Coil of compound voltage compensation autotransformer

An autotransformer, voltage compensation technology, applied in the direction of transformer/inductor coil/winding/connection, transformer, fixed transformer, etc. The effect of increasing the voltage regulation range and accuracy, and facilitating the calculation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

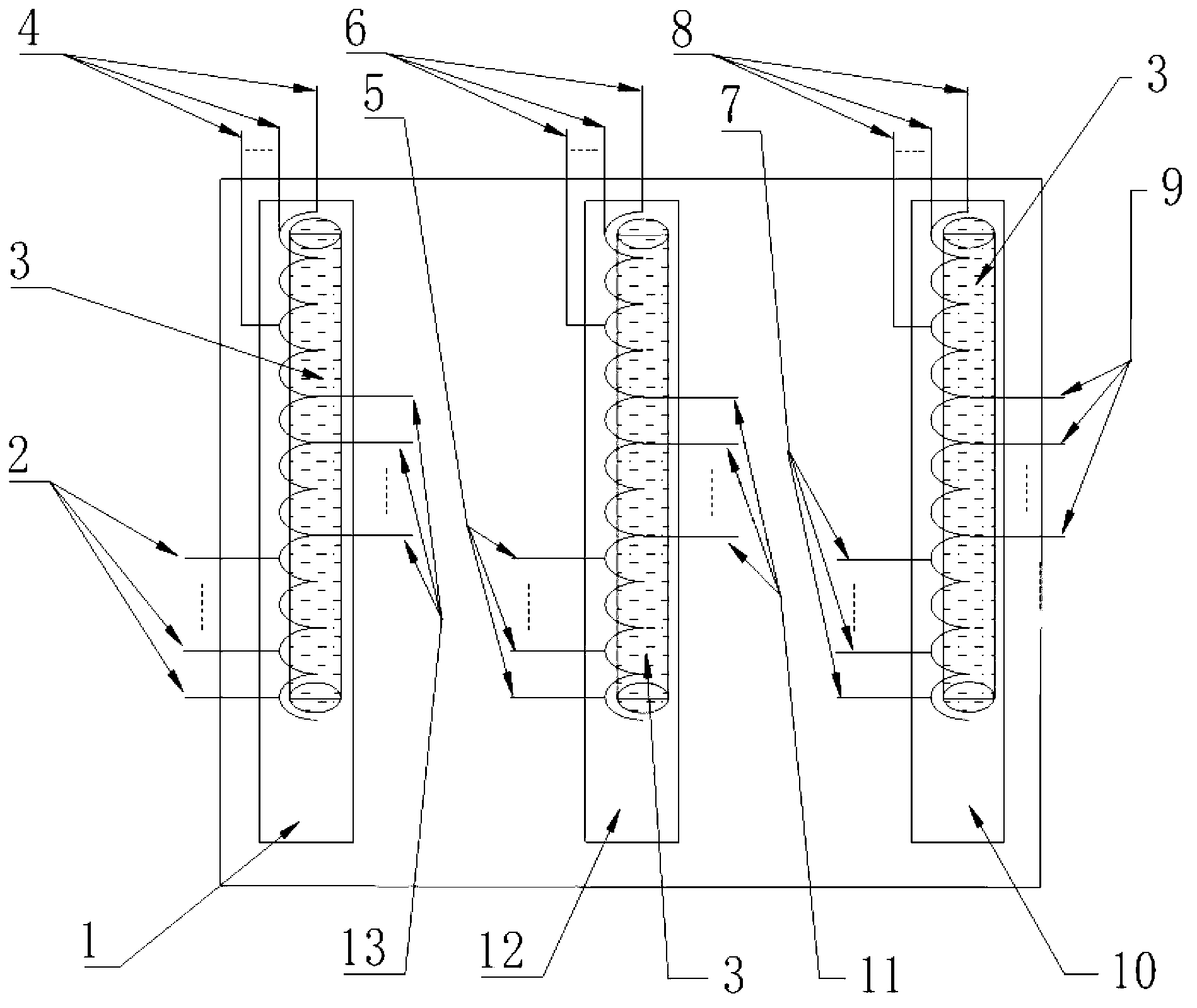

[0049] The technical solution adopted by the present invention is a coil of a compound voltage compensation autotransformer, the autotransformer is provided with an A-phase coil 1, a B-phase coil 12 and a C-phase coil 10 respectively connected to the three-phase alternating current, in order to realize the output For voltage adjustment, there are 20 sets of primary taps on the coil, that is, the primary tap 4 of the A-phase coil, the primary tap 6 of the B-phase coil, and the primary tap 8 of the C-phase coil each have 20 taps; there are also 20 sets of taps on the coil. The secondary taps, that is, the secondary tap 13 of the A-phase coil, the secondary tap 11 of the B-phase coil, and the secondary tap 9 of the C-phase coil each have 20 taps; there are also 20 groups of neutral zero-point taps on the coil, namely The neutral zero tap 2 of the A phase coil, the neutral zero tap 5 of the B phase coil and the neutral zero tap 7 of the C phase coil each have 20 taps; the A phase c...

Embodiment 2

[0051] On the basis of Embodiment 1, in order to realize the voltage regulation output for high-voltage alternating current in the present invention, a preferred implementation mode also includes eight coils in the A-phase coil 1, the B-phase coil 12 and the C-phase coil 10. Primary tap, 8 secondary taps and 8 neutral zero point taps, a group of primary taps of A-phase coil 1, B-phase coil 12 and C-phase coil 10 are respectively connected to the input AC power supply, A-phase coil 1, B-phase A group of secondary taps in the phase coil 12 and the C-phase coil 10 are respectively connected to the output lines, and a group of neutral zero-point taps in the A-phase coil 1, B-phase coil 12 and C-phase coil 10 are connected to each other, and other parts are connected with the implementation Example 1 is exactly the same.

Embodiment 3

[0053] On the basis of Embodiment 2, in order to realize the step-down output of the input AC power supply, and to realize stepless voltage regulation, it is convenient to calculate and set the ratio of the input voltage to the output voltage. The coil 1, the B-phase coil 12 and the C-phase coil 10 are respectively provided with 40 primary taps, 40 secondary taps and 40 neutral zero-point taps, and the A-phase coil 1, the B-phase coil 12 and the C-phase coil 10 The primary taps are evenly arranged on the upper part of the coils, the secondary taps of the A-phase coil 1, B-phase coil 12 and C-phase coil 10 are evenly arranged in the middle of the coils, and the A-phase coil 1, B-phase coil 12 and C-phase coil 10 The neutral zero-point taps of the coil are evenly arranged on the lower part of the coil, and the other parts are exactly the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com