Semiconductor LED bulb light

A technology for LED bulbs and semiconductors, applied in lighting devices, cooling/heating devices for lighting devices, light sources, etc., can solve problems such as being unsuitable for automated mass production, slow assembling, and using many materials. The effect of automated mass production, fast assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

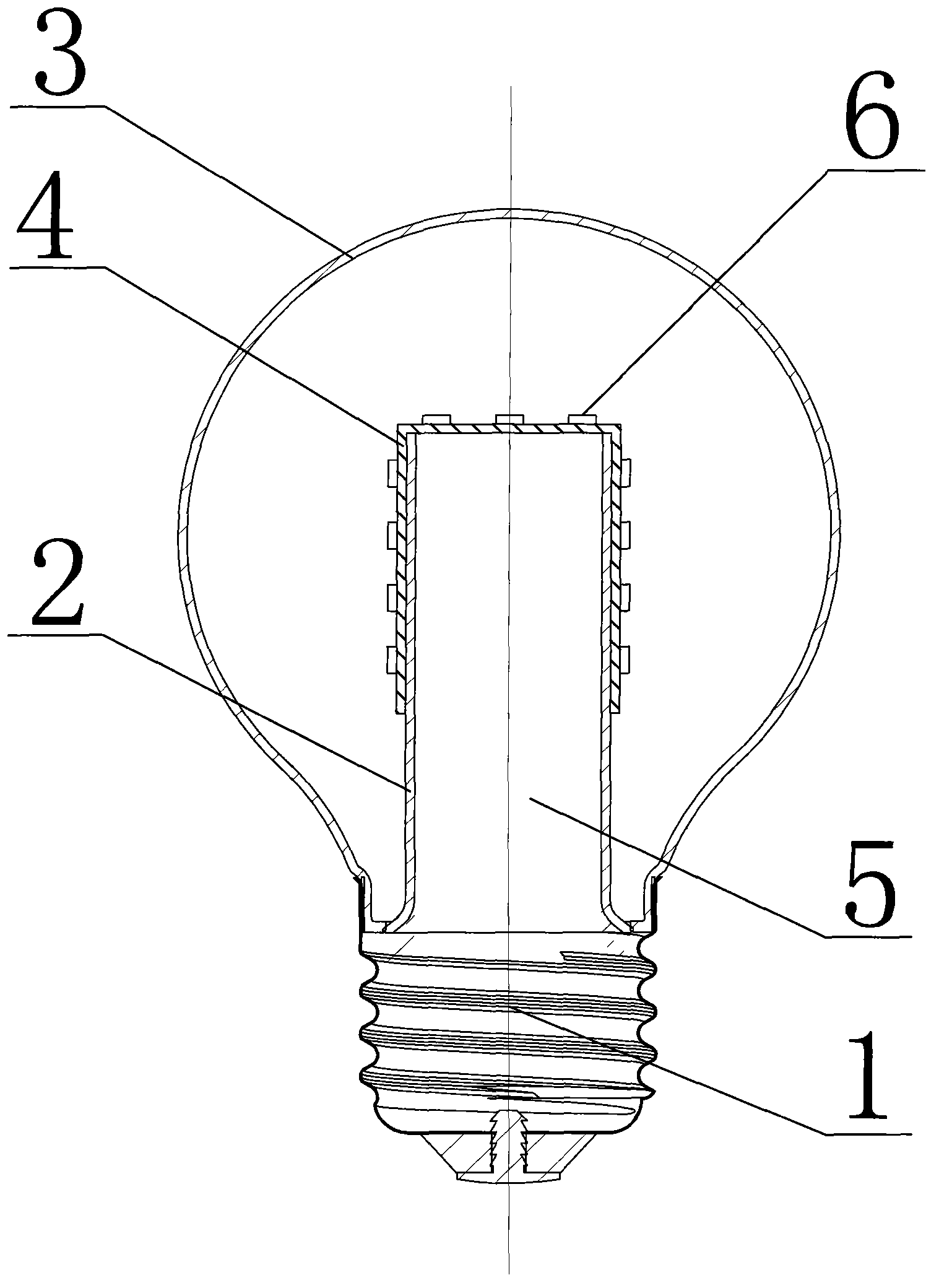

[0010] Such as figure 1 As shown, the present invention discloses a semiconductor LED bulb lamp, which includes a lamp base 1, a driver 5, a glass shell 3, a substrate 4 and a semiconductor lamp bead 6, and also includes a horn mouth glass tube column 2, and the substrate 4 is arranged on the horn The upper end of the glass tube column 2, the substrate 4 is provided with a semiconductor lamp bead 6, and the bell mouth glass tube column 2 is arranged inside the glass shell 3, and the bell mouth and the glass shell 3 are heat-sealed together to form a heat-dissipating whole , the bell-mouthed glass tube column 2 is in the shape of a cylinder or a polygonal column.

[0011] The assembly process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com