Structural design optimization method for deepwater catenary mooring rope

A technology of structural design and optimization method, applied in the field of deep water marine engineering, which can solve the problems of not well covering design requirements, unfavorable direct application of engineering, and inability to directly apply deep water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

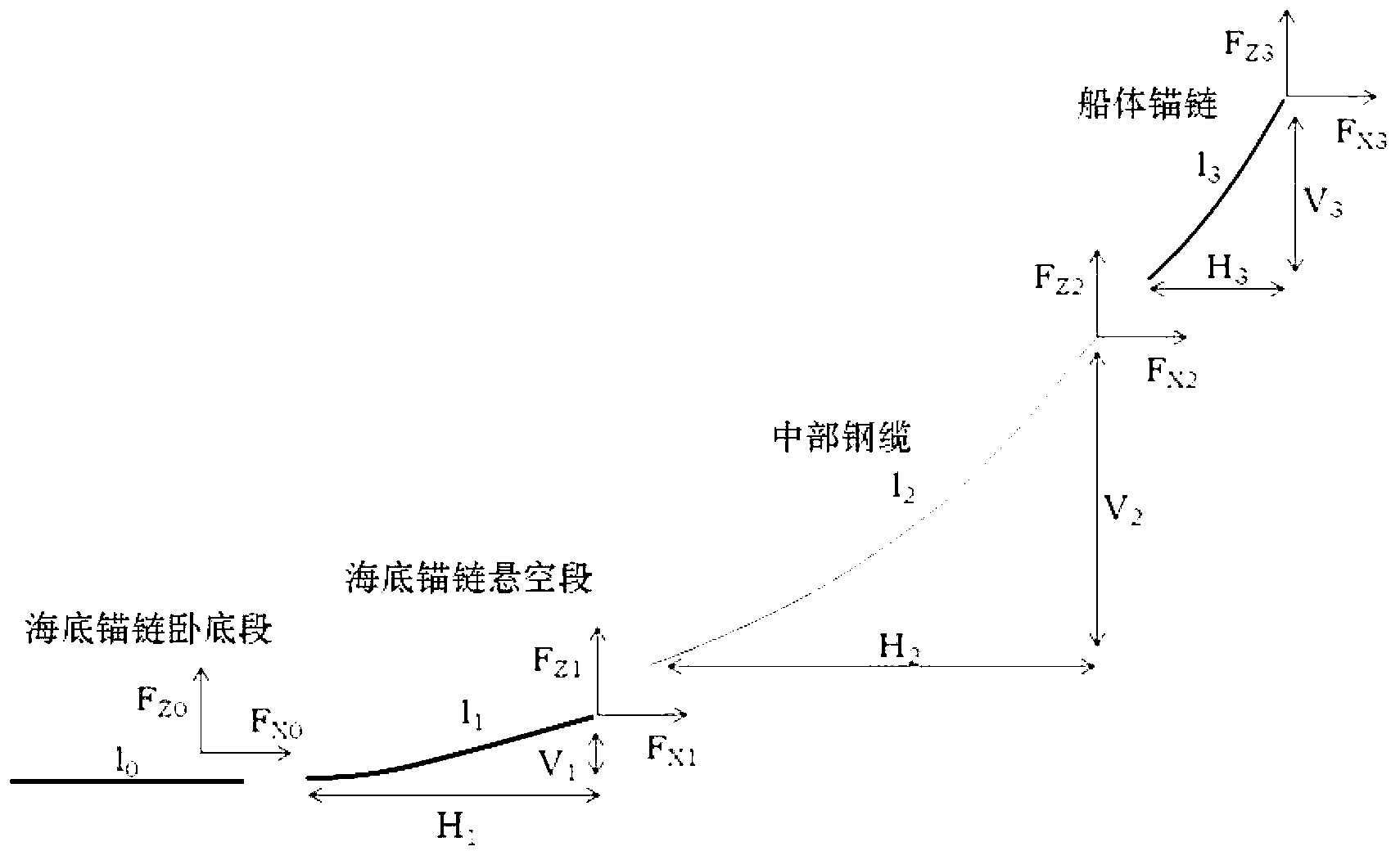

[0036] figure 1 Shows the segmental diagram of the deepwater catenary mooring line structure, first refer to figure 1 Define the parameters as follows:

[0037] l 0 is the length of the undercover section of the submarine anchor chain, l 1 is the length of the suspended section of the seabed anchor chain, l 2 is the length of the steel cable in the middle, l 3 is the hull anchor chain length;

[0038] h i , V i are the horizontal span and vertical height of the three suspended cables (i.e. the suspended section of the submarine anchor chain, the middle steel cable and the hull anchor chain), i=1,2,3;

[0039] f Xi , F Zi are the horizontal tension and vertical tension at the upper end points of the cables in the three sections of suspension respectively, i=1,2,3;

[0040] f X0 , F Z0 are the horizontal tension and vertical tension at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com