Mining explosive-proof and intrinsically safe battery charger

An intrinsically safe charging machine technology, applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems that the charging process of lithium batteries cannot be met, manual guarding is required for charging, and the charging process requires high requirements. It achieves weight reduction, High output power and great pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

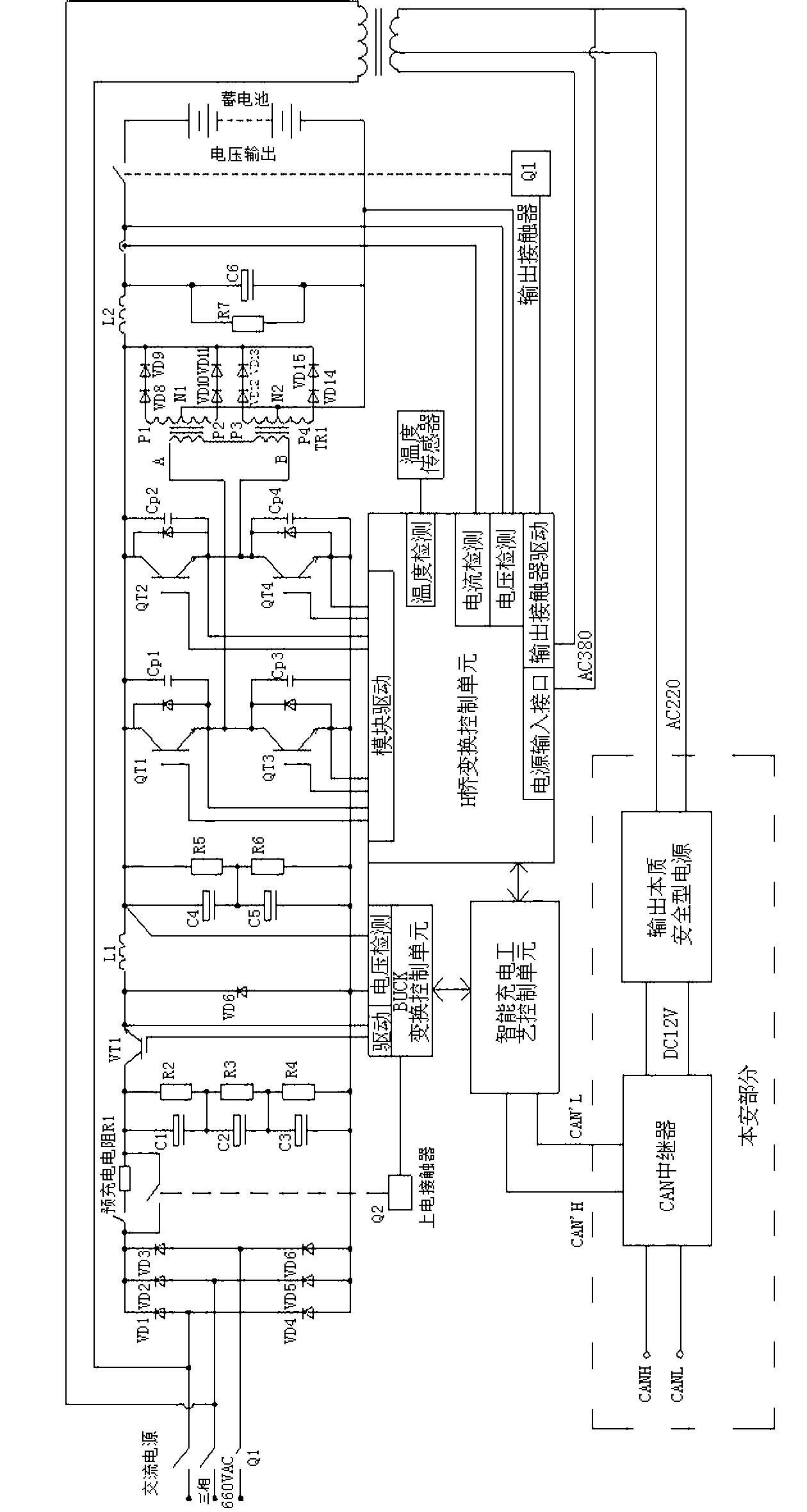

[0017] Embodiment: This embodiment specifically relates to an explosion-proof and intrinsically safe charger for mining lithium-ion battery power supply. It adopts high-frequency technology, soft-switching technology and digital control technology to replace the traditionally used bulky Power frequency transformers and power frequency variable voltage chargers that require a lot of maintenance and consume a lot of power.

[0018] The charger is mainly composed of two parts, a power conversion circuit and a charging control circuit.

[0019] Such as figure 1 As shown, the power conversion circuit is directly powered by a 660VAC AC power supply. The power conversion circuit specifically includes a three-phase rectification circuit, a BUCK conversion circuit, an H-bridge conversion circuit and a high-frequency rectification circuit connected in sequence, as follows:

[0020] ① Three-phase rectification circuit consists of input switch (Q1), power rectification module (VD1, VD2, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap