Air-suction type impeller case

An impeller, air suction technology, applied in mechanical equipment, non-variable volume pumps, machines/engines, etc., can solve problems such as insufficient scope, inability to maximize the use of impellers, low energy conversion rate, etc., to ensure the use of life, improve the effective utilization rate, and protect the effect of the impeller structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

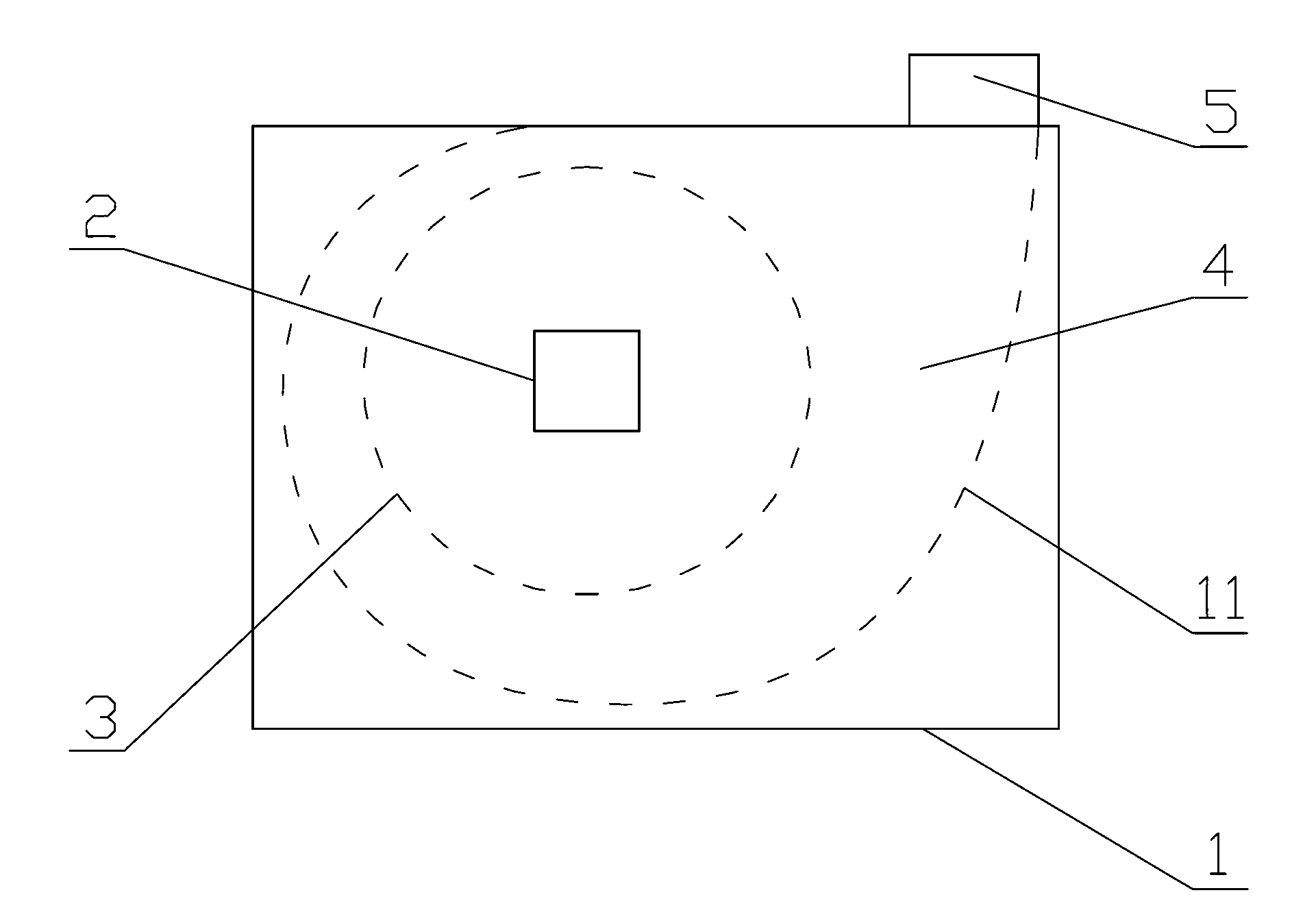

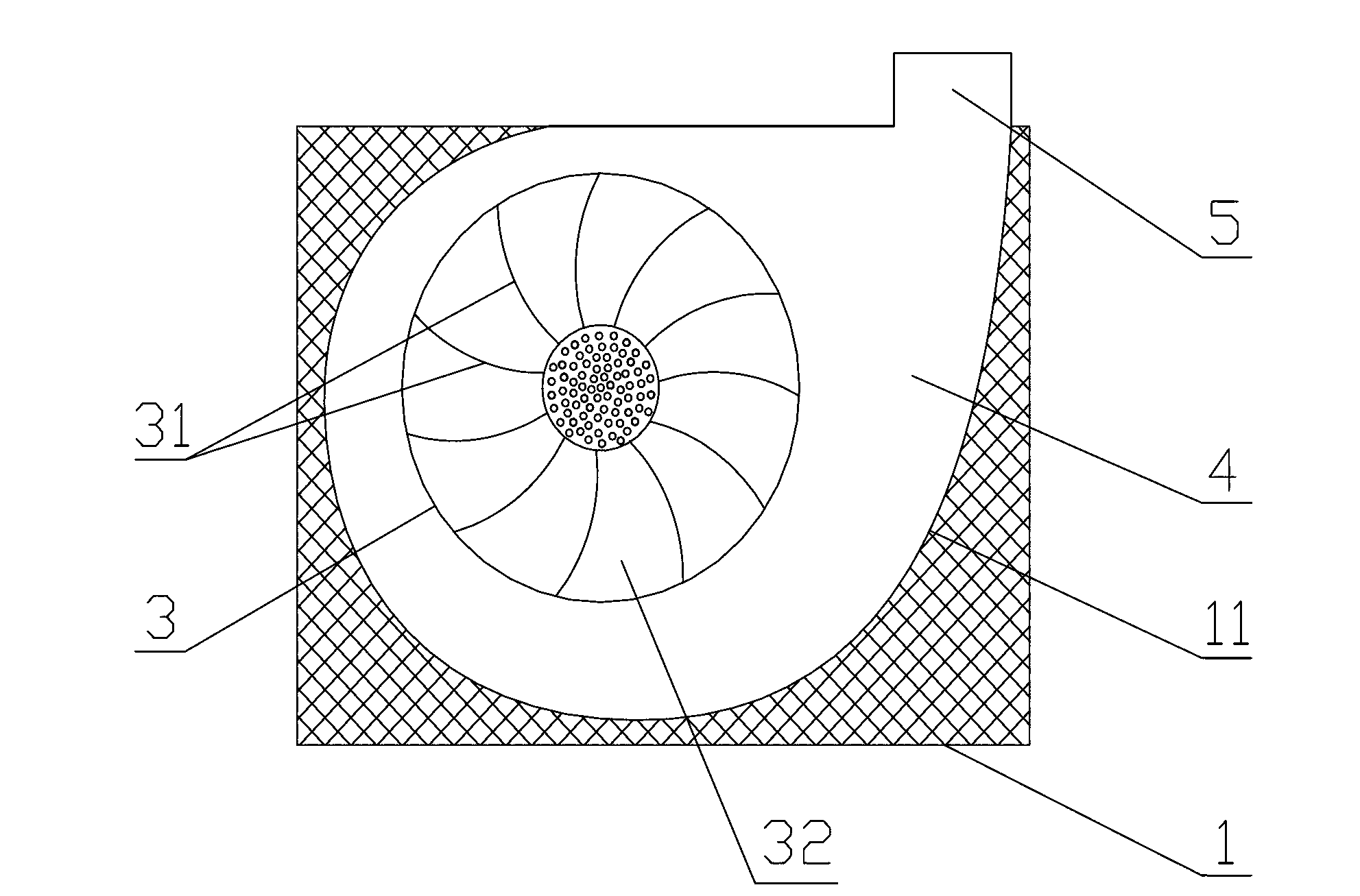

[0026] Such as Figure 1 ~ Figure 2 As shown, an air suction type impeller case mainly consists of a case case 1 and an impeller 3 arranged in an internal cavity of the case case 1. The outer wall of the case case 1 is provided with an inlet 2 communicating with its internal cavity. 2 The port of the internal cavity of the case shell 1 is located at the center of the impeller 3. In this way, the inlet of the casing 1 is attracted by the wind of the impeller 3, and the material (when used for picking cotton, the material is cotton) follows the wind from the inlet directly to the center of the impeller 3. Because the inlet 2 is located at the center of the casing 1. The port is at the center of the impeller 3, so that the rotating wind force of the impeller 3 is fully utilized, so that the effective wind suction force is the largest, and the wind is sucked in through the optimal position, so the rotating wind force of the impeller 3 is utilized to the maximum efficiency.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com