Filter tip trapped benzopyrene concentration distribution pattern measuring method

A concentration distribution, benzopyrene technology, applied in the field of cigarette technology research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example 1

[0030] Six longitudinal distribution patterns of benzopyrene retained by filters

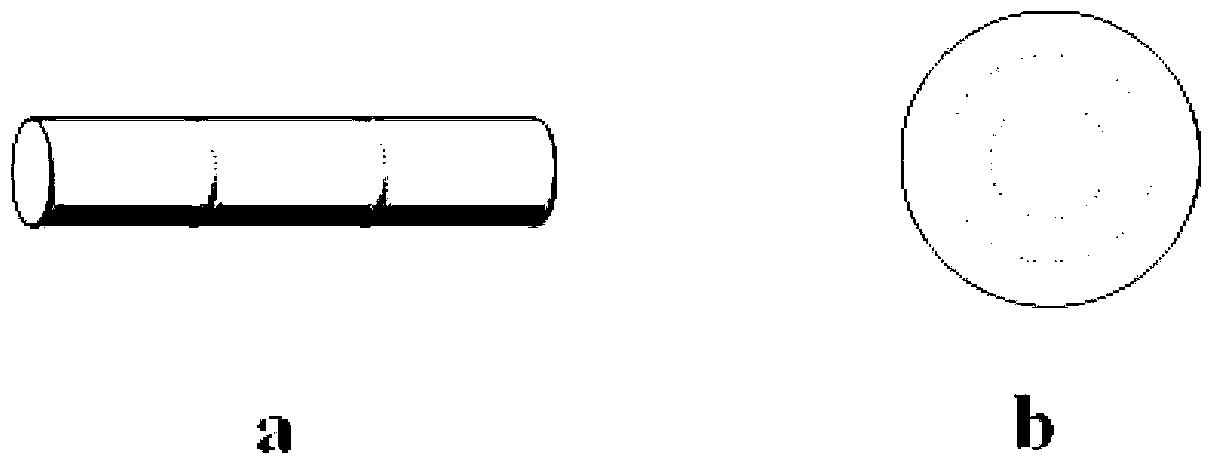

[0031] By cutting the six kinds of filters in different positions in the radial direction multiple times after suction, the content of benzopyrene in each part of the filter is analyzed, and the concentration of benzopyrene retained in the different parts of the filter is calculated. Polynomial fitting was performed on the concentration distribution of benzopyrene, and six longitudinal distribution modes of benzopyrene rejection by unstructured filters were obtained.

[0032] figure 2 The longitudinal distribution pattern of benzopyrene retention for six kinds of filters. Ordinary filter, external groove filter, column cavity filter, paper / vinegar composite filter, the longitudinal distribution pattern of retained benzopyrene concentration is similar ( figure 2 , A, B, E, F), showing a decreasing trend from the tobacco end of the filter tip to the smoking end. The built-in groove...

Example Embodiment

[0033] Example 2

[0034] Six cross-sectional radial distribution modes of benzopyrene retained by filters

[0035] In the study on the radial distribution of benzopyrene retained by the filter, on the basis of the radial cutting of the filter, the filter is cut in concentric circles with different radii in the radial direction. Analyze the amount of benzopyrene in the inner and outer parts of the cut filter separately (the three-segment filter is combined), and the filter can be obtained by calculating and using the relationship model between the radial cutting benzopyrene loss rate and the cutting area to correct The amount of benzopyrene and the concentration of benzopyrene retained in the mouth equidistant from the inside, middle and outside. A polynomial fitting was performed on the change law of the concentration of benzopyrene in the radial direction of the cross section of the filter, and the radial distribution pattern of the cross section of benzopyrene in different filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com