A method for testing the colloidal strength of fumed silica

A fumed silica, strength testing technology, applied in strength characteristics, measuring devices, instruments, etc., can solve the problems of not meeting the higher requirements of colloidal strength performance, not being able to quickly measure the strength, and time-consuming, saving labor and time. The effect of manual measurement of time and convenient and quick testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

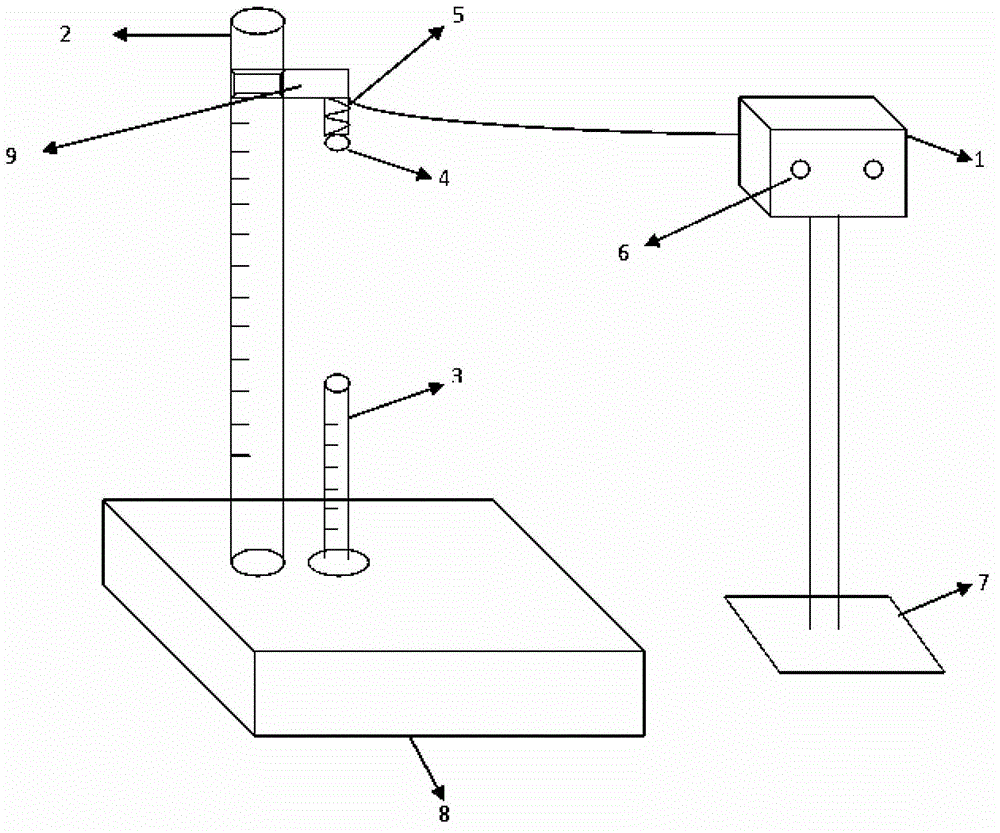

[0012] figure 1 The specific structure of the gas-phase silica colloidal strength tester is shown, which includes an automatic ball drop device, and the automatic ball drop device includes a steel ball adsorption device with a scale rod 2 and is arranged on the tape scale rod for absorbing steel balls 4. A graduated cylinder 3 containing the colloid to be measured is arranged directly below. The automatic ball drop device also includes an automatic ball drop box 8, and the bottom of the tape bar and measuring cylinder are placed in the automatic ball drop box. The steel ball adsorption device includes a connecting piece 9 with a scale rod arranged on a scale rod, the end of the connecting piece with a scale rod is provided with an adsorption coil 5, and the adsorption coil is connected with the power supply 1 of the automatic ball drop device, and the power supply of the automatic ball drop device A control switch 6 is provided to control the adsorption or release of the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com