Preparation method of millet beverage

A millet and beverage technology, applied in food preparation, application, food science, etc., can solve the problems of long time consumption and high energy consumption, and achieve the effect of reducing operation steps, low energy consumption and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

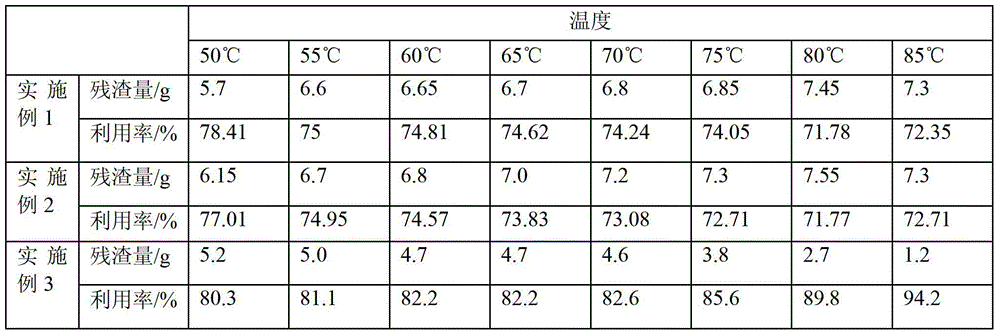

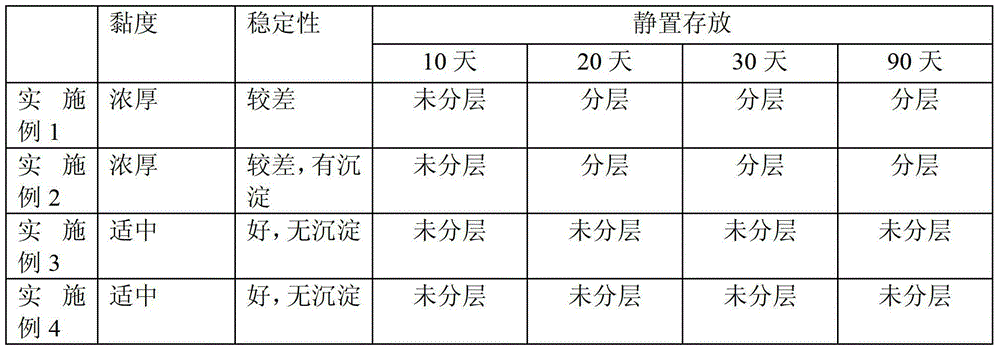

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: millet beverage of this embodiment is prepared according to the following steps:

[0021] 1. After pulverizing the millet, mix and stir evenly according to the mass ratio of millet powder and water 1:8-12;

[0022] 2. Add protease, high-temperature amylase compound enzyme preparation and salt to the mixed liquid in step 1, and then enzymolyze it for 45 minutes at a temperature of 85-90°C and a pH value of 5-8;

[0023] 3. After enzymatic hydrolysis and liquefaction in the second step, add cellulase and glucoamylase, and carry out the second enzymatic hydrolysis under the conditions of pH value 4.8-7.0 and temperature 55-60°C, and the enzymatic hydrolysis time is 45 minutes;

[0024] 4. Heat the millet mixture that has been enzymatically hydrolyzed twice to boiling and keep it for 5 minutes, then cool and filter for 2 times, use a 120-mesh sieve for the first filter, and a 500-mesh sieve for the second filter, to obtain millet emulsion;

[0025]...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: use broken millet in step one. Other steps and parameters are the same as those in Embodiment 1.

[0037] With the improvement of people's living standards, the processing precision is continuously improved, and the product classification is gradually strengthened, and more and more broken millet is produced. The nutritional content of broken millet is basically the same as that of millet, but its price is only 1 / 3~ of millet. 1 / 2, the selection of crushed millet can not only effectively reduce costs, save resources, greatly increase its added value, but also reduce the cost of crushing.

specific Embodiment approach 3

[0038] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: 1, millet is pulverized and mixed by the mass ratio of 1:10 and stirred evenly. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com