Weighing cell operating on the principle of magnetic power compensation with optoelectronic position sensor

A technology of compensation principle and electromagnetic force, which is applied in the direction of weighing equipment, weighing, and optical components using electromagnetic balance, and can solve problems such as increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

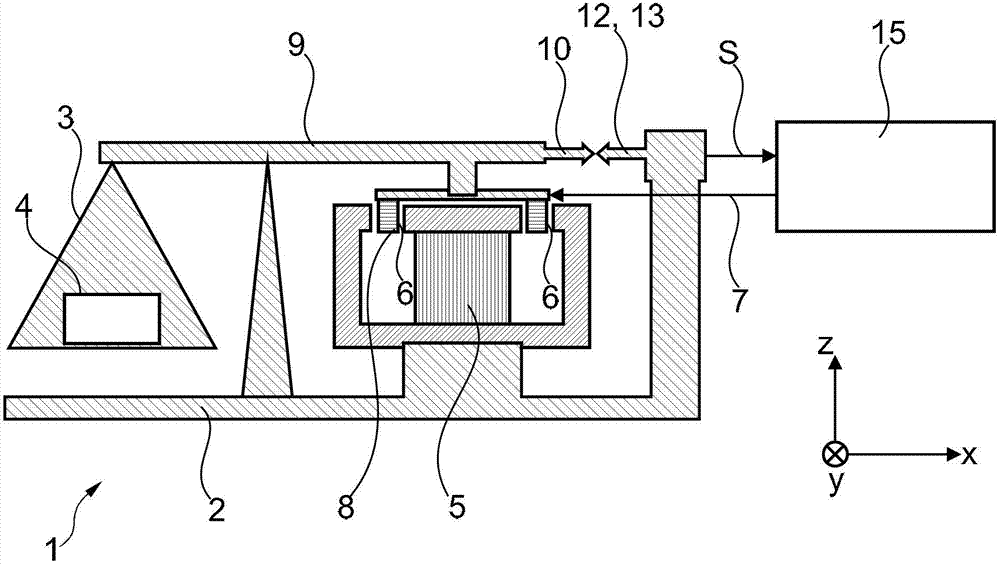

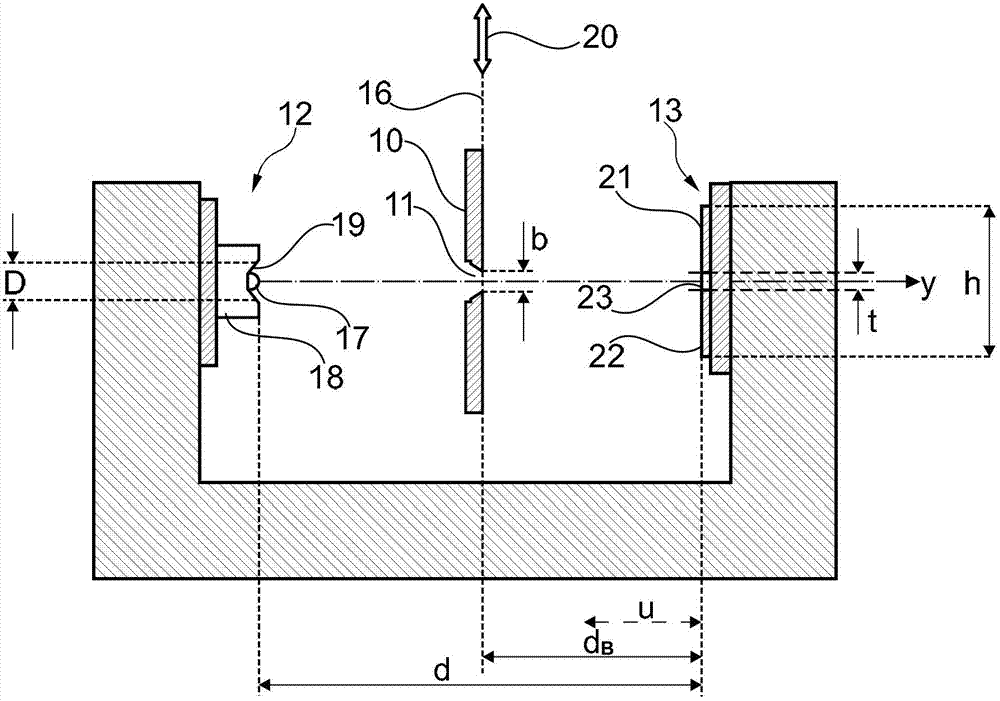

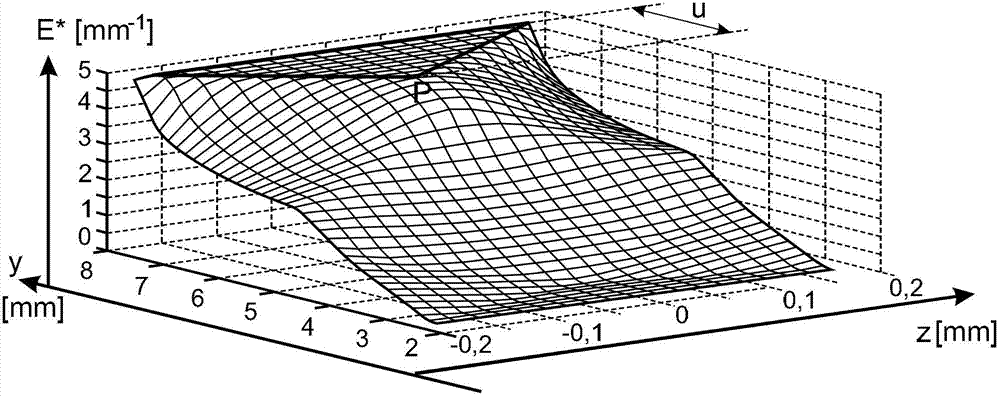

[0041] exist figure 1 A scale or weighing unit 1 with electromagnetic force compensation and photoelectric position sensor is schematically shown in . Add a Cartesian coordinate system as a reference for spatial orientation, the x and z axes of this coordinate system are located at figure 1 In the plane of the drawing, the y-axis points to the half-space behind the plane of the drawing. The shown components include: a fixed base part 2; a load receiver 3, which is constrained to the base part 2 for guided mobility and is used to receive the gravity of a weighing load 4; a cup-shaped permanent magnet system 5, which has an air gap 6 (in cross-sectional view), the system is rigidly mounted on the base part 2; a coil 8, which is movably suspended in the air gap 6 and directs the flow of a compensating current 7; and a force-transmitting mechanical connection 9 , which is located between the load receiver 3 and the coil 8, here shown in the shape of a balanced beam. Photoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com