Novel cement-based plastering mortar construction method

A technology of plastering mortar and construction method, applied in covering/lining, building, building structure, etc., can solve the problems of low bonding strength, poor water retention, poor performance, etc., and achieve high mortar bonding strength, excellent water resistance, Easy to use and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

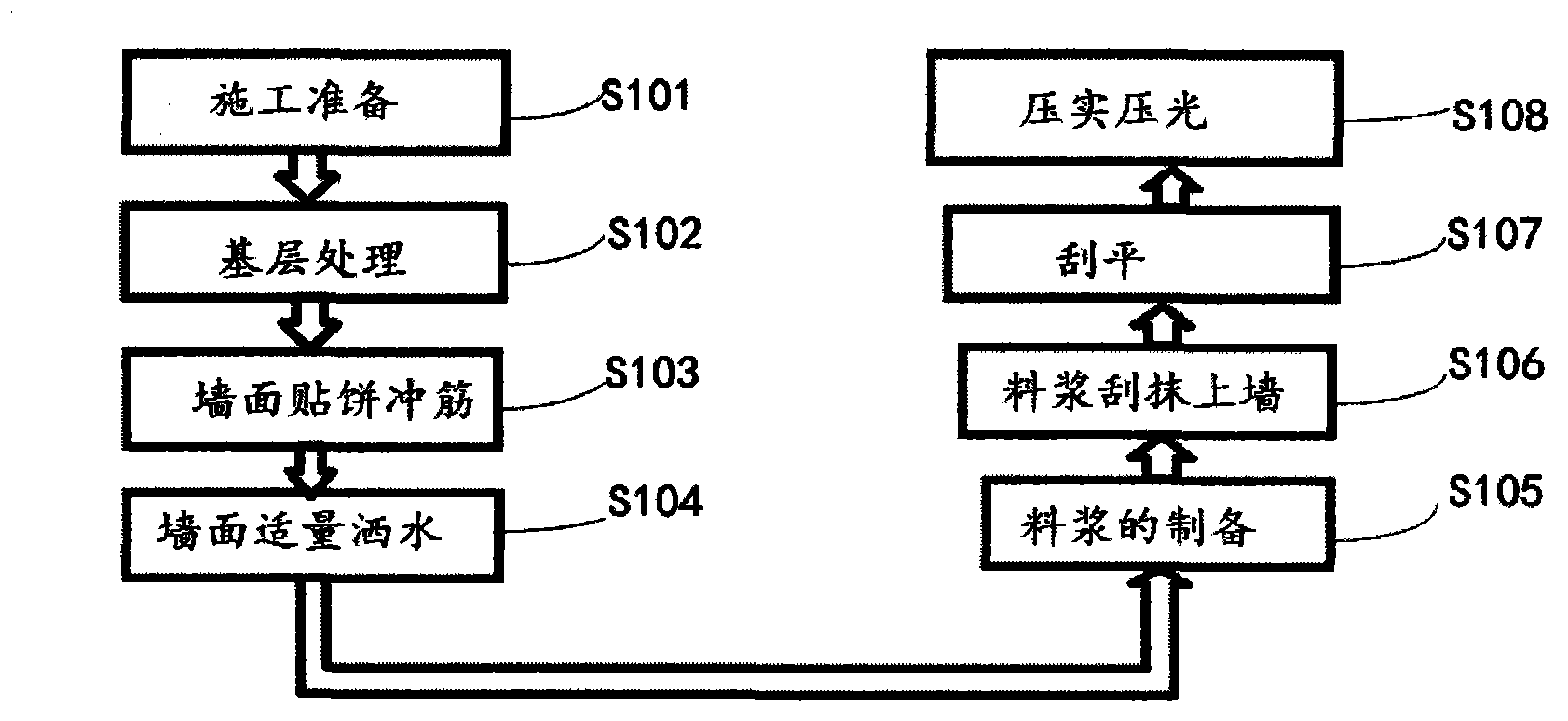

Image

Examples

preparation example Construction

[0023] S105, preparation of slurry:

[0024] The ratio of ash to water is 1:0.18. First pour the water into the mixing tank, then pour the ash, and stir for 2 to 3 minutes to make the slurry reach a suitable consistency. The amount of slurry should be prepared according to the plastering area each time. , not too much, should be mixed and used frequently.

[0025] S106, scraping the slurry on the wall:

[0026] After preparing the slurry according to the requirements, use the sizing tool to scrape the wall.

[0027] S107, scraping:

[0028] After scraping the slurry on the wall, first roughly smooth it into a layer, and then scrape it carefully; the thickness of each layer is controlled between 1-1.5cm, and the amount of cement-based plastering mortar per square meter is about 10 kg; After the initial setting of the first layer, scrape the next layer; when the total thickness of the plaster is 3-4cm, use a scraper to scrape against the ash cake along the vertical and horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com