Anti-blocking gearbox

A kind of gear box, anti-locking technology, applied in the direction of hoisting device, etc., can solve the problems of motor, screw pair transmission parts damage, reducing the service life of ordinary gearboxes, screw locking and other problems, to eliminate the screw locking, The effect of eliminating impact and protecting the screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

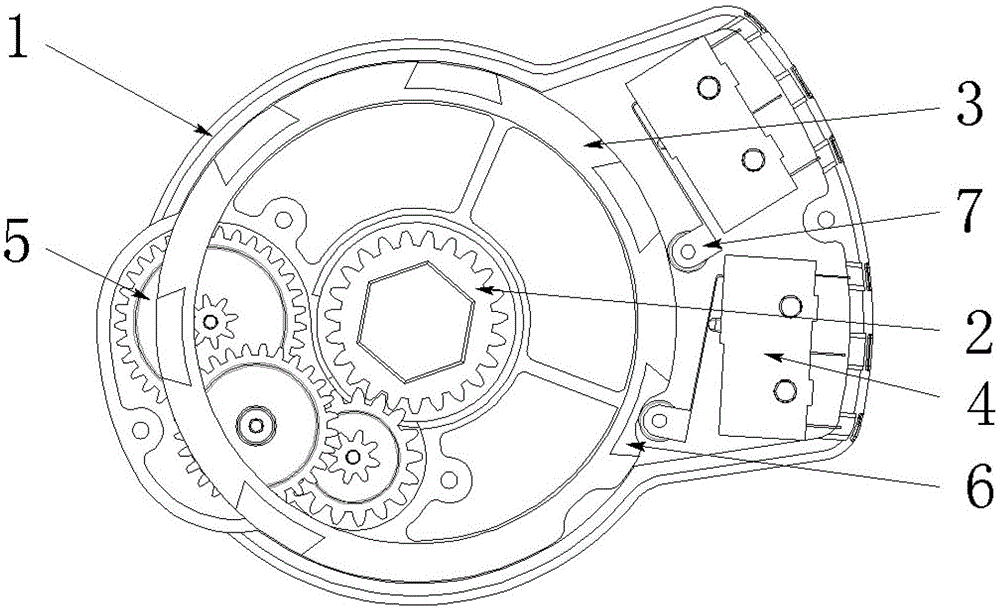

[0017] The anti-stall gearbox includes a box body 1, and the box body 1 is equipped with a driving gear 2, an execution gear 3 and a micro switch 4. The driving gear 2 meshes with the execution gear 3 through the reduction gear 5, and the execution gear 3 drives the micro switch 4 actions.

[0018] The outer edge of the driving gear 2 is provided with teeth, and the central position of the driving gear 2 is provided with a shaft hole. The screw mandrel outside the casing is inserted in the shaft hole, and when the outer screw mandrel rotates, it will drive the driving gear 2 to rotate. The driving gear 2 drives the reduction gear 5 to rotate through the teeth.

[0019] Reduction gear 5 is a duplex gear. Double gears are coaxially combined by two gears, and they rotate or stop synchronously.

[0020] The number of reduction gears 5 is A, and A≥1.

[0021] The execution gear 3 is an internal ring gear, and the outer edge of the execution gear 3 is provided with grooves 6 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com