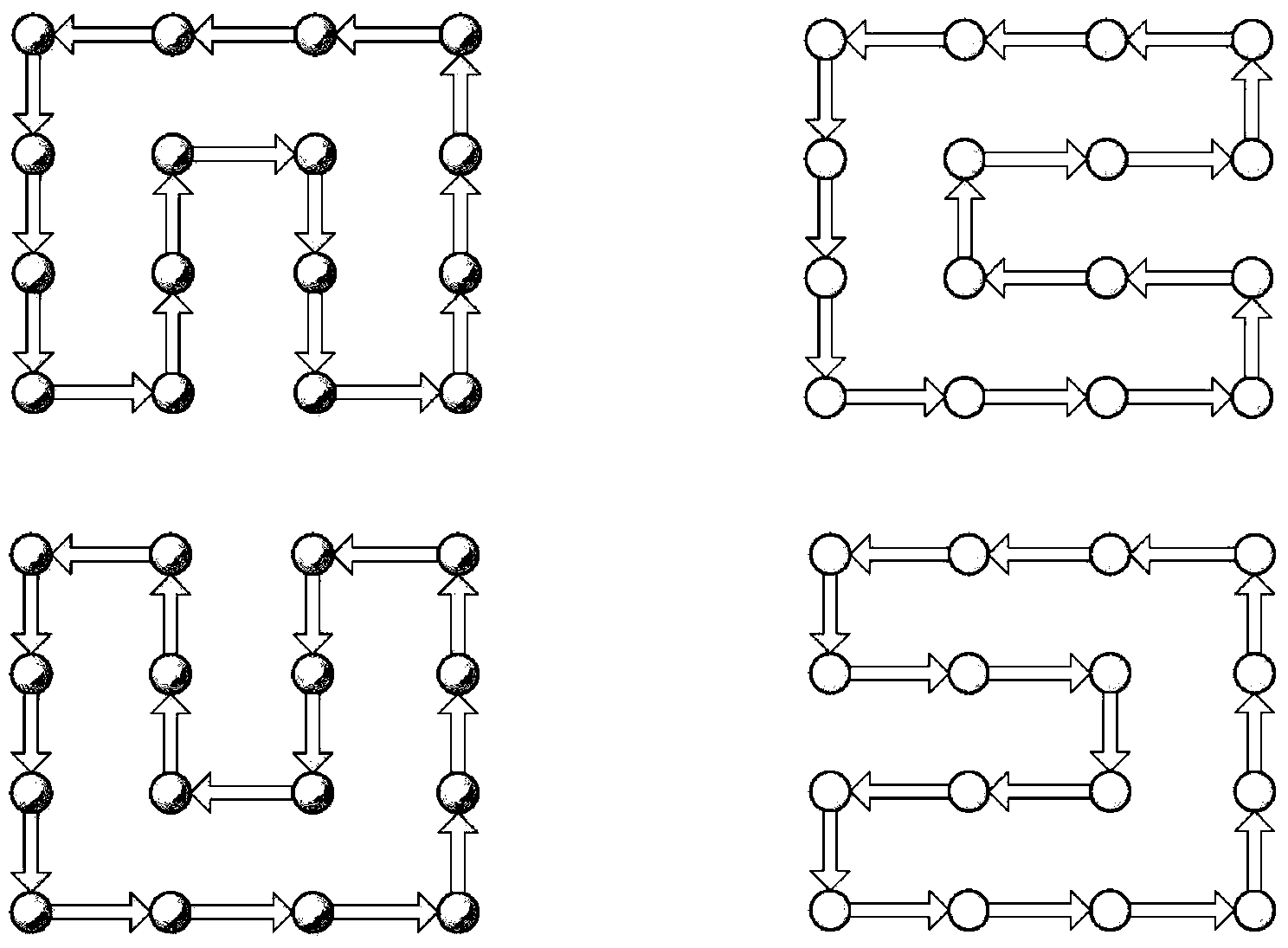

[0056] (2) According to the user's location and demand, under the condition of satisfying the load constraints of the distribution vehicles, the matrix scanning method is used to assign the distribution tasks of each user to different vehicles. According to the different scanning starting points, the scanning method produces different results. Vehicle task di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com