Fixing mechanism for riveting device for horizontal directional drilling machine

A technology of horizontal directional drilling rig and fixed mechanism, which is applied in directional drilling and other directions, can solve the problems of time-consuming and labor-intensive, and achieve the effect of avoiding potential danger and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention is further described below in conjunction with specific embodiment and accompanying drawing, but it is not limited thereto:

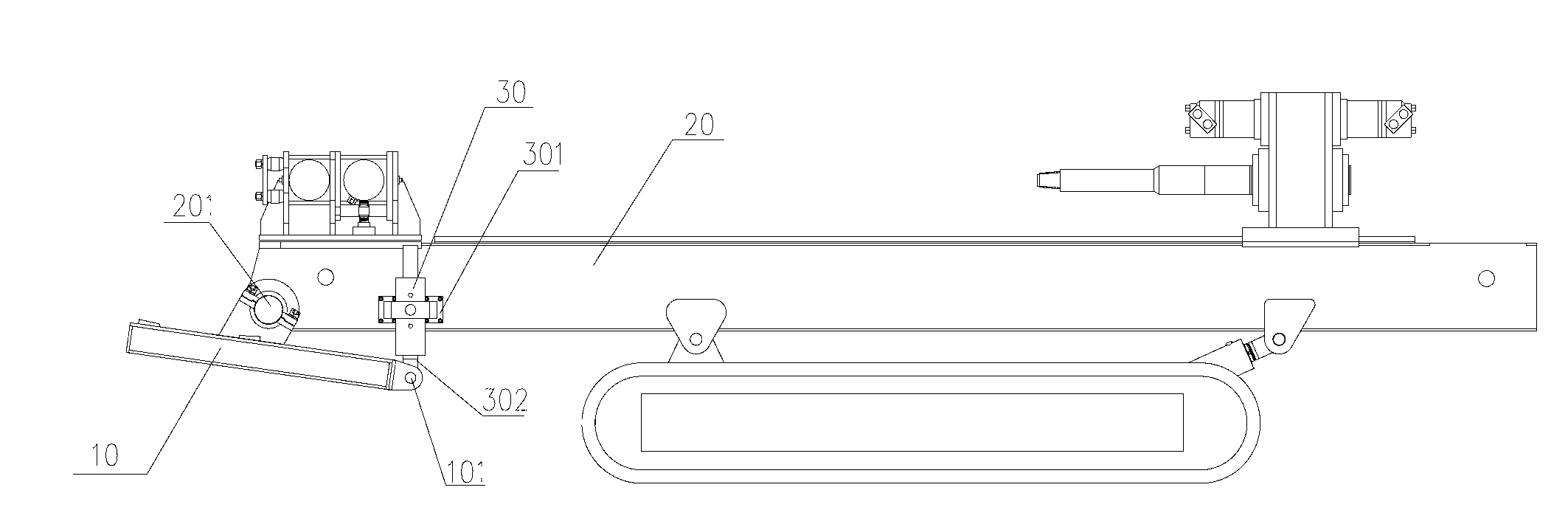

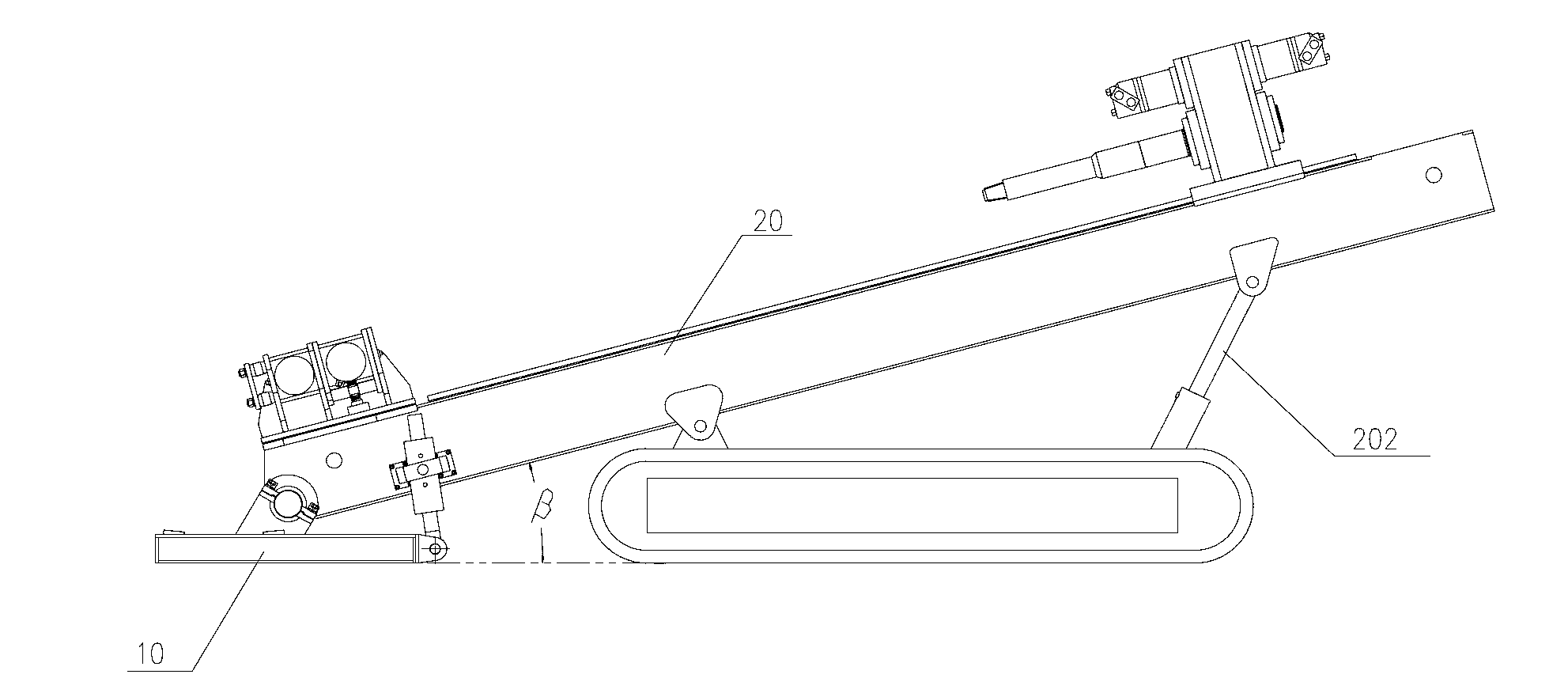

[0016] Such as figure 1 As shown, the fixing mechanism of the horizontal directional drilling rig riveting device provided by the present invention includes a riveting device 10, a girder 20 and a floating oil cylinder 30, wherein the riveting device 10 is hinged on the pin shaft 201 at the front end of the girder 20 , the floating oil cylinder 30 is hinged on the girder 20 through the floating oil cylinder hinge seat 301, the floating oil cylinder 30 can rotate around the floating oil cylinder hinge seat 301, and the piston rod 302 of the floating oil cylinder 30 is hinged to the pin shaft at one end of the anchor 10 101 on.

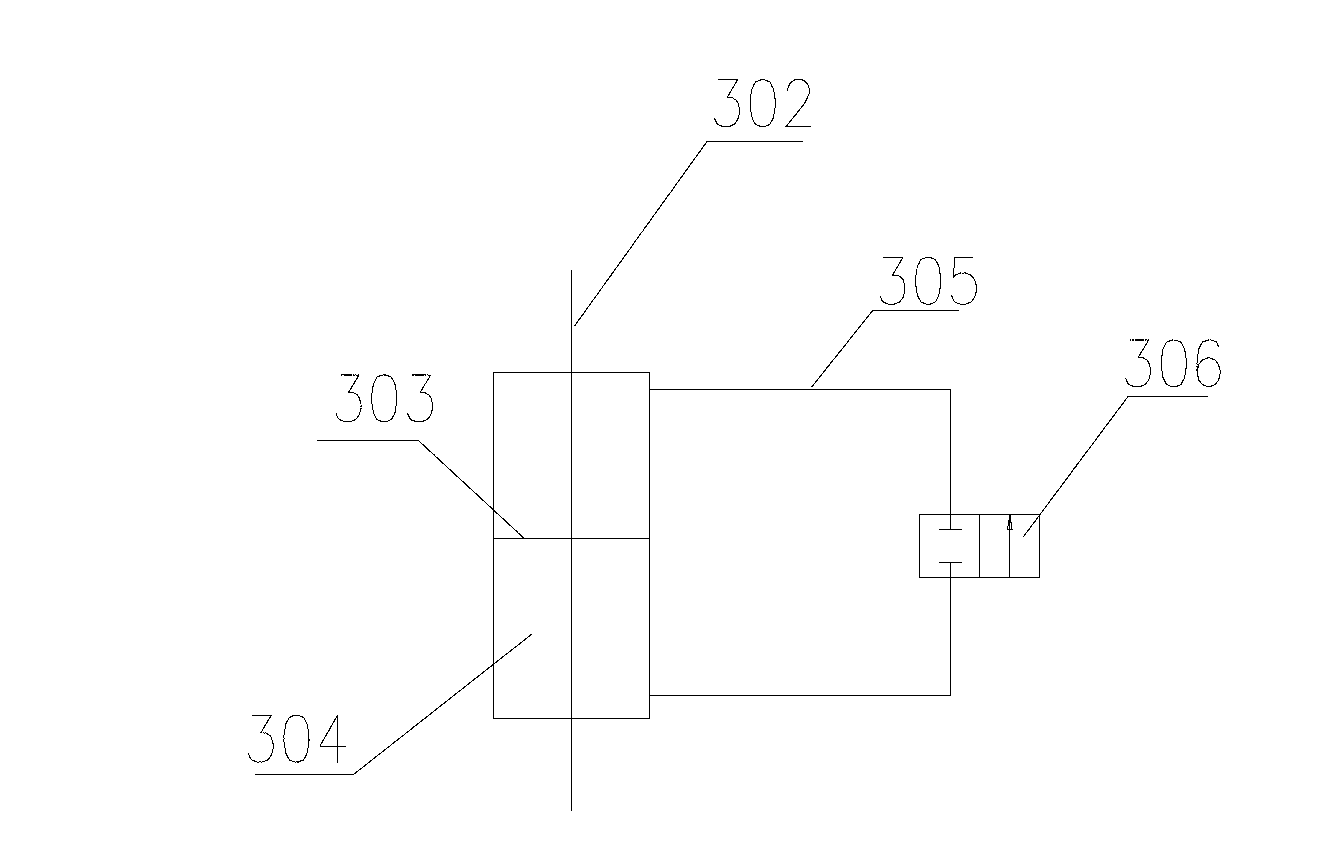

[0017] Further, such as figure 2 As shown, the two ends of the piston 303 of the floating oil cylinder 30 are respectively provided with cavities 304, the piston rod 302 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com